Degradable nonwoven fabric and method for producing same

A technology of non-woven fabrics and production methods, applied in the direction of non-woven fabrics, textiles and papermaking, chemical instruments and methods, etc., can solve problems such as non-degradable, fragile slag, product quality stability, etc., to achieve the elimination of surface Rough, excellent hygroscopicity, ideal strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

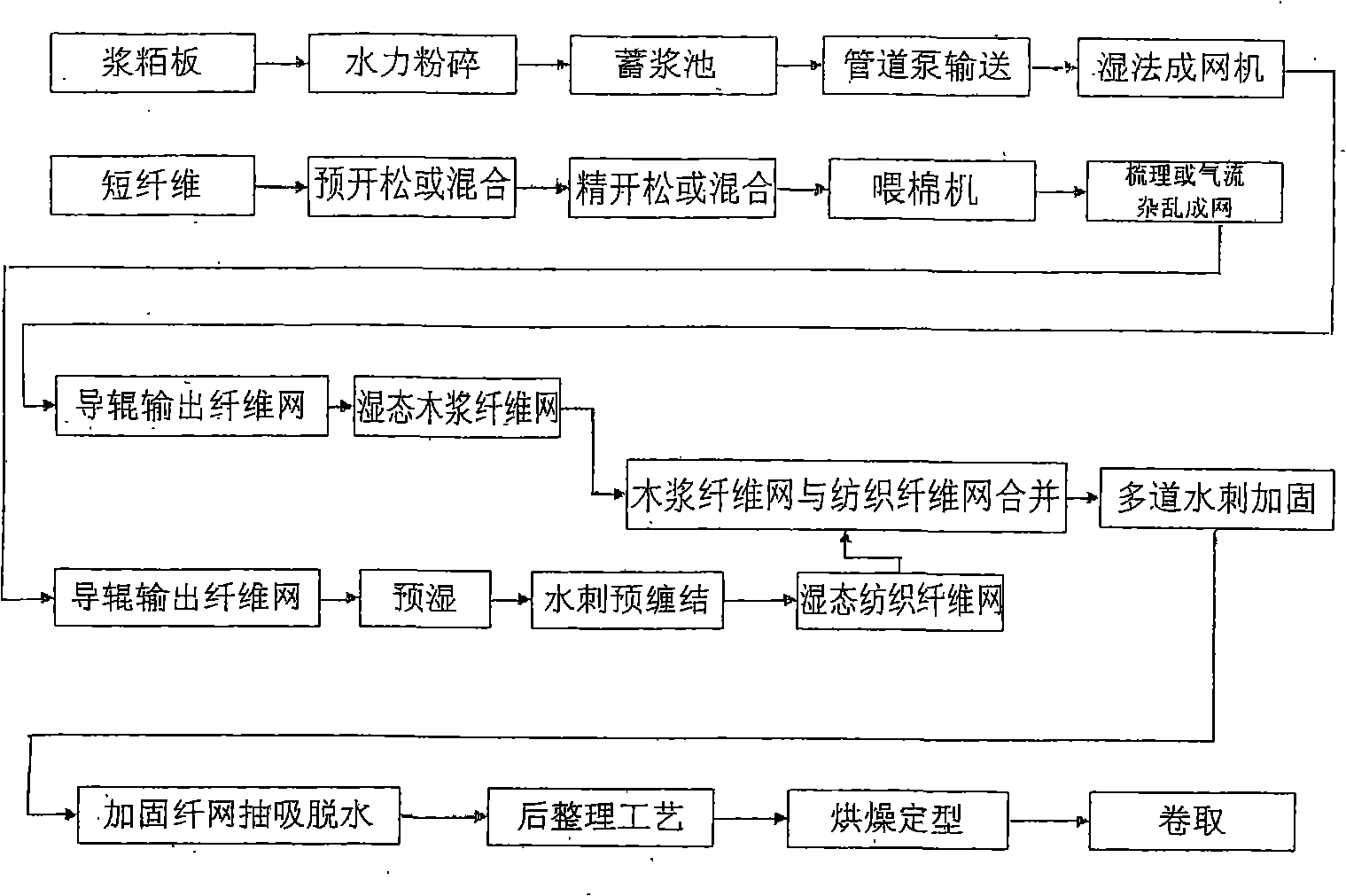

Method used

Image

Examples

Embodiment 1

[0021] A) to produce wood pulp fiber web, the wood pulp short cellulose pulp board that will buy from the market is 3mm, average fineness is 800 purpose wood fiber processing into material tank soaking and dissolving, then use papermaking The hydraulic pulverizer commonly used in the industry performs hydraulic pulverization to obtain wood pulp cellulose slurry, and introduces the wood pulp cellulose slurry into the storage tank with a conveying device such as a feeding pump, and the concentration of wood pulp cellulose in the storage tank The control is 3.5%, and then the pipeline pump transports the wood pulp cellulose in the storage tank to the wet-laid machine for suction and dehydration to form a web. After suction and dehydration, the moisture content is 80%, and the wood pulp is stripped by the guide roller and Pulp fiber web output, the obtained grammage is 125g / m 2 The wet state wood pulp fiber web, stand-by;

[0022] B) produce the textile fiber web, the polyester s...

Embodiment 2

[0025] A) produce wood pulp fiber net, the bamboo pulp short cellulose pulp board that will buy from the market is that 15mm, average fineness are processed into the bamboo fiber of 900 purpose bamboo fiber by fiber length and send into bucket soaking and dissolving, then use papermaking The customary water pulverizer in the industry carries out hydraulic pulverization to obtain bamboo pulp cellulose slurry, and the bamboo pulp cellulose slurry is introduced in the slurry storage tank with a conveying device such as a feed pump, and the concentration of the bamboo pulp cellulose in the slurry storage tank The control is 3%, and then the bamboo pulp cellulose in the storage tank is transported by the pipeline pump to the wet-laid machine for suction and dehydration to form a web. Pulp fiber web output, the obtained grammage is 120g / m 2 The wet state bamboo pulp fiber net, stand-by;

[0026] B) use the polypropylene staple fiber that is 30mm and the fineness is 2 deniers (2dtex...

Embodiment 3

[0029] A) produce wood pulp fiber net, only change fiber length into 8mm, average fineness into 850 orders, change the concentration control of wood pulp cellulose in the storage tank into 2.5%, the water content after suction dehydration is 85%, and the grammage of the wood pulp fiber net obtained is 16.7g / m 2 , all the other are the same as the description of the A) step of embodiment 1;

[0030] B) produce the textile fiber web, only change the short textile fiber to polypropylene fiber, nylon fiber and viscose fiber with a weight ratio of 1:1:1, the length of each of the above-mentioned fibers is 45mm, and the fineness is each 3 deniers (3dtex ), according to the description of step B) in Example 1, the grammage obtained is 66g / m 2 , A wet textile fiber web made of polypropylene, nylon and viscose fibers with a moisture content of 28%;

[0031] C) Composite forming, according to the description of step C) in Example 1, obtain wood fiber and account for 5% (2.5g / m 2 ), w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com