Multifunctional high-temperature microwave metal smelting equipment

A smelting equipment and multi-functional technology, applied in the field of multi-functional high-temperature microwave metal smelting equipment, can solve the problems of shortened life of the magnetron, power supply, high cooling system requirements, large heat dissipation area, etc., to reduce power requirements and installation conditions , Requirements for power supply equipment are reduced, and the effect of reducing the strong mutual coupling of microwave sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the present invention is not limited in any way. Any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

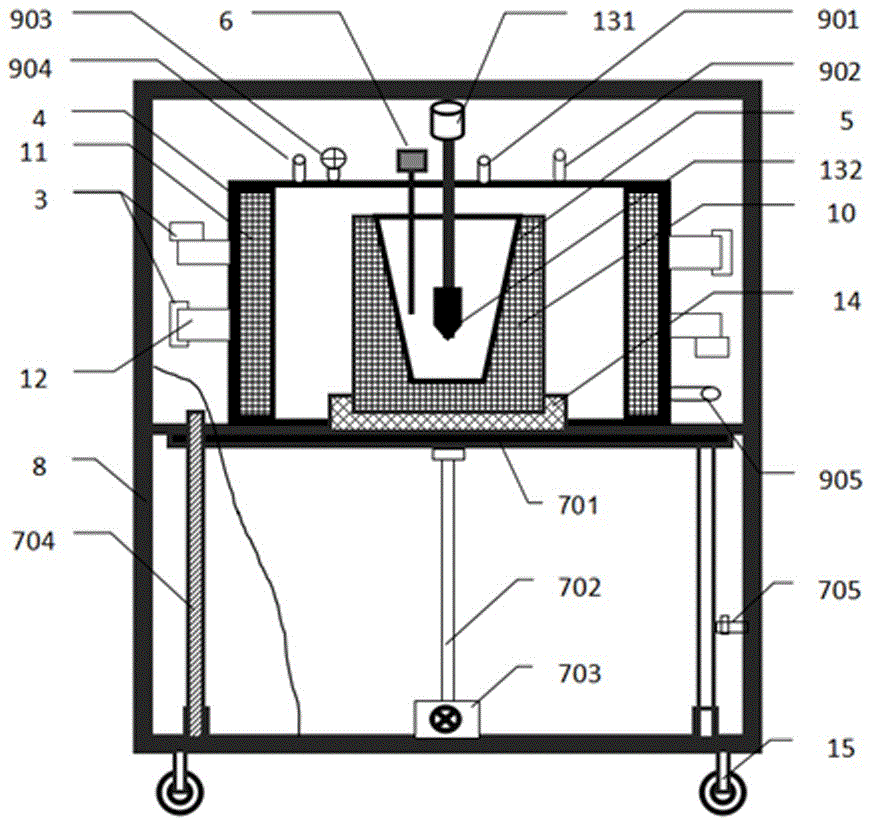

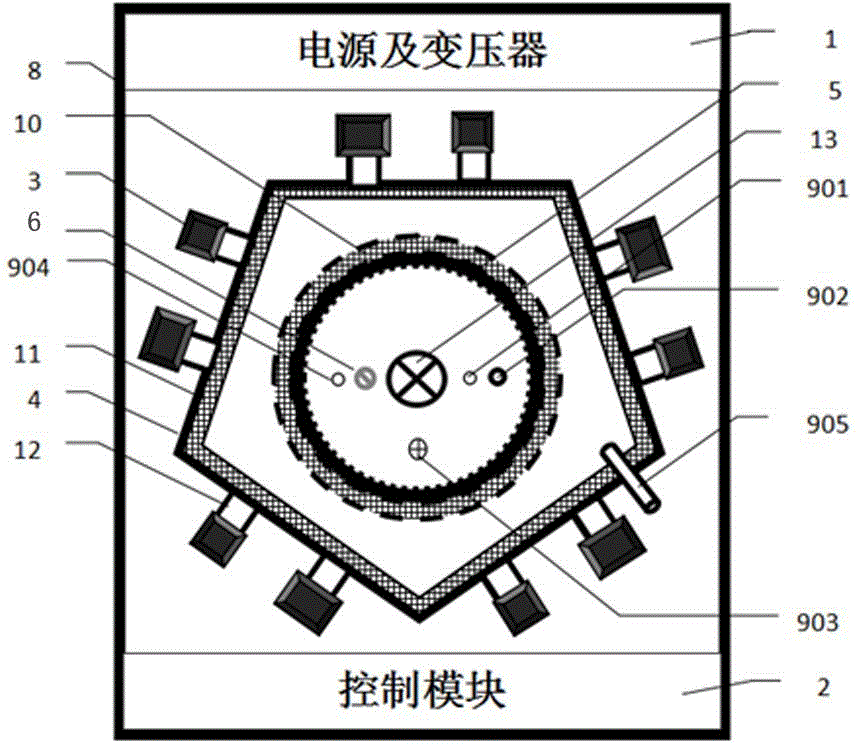

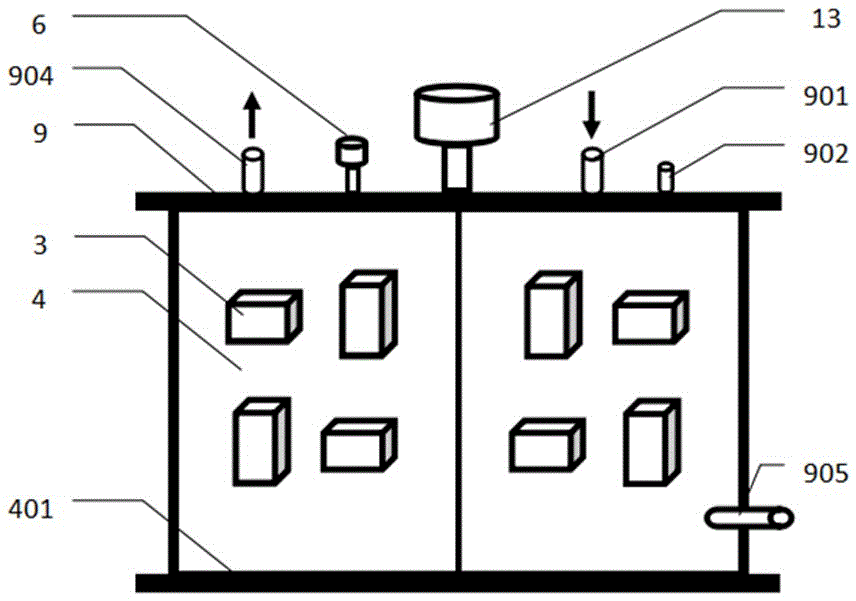

[0021] Such as Figures 1 to 6 As shown, the present invention includes a power supply system 1, a control module 2, a microwave source 3, a microwave reaction chamber 4, a microwave-absorbing heating container 5, a temperature measuring device 6, and a discharge device 7, and the microwave reaction chamber 4 is many On the metal structure of odd-numbered faces on five sides, the microwave reaction chamber 4 is fixedly connected to the equipment frame 8, and each side wall of the microwave reaction chamber 4 is respectively provided with a microwave source 3, and the microwave source 3 passes through the control module 2 is connected to the power supply system 1, the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com