Crystal glass production and manufacturing assembly line

A crystal glass and assembly line technology, which is applied to glass manufacturing equipment, manufacturing tools, glass furnace equipment, etc., can solve the problems of inflexible crystal glass trimming devices, low work efficiency, and low safety, so as to improve melting efficiency, Avoid heat loss, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

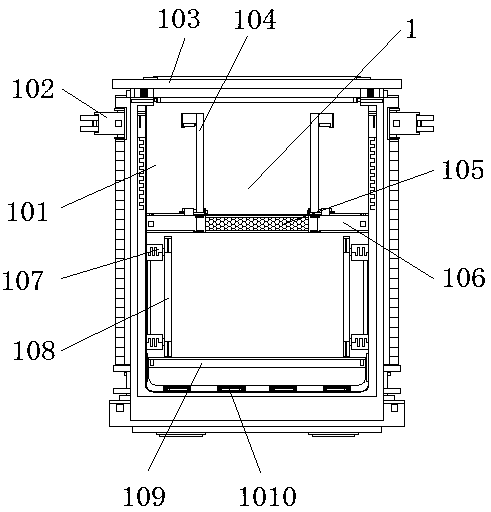

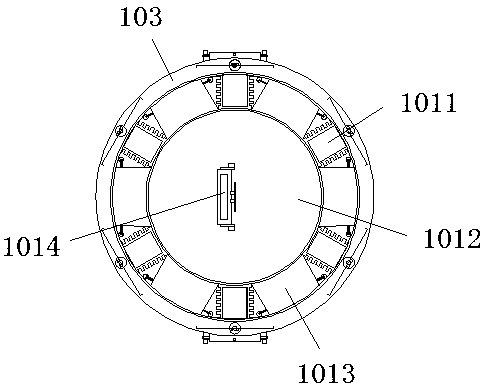

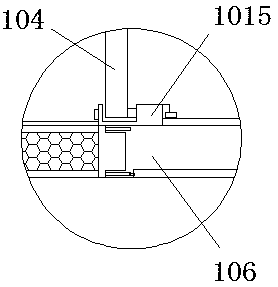

[0035] Crystal glass production and manufacturing assembly line, including crystal glass batching device 1, crystal glass melting device 2, bubble clarification device 3, crystal glass polishing device 4 and crystal glass trimming device 5; crystal glass batching device 1 combines different crystal glass raw materials The batching is carried out in appropriate proportions, and after the batching is taken out, it is sent to the feed port 202 of the crystal glass melting device 2 for heating and melting, and the crystal glass liquid after heating and melting enters the fixed ring 3010 of the bubble clarification device 3 through the discharge port 2016, The crystal glass liquid is heated and bubble clarified, and the crystal glass liquid that has been clarified by the bubbles enters the compression molding machine through the glass liquid outlet 303 for preliminary compression molding, and the preliminary compression molding crystal glass plate is transported to the crystal glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com