Preparation method of graphene electroconductive composite fiber

A conductive composite fiber, graphene composite technology, applied in the direction of fiber type, fiber treatment, plant fiber, etc., to achieve the effect of simple production process, less dosage, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

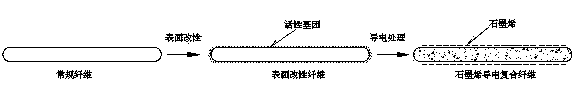

[0016] A specific embodiment of the preparation method of a graphene conductive composite fiber of the present invention, comprising the steps of surface modification of textile fiber, preparation of graphene dispersion system, and preparation of graphene composite fiber carried out in sequence;

[0017] The surface modification process of textile fibers is as follows: soak the textile fibers in a solution of silane coupling agent KH560 with a concentration of 1%-30% for 2-3 hours, place them in an oven at 50-65°C and dry them to obtain a surfactant Modified textile fibers;

[0018] The preparation process of the graphene dispersion system is as follows: the graphene oxide aqueous solution prepared by the Hummer's method is prepared by a chemical reduction method to prepare graphene, and a uniform and stable graphene dispersion system is prepared under the action of a dispersant, and its concentration is 0.1%-5%. ;

[0019] The preparation process of the graphene composite fi...

Embodiment 1

[0021] Embodiment 1: a kind of preparation method of graphene conductive composite polyester fiber, comprising the polyester fiber surface modification process, graphene dispersion system preparation process and graphene polyester composite fiber preparation process carried out successively, wherein:

[0022] The polyester fiber surface modification process is as follows: soak the polyester fiber in a 30% silane coupling agent KH560 solution for 3 hours, place it in a 65°C oven and dry it to obtain a surfactant-modified polyester fiber; silane The coupling agent KH560 solution is a water-alcohol mixed solution, and the water-alcohol ratio is 1:5;

[0023] The preparation process of the graphene dispersion system is as follows: the concentration of the graphene oxide aqueous solution prepared by the Hummer's method is 0.5%, and the graphene is prepared by a chemical reduction method, the reducing agent is hydrazine hydrate, the reduction temperature is 90 ° C, and the reduction ...

Embodiment 2

[0025] Embodiment 2: a kind of preparation method of graphene conductive composite cotton fiber, comprises the cotton fiber surface modification operation carried out successively, graphene dispersion system preparation operation and graphene cotton composite fiber preparation operation, wherein:

[0026] The cotton fiber surface modification process is as follows: soak the cotton fiber in a 20% silane coupling agent KH560 solution for 3 hours, place it in a 65°C oven and dry it to obtain a surfactant-modified cotton fiber; silane The coupling agent KH560 solution is a water-alcohol mixed solution, and the water-alcohol ratio is 1:3;

[0027] The preparation process of the graphene dispersion system is as follows: the concentration of the graphene oxide aqueous solution prepared by the Hummer's method is 1%, the graphene is prepared by the chemical reduction method, the reducing agent is hydroiodic acid, the reduction temperature is 90 ° C, the reduction time is 4 hours, and A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com