Metal powder-cored type nitrogen austenite stainless steel flux-cored wire and method for manufacturing same

A technology of austenitic stainless steel and metal powder core, applied in metal processing equipment, welding equipment, welding medium, etc., can solve the problems of mechanical properties, impact resistance and corrosion resistance, loss and other problems, and achieve the effect of corrosion resistance Good, small smoke and dust, reasonable ratio effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

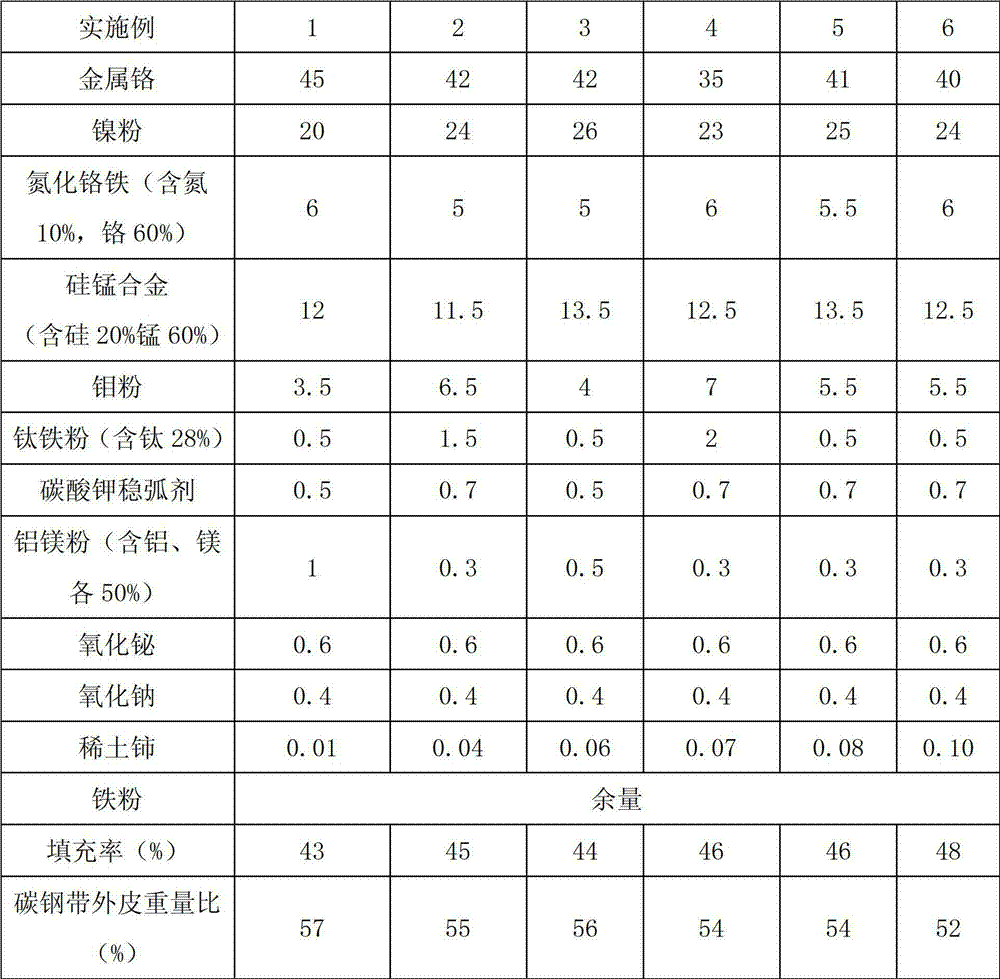

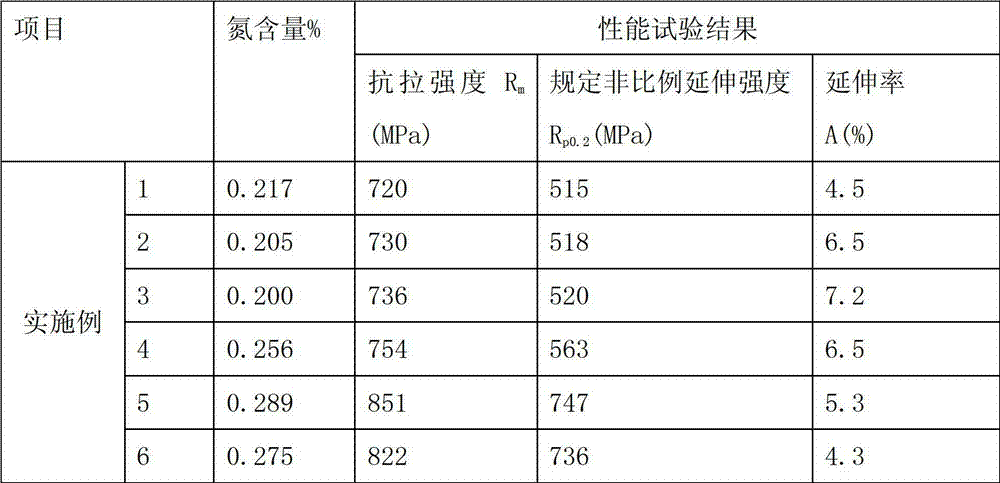

[0033] Below in conjunction with embodiment the present invention is described in further detail.

[0034] 1. Preparation of metal powder cored nitrogen-containing austenitic stainless steel flux cored wire

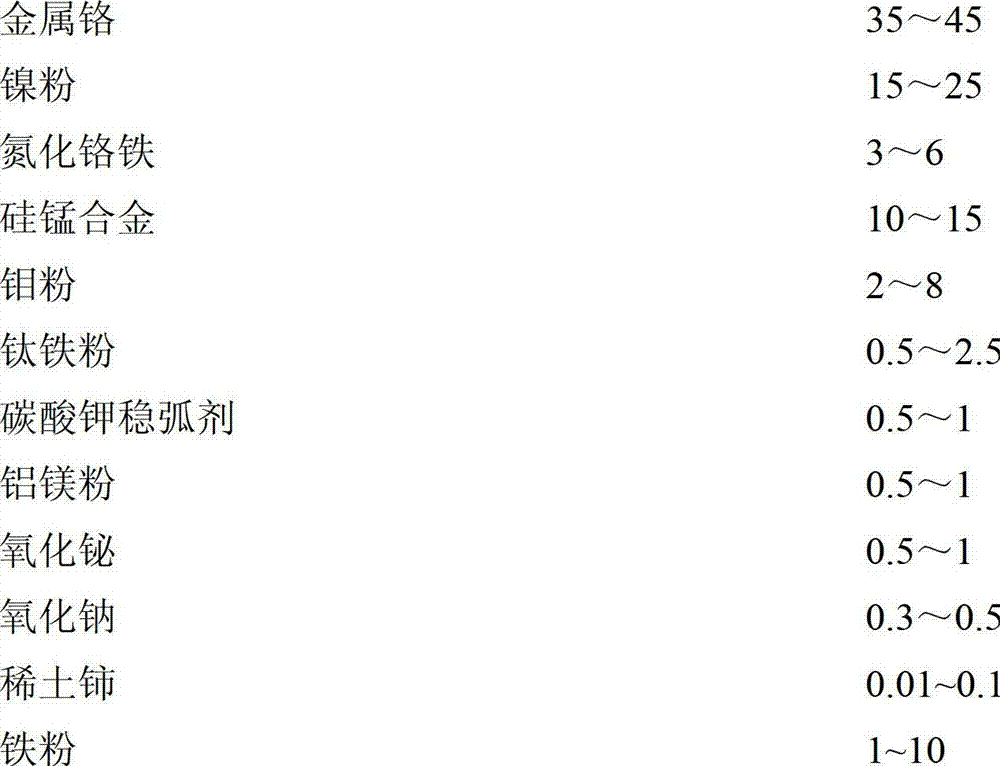

[0035] 1. Weigh the powders used to prepare the drug core according to the formula in Table 1, and each component passes through an 80-mesh standard sieve, and mix the weighed powders evenly, and set aside;

[0036] 2. The low-carbon steel strip is pressed into a trough-shaped structure by a forming machine; the following embodiments all use the low-carbon steel strip of the brand SYHS, the thickness of the steel strip is 0.3mm, and the width is 8.25mm. The content of each element in the steel strip is C≤0.050%, Mn≤0.200%, Si≤0.010%, S≤0.010%, P≤0.020%, Fe balance.

[0037] 3. Put the evenly mixed drug material into the tank pressed by the steel belt. The filling rate, that is, the percentage of the weight of the powder to the weight of the welding wire is 40-50%; Seal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com