Welding fixture for friction stir welding of water channels of water-cooled motor shell and annular welding technology

A water-cooled motor and welding fixture technology, applied in welding equipment, non-electric welding equipment, manufacturing tools, etc., can solve the problems of time-consuming and laborious loading and unloading of workpieces, low welding efficiency, poor positioning stability of workpieces, etc., to reduce manufacturing costs and improve welding Efficiency, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the present invention will be described in detail below in conjunction with preferred embodiments.

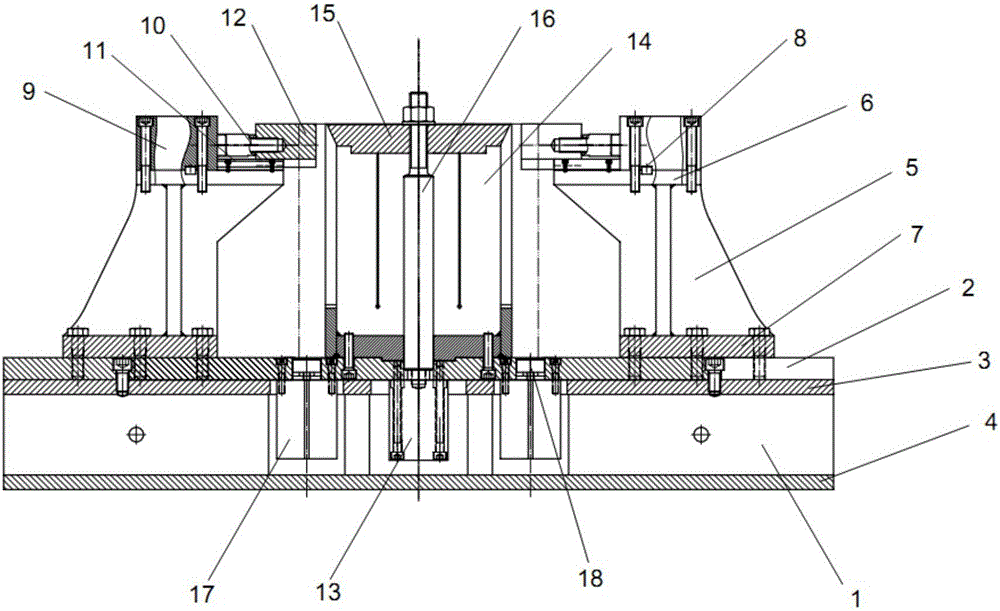

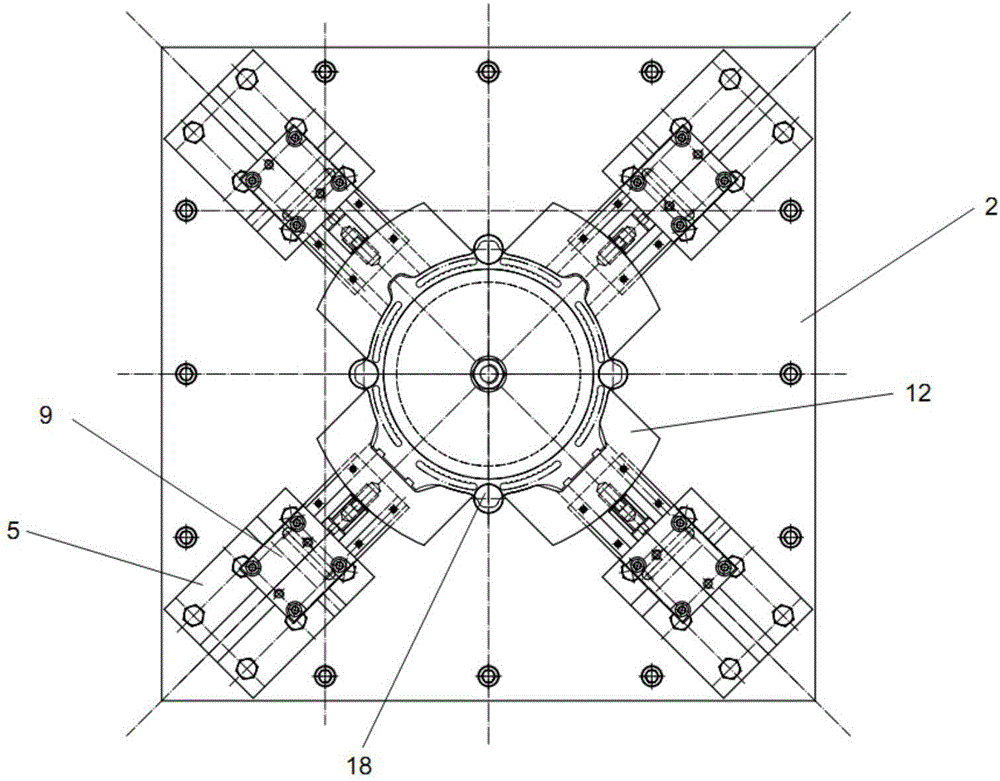

[0024] See the accompanying drawings for details, a welding fixture for friction stir welding of water-cooled motor shells, including a fixture base, an oil cylinder support mechanism, a top block clamping mechanism, an expansion sleeve locking mechanism and a PLC control system. The oil cylinder support mechanism includes four An oil cylinder support seat arranged in a cross, the oil cylinder support seat is fixedly connected to the fixture base; a top block clamping mechanism is fixedly connected to the oil cylinder support mechanism, and the top block clamping mechanism includes a thin horizontal oil cylinder and a linear guide rail and the top block of the oil cylinder, the thin horizontal oil cylinder is connected with the linear guide rail through the connecting screw, the linear guide rail is connected with the top block of the oil cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com