Coffee freeze-drying equipment and process

A coffee and freeze-drying technology, which is applied in the direction of lighting and heating equipment, drying, drying machines, etc., can solve the problems of loss of radiation medium, inability to flow uniformly, and inability to guarantee coffee quality, so as to achieve good coffee quality and improve coffee quality. The effect of coffee quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

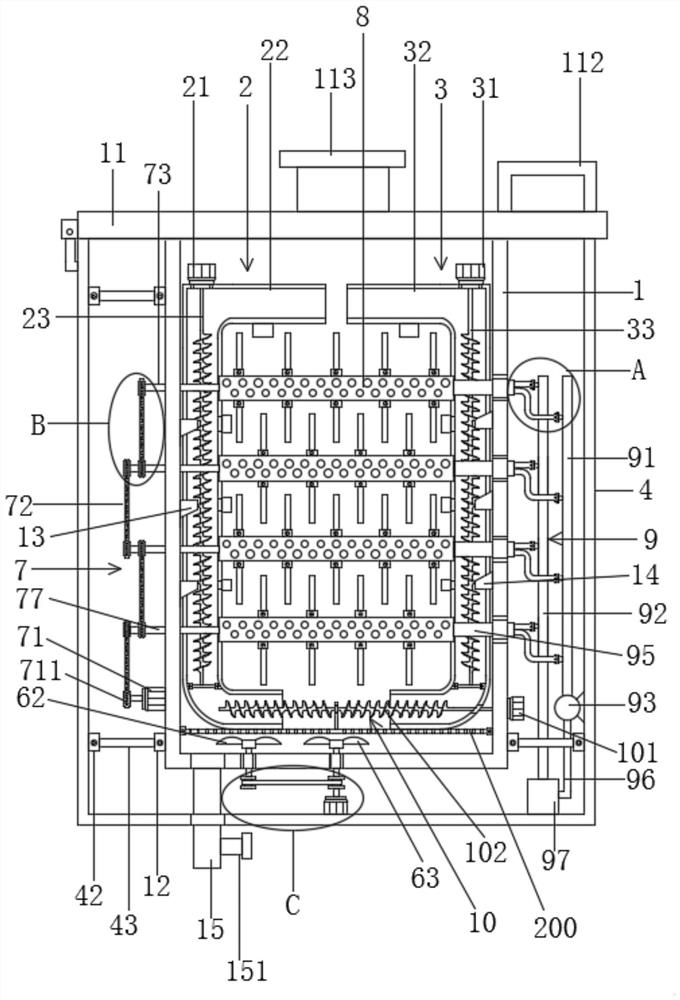

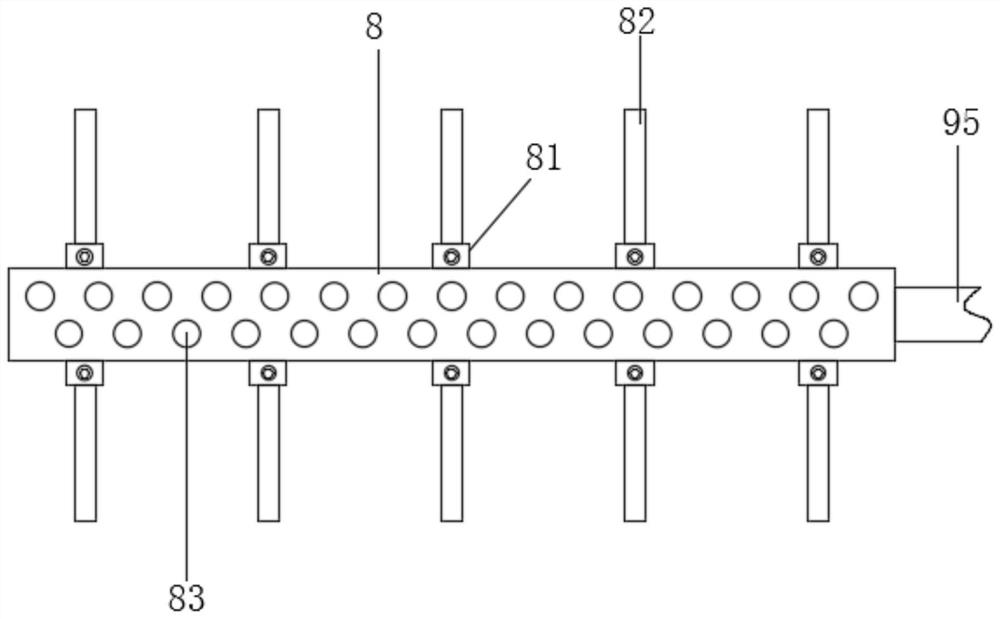

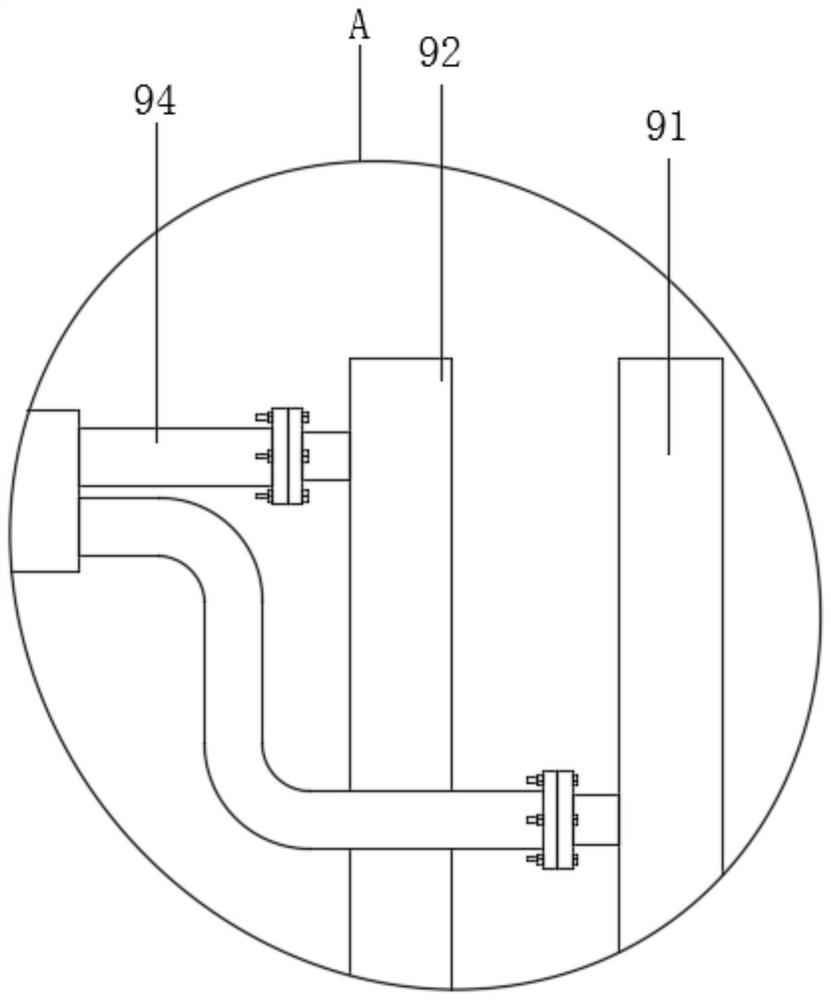

[0046] The present invention provides coffee freeze-drying equipment, please refer to Figure 1-13 , including an inner casing 1, a plurality of radiation plates 8 are arranged in the inner casing 1, a third fixing seat 81 is arranged on the outer wall of the radiation plate 8, and the inner wall of the third fixing seat 81 is inserted into the stirring rod 82, and the function of the stirring rod 82 It is to stir the coffee in the inner casing 1, so that the coffee is stirred, so that the coffee can be freeze-dried evenly. The third fixing seat 81 and the stirring rod 82 are fixed by bolts. The function of the wind deflector 13, the first wind deflector 13 and the second wind deflector 14 is to guide the wind generated by the second fan blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com