Re-containing high-density ReWTaMoNbx high-entropy alloy material and preparing method thereof

A high-entropy alloy and alloy material technology, applied in the field of high-density ReWTaMoNbX high-entropy alloy materials and preparation, can solve the problems of low density of high-entropy alloys, achieve the effects of reducing air content, improving alloy uniformity, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

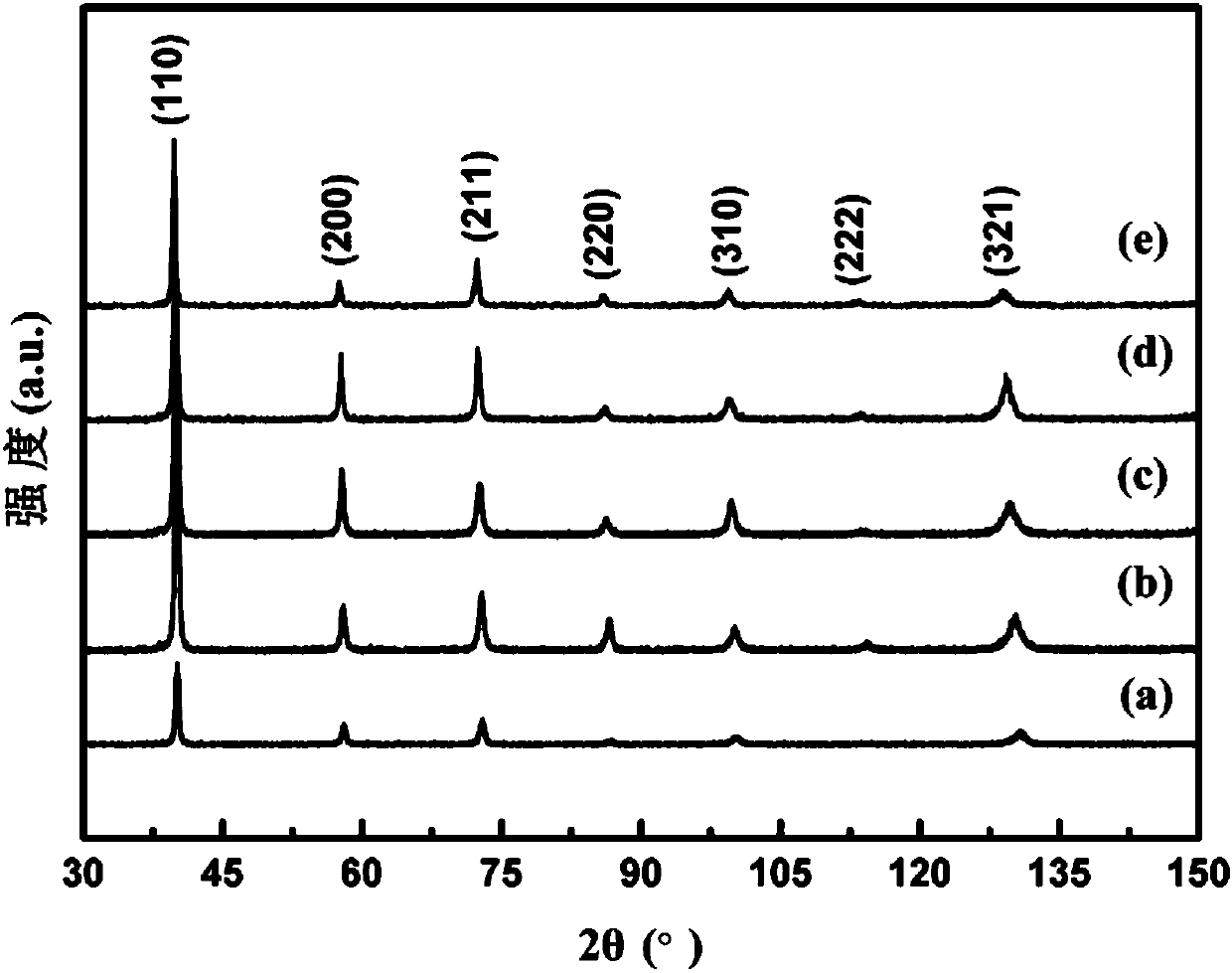

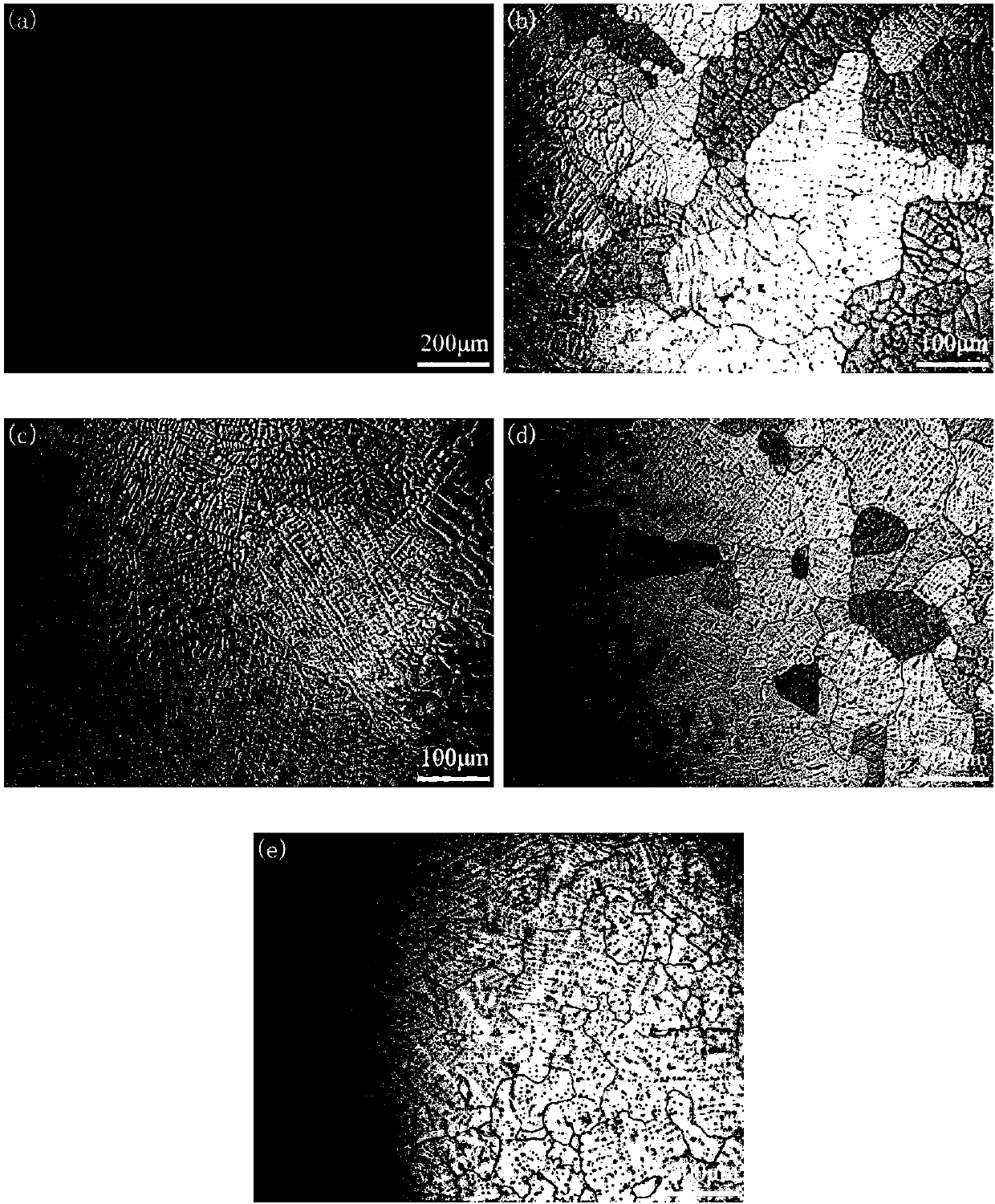

Embodiment 1

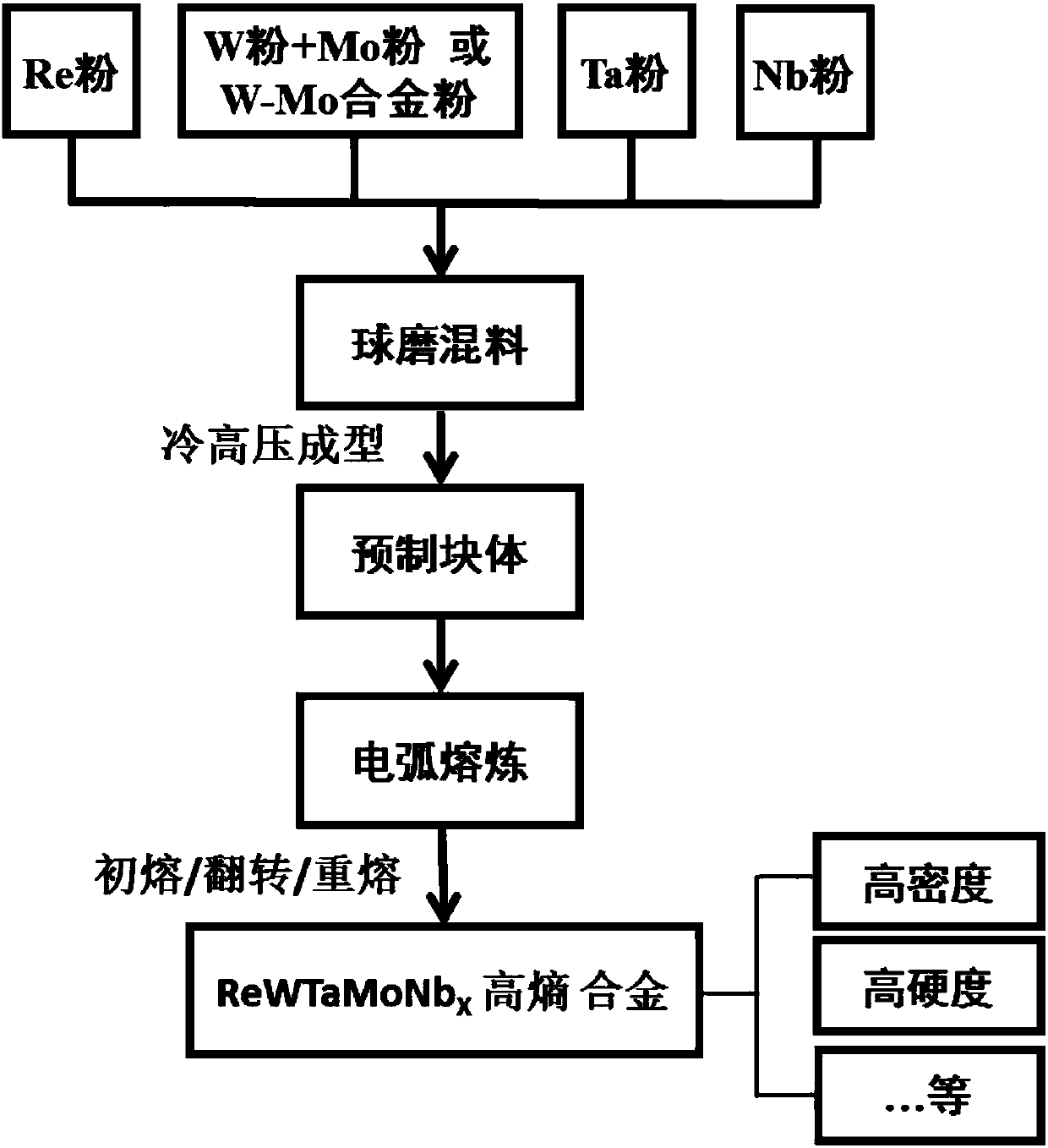

[0034] Preparation of ReWTaMo high-entropy alloys. The specific steps are as follows:

[0035] (1) Mixing: Weigh 5.2794g of Re powder, 4.9750g of W powder, 4.9853g of Ta powder, and 2.5935g of Mo powder with a purity of 99.9% (Re / W / Ta / Mo / Nb molar ratio is 1.05:1:1.02 :1:0), the particle size of the powder is 20 μm; use a light ball mill to mix evenly for 30 hours to obtain a mixed powder.

[0036] (2) Preparation of prefabricated block: put the mixed powder obtained in step 1 into a WC mold, and perform cold high-pressure molding (pressure 300 MPa) with a tablet press for 10 minutes to obtain a prefabricated block.

[0037] (3) Preparation of high-entropy alloys by electric arc melting: close the furnace door to vacuumize, and then pass 99.999% high-purity argon gas to make the pressure in the furnace reach -0.01MPa relative to the standard atmospheric pressure, and quickly start the arc to reduce the output power. Adjust to 45%-50% (current: 225-250A) for smelting for 2 minut...

Embodiment 2

[0040] Preparation of ReWTaMoNb 0.2 . The specific steps are as follows:

[0041] (1) Mixing: Weigh 5.0280g of Re powder, 7.7199g of W-Mo alloy powder, 4.7410g of Ta powder, and 0.5023g of Nb powder with a purity of 99.9% (Re / W / Ta / Mo / Nb molar ratio is 1: 1.02:0.97:1.02:0.2), the particle size of the powder is 2 μm; use a light ball mill to mix evenly for 24 hours to obtain a mixed powder.

[0042] (2) Preparation of prefabricated block: put the mixed powder obtained in step 1 into a WC mould, and perform cold high-pressure molding (pressure 350 MPa) using a tablet press, with a holding time of 8 minutes to obtain a prefabricated block.

[0043] (3) Preparation of high-entropy alloys by electric arc melting: close the furnace door to vacuumize, and then pass 99.999% high-purity argon gas to make the pressure in the furnace reach -0.01MPa relative to the standard atmospheric pressure, and quickly start the arc to reduce the output power. Adjust to 45%-50% (current: 225-250A) ...

Embodiment 3

[0046] Preparation of ReWTaMoNb 0.5 . The specific steps are as follows:

[0047] (1) Mixing: take by weighing 99.9% of Re powder 5.0280g, W powder 4.7263g, Ta powder 4.8876g, Mo powder 2.7232g, Nb powder 1.2558g (Re / W / Ta / Mo / Nb mol ratio is 1:0.95:1:1.05:0.5), the particle size of the powder is 10 μm; use a light ball mill to mix evenly for 20 hours to obtain a mixed powder.

[0048] (2) Preparation of prefabricated block: put the mixed powder obtained in step 1 into a WC mold, and perform cold high-pressure molding (pressure 400 MPa) with a tablet press for 5 minutes to obtain a prefabricated block.

[0049] (3) Preparation of high-entropy alloys by electric arc melting: close the furnace door to vacuumize, and then pass 99.999% high-purity argon gas to make the pressure in the furnace reach -0.01MPa relative to the standard atmospheric pressure, and quickly start the arc to reduce the output power. Adjust to 45%-50% (current: 225-250A) for smelting for 3 minutes. Afterwa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com