Loading method of high-efficiency crucible for producing polycrystalline silicon

A polysilicon, high-efficiency technology, applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve the problems of increasing the risk of silicon leakage, different shapes of quartz sand, crucible impact, etc., to improve melting efficiency , shorten the melting time, shorten the length of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

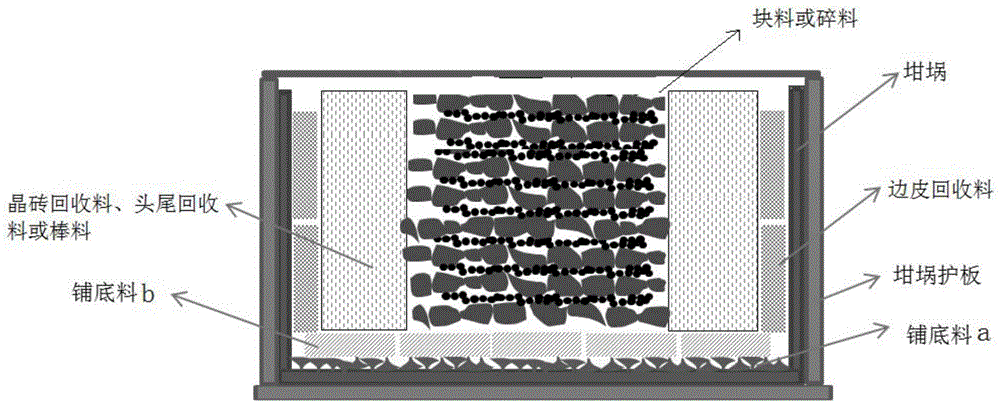

[0037] Screen polycrystalline fragments with a length of 3-12mm, pickle, rinse until there is no acid residue, and dry to obtain the base material a; sort silicon materials with a thickness of 3-5cm and a size of 156mm*156mm to obtain the base material b;

[0038] Sprinkle a layer of the above-mentioned primer a evenly on the bottom of the high-efficiency crucible until the coating on the bottom of the high-efficiency crucible cannot be seen visually, then spread the above-mentioned primer b on top of the primer a and press it to make it flat. leave no gaps;

[0039] Spread the edge skin reclaimed material around the high-efficiency crucible, then stack the crystal brick recycled material, head and tail recycled material or bar material inside the edge skin recycled material, and fill the crystal brick recycled material, head and tail recycled material with blocks or scraps In the space formed by recycled materials or rods, go up one by one until the crucible is full.

[004...

Embodiment 2

[0043] Screen the single crystal fragments with a length of 5-10mm, pickle, rinse until there is no acid residue, and dry to obtain the bottom layer a; sort the silicon material with a thickness of 3-5cm and a size of 156mm*156mm to obtain the bottom layer material b;

[0044] Sprinkle a layer of the above-mentioned primer a evenly on the bottom of the high-efficiency crucible until the bottom coating of the high-efficiency crucible cannot be seen visually, then spread the above-mentioned primer b on top of the primer a, leaving no gap between the silicon materials of the primer b ;

[0045] Spread the edge skin reclaimed material around the high-efficiency crucible, then stack the crystal brick recycled material, head and tail recycled material or bar material inside the edge skin recycled material, and fill the crystal brick recycled material, head and tail recycled material with blocks or scraps In the space formed by recycled materials or rods, go up one by one until the ...

Embodiment 3

[0049] Screen the primary polycrystalline fragments with a length of 5-10mm, rinse them after pickling until no acid remains, and dry them. The acid volume ratio during pickling is hydrofluoric acid: nitric acid: water is 1:12:13, and the obtained Base material a; sort silicon material with a thickness of 3 to 5 cm and a size of 156mm*156mm to obtain base material b;

[0050] Sprinkle a layer of the above-mentioned primer a evenly on the bottom of the high-efficiency crucible until the bottom coating of the high-efficiency crucible cannot be seen visually, then spread the above-mentioned primer b on top of the primer a, leaving no gap between the silicon materials of the primer b ;

[0051] Spread the edge skin reclaimed material around the high-efficiency crucible, then stack the crystal brick recycled material, head and tail recycled material or bar material inside the edge skin recycled material, and fill the crystal brick recycled material, head and tail recycled material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com