Automatic welding device and automatic welding method for thin-shell car body

An automatic welding and car body technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of welding rod waste, complicated welding seam, poor appearance consistency, etc., achieve continuous and beautiful welding seam, improve production efficiency, and weld The effect of small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0038] Firstly, the thin-shell car body automatic welding device of the present invention is introduced.

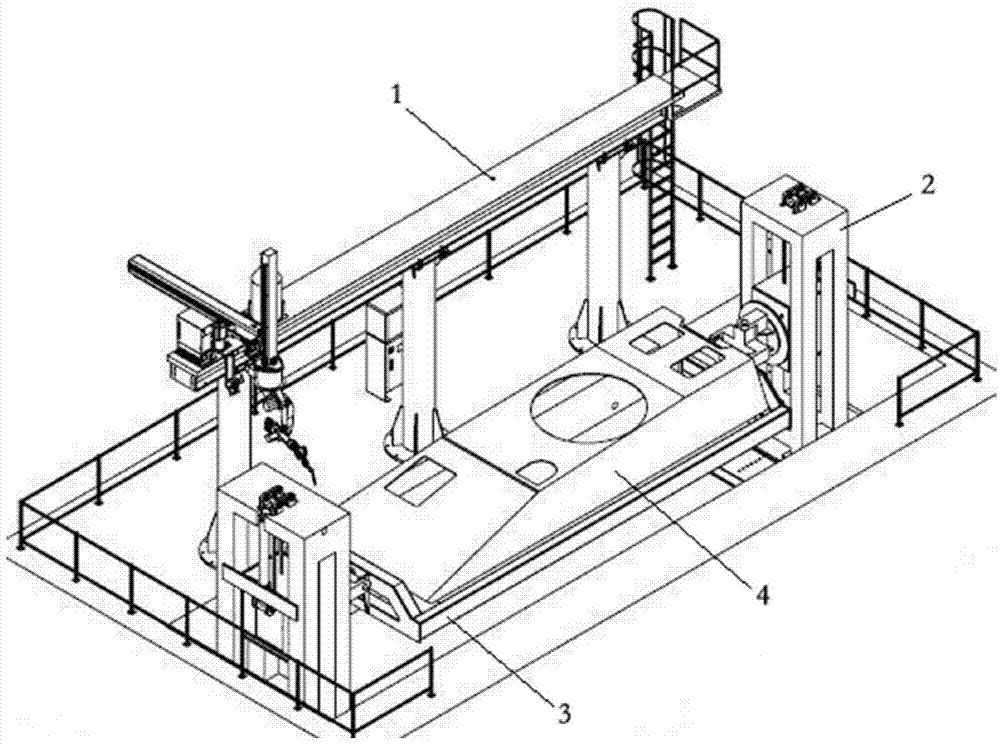

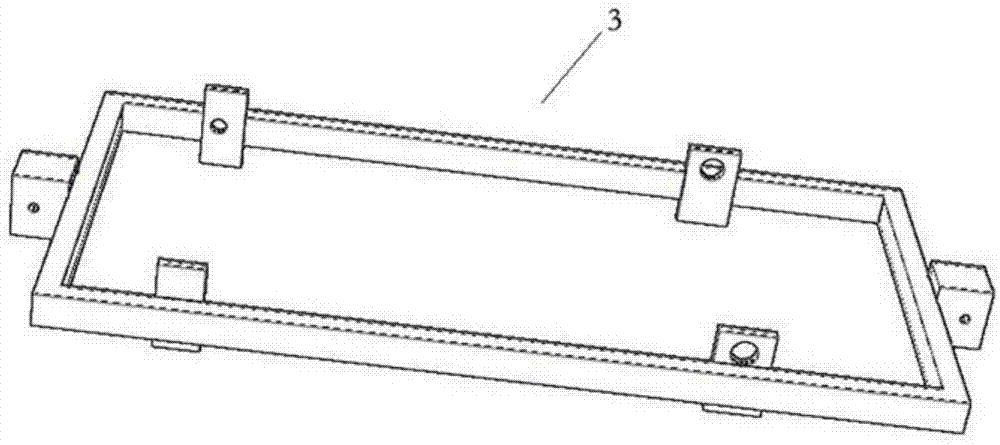

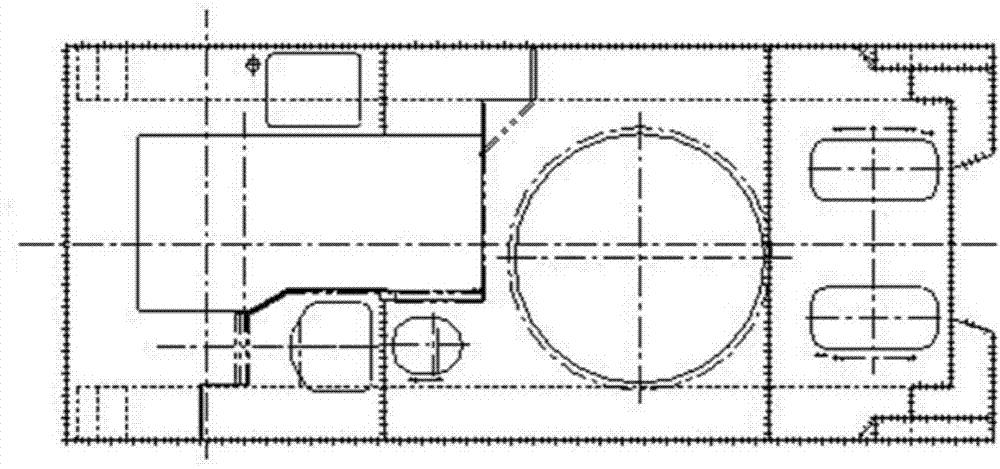

[0039] refer to figure 1 with figure 2 , the thin-shell car body automatic welding device of the present invention includes: a gantry type welding robot 1, a lifting type head and tail frame type displacer 2 arranged on the side of the gantry type welding robot 1, installed on a lifting type head and tail frame type The flip frame 3 between the positioners 2, and the control mechanism (not shown) for controlling the welding robot and the work of the positioners. Among them, the lift-type head and tail frame positioner 2 adopts a hydraulic lifting mechanism for lifting, which can realize the clamping and flipping of various types of car bodies 4 to be welded. The rotation range is ±185°. It adopts AC servo technology and can be fre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com