Process and Apparatus for Controlling the Preparation of Beverages

a technology of beverage preparation and process, applied in the direction of food preparation, testing food, instruments, etc., can solve the problems of not being able to adapt to conditions, not being able to achieve the adaptation of conditions, etc., to achieve the effect of improving the quality of coffee brewed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

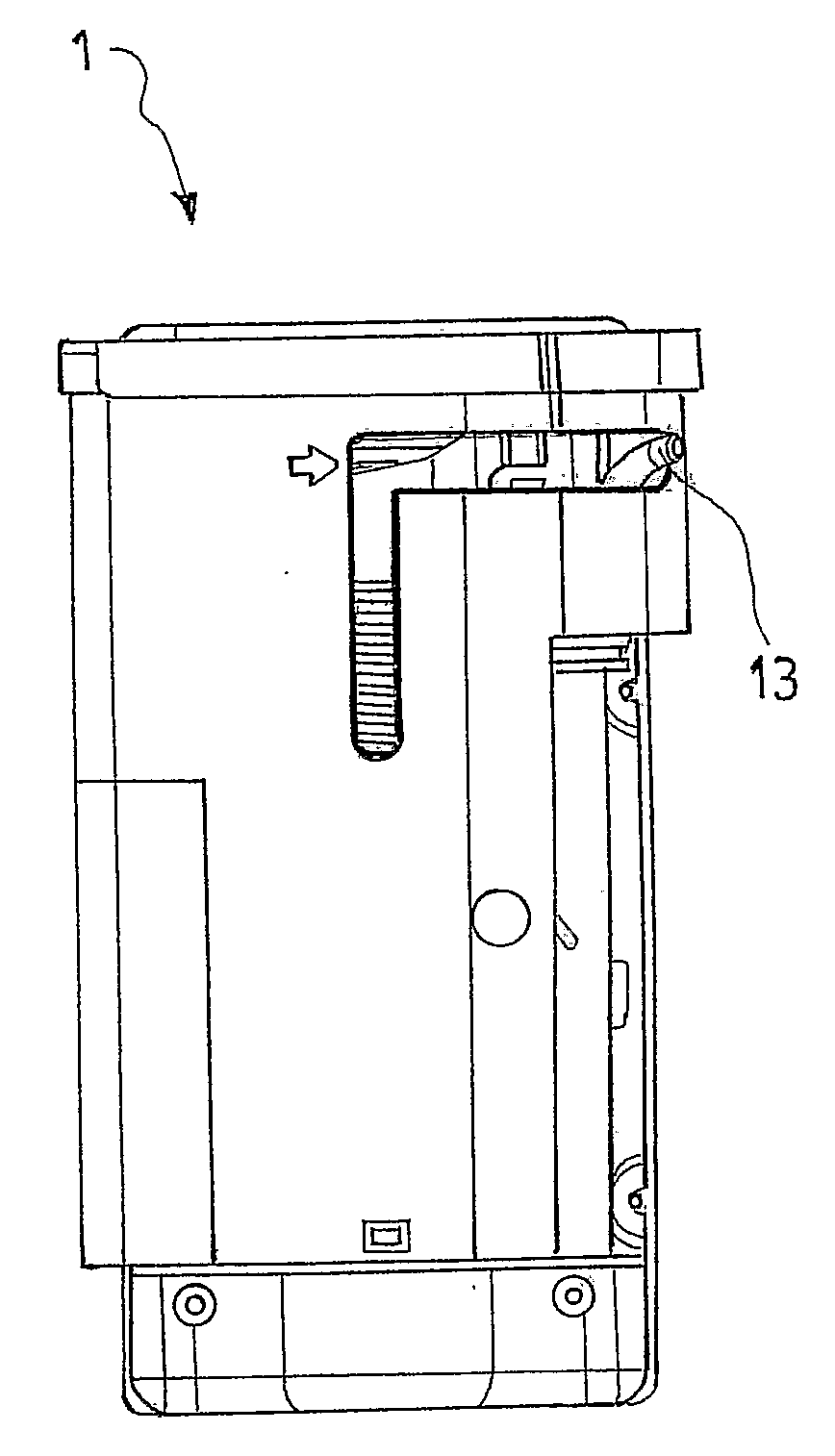

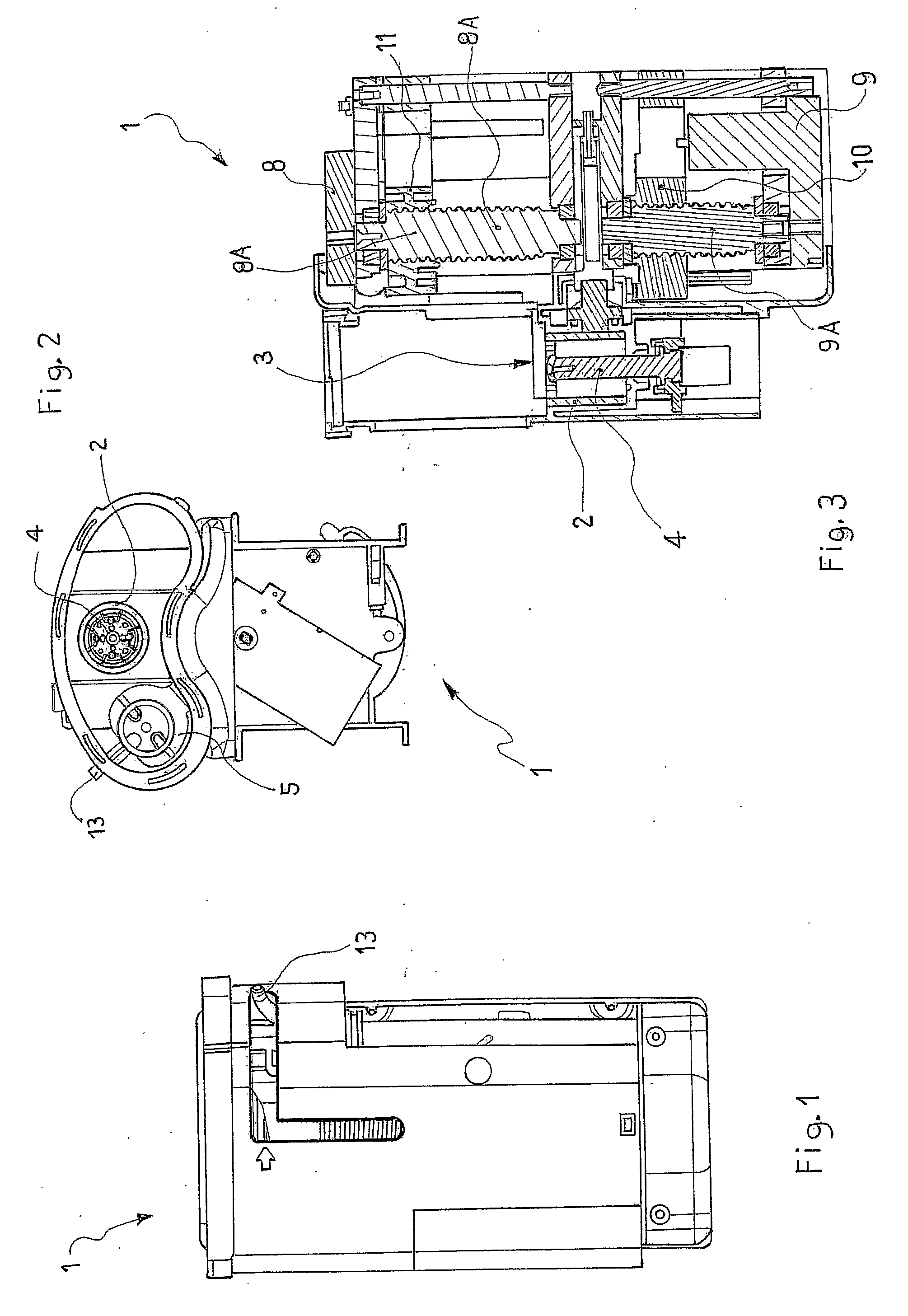

Image

Examples

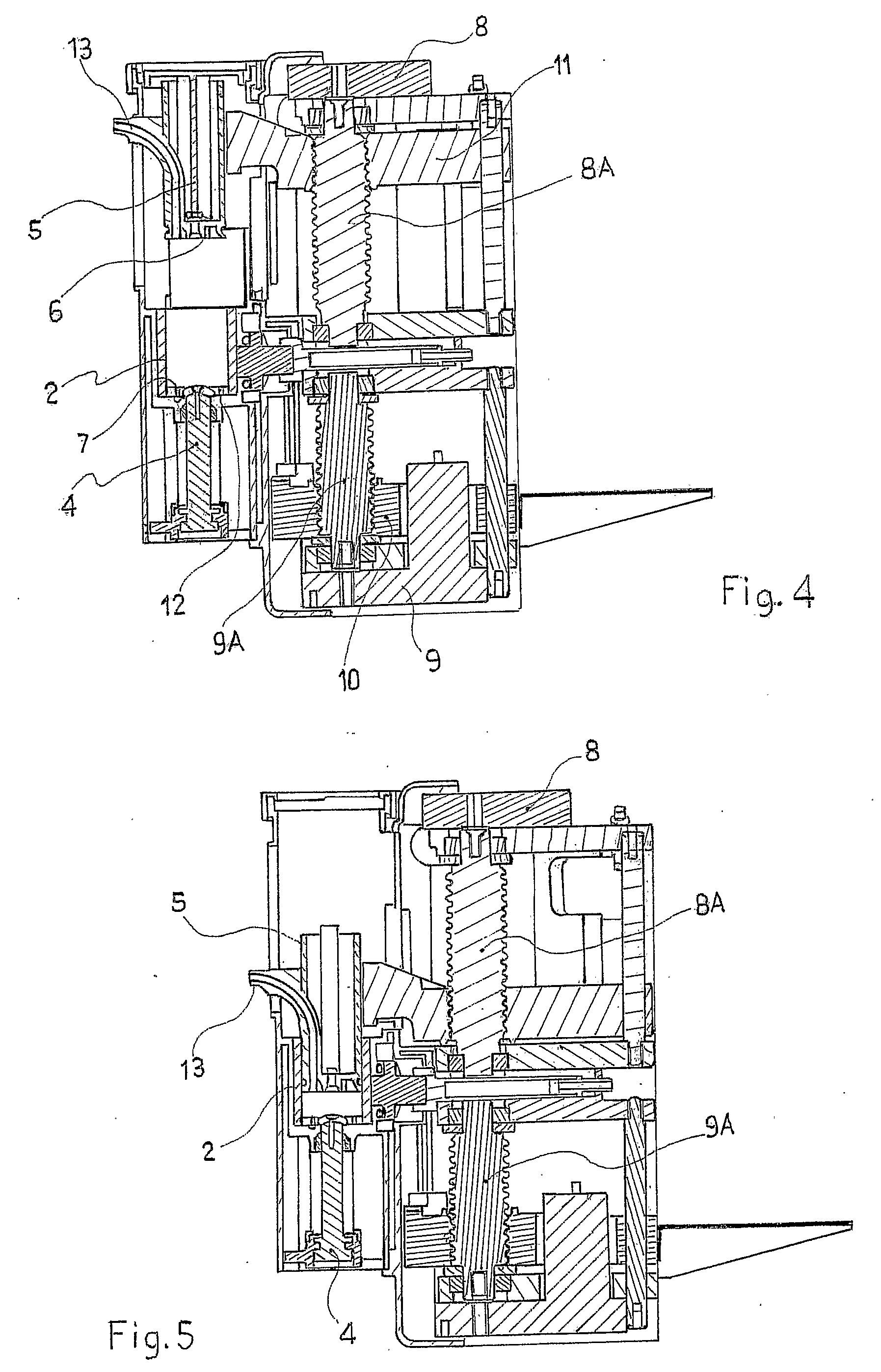

first embodiment

[0076] If there is a discrepancy between the two data, in a first embodiment, at least one of the piston's displacement length is changed as a consequence of the feedback, so that the volume of brewing chamber 2 is adjusted and the flow rate is maintained as close as possible to the pre-set dispensing curve. The minimum displacement step controllable by the controller should not vary the internal volume of the chamber for volumes higher than 0.5 cc. preferably 0.3 cc.

second embodiment

[0077] In the invention, the flow rate of water fed into the brewing chamber is changed and adjusted. This can be carried out e.g. by using a pump having variable speed, such as a rotative pump, to dispense pressurised water into the brewing chamber. A change of speed can be obtained also by changing the frequence of vibration of a vibration pump.

[0078] Alternatively, as shown in FIG. 7, when the sensor 18 provides controller 16 with the information that the flow rate of the incoming water should be reduced, valve 24 is operated to send a portion of the flow of water to a circuit including plenum chamber 25 and connected to reservoir 15, or to the pump or to a discharge means.

[0079] A preferred embodiment is shown in FIG. 11, where the apparatus of the invention comprises two pumps 14 and 14A connected in series. The two pumps are preferably vibration pumps and are operated separately or at the same time according to the actual requirements of the brewing procedure. Suitable pumps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com