Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

134results about How to "Precise adjustment and control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

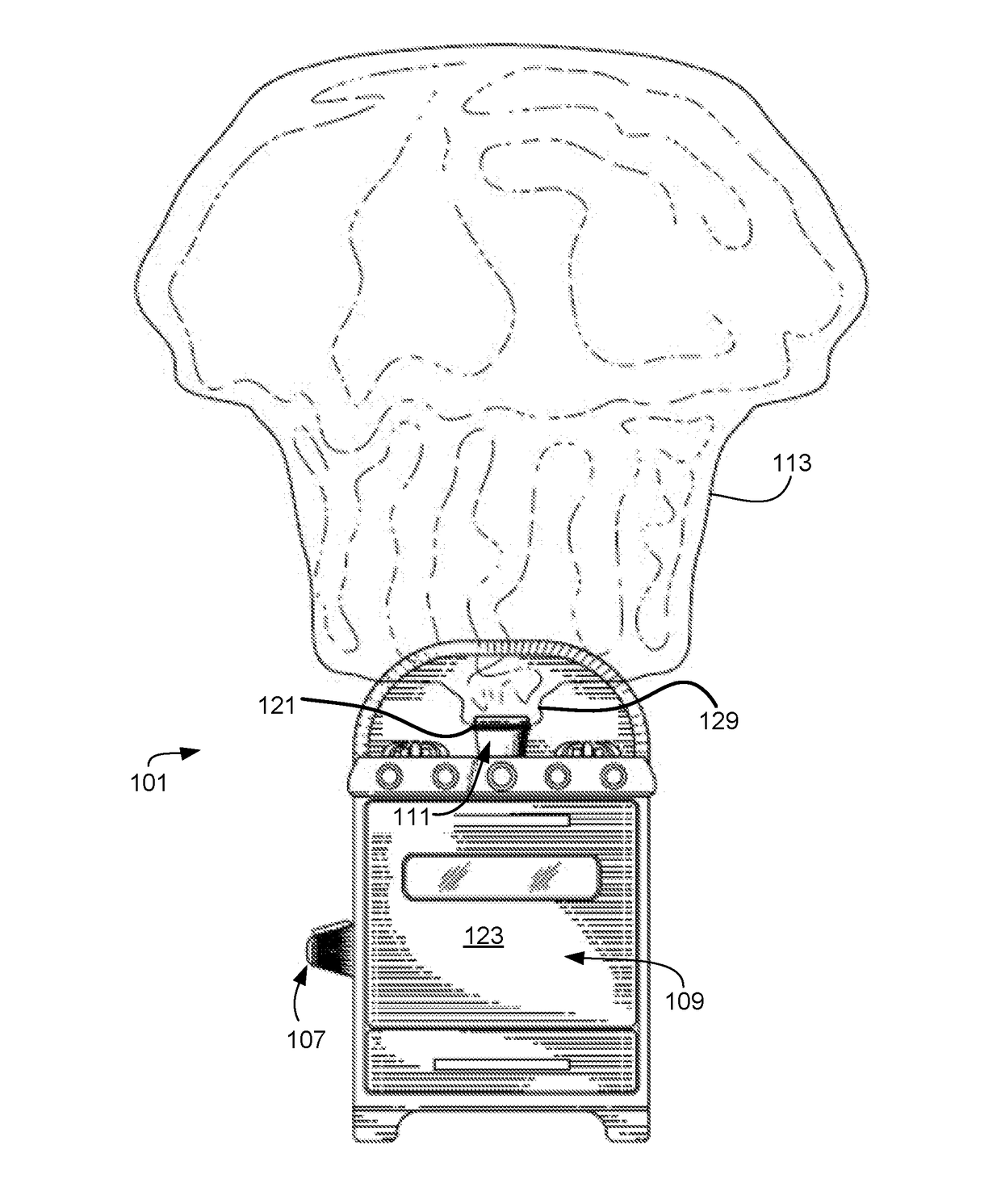

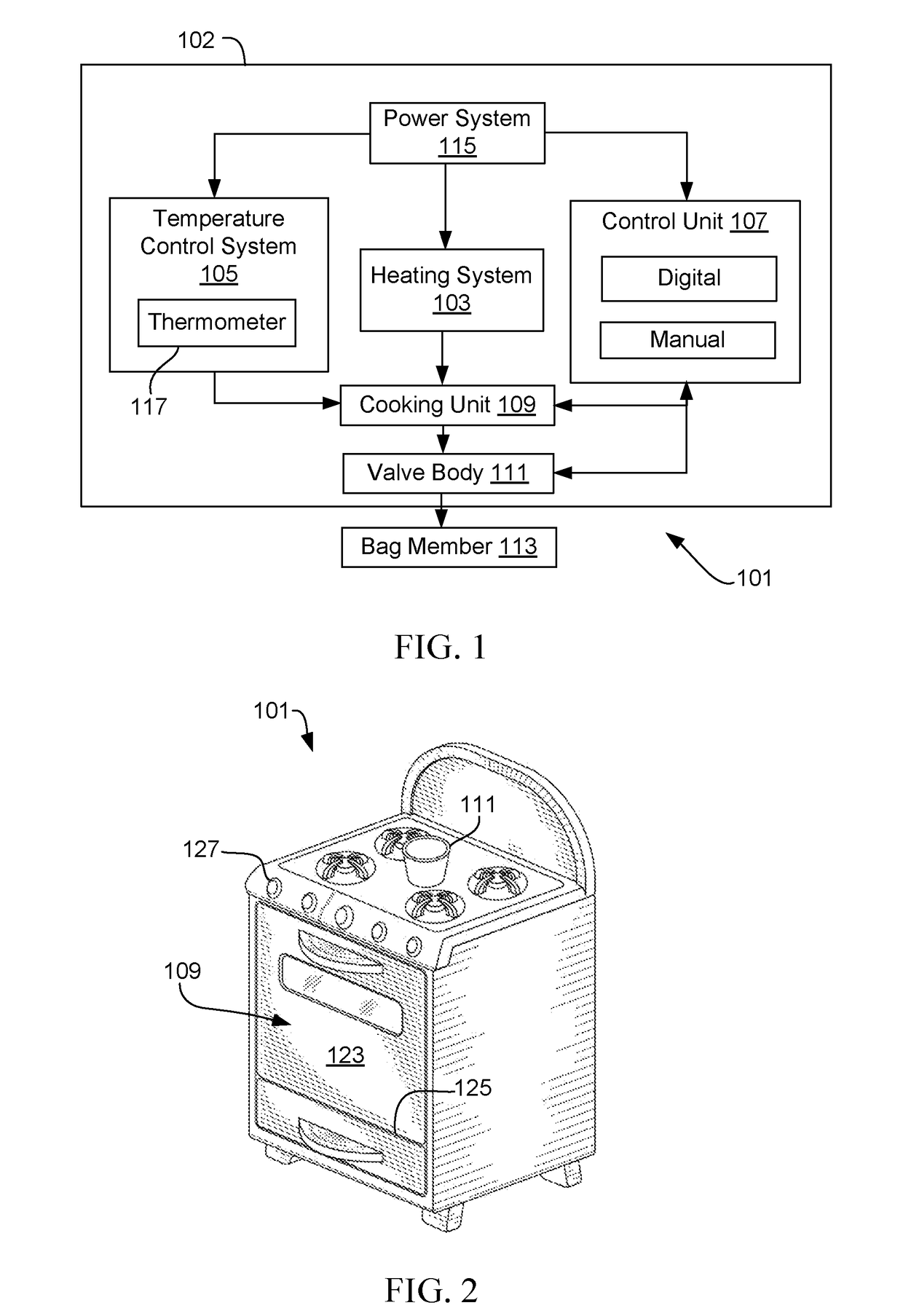

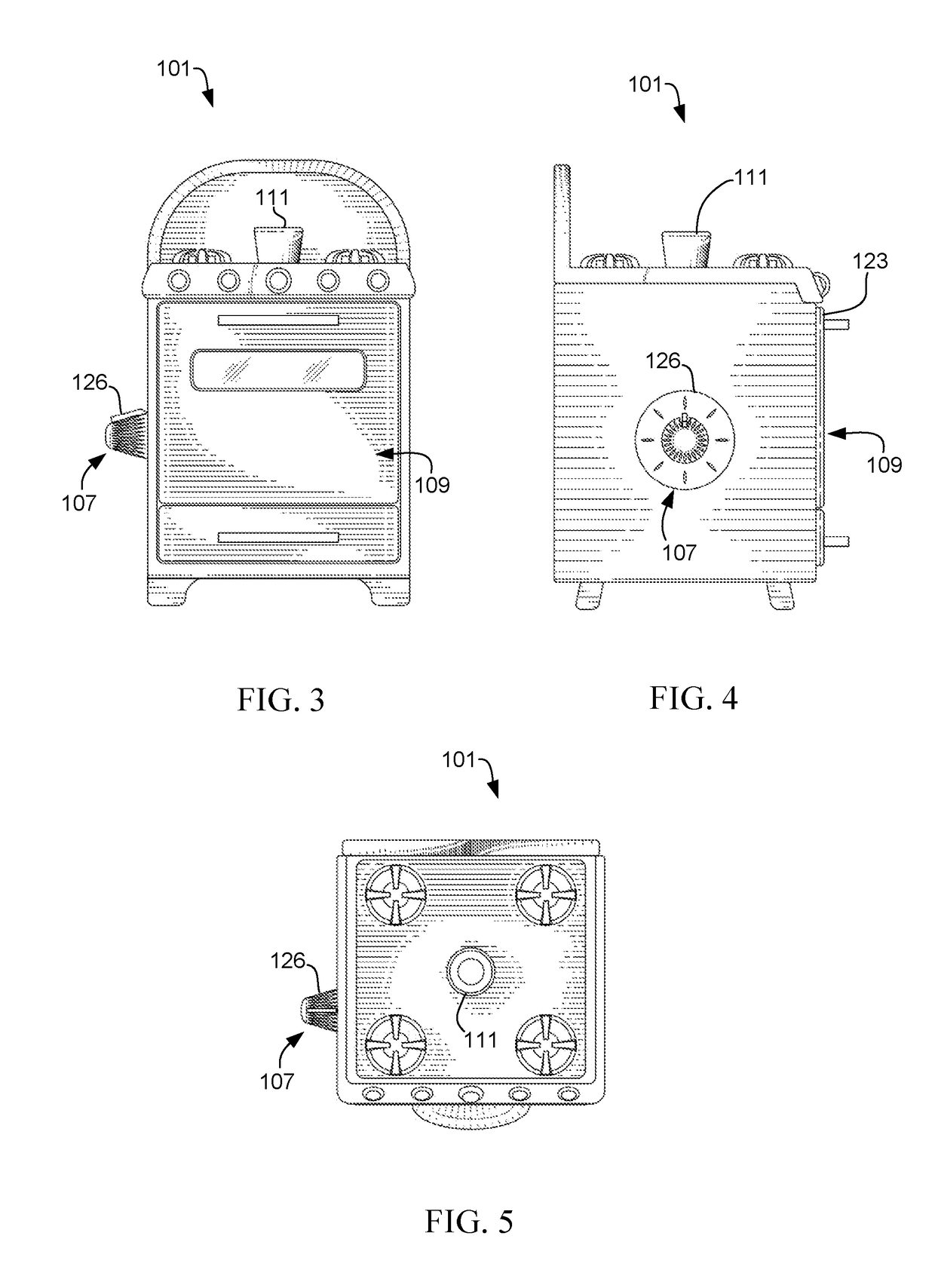

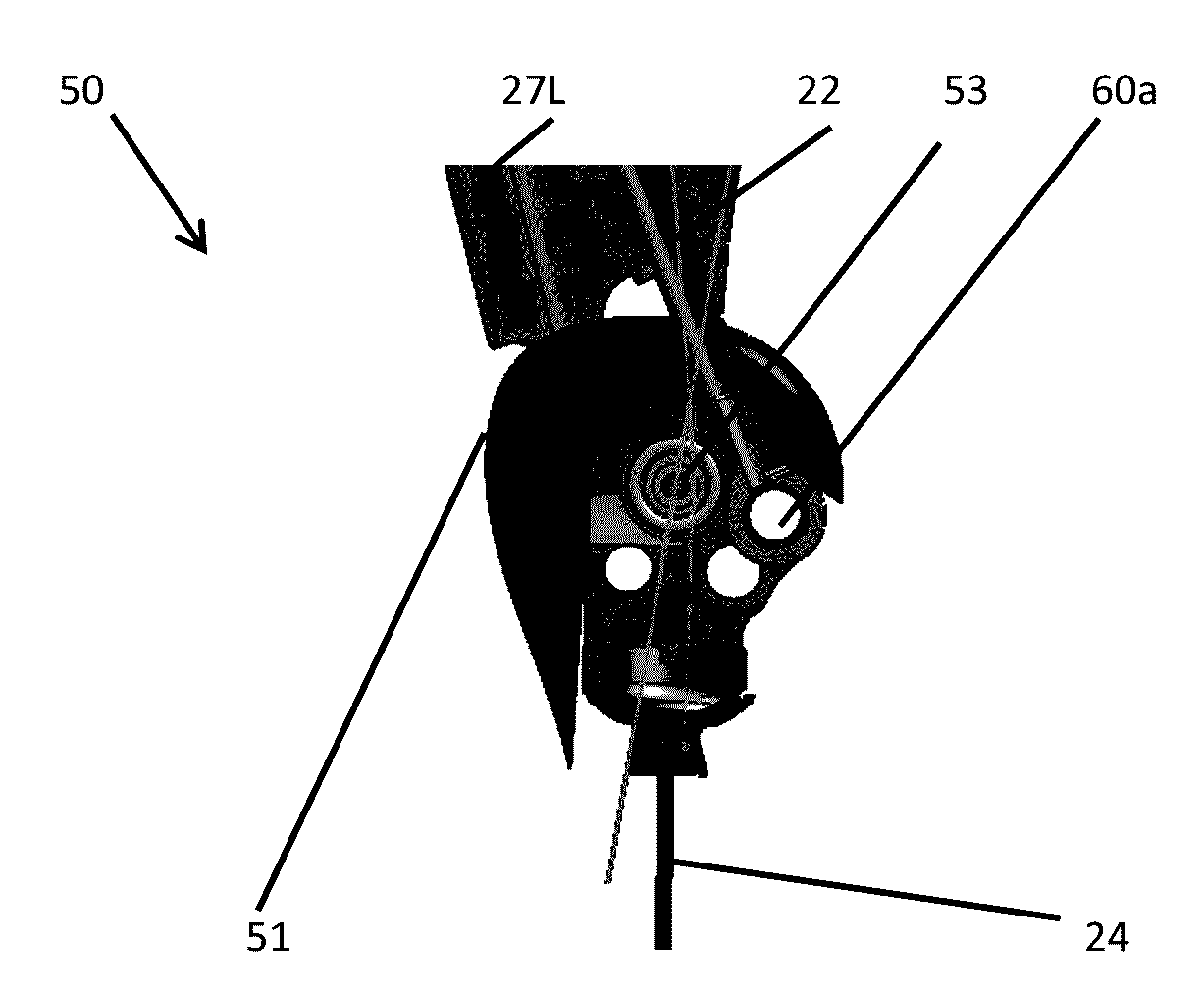

Desktop vaporizer

InactiveUS20170261200A1Easy to controlPrecise regulationRespiratorsSteam generation heating methodsControl systemProcess engineering

A system and method for the production and capturing of clean vapors from the vaporizing of a plant substance is described. The system includes a heating system configured to generate heat within a cooking unit. A temperature control system is configured to monitor the level of heat generated by the heating system. Both systems are regulated by a control unit. The control unit is configured to provide an interface for a user to regulate the performance of the temperature control system and the heating system. The cooking unit defines a fully enclosed volume to contain the heat generated. A valve body is in communication with the cooking unit and configured to regulate the release of gases within the cooking unit as it passes into a bag member. The bag member is used to capture released vapor generated by vaporizing the plant substance.

Owner:STULTZ DAVID

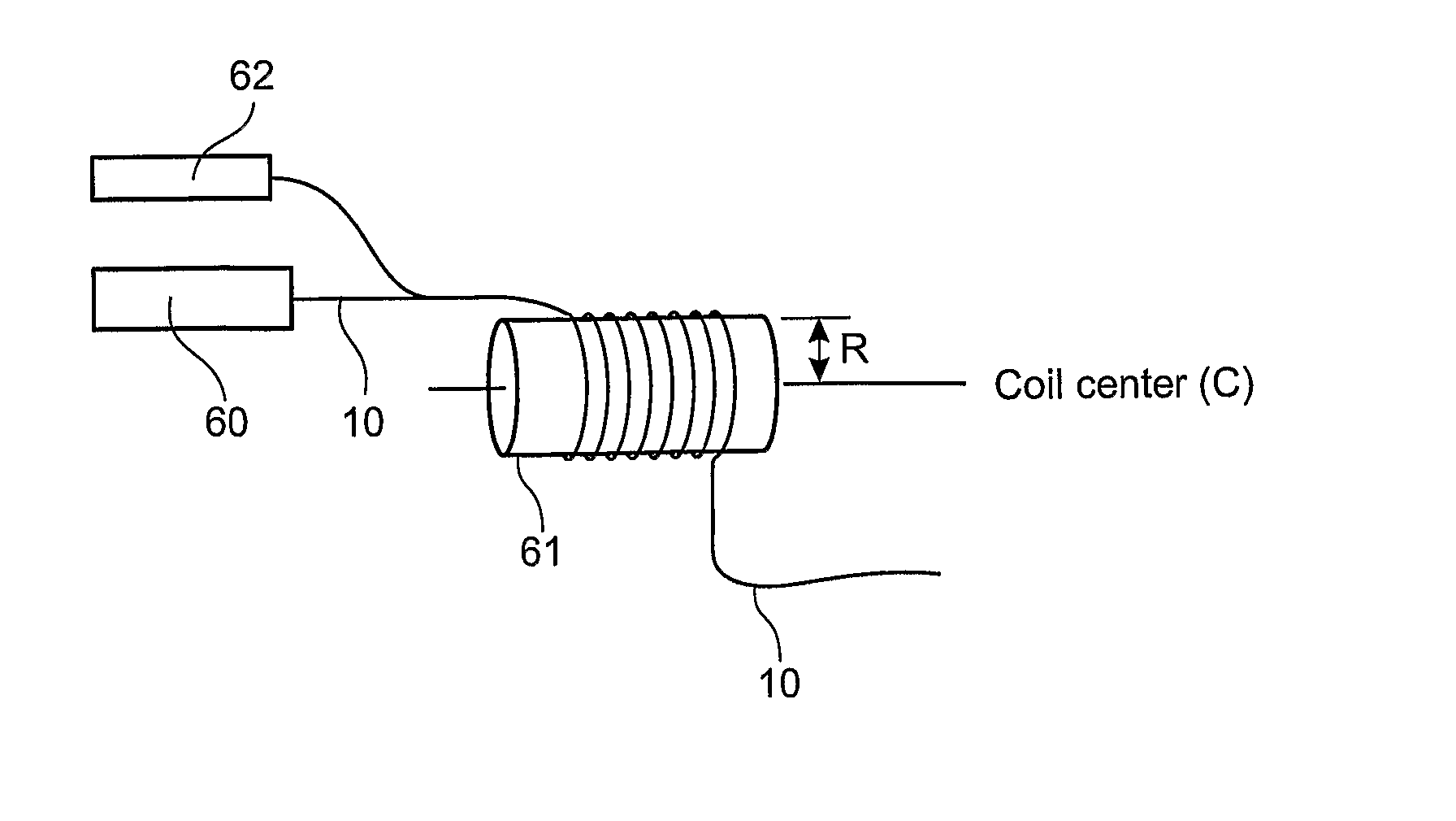

Optical Fiber Gain Medium with Modal Discrimination of Amplification

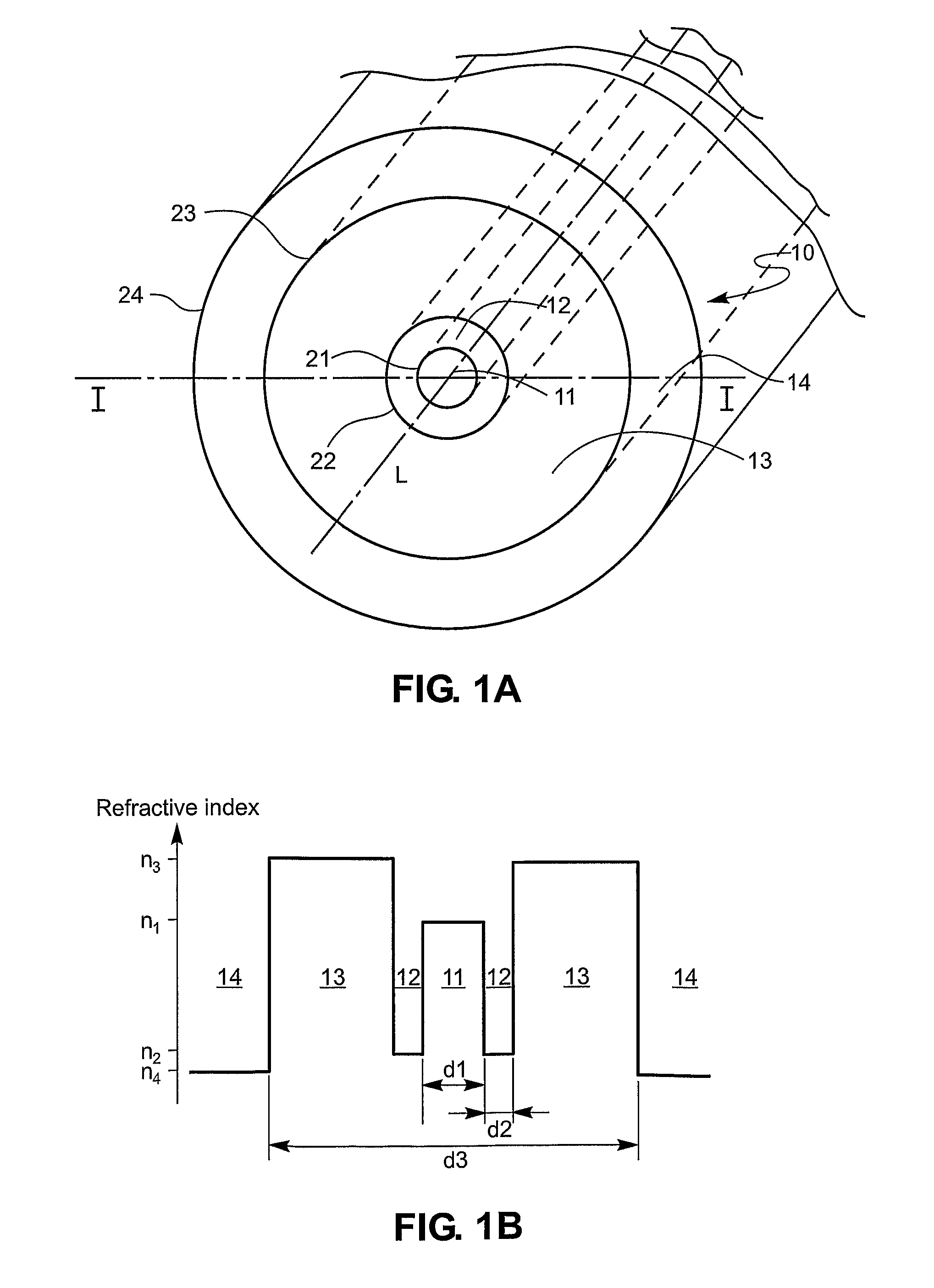

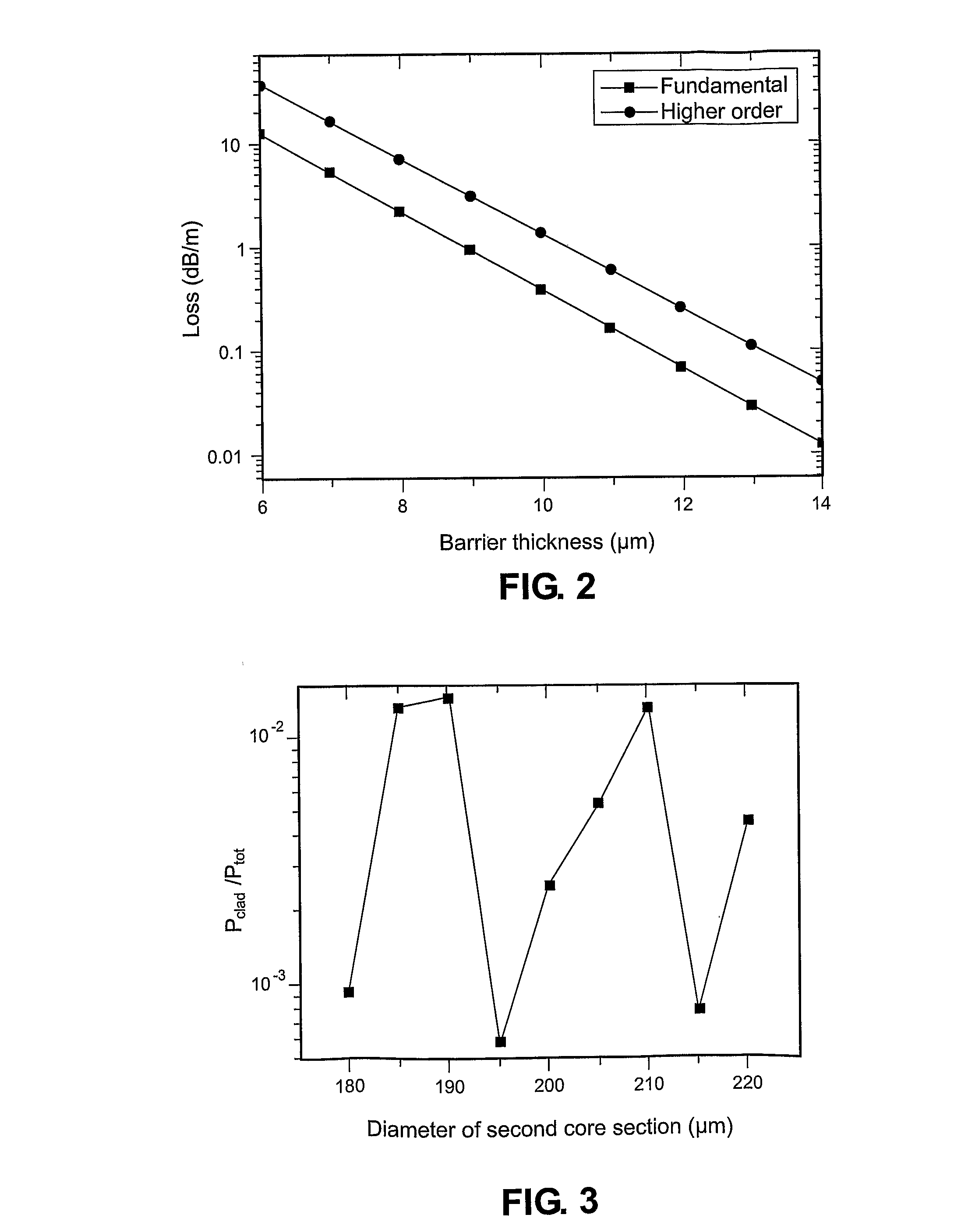

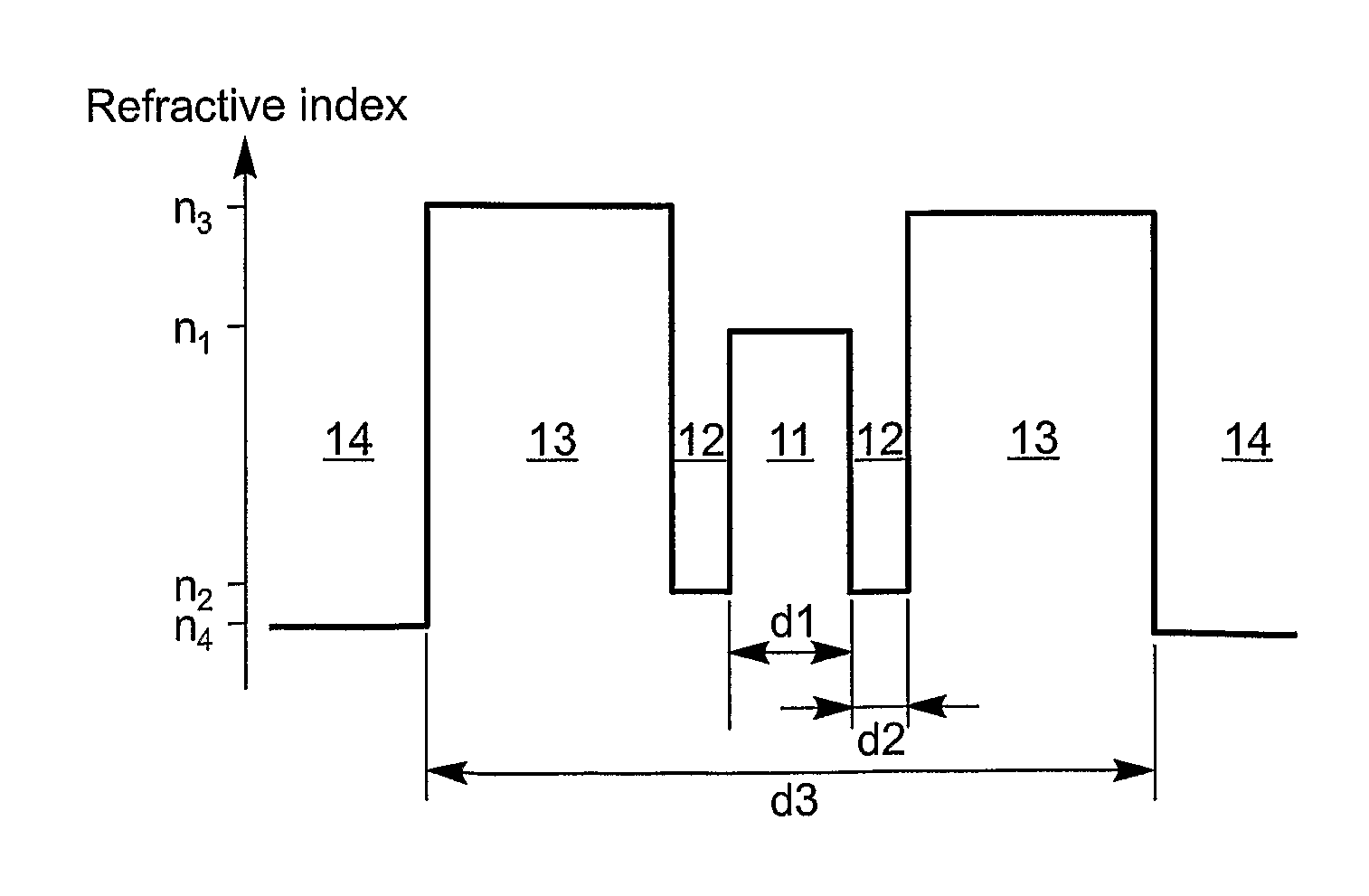

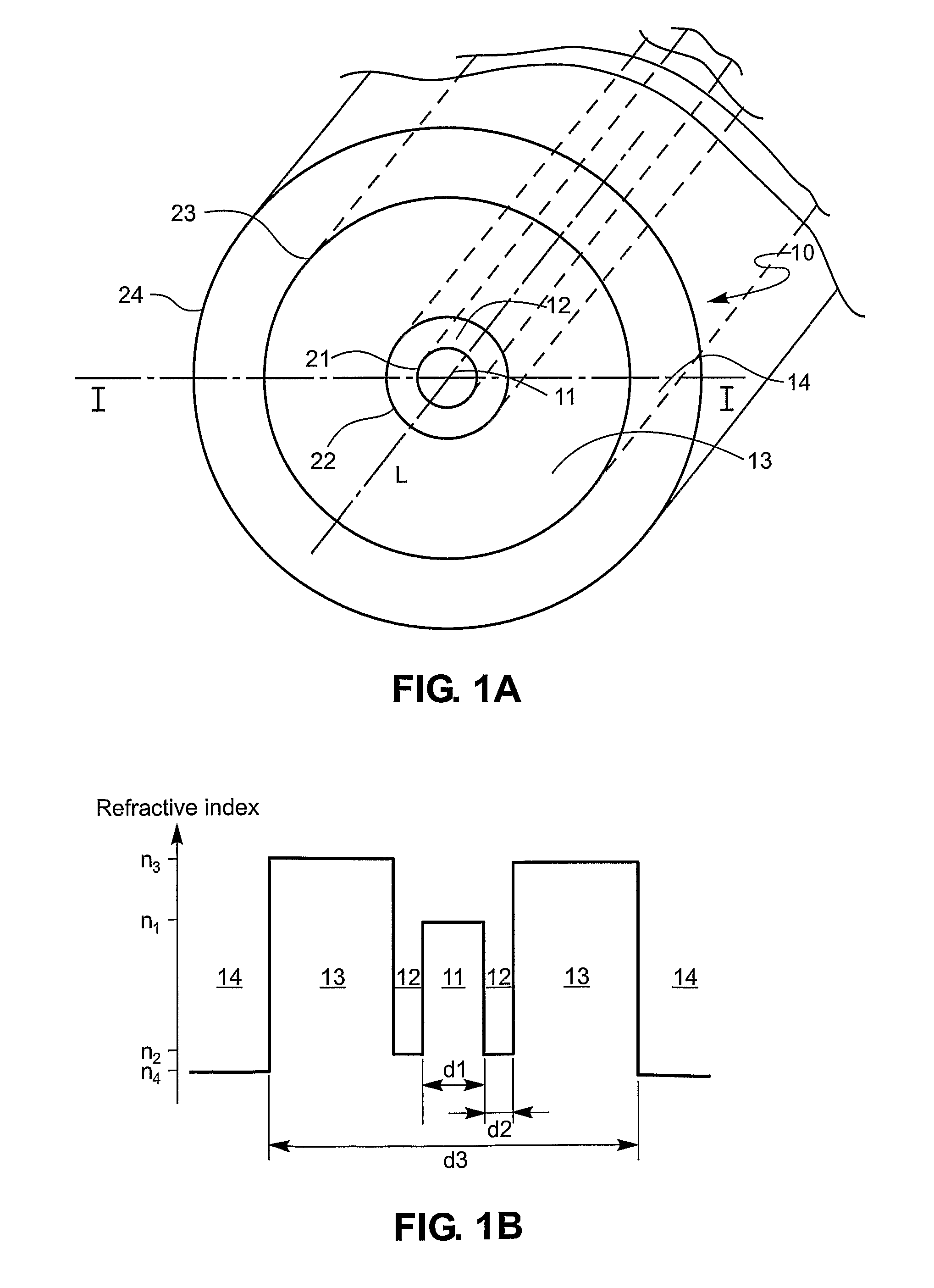

InactiveUS20080025363A1Easy to controlEasy to adjustLaser using scattering effectsOptical fibre with multilayer core/claddingFiberRefractive index

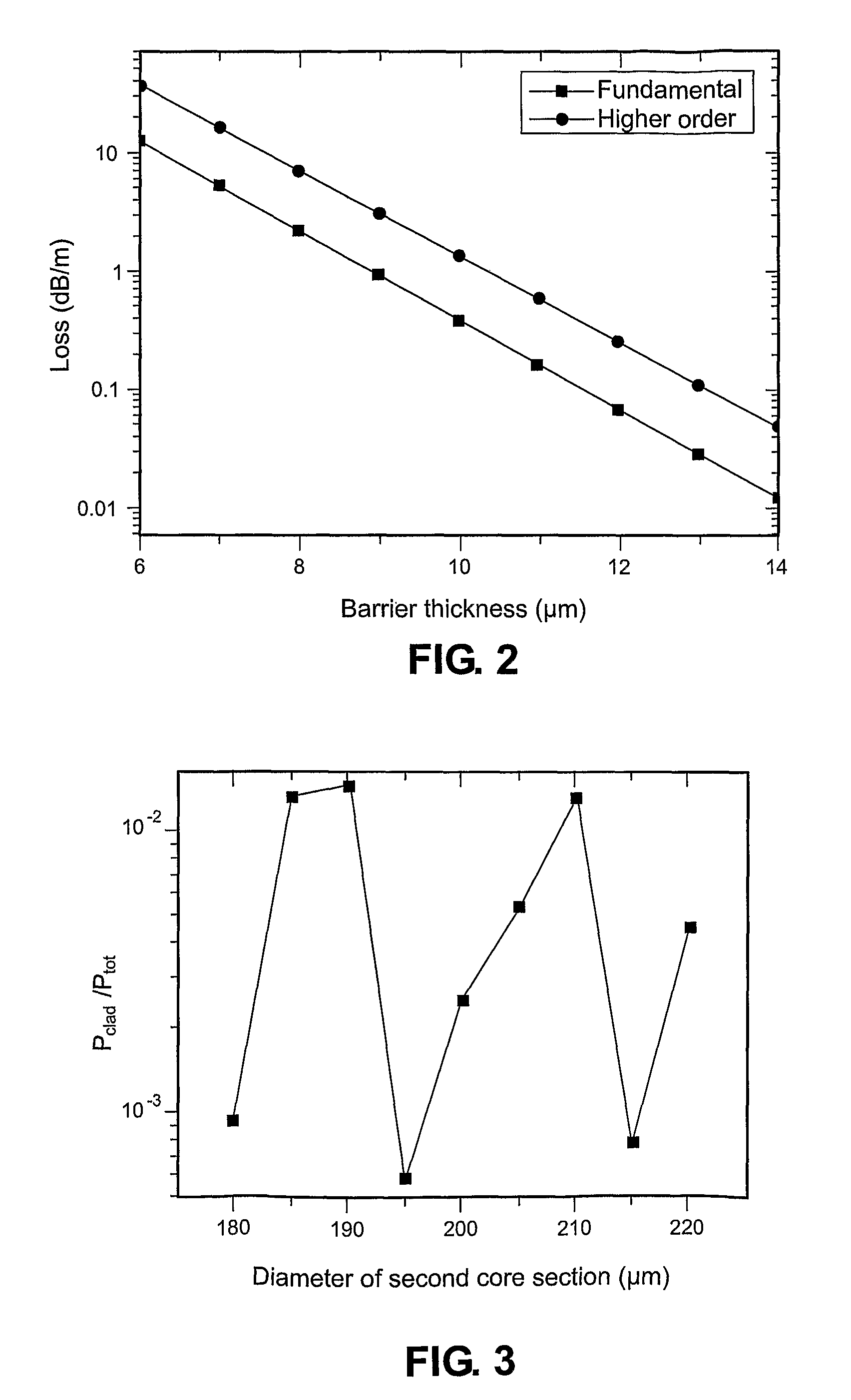

An active multimode optical fiber consisting of a first core section (11), a thin barrier layer (12) material having a thickness (d2) and a lower refractive index than that of the first core section by an index difference (Δn), a second core section (13) having a refrective index equal or higher than that of the first core section, and a cladding (14) having an index lower than that of the first core section. Said index difference and said thickness are selected so that a fundamental core mode couples less strongly with said cladding modes than higher order core modes. A scheme of changing the symmetry of the fiber for reduced sensitivity of the fundamental mode of the first core section to resonance effects.

Owner:ROFIN SINAR LASER

Optical fiber gain medium with modal discrimination of amplification

InactiveUS7760771B2Precise adjustment and controlHigh gainLaser using scattering effectsOptical fibre with multilayer core/claddingFiberRefractive index

An active multimode optical fiber consisting of a first core section (11), a thin barrier layer (12) material having a thickness (d2) and a lower refractive index than that of the first core section by an index difference (Δn), a second core section (13) having a refractive index equal or higher than that of the first core section, and a cladding (14) having an index lower than that of the first core section. Said index difference and said thickness are selected so that a fundamental core mode couples less strongly with said cladding modes than higher order core modes. A scheme of changing the symmetry of the fiber for reduced sensitivity of the fundamental mode of the first core section to resonance effects.

Owner:ROFIN SINAR LASER

Methods and apparatus for rate control during dual pass encoding

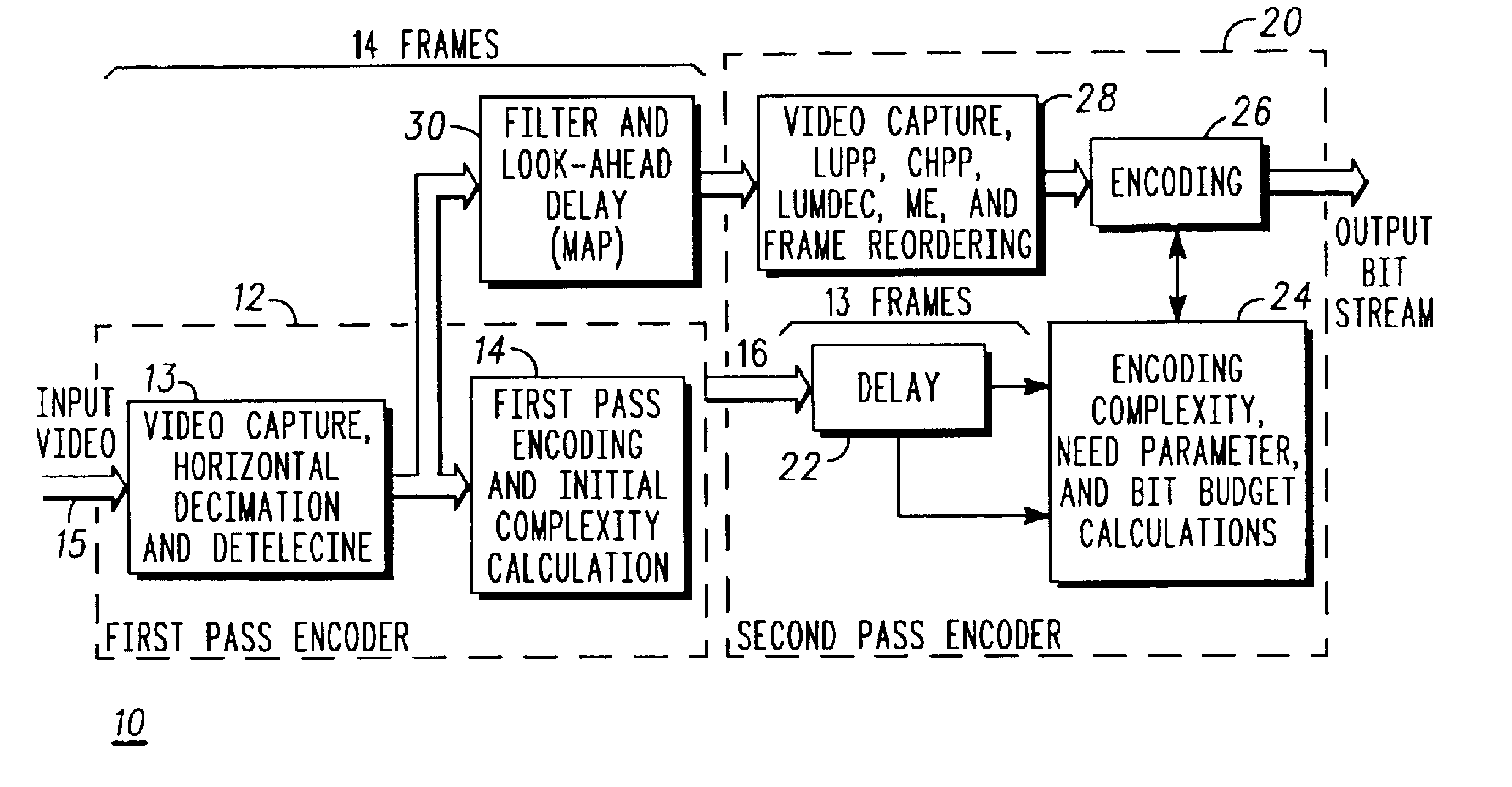

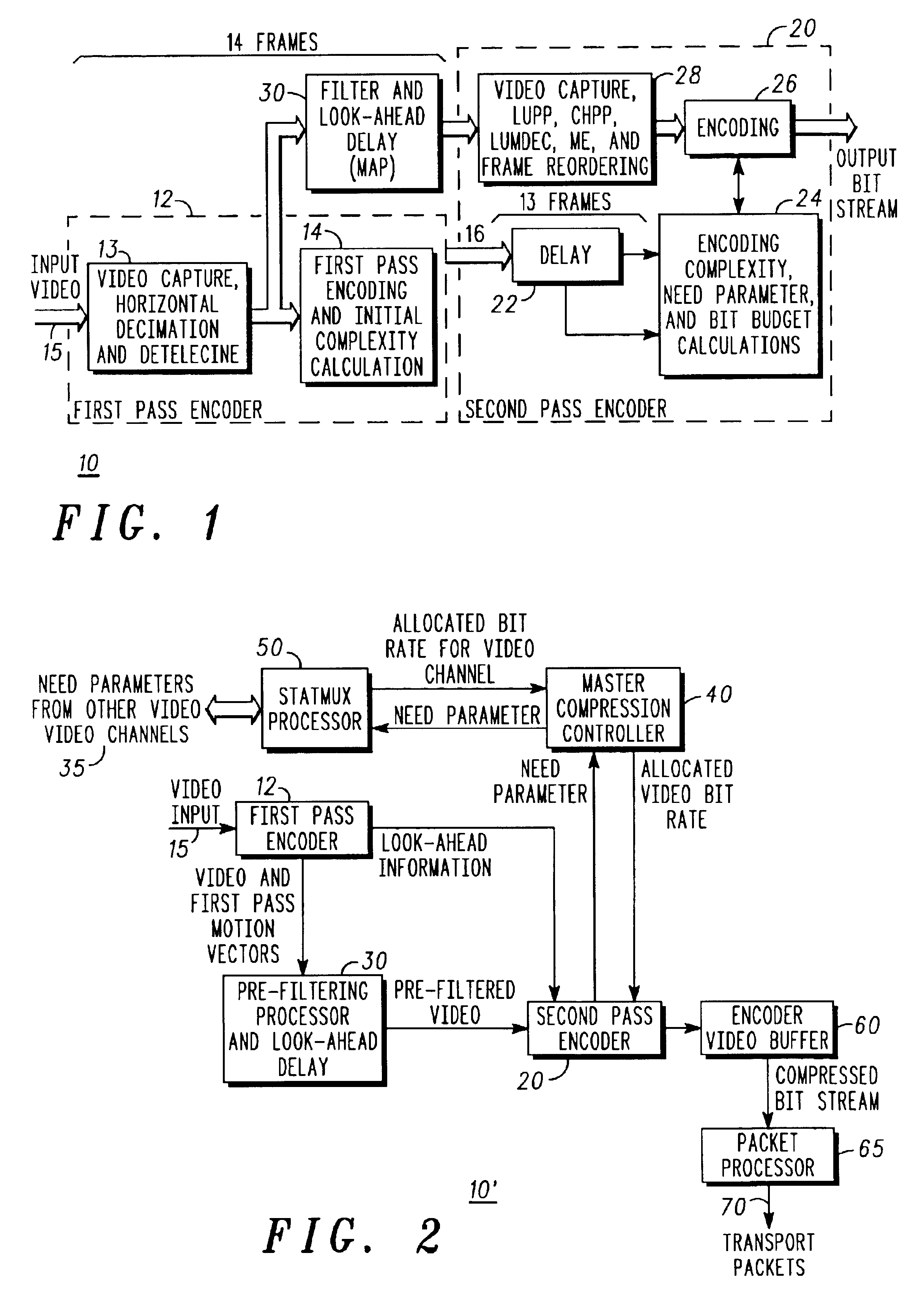

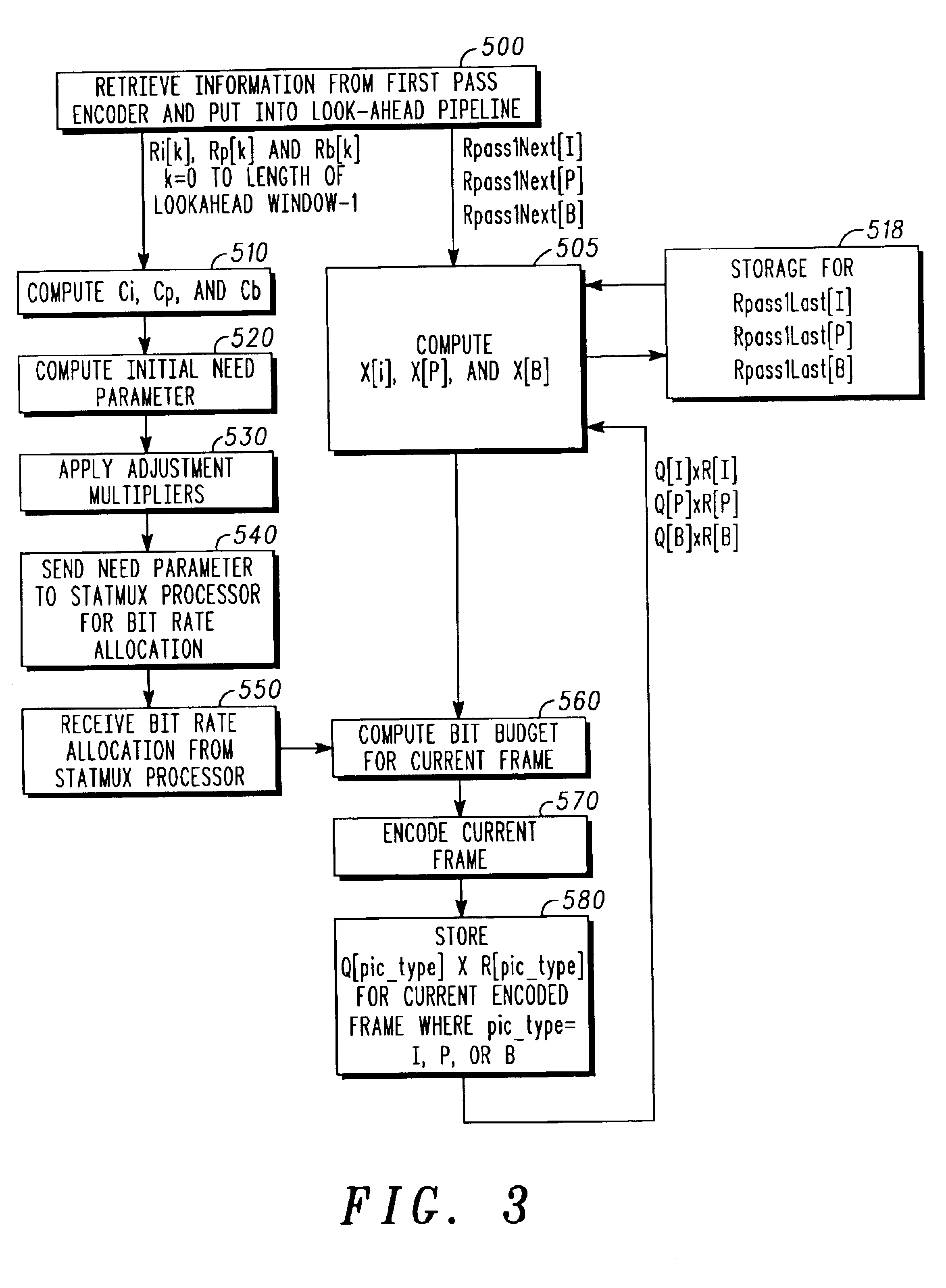

ActiveUS6961376B2Precise adjustment and controlColor television with pulse code modulationColor television with bandwidth reductionFrame basedComputer science

Methods and apparatus for rate control in a dual pass encoding scheme are provided. A first pass encoder encodes alternate slices of anchor frames as I-slices and P-slices respectively in order to generate statistics for both I and P frame encoding for the same anchor frame. An initial complexity estimate for encoding a current frame is determined by the first pass encoder based on statistics from first pass encoding of the current frame and from first pass encoding of a prior encoded frame. A second pass encoder estimates an encoding complexity for the current frame based on the initial complexity and statistics from second pass encoding of the prior encoded frame. The second pass encoder then determines a bit budget for second pass encoding of the current frame based on the encoding complexity.

Owner:ARRIS ENTERPRISES LLC

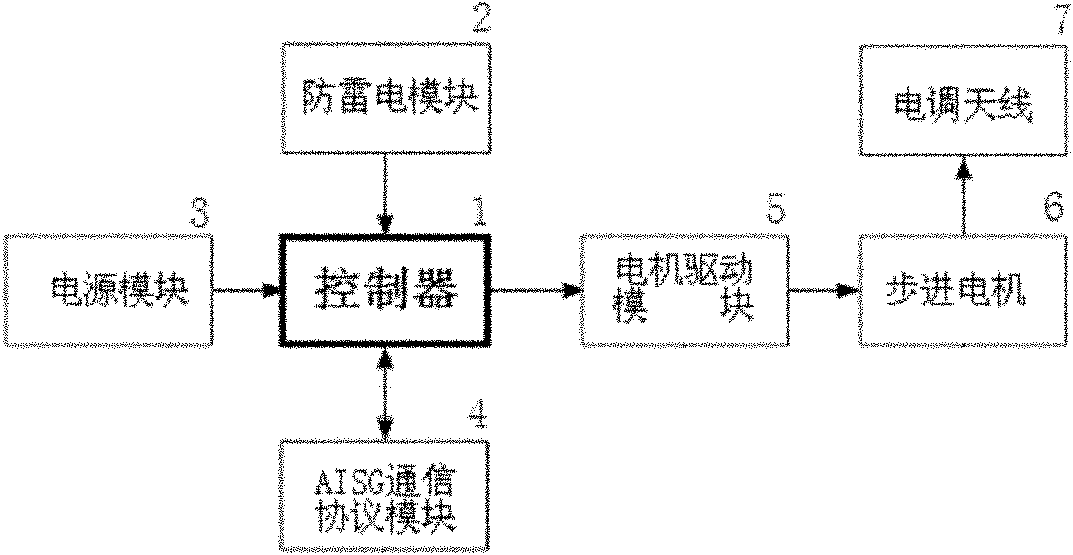

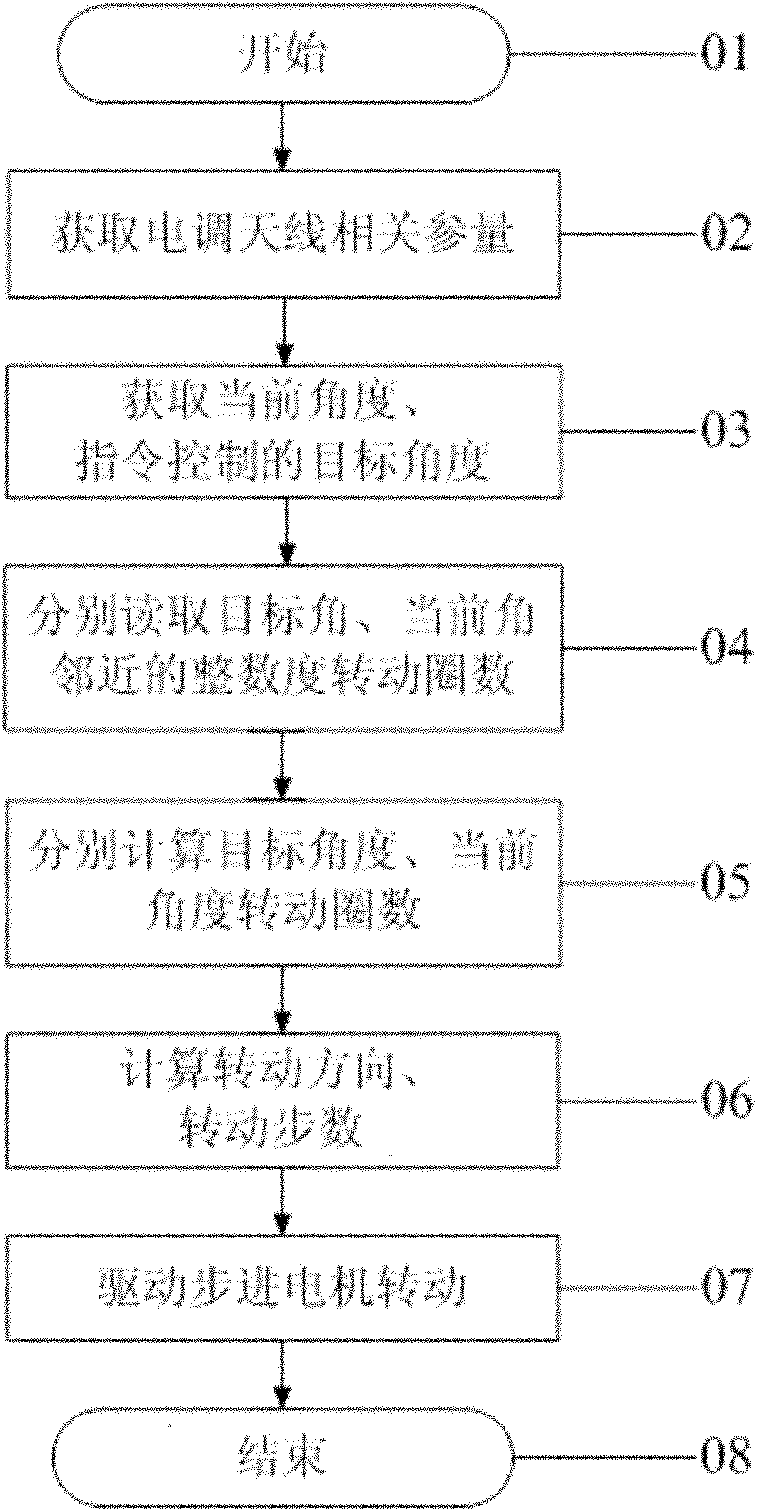

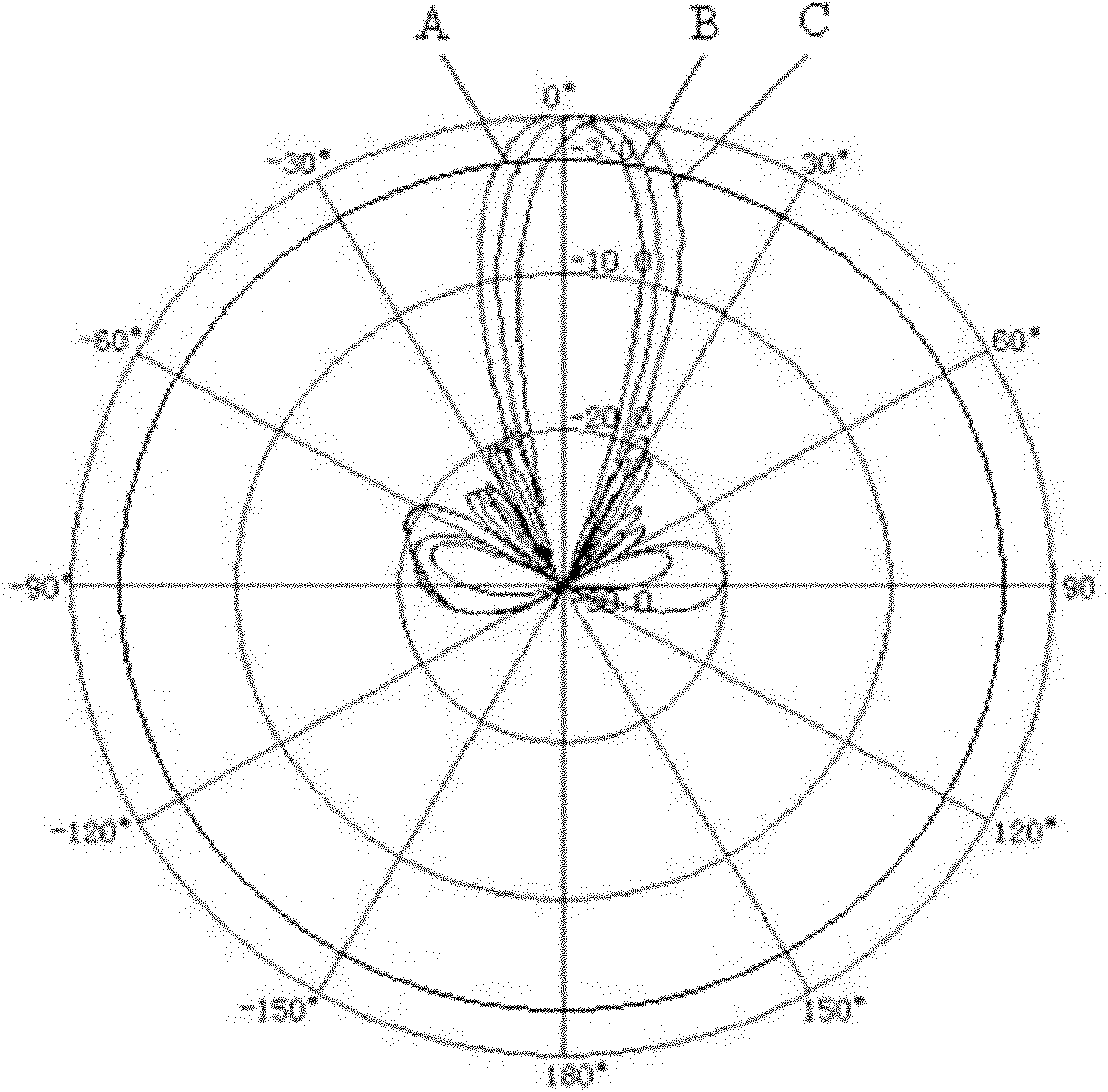

Nonlinear algorithm for controlling downtilt angles of electrically-adjustable antenna

ActiveCN102064388AEasy to controlPrecise adjustment of electric downtilt angleAntennasElectricityNonlinear algorithms

The invention discloses a nonlinear algorithm for controlling downtilt angles of an electrically-adjustable antenna, relating to the technical field of base station antenna. Based on a remote control system for the electrically-adjustable antenna, the invention is characterized in that the algorithm set in a controller of the control system comprises the following steps of: 1, storing parameters associated with various modes of the electrically-adjustable antennae which are regarded as controlled objects as well as the number of adjusting rotation of each downtilt angle of various modes of the electrically-adjustable antennae in relation to zero reference; 2, when information of an order for the adjustment of the electrically-adjustable antennae is received, determining, according to the information, the type of the electrically-adjustable antennae to be adjusted and the associated parameters of the controlled electrically-adjustable antennae; and 3, adjusting target downtilt angles of the electrically-adjustable antennae by determining adjusting rotation direction and rotation quantity based on the angle adjusting rotation parameters of the controlled electrically-adjustable antennae and on the current downtilt angle. The algorithm is convenient in use, high in adjustment precision and is suitable for remotely adjusting the electric downtilt angles of various types of the electrically-adjustable antennae in mobile communication.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

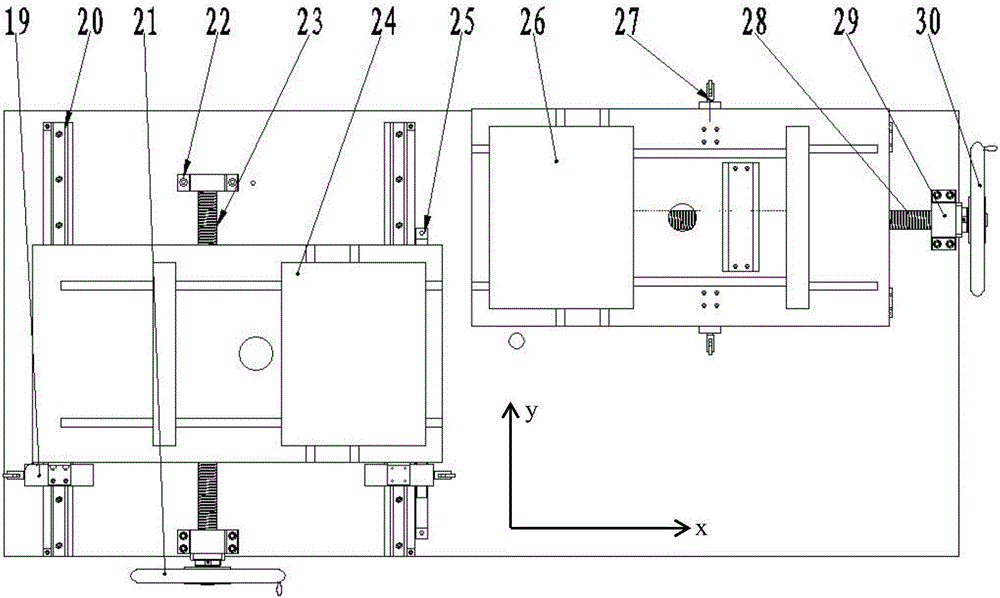

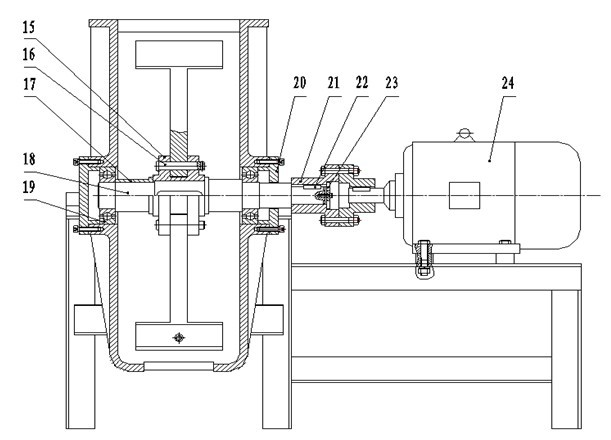

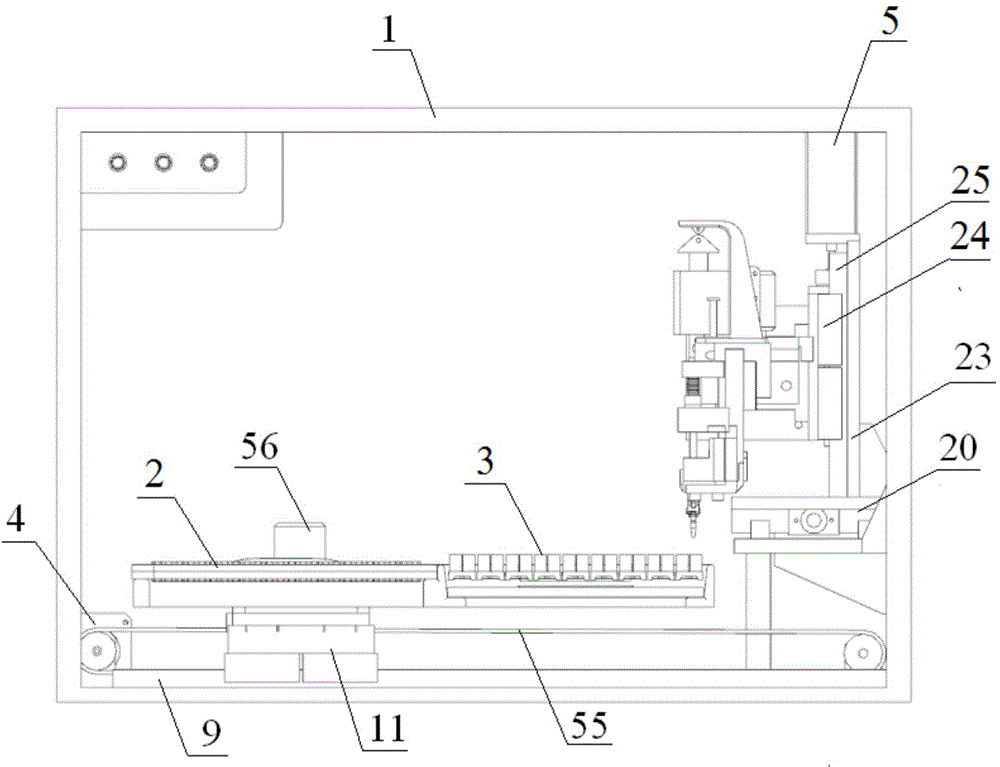

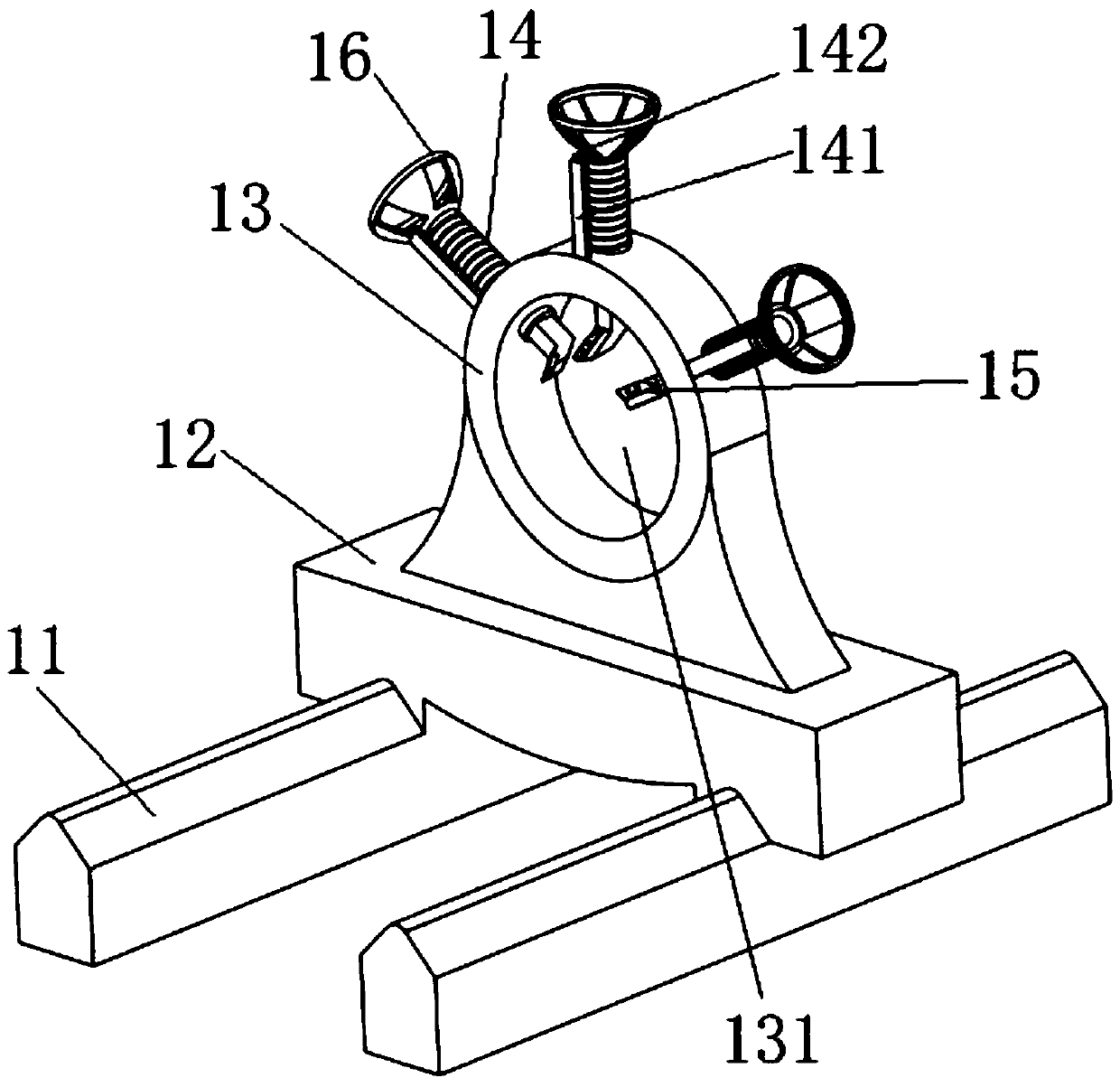

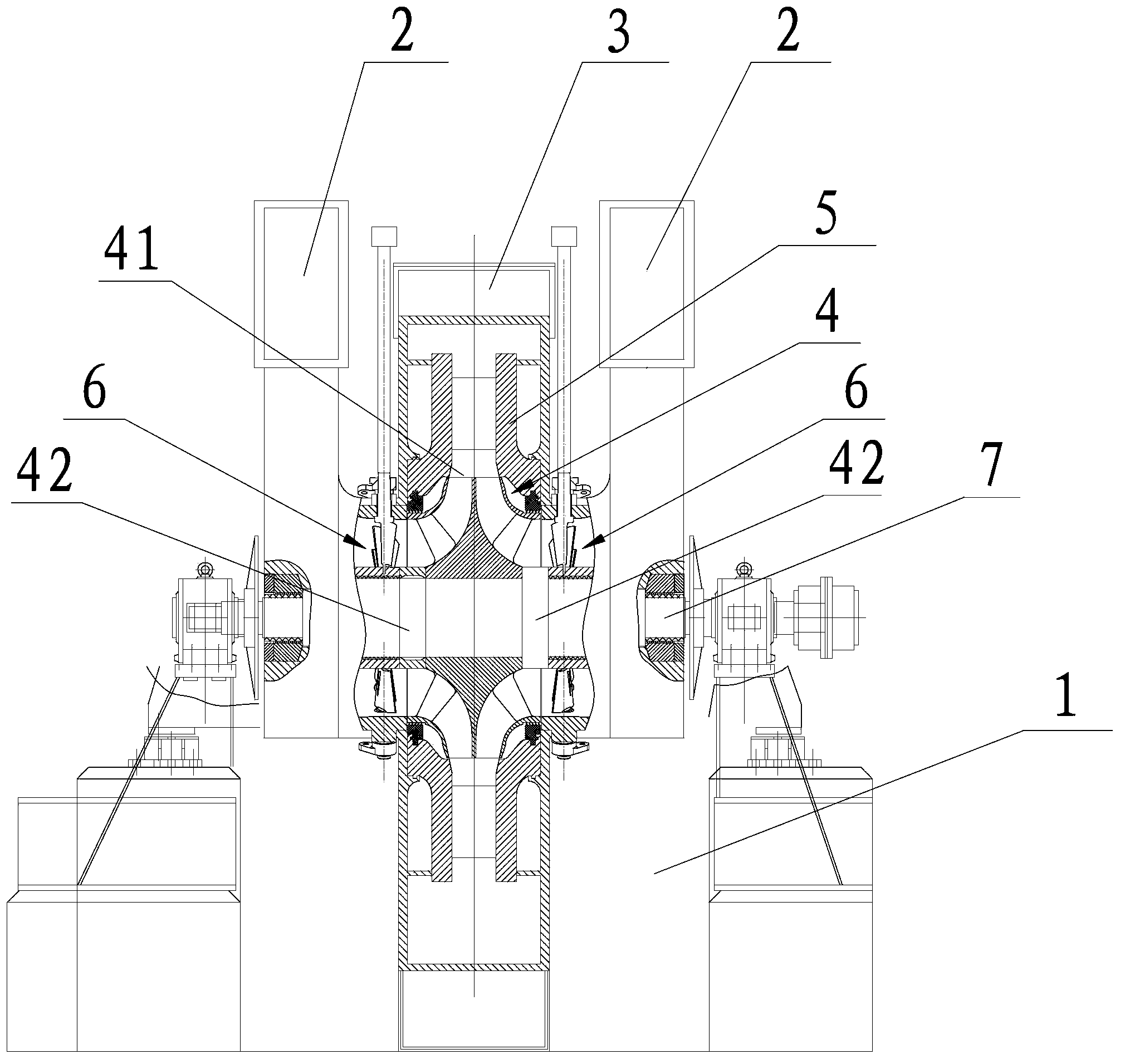

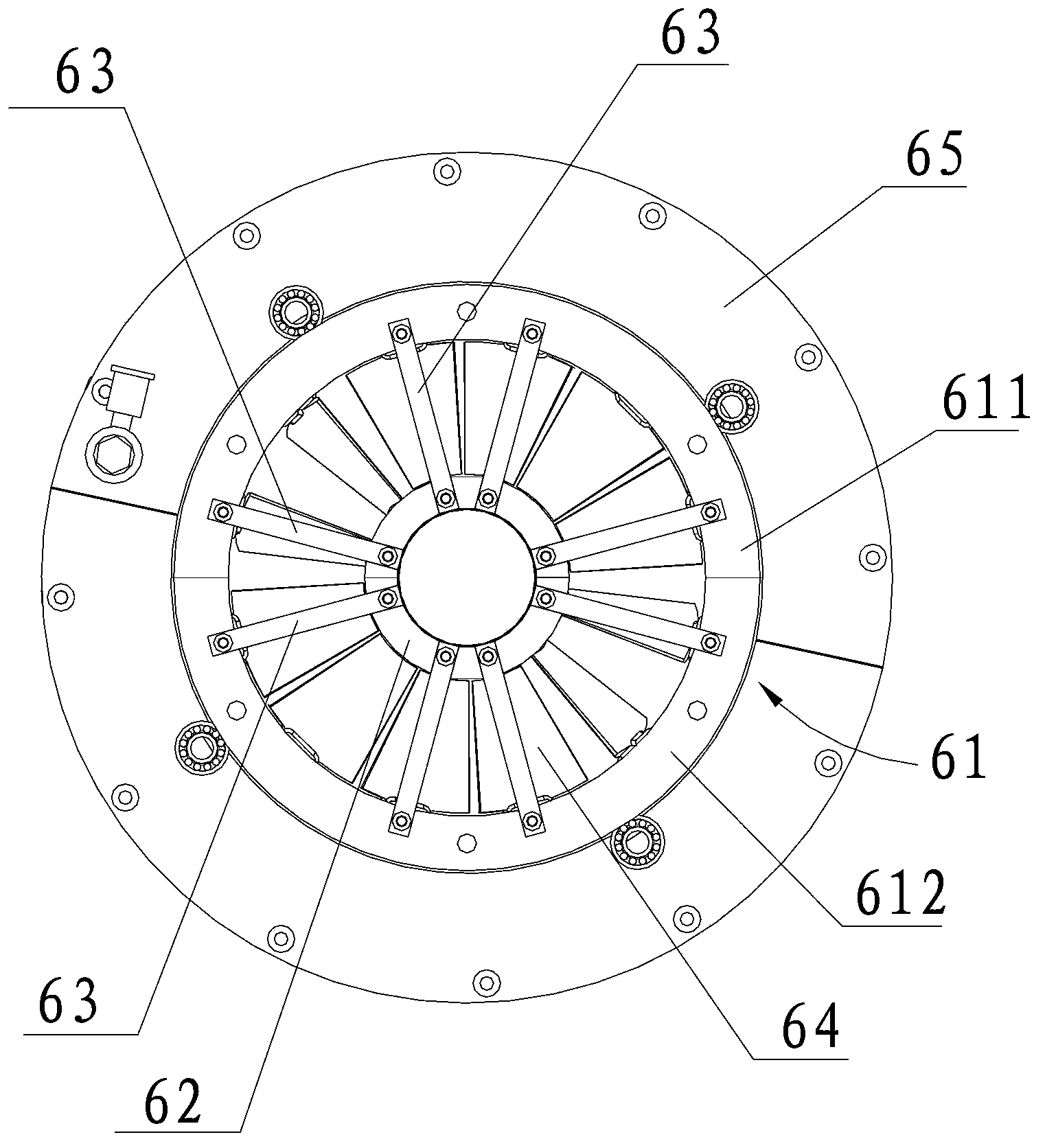

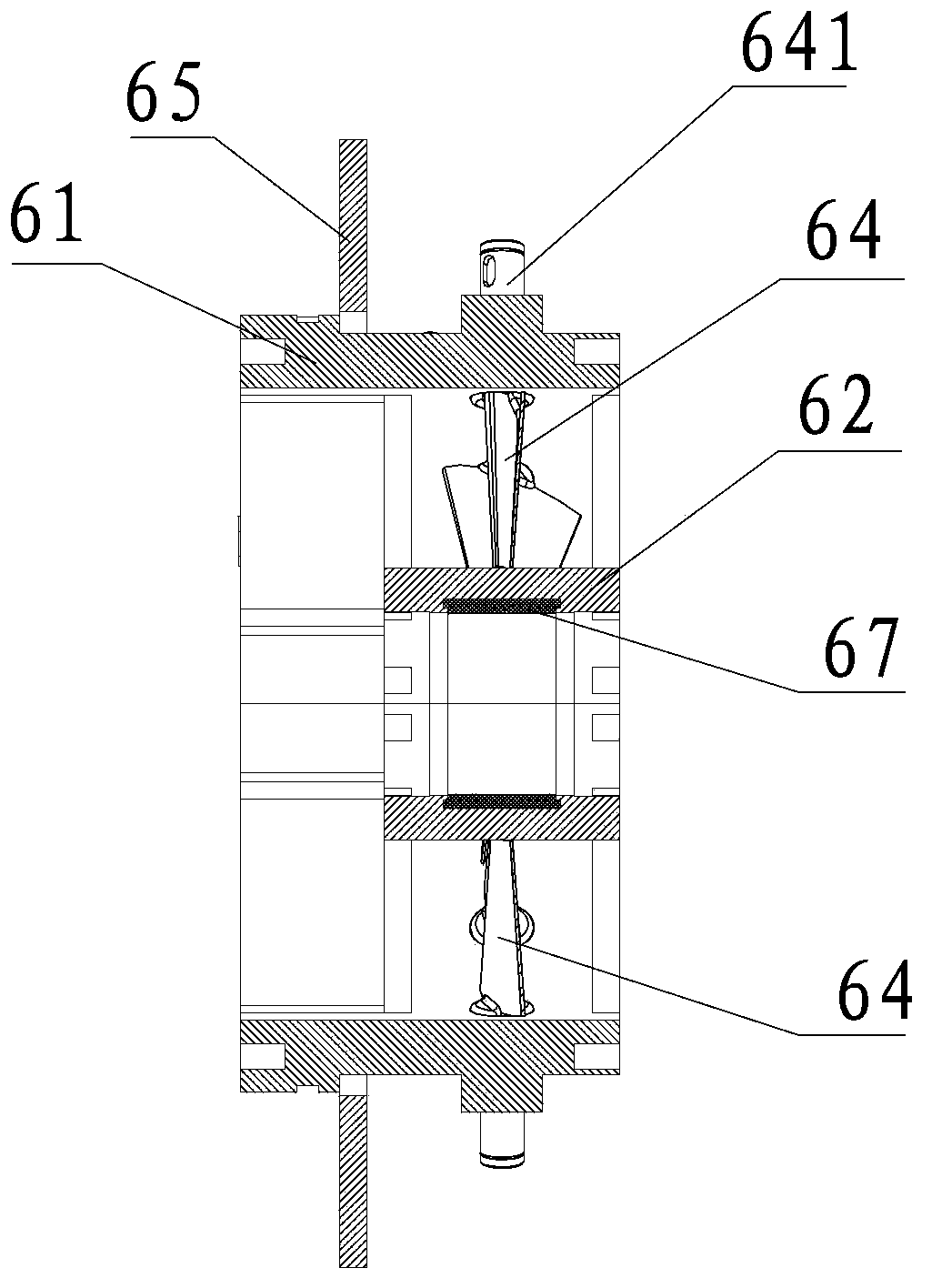

Gear dynamic transmission error measurement method and gear dynamic transmission error measurement device

ActiveCN106813922AWorking conditions are realReliable measurement resultsMachine gearing/transmission testingMeasurement deviceGear geometry

The present invention relates to a gear dynamic transmission error measurement method and a gear dynamic transmission error measurement device, and belongs to the gear transmission precision measurement technology field. Aiming at the development tendency that a conventional gear measurement device is required to use the gear dynamic precision taking a gear dynamics research result as the basis to substitute for the gear static precision taking the gear geometry and kinematics research results as the basis, the present invention provides the gear dynamic transmission error measurement method and the gear dynamic transmission error measurement device. By a gear rapid assembling device, the gears of different sizes and specifications are replaced rapidly and at a high precision; by a precise movement platform, the adjustment of a center distance and the tooth width direction parameters is controlled accurately; and by utilizing a working condition simulation system to simulate the state of a gear actual working system, the measurement precision and the credibility of a dynamic transmission error are improved. By considering the gear working load and the lubrication conditions, adopting an unconnected high-precision circular grating to obtain the information of the angular positions of the driving and driven gears, and utilizing a digital phase comparison method to process the data, the gear dynamic transmission error is obtained.

Owner:BEIJING UNIV OF TECH

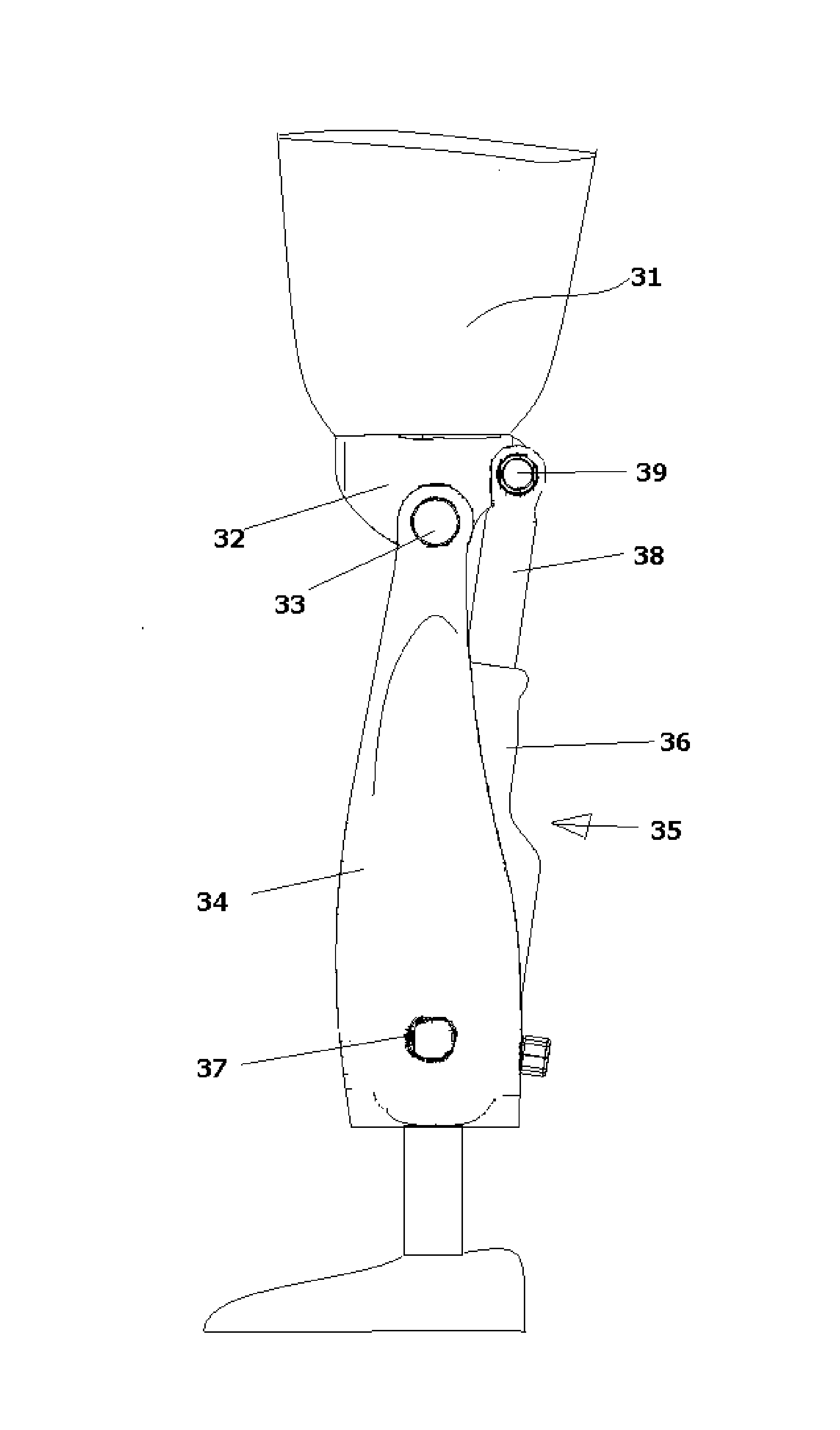

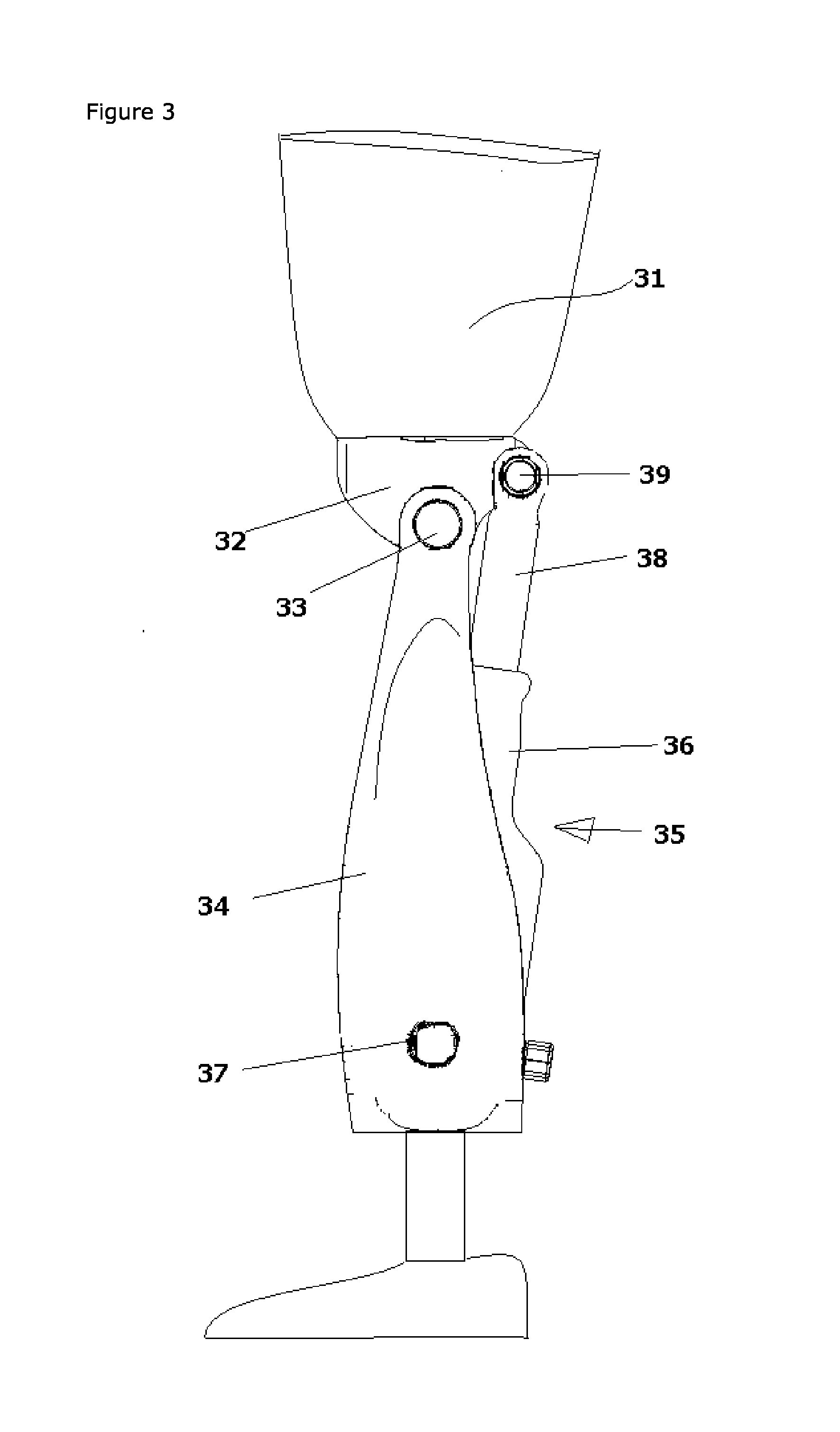

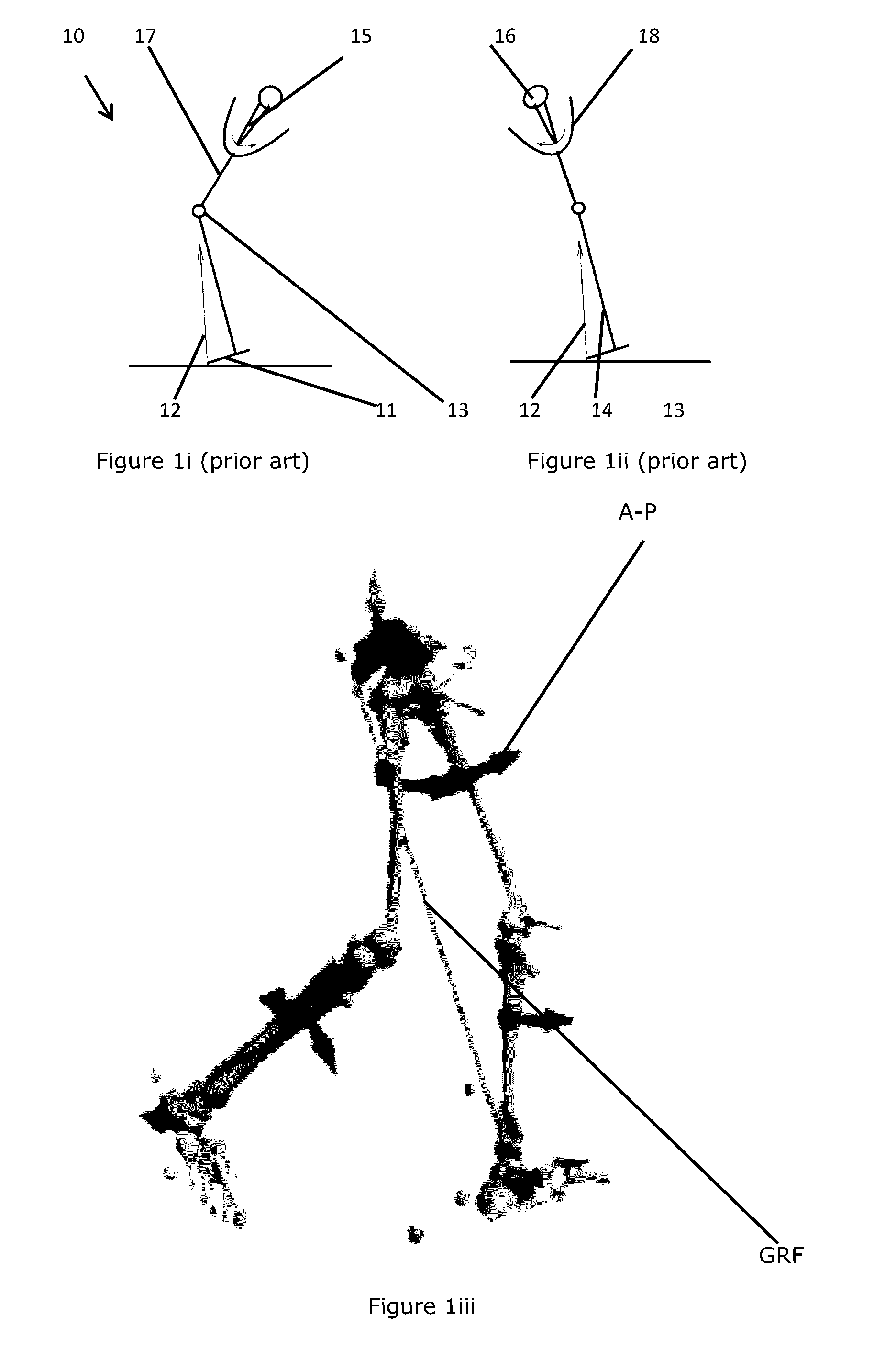

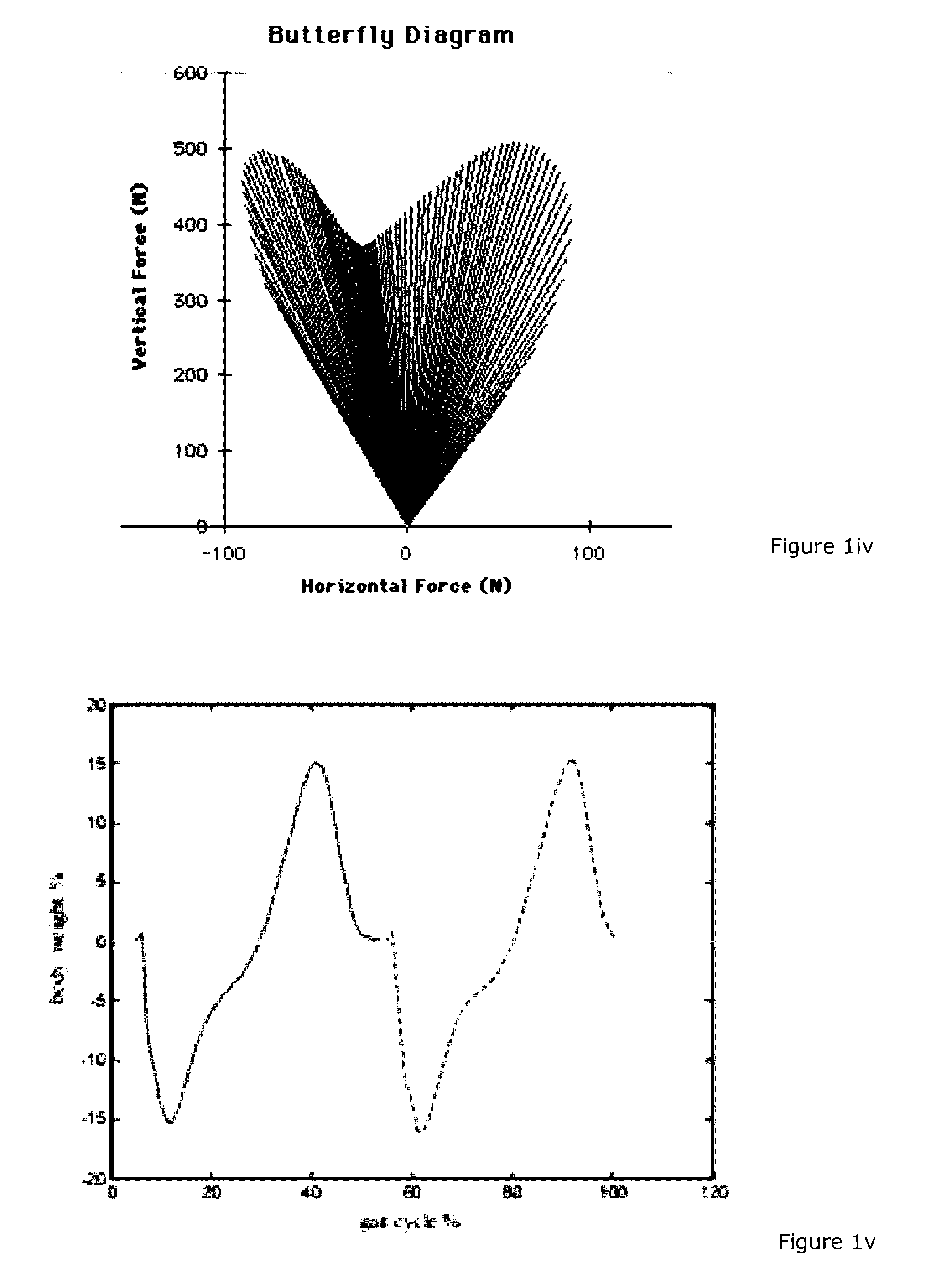

Hydrualic prosthetic joint

ActiveUS20160235558A1Keep openMemory is also lostSpringsArtificial legsDifferential pressureHuman motion

Owner:BOENDER JACOB QUINTUS LAURENCE ANTHONY +1

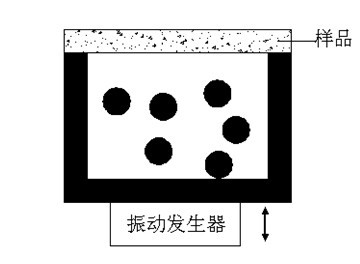

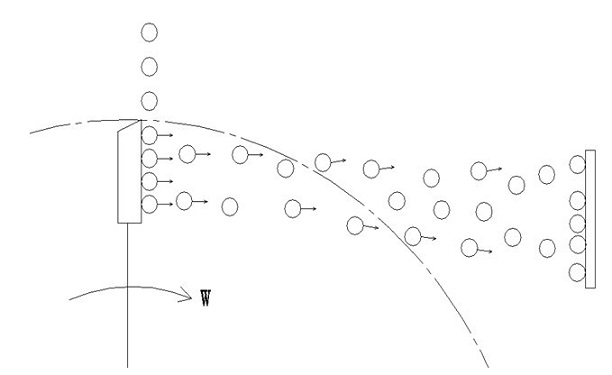

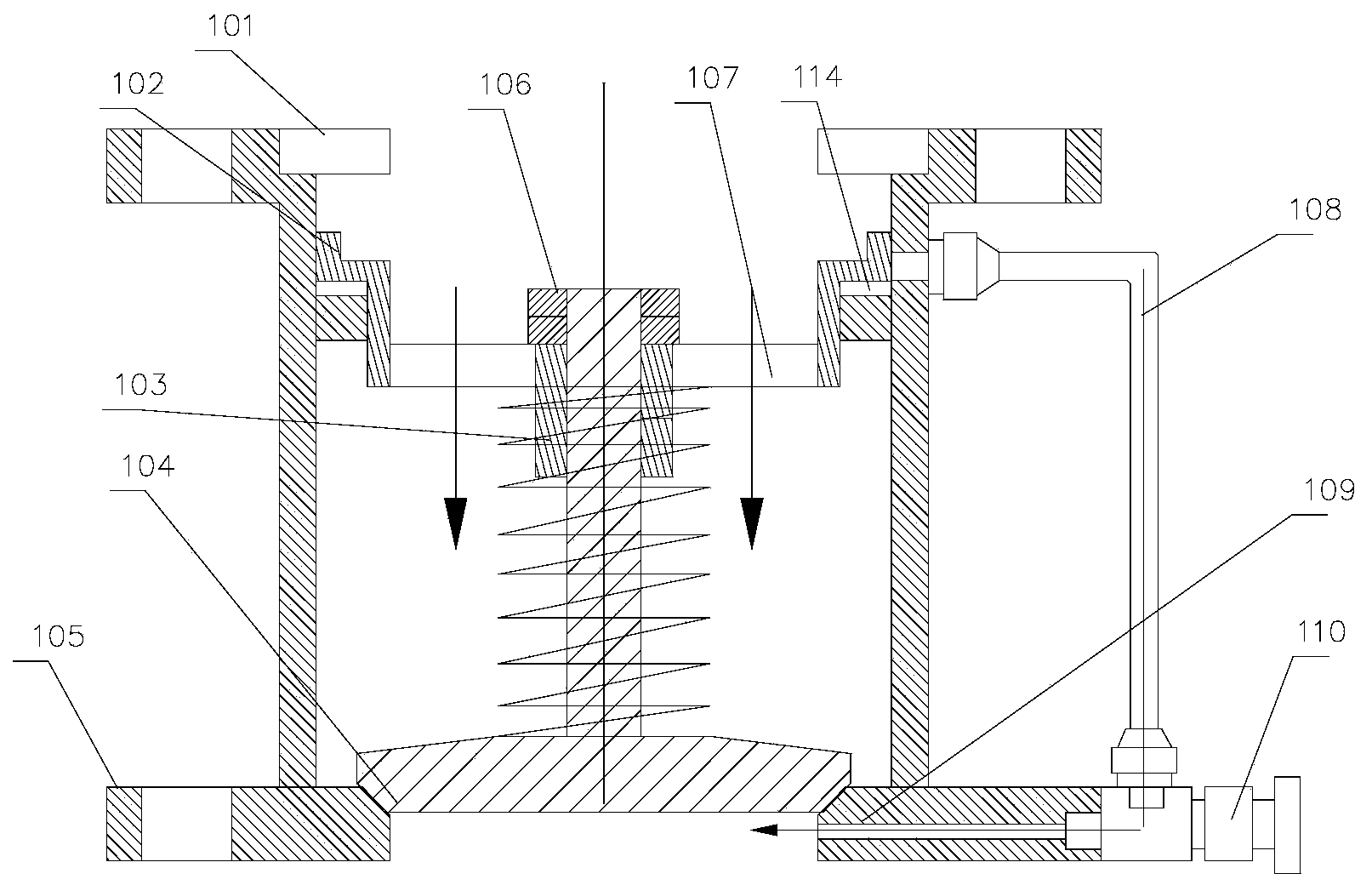

Device for accelerating nanocrystallization of impact surfaces of metal round spheres by beating

InactiveCN102586557ASimple structureSimple and practical device constructionImpeller wheelsRotor bladesPhysicsEngineering

The invention provides a novel method and device for the nanocrystallization of surfaces to solve the problems of small machining area, long process time, complex equipment structure and the like. According to the technology, a simple power device is adopted for providing enough kinetic energy for a large number of small hard metal round spheres so that the round spheres can continuously impact the surface of a machined sample at a certain speed, severe plastic deformation happens on a certain depth region of the surface of the sample; the impact of the metal round spheres on the sample embodies certain uniform clustered spreadability, thereby the severe plastic deformation of the surface of a material is ensured to generally and relatively occur, the nanocrystallization modification of the surface of the material is realized, the special microstructure with gradient distributed grain sizes is obtained, and the performance of the material is increased. Simultaneously, the investment cost and the complexity level of the technology implementing device are reduced to the greatest extend, the range of service environments of the material is widened, and the industrial application process is promoted.

Owner:NANJING UNIV OF SCI & TECH

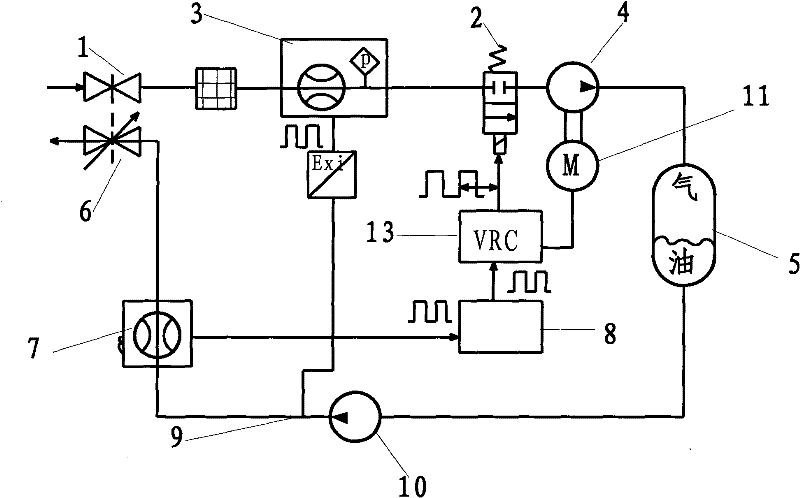

Novel oil gas recovery control system of gas station

InactiveCN102173371APrecise adjustment and controlRealize variable frequency adaptive controlLiquid transferring devicesFrequency conversionControl system

The invention discloses a novel oil gas recovery control system of a gas station. The system comprises a flow metering pulse sensor, a controller, a recovery motor, a recovery oil pump and a gas flow regulating valve, wherein the flow metering pulse sensor is in signal connection with a flow meter on an oil filling pipeline; the flow metering pulse sensor is in signal connection with the controller, the recovery motor and the recovery oil pump sequentially; and the gas flow regulating valve is connected with the recovery oil pump and an oil tank sequentially. The oil gas recovery control system of the gas station is characterized by also comprising a temperature sensor and a gas flow regulating valve control device, wherein the temperature sensor is arranged on the oil filling pipeline; the gas flow regulating valve control device is in signal connection with the temperature sensor; and the gas flow regulating valve control device is in signal connection with the gas flow regulating valve and controls opening of the gas flow regulating valve. In the system, the proportion of oil gas recovery is controlled by a flow signal and a temperature signal simultaneously, regulation and control are more accurate, and frequency-conversion self-adaptive control of the oil gas recovery can be realized. The system is particularly in accordance with the practical condition of the gas station of China.

Owner:SOUTH CHINA UNIV OF TECH

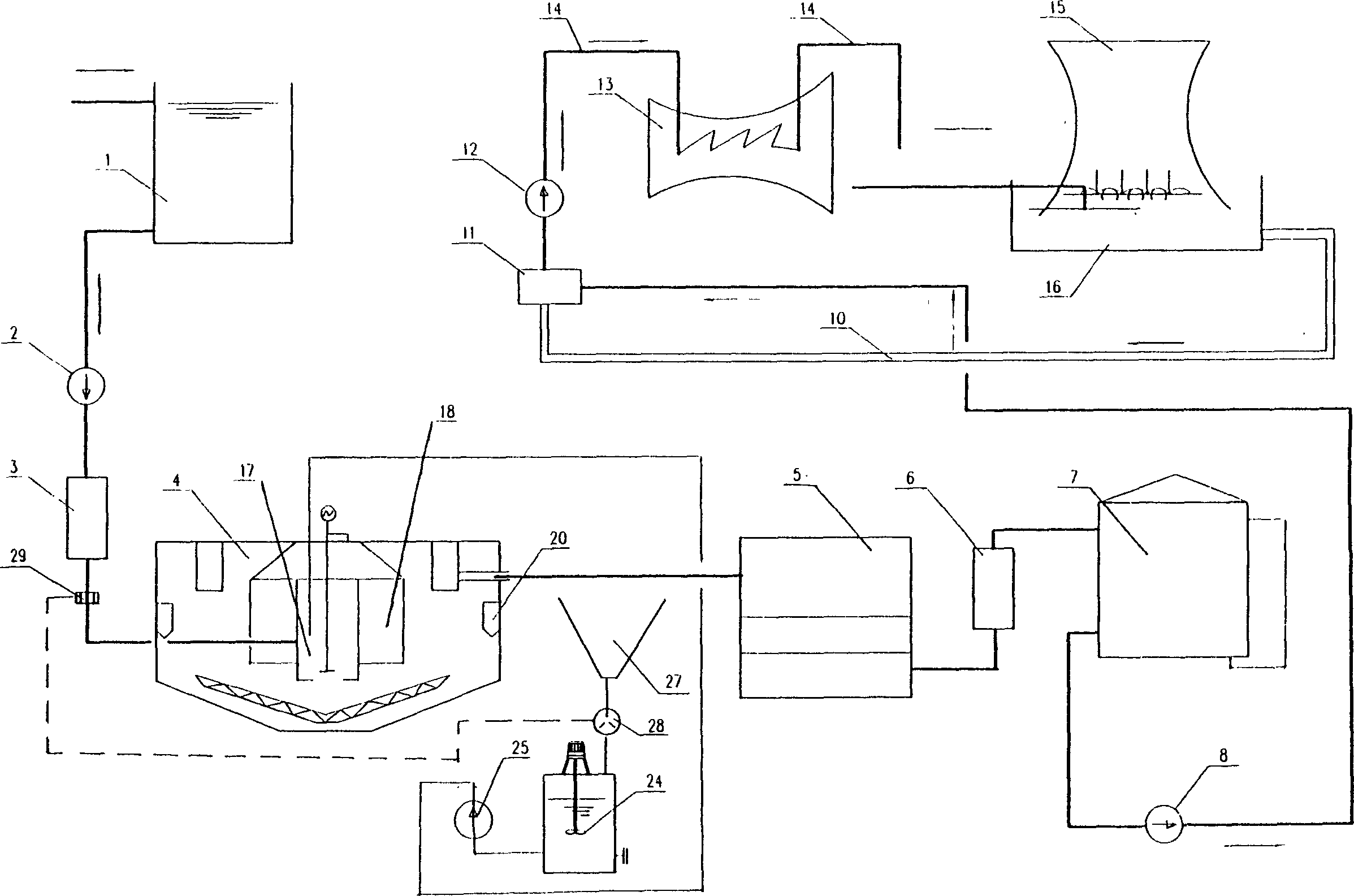

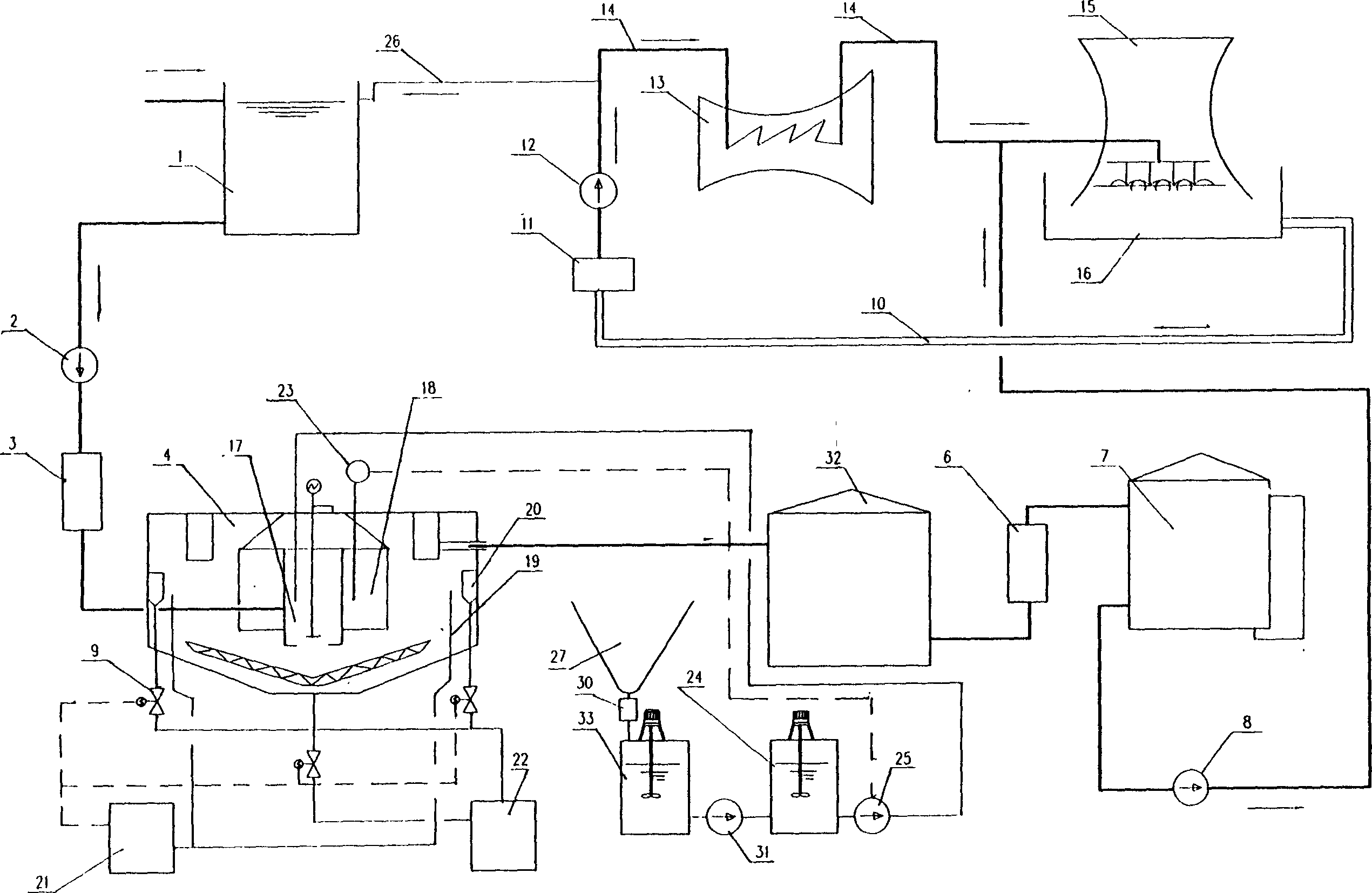

Advanced treatment method for urban middle water as industrial recirculated cooling water

InactiveCN1524807AHigh degree of automationPrecise adjustment and controlMultistage water/sewage treatmentWater flowReclaimed water

The invention discloses a deep processing method of urban recycled water by using it as industrial cycling cooling water comprising the steps of, the urban recycled water being collected and entering the recycled water pool, then entering pressure type mixer, entering into clarification tank, liming by wet method for softening, condensation, settlement and automatic de-sludging, the output water flowing into the circular double chamber filter, then entering clean water tank through pressure type mixer, the clean water being pumped to the cycling water pump discharge pressure tube after the compensator to be used for re-circulated cooling water system.

Owner:胡笳

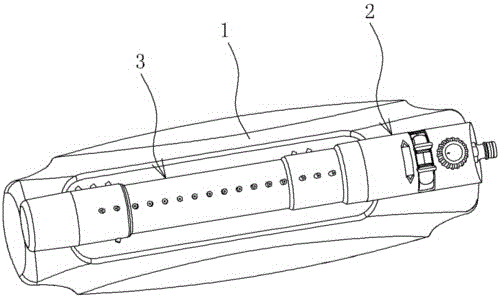

Swing sprayer adjustable in spraying area

InactiveCN105817356AEasy to useSimple structural designWatering devicesMovable spraying apparatusJet flowSprayer

The invention discloses a swing sprayer adjustable in spraying area and relates to a garden irrigation tool, and by the adoption of the garden irrigation tool, the sprayed water flow is swung through the jet flow principle of water flow pressure, and accordingly spraying area is formed. The swing sprayer comprises a base, a swing gearbox, a spraying assembly and the like. The swing sprayer is characterized in that the ends of a spray pipe of the spraying assembly are provided with water through holes communicating with a water cavity in the spray pipe, and adjusting spray sleeves, wherein the adjusting spray sleeves are rotatably sleeved with the ends of the spray pipe and can seal the water through holes in the spray pipe; a plurality of rows of adjusting spray nozzles with different numbers are formed in the adjusting spray sleeves; and the adjusting spray nozzles communicate with the water through holes sequentially and selectively under the rotation action of the adjusting spray sleeves. In this way, when original fixed spray nozzles in the spray pipe and the adjustable adjusting spray nozzles in the ends of the spray pipe are combined to use, the whole swing sprayer has a function of controlling and adjusting the spraying area; and the improved swing sprayer has the advantages of being simple in structural design, flexible in adjustment operation, convenient to use, capable of controlling adjustment for spraying area accurately, low in production cost and the like.

Owner:NINGBO DAYE GARDEN IND

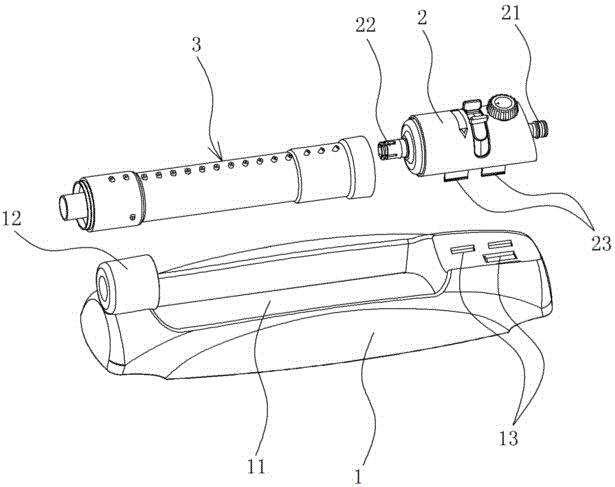

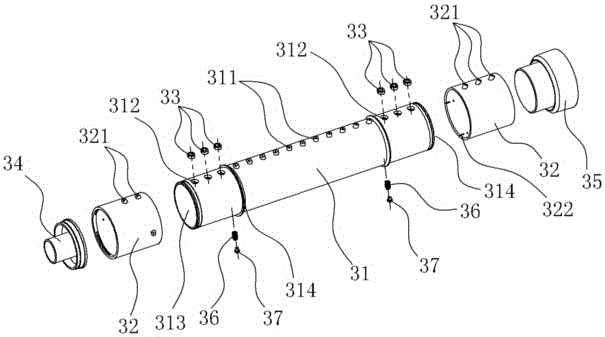

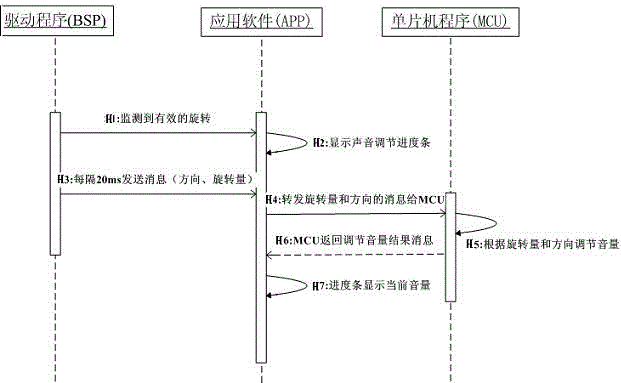

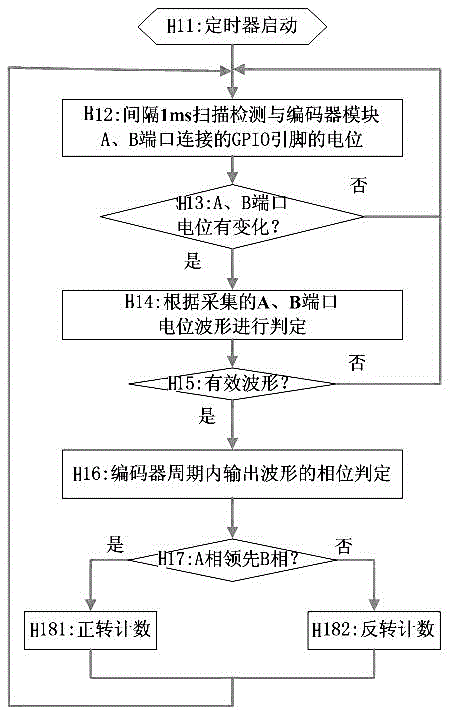

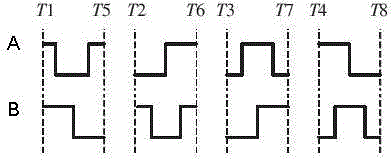

Turn button control-adjustment method and system of vehicle-mounted encoder

InactiveCN104898763APrecise adjustment and controlAvoid interferenceControlling membersIn vehicleEmbedded system

The invention provides a turn button control-adjustment method and system of a vehicle-mounted encoder. The potentials of a phase-A port and a phase-B port of an encoder circuit are collected every first preset time, and whether the collected potentials change in the first preset time is determined; if the potentials change, whether the phase-A port and a phase-B port output effective waveforms is determined, and if yes, the turning direction and adjustment amount of the turn button of the encoder are determined according to the effective waveforms, and a control and adjustment circuit implements corresponding adjustment. Thus, waveforms generated by jittering of a vehicle are prevented from interfering the turning and adjustment of the turn button of the encoder, and the vehicle-mounted encoder can realize accurate control and adjustment.

Owner:GUANGDONG COAGENT ELECTRONICS SCI & TECH

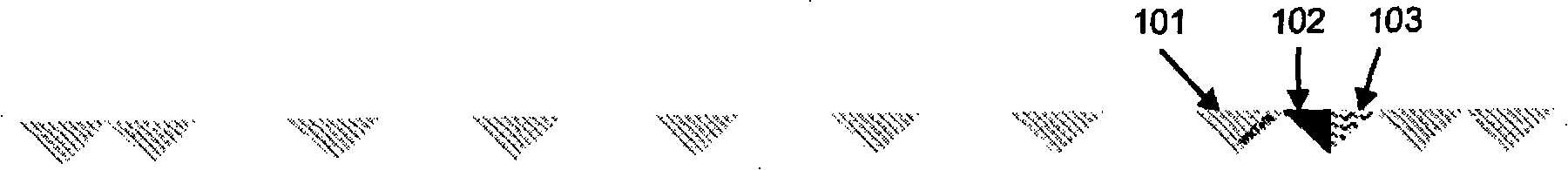

Multiple primitive color printing quality control method

ActiveCN102120384ASimplify Color Difference Study TimeReduce color adjustment timeColour-separation/tonal-correctionPrinting press partsVisual technologyColor printing

The invention provides a multiple primitive color printing color value correcting method. In the method, a color value zone is set on a printing material, a secondary primitive color generated by combining main primitive colors and corresponding primitive colors are overprinted according to a predetermined percentage to form a neutral grey scale of combination of the main primitive colors and the secondary primitive color; in a set color value zone, a black 'K' halftone is used as reference to compare a monochromatic grey scale and the neutral grey scale so as to correct the color value and control color changes. By utilizing WKTone neutral grey balance principle and adopting a visual technology, an operator can accurately control color ink usage comparison, and color reading equipment can read color value changes to correct colors in real time. The method can be used for surmounting three-color sampling, and used for large-scale production and printing.

Owner:永经堂印刷有限公司

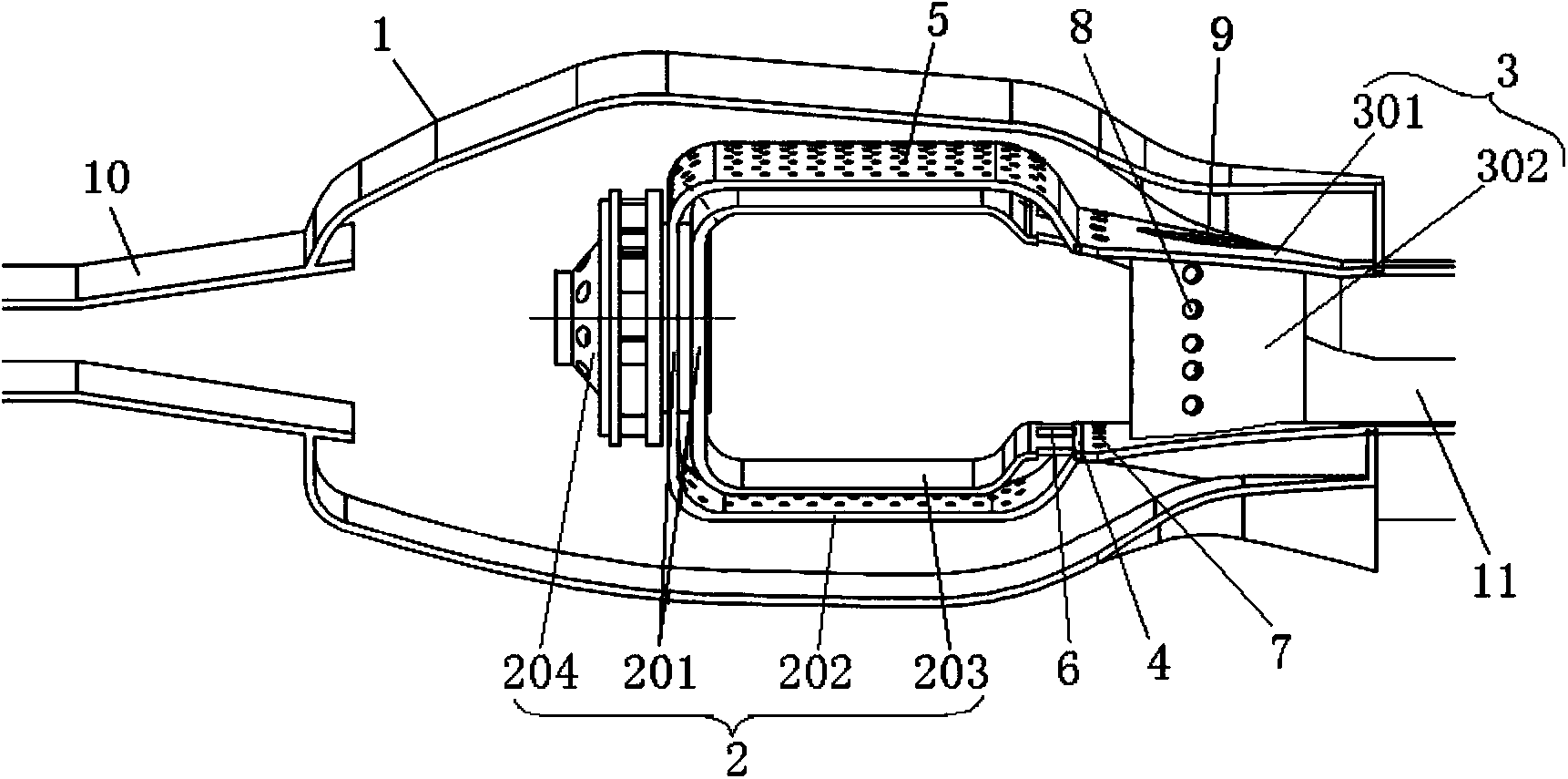

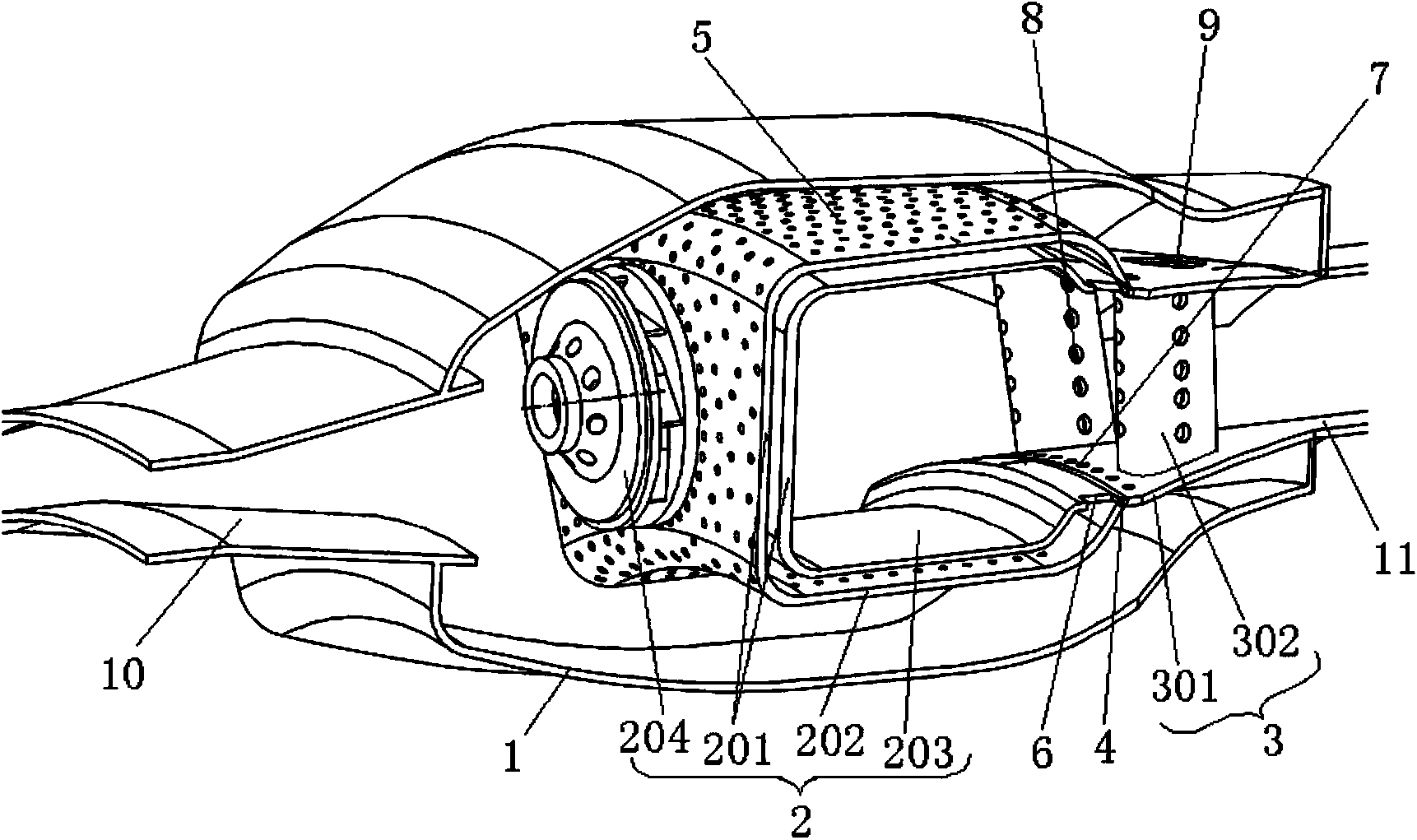

Combustion chamber based on RQL principle and aircraft engine with same

ActiveCN104033927APrecise adjustment and controlContinuous combustion chamberAviationCombustion chamber

The invention discloses a combustion chamber based on the RQL principle and an aircraft engine with the same. The combustion chamber based on the RQL principle comprises a combustion chamber casing and a double-layer flame cylinder arranged in the combustion chamber casing, the inner cavity of the double-layer flame cylinder forms a fuel rich combustion zone, the double-layer flame cylinder comprises a flame cylinder head, a flame cylinder outer wall, a flame cylinder inner wall and a swirler, and a high-pressure turbine guide vane component forming a quenching mixing zone and lean combustion zones is arranged between the double-layer flame cylinder and the combustion chamber casing; the double-layer flame cylinder and the high-pressure turbine guide vane component are connected integrally, and the high-pressure turbine guide vane component and the combustion chamber casing are connected integrally; the quenching mixing zone is arranged at the connection of the high-pressure turbine guide vane component and double-layer flame cylinder; the high-pressure turbine guide vane component comprises high-pressure turbine guide vanes, guide vane passages are formed between adjacent high-pressure turbine guide vanes, and the lean combustion zones are formed in the guide vane passages. The high-pressure turbine guide vane component is prevented from ablation through cold gas flowing through the guide vanes.

Owner:CHINA AVIATION POWER MACHINE INST

Method for controlling primary powder apparent density accurately by utilizing ball mill

InactiveCN104148159APromote repairStable feeding and dischargingGrain treatmentsApparent densityPower flow

The invention discloses a method for controlling the primary powder apparent density accurately by utilizing a ball mill. The method comprises the following steps: (1) feeding, namely, carrying out flushing, crush breaking, hammer breaking or jaw breaking on qualified sponge iron, lifting powder with the particle size being 10-15mm to a ball milling front stock bin, conveying the powder into the ball mill by a vibration feeder, and grinding; (2) carrying out parameter control, namely adjusting the current of the vibration feeder arranged at the feeding end of the ball mill so as to control the feeding quantity, adjusting the current of the ball mill so as to control the rotation speed of the ball mill, thus controlling the grinding speed, adjusting dedusting air suction capacity so as to control the fine powder feeding quantity; (3) discharging through three parts; and (4) screening, namely after screen underflow conforming to the granularity need enters a magnetic separator at the lower part of a drum screen, carrying out magnetic separation, lifting the screen underflow to a storage bin, conveying oversized products not conforming to the granularity need to the ball milling front material feedback storage bin by a material returning belt, adding the oversized products into the ball mill quantitatively according the need of primary powder ingredients, and grinding. According to the method, the apparent density and the particle constitution can be effectively controlled, the production cost is lowered, and the yield is increased.

Owner:LAIWU TAIDONG POWDER TECH

Incubation method for enhancing day hatchability rate of silkworm eggs

InactiveCN101911927ARealize numerical quantificationPrecise adjustment and controlAnimal husbandryLower limitEmbryo

The invention discloses an incubation method for enhancing the day hatchability rate of silkworm eggs, comprising the following steps of: concretely setting the environmental parameters of embryonic development stages from D1 to F5 by taking the D1 as an incubating and temperature-increasing initial embryo; when staged embryonic development lag rate alpha is higher than or equal to 5 percent, regulating the environmental temperate of the embryonic development stage to be higher than the temperature upper limit value of a corresponding embryonic development stage by 0.5-1 DEG C, wherein the environmental humidity of the embryonic development stage is increased by 3-5 percent on the basis of a humidity upper limit value of the corresponding embryonic development stage; and when staged embryonic development advance rate beta is higher than or equal to 5 percent, regulating the environmental temperate of the embryonic development stage to be lower than the temperature lower limit of the corresponding embryonic development stage by 0.5-1 DEG C. The incubation method not only reasonably and accurately determines the environmental condition parameters of the development stages of the silkworm egg, but also carries out the mutual matching and coordination among the environmental parameters of the embryonic development stages, is convenient to implement the staged regulation for the silkworm eggs and has very wide popularization and application prospect.

Owner:JIANGSU MINXING COCOON & SILK +1

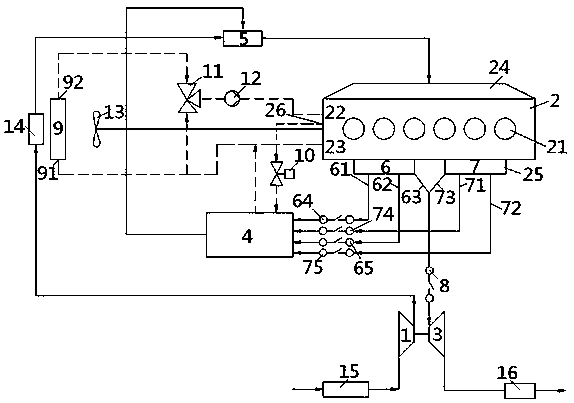

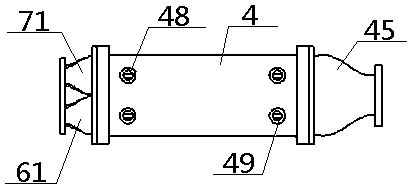

Controllable EGR system using integrated dual-channel EGR cooler

ActiveCN110500208ALarge adjustment rangeMeet needsInternal combustion piston enginesExhaust gas recirculationPulse energyEngineering

The invention relates to a controllable EGR system using an integrated dual-channel EGR cooler. The system involves the integrated cooler and a double-channel structure formed by two exhaust manifolds, wherein the integrated cooler comprises two cold channels and two heat channels which are independent from one another, each exhaust manifold is connected with air inlet ends of one cold channel, one heat channel and a turbine through three air channels, the air outlet ends of the cold channels and the air outlet ends of the heat channels are connected with the air inlet end of a device air outlet cavity arranged in the integrated cooler, and the air outlet end of the device air outlet cavity and the air outlet end of an air compressor are connected with an engine after sequentially througha mixer and an air inlet manifold. According to the system, the EGR temperature and the EGR rate can be adjusted through a cold EGR and heat EGR combined mode, so that the adjusting capacity is high,and the EGR can be driven by utilizing exhaust pulse energy, so that the EGR rate and the driving capacity are improved.

Owner:DONGFENG COMML VEHICLE CO LTD

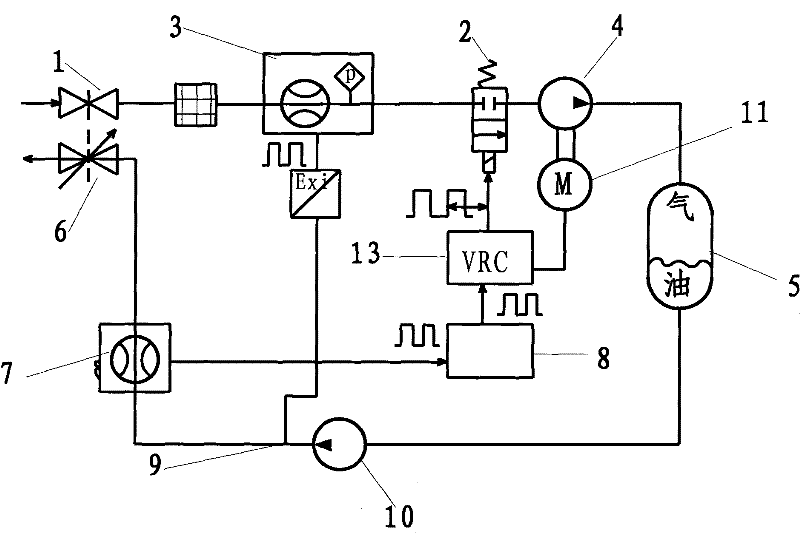

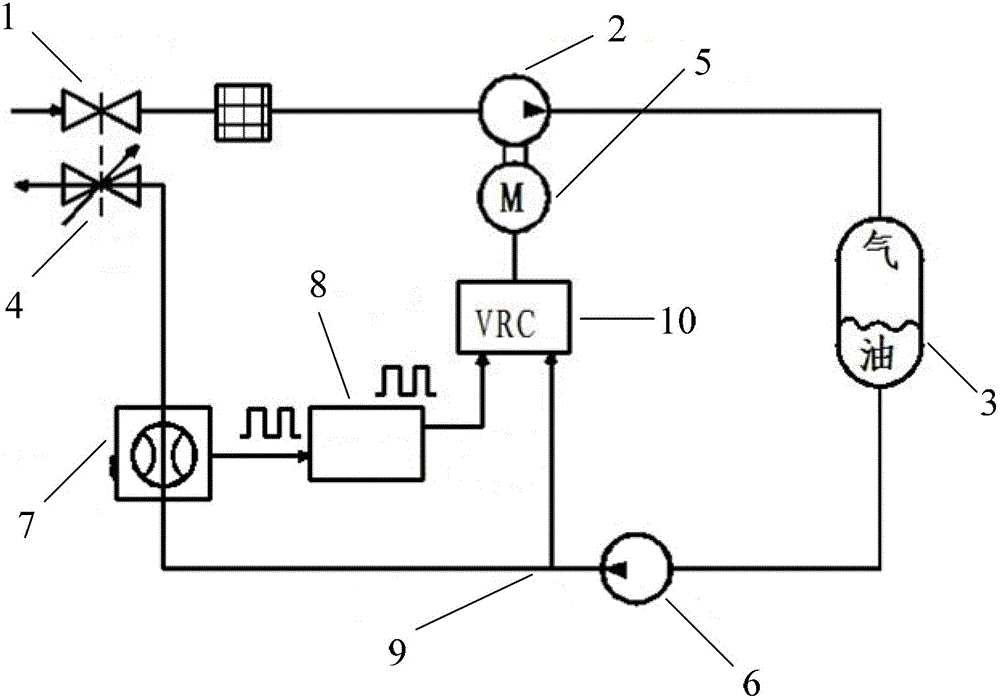

Variable-frequency oil gas recovery control system of fuel dispenser

InactiveCN102718178APrecise adjustment and controlHigh trafficLiquid transferring devicesFrequency changerControl system

The invention is provides a variable-frequency oil gas recovery control system of a fuel dispenser. The system comprises a flow metering impulse sensor, a controller, a recovery motor, a recovery oil pump and a temperature sensor arranged on an oil filling pipeline; the flow metering impulse sensor is in signal connection with a flowmeter arranged on the oil filling pipeline, and the flow metering impulse sensor is sequentially in the signal connection with the controller, the recovery motor and the recovery oil pump; and the temperature sensor is further in the signal connection with the controller so as to control the recovery motor and the recovery oil pump through a temperature signal. According to the variable-frequency oil gas recovery control system of the fuel dispenser, disclosed by the invention, a frequency converter is directly controlled by the temperature signal and a flow signal, so that the speed regulation of the variable frequency motor is controlled, the self-adapting oil gas recovery is realized, and the adjustment and the control are relatively exact, and therefore, the oil gas recovery ratio is within a range from 1-1.4, furthermore, the variable-frequency oil gas recovery control system disclosed by the invention does not adopt an oil gas recovery control system of a proportioning valve, so that the flow of gas can be greatly improved.

Owner:FOSHAN HAIZHUORUI FLUID CONTROL ENG

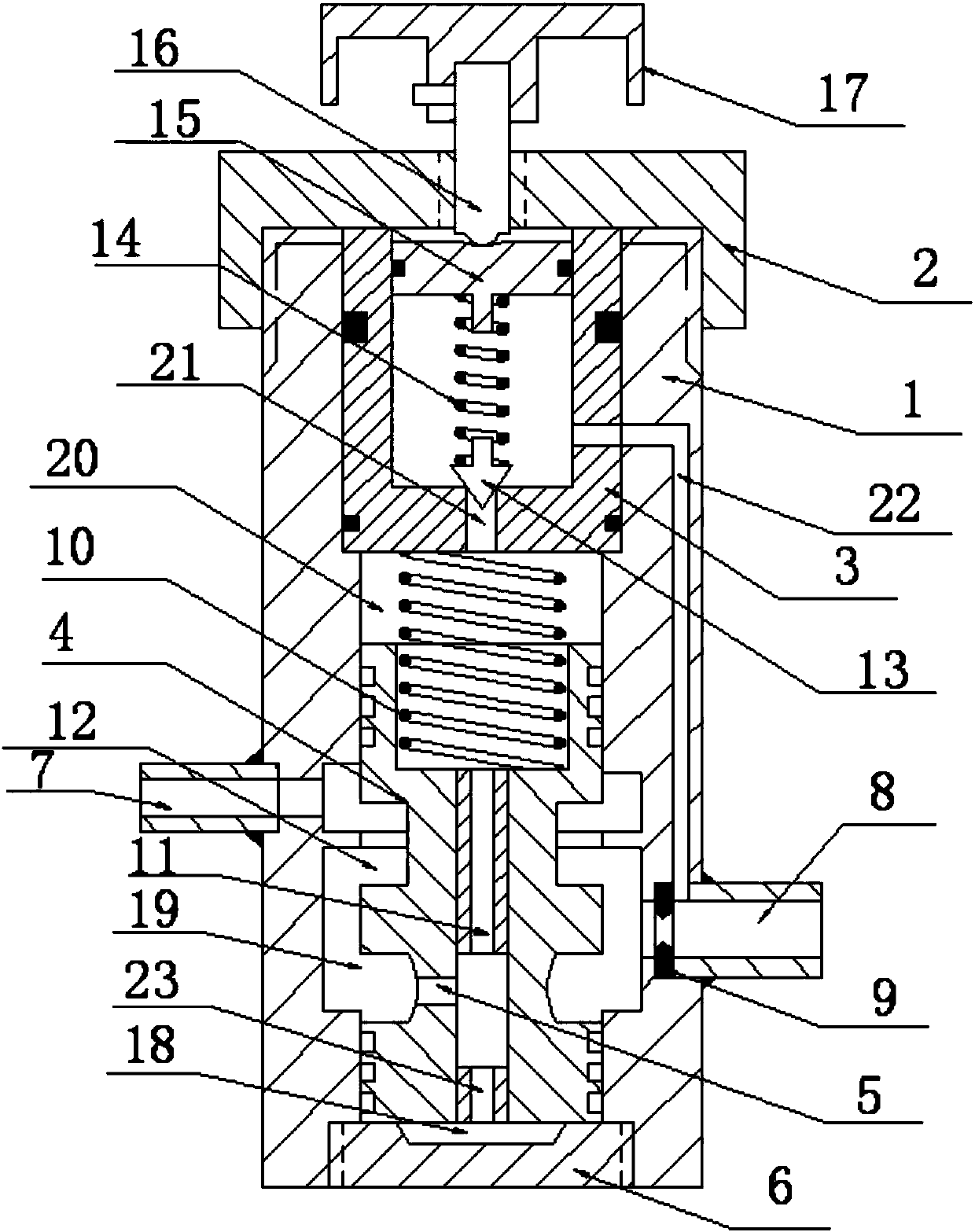

Constant flow valve and working method thereof

ActiveCN107631065APrecise adjustment and controlOvercome water pressure fluctuationsEqualizing valvesSafety valvesPipingEngineering

The invention relates to a constant flow valve and a working method thereof. An upper valve seat is arranged on the upper portion of a valve body. The lower portion of the valve body is fixedly lockedthrough a lower locking nut at the bottom. A valve element is arranged in the middle of the valve body. The portion between the valve element and the upper valve seat is provided with an upper valvecavity and a main spring. A lower valve cavity is formed between the lower portion of the valve element and the lower portion of the valve body. A backpressure cavity is formed between the bottom of the valve element and the lower locking nut. A water outlet pipe and a water inlet pipe are arranged at the two sides of the vale body correspondingly. The water inlet pipe communicates with the wateroutlet pipe through the lower valve cavity. The upper valve cavity communicates with the upper valve seat through a channel (a). A conical pilot valve arranged in the upper valve seat abuts against one end of the channel (a). The upper valve seat communicates with the water outlet pipe through a channel (b). The interior of the valve element communicates with the lower valve cavity through a channel (d), communicates with the backpressure cavity through a channel (c) and communicates with the upper valve cavity through a damping hole. By means of the constant flow valve and the working methodthereof, the water yield of tap water can be precisely adjusted and controlled; fluctuation of the water pressure is overcome; the water yield is maintained to be constant; the constant flow valve issimple in structure and convenient to mount and use; and saving and rational utilization of water resources are promoted.

Owner:ANGANG STEEL CO LTD

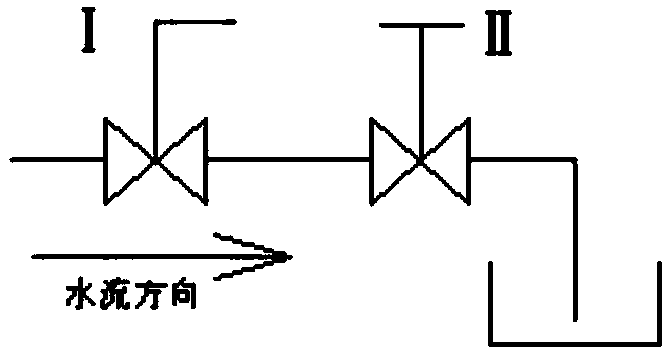

Backflow blocking valve

The invention discloses a backflow blocking valve. A valve body is provided with a first limit end located in the liquid inlet direction and a second limit end located in the liquid outlet direction; an auxiliary piston, a valve rod and a backstop part which are capable of sliding along the axial direction of a valve cavity are arranged in a valve cavity body formed between the first limit end and the second limit end; a liquid storage space is formed between the outer side wall of the auxiliary piston and the inner cavity wall of the valve body; when the pressure of liquid conveyed from a liquid inlet end is increased, the backstop part is opened by washing, and a fluid passes through a main flow channel of the auxiliary piston; when the pressure of the liquid conveyed from the liquid inlet end is decreased or disappears, the valve is closed in two steps, the backstop part is quickly returned toward the direction of the first limit end, the auxiliary piston is gradually returned, and the auxiliary piston, the backstop part and the first limit end jointly act to intercept liquid backflows coming from the liquid outlet direction when the auxiliary piston is returned to a close position. The valve manufacturing process is not limited by materials and overall dimensions, and is wide in application range.

Owner:黄健山

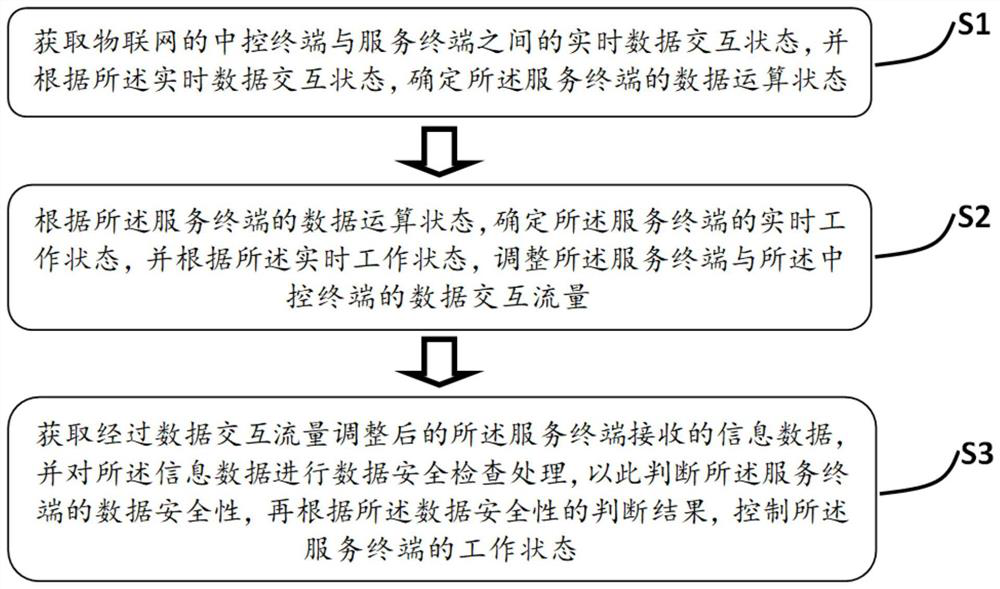

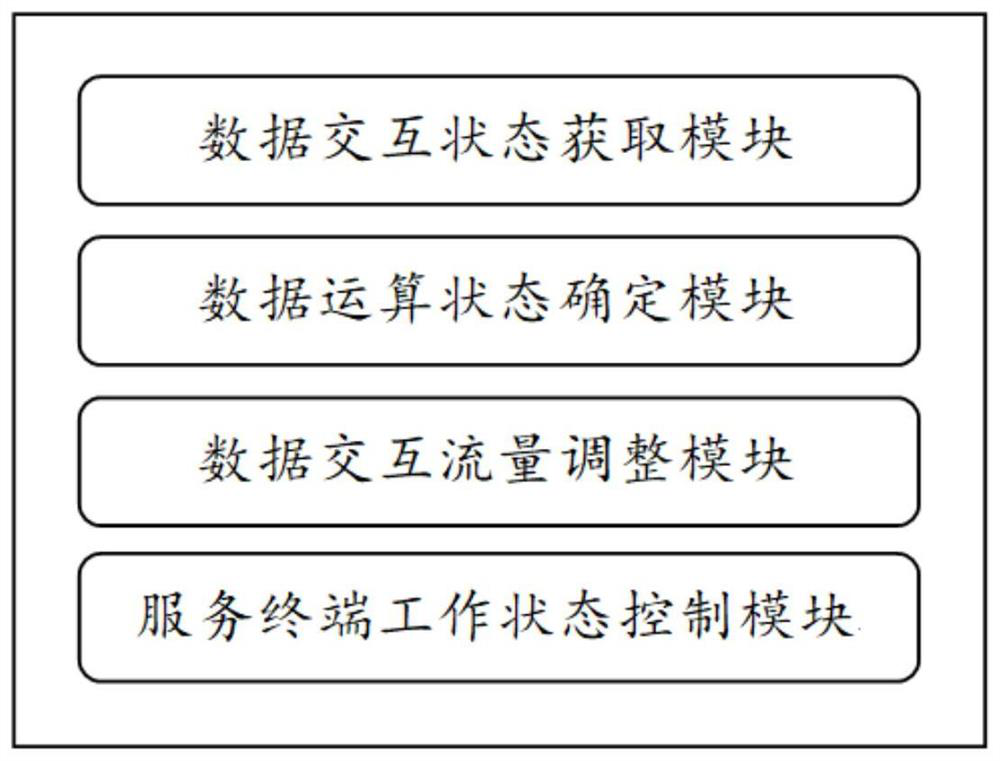

Method and system for managing and controlling station control information flow in Internet of Things

ActiveCN112769904AAvoid overloadImprove safety and reliabilityTransmissionInstrumentsData transmissionData processing

The invention provides a method and a system for managing and controlling channel control information flow in the Internet of Things, and the method comprises the steps: determining the data operation state of a service terminal according to the real-time data interaction state between a central control terminal and the service terminal of the Internet of Things, and then determining the real-time working state of the service terminal to adjust the data interaction flow between the service terminal and the central control terminal; and enabling the information data after flow adjustment to be subjected to security check processing so as to judge the data security of the service terminal and control the working state of the service terminal, so that the data transmission flow between the central control terminal and the service terminal can be effectively and accurately controlled and adjusted. Therefore, the condition of data processing overload of the service terminal is avoided, and the reliability and safety of data transmission between the central control terminal and the service terminal can be improved.

Owner:慧之安信息技术股份有限公司

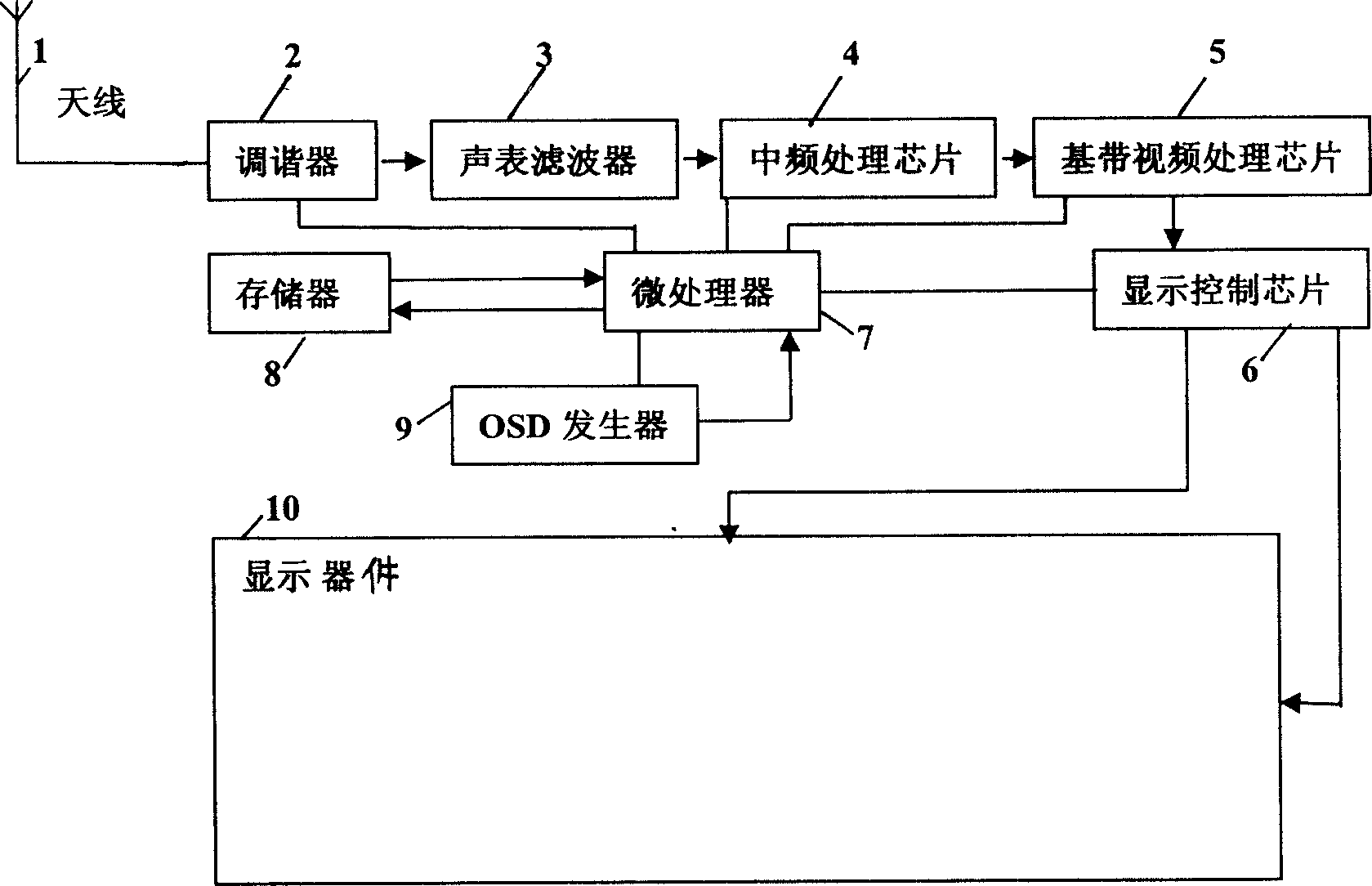

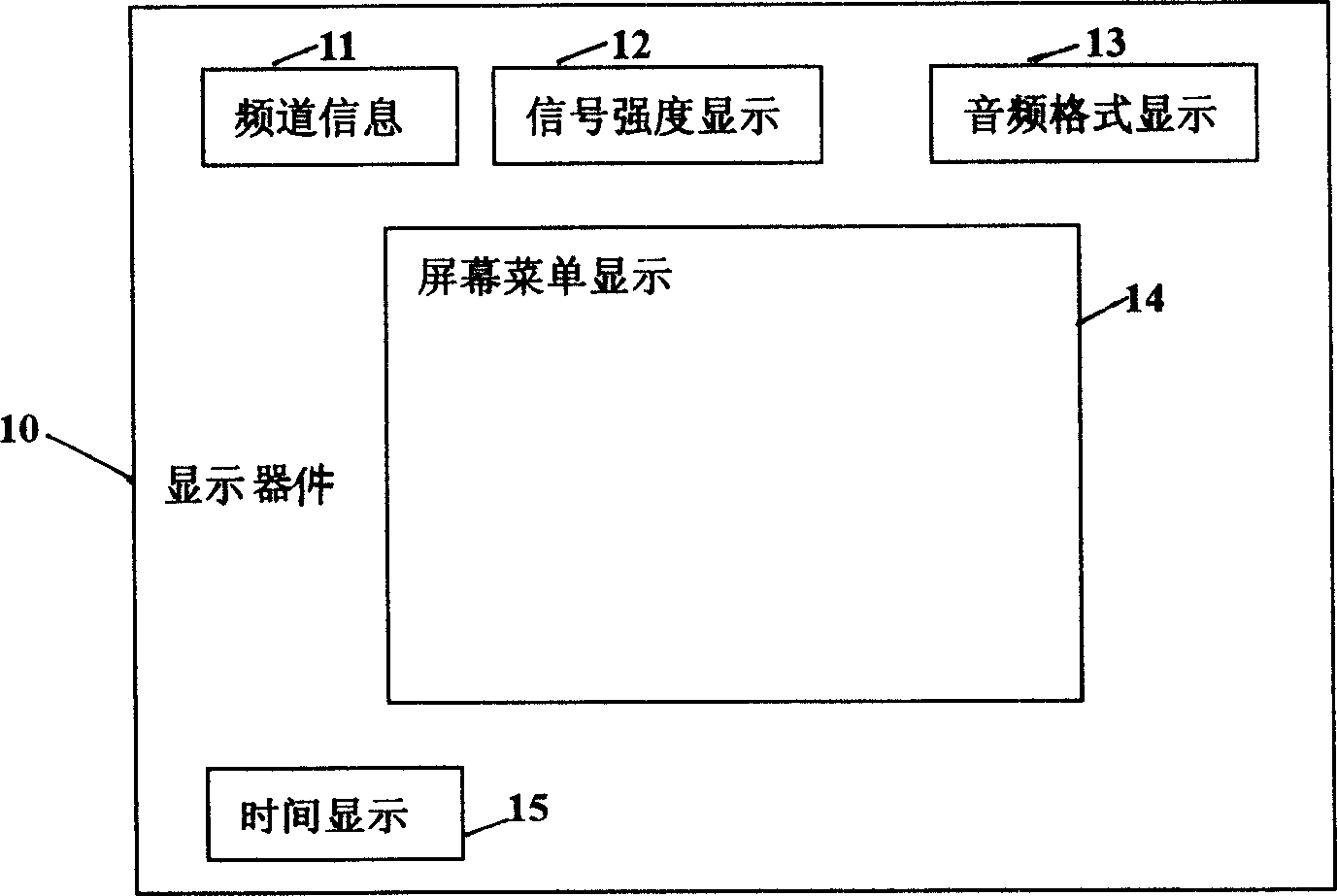

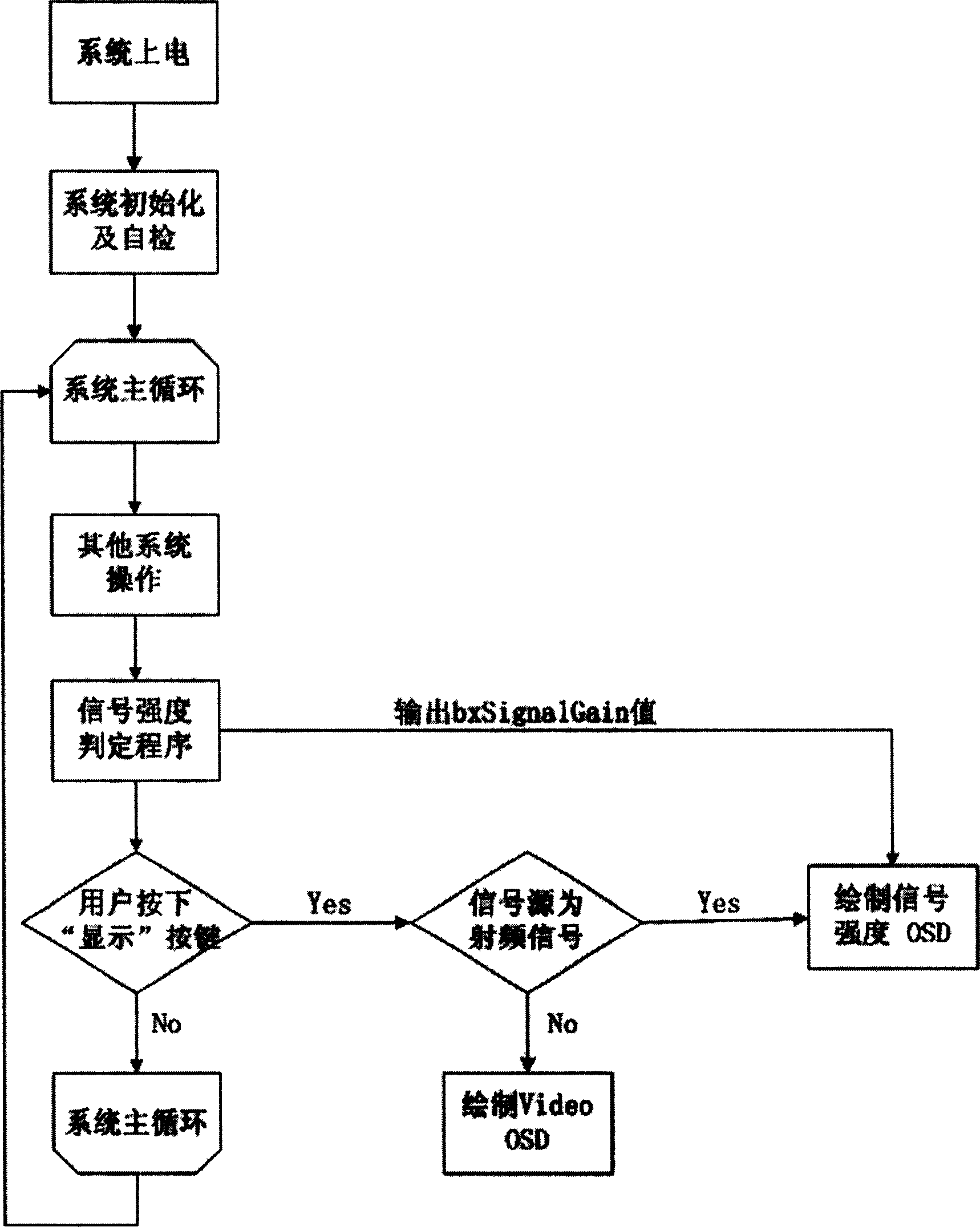

Method for realtime display of signal intensity of analogue television signal receiving system

InactiveCN1595996AUnderstand signal strengthAccurate adjustment effectTelevision systemsRadio frequencyReal time display

The invention discloses a method for displaying signal intensity in real-time in analog television signal receiving system. The method includes following steps: system powering, parameter initialization and self test; enters the system primary circulation; in the primary circulation, it calls the signal intensity judging program, outputs a bxSignalGain value; carries on judgment to real-time operation, presses down the 'display' button on the remote controller, judges if the real-time displayed image is radio frequency analog television signal or not; if not, it paints the Video OSD; if yes, it enters the signal intensity OSD program; carries on judgment to the inputted bxSignalGain, paints signal intensity signs with correspondent grade to the judgment value and displays it on the screen. The method is simple, direct and accurate.

Owner:TIANJIN SAMSUNG ELECTRONICS CO LTD

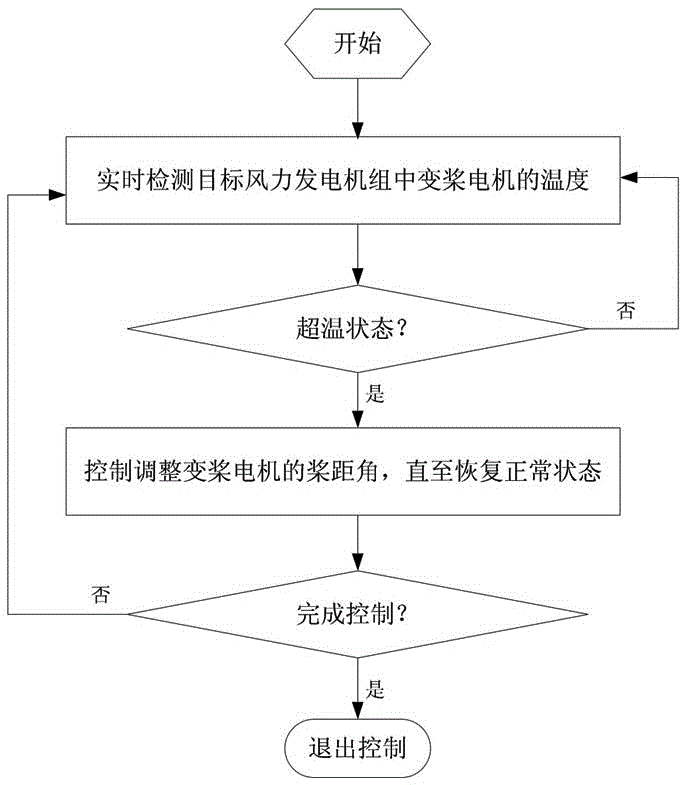

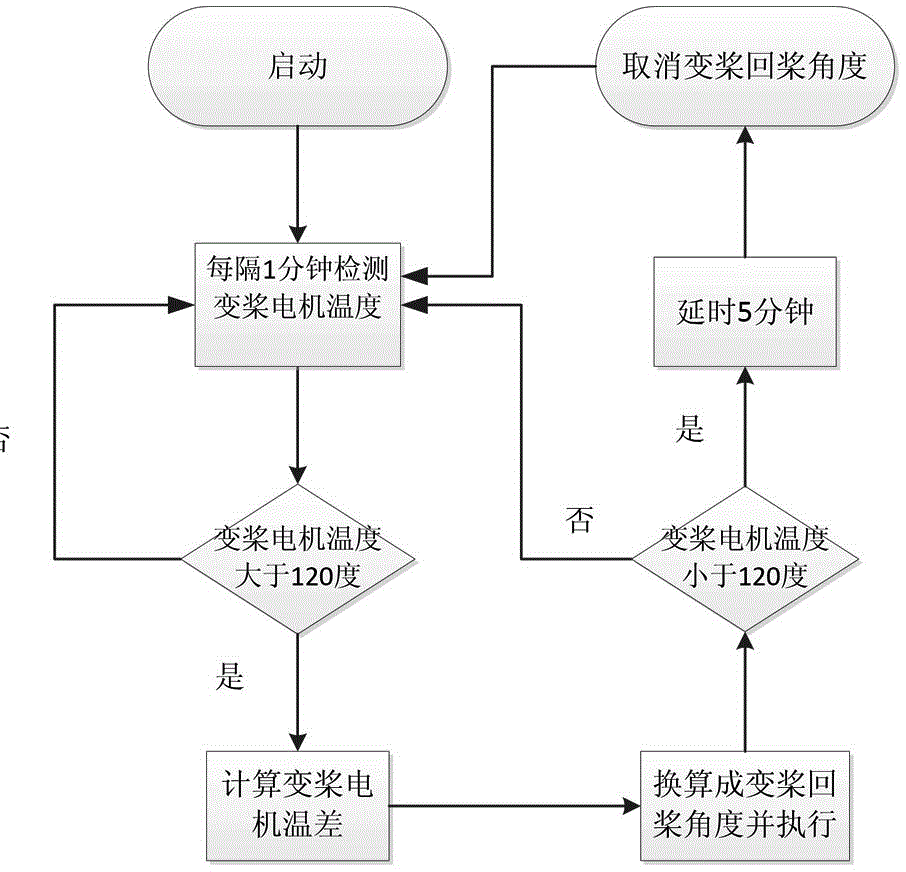

Control method for preventing over-temperature of variable pitch motor in wind power generator set

ActiveCN105529982ALow costReal-time monitoring of temperature statusElectric motor controlWind motor controlControl theoryWind force

The invention discloses a control method for preventing over-temperature of a variable pitch motor in a wind power generator set. The control method comprises the following steps of (1) detecting the temperature of the variable pitch motor in a target wind power generator set in real time, forwarding to execute a step (2) if the detected temperature reaches an over-temperature state; and (2) controlling and adjusting a pitch angle of the variable pitch motor to reduce the temperature of the variable pitch motor to a normal state, and returning to execute the step (1) until exiting control. The control method has the advantages of simplicity in implementation and operation and high control efficiency and precision, and the over-temperature of the variable pitch motor can be prevented in real time.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

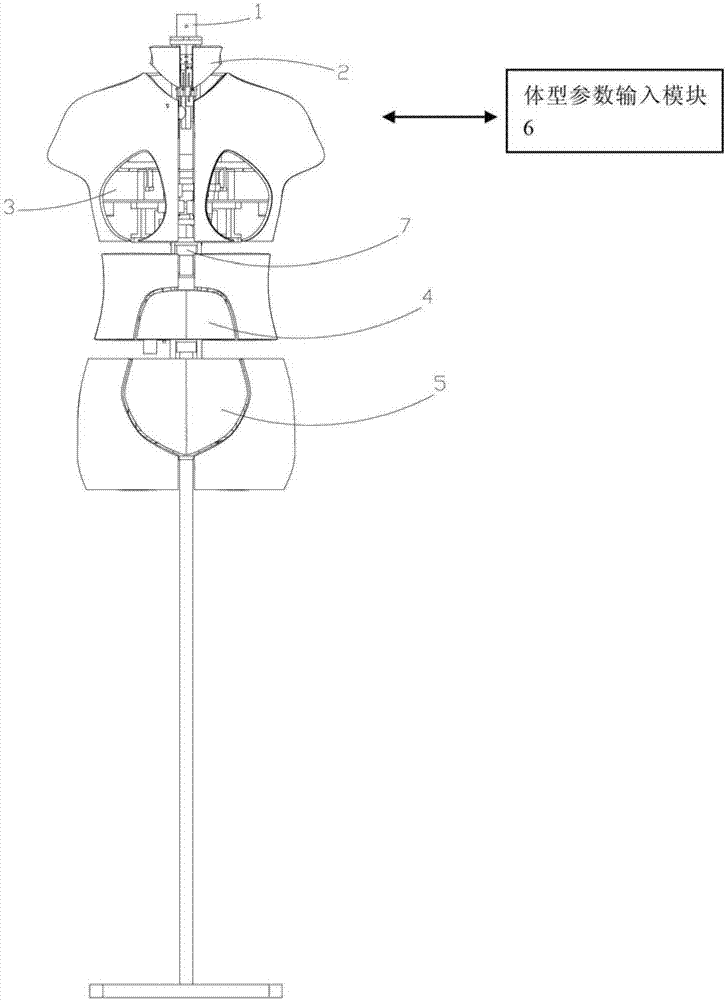

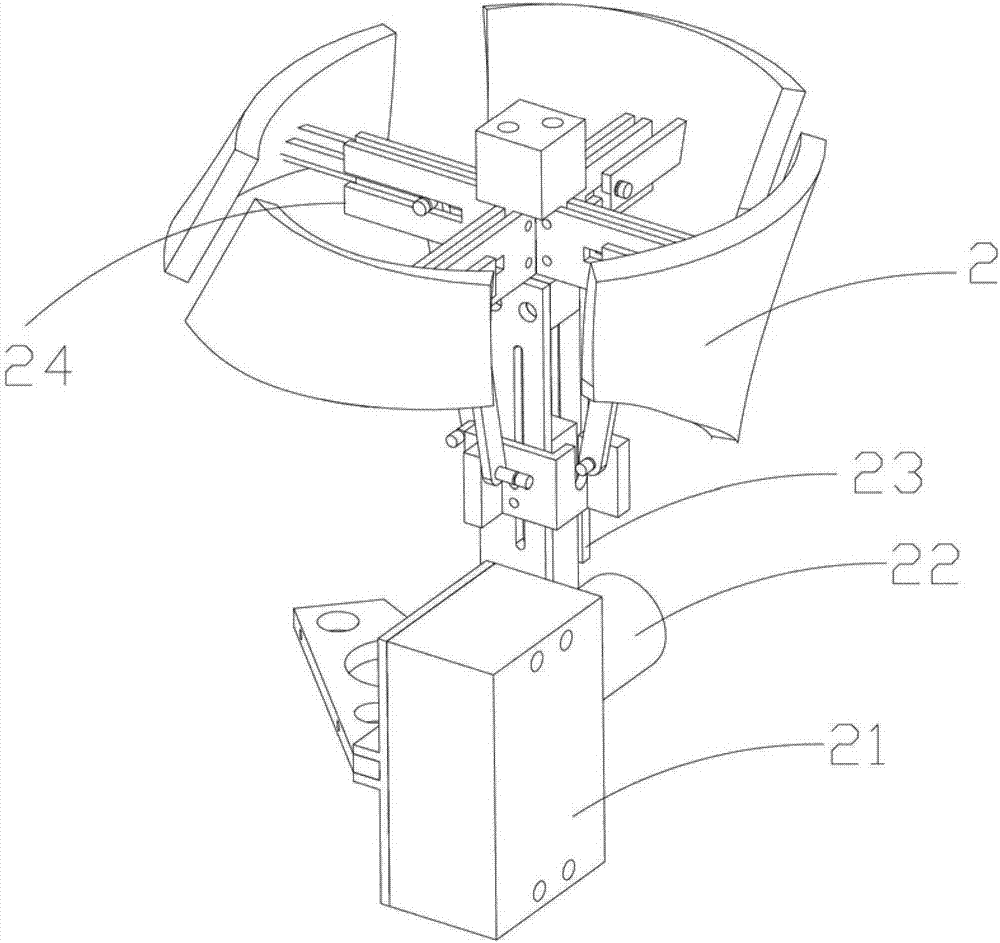

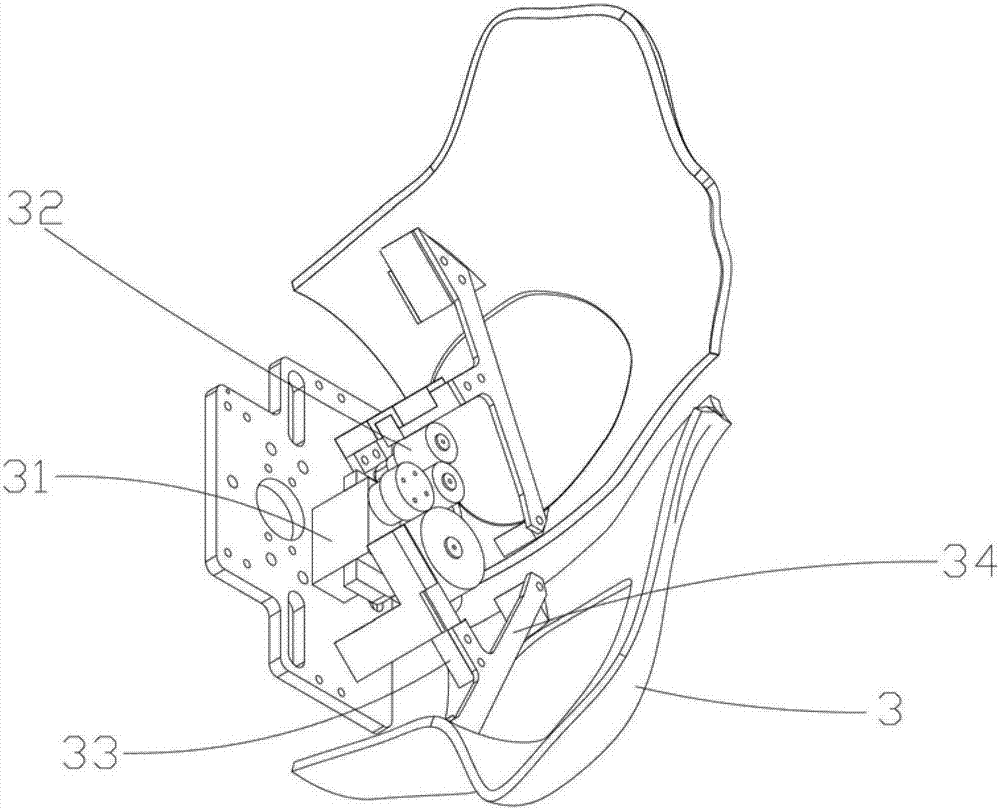

Intelligent adjustable human model

ActiveCN106858863AEasy to operateReduce manufacturing costsDummiesClothes making applicancesPhysical medicine and rehabilitationWaist Circumferences

Owner:THE HONG KONG POLYTECHNIC UNIV

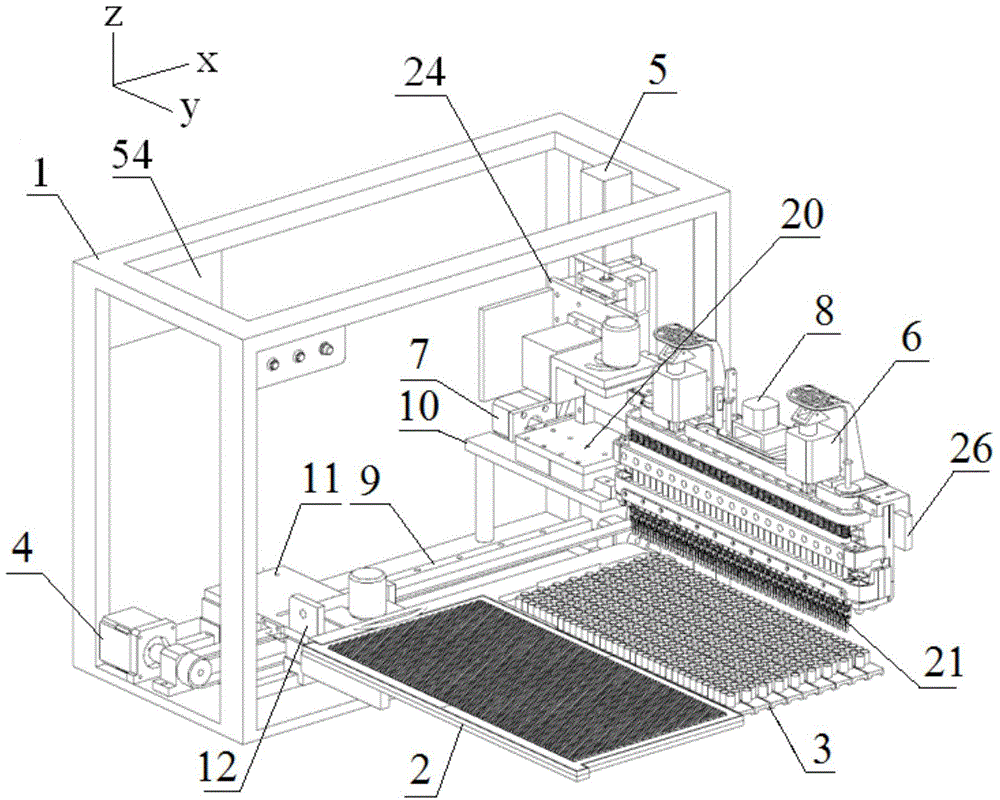

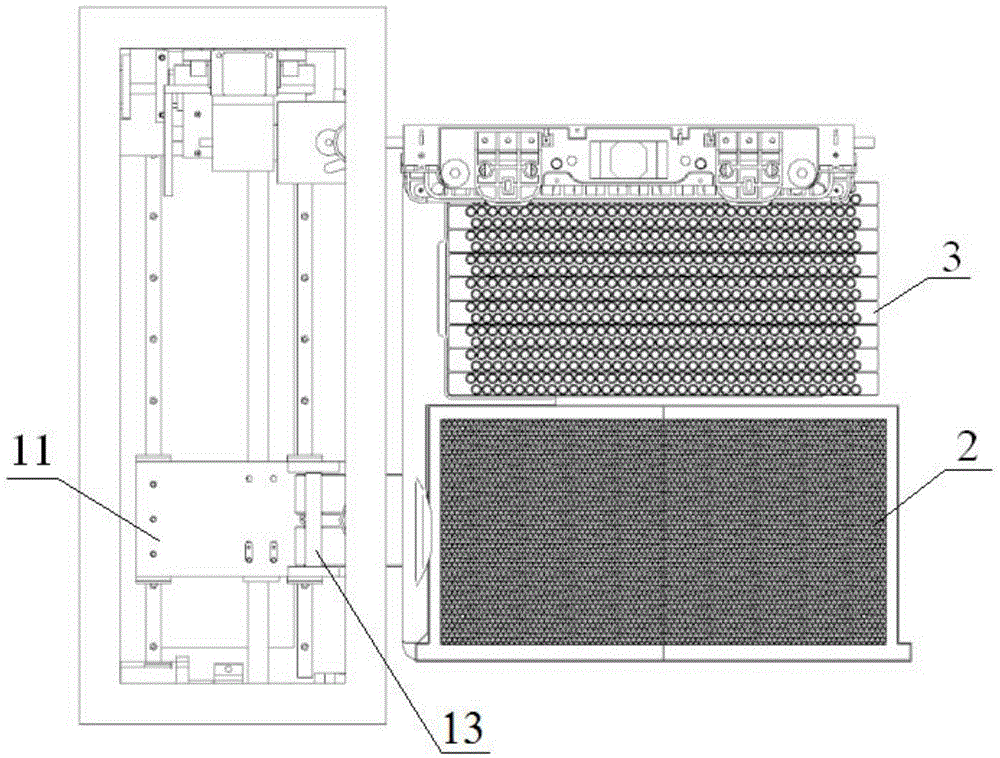

Intelligent larval transplantation machine with automatic larval transplantation clamp

InactiveCN104686395AImprove efficiencyQuality improvementHoney collectionEngineeringObserved Survival

The invention discloses an intelligent larval transplantation machine with an automatic larval transplantation clamp. The intelligent larval transplantation machine with the automatic larval transplantation clamp comprises an installation support and the larval transplantation clamp which is arranged on the installation support; the larval transplantation clamp comprises two clamping arms which are mutually hinged, a reset part which is arranged between the two clamping arms to guarantee the two clamping positions to get close to each other and an adjusting mechanism which drives the two clamping positions to separate from each other; end portions of the two clamping arms are respectively provided with clamping positions which are matched with each other. According to the intelligent larval transplantation machine with the automatic larval transplantation clamp, automation of the larval transplantation process is achieved by improving the larval transplantation clamp structure, larval samples are avoided from falling off during the larval transplantation process, and the larval transplantation process is improved; the larval samples are avoided from being damaged; the larval transplantation survival rate is improved.

Owner:叶达华

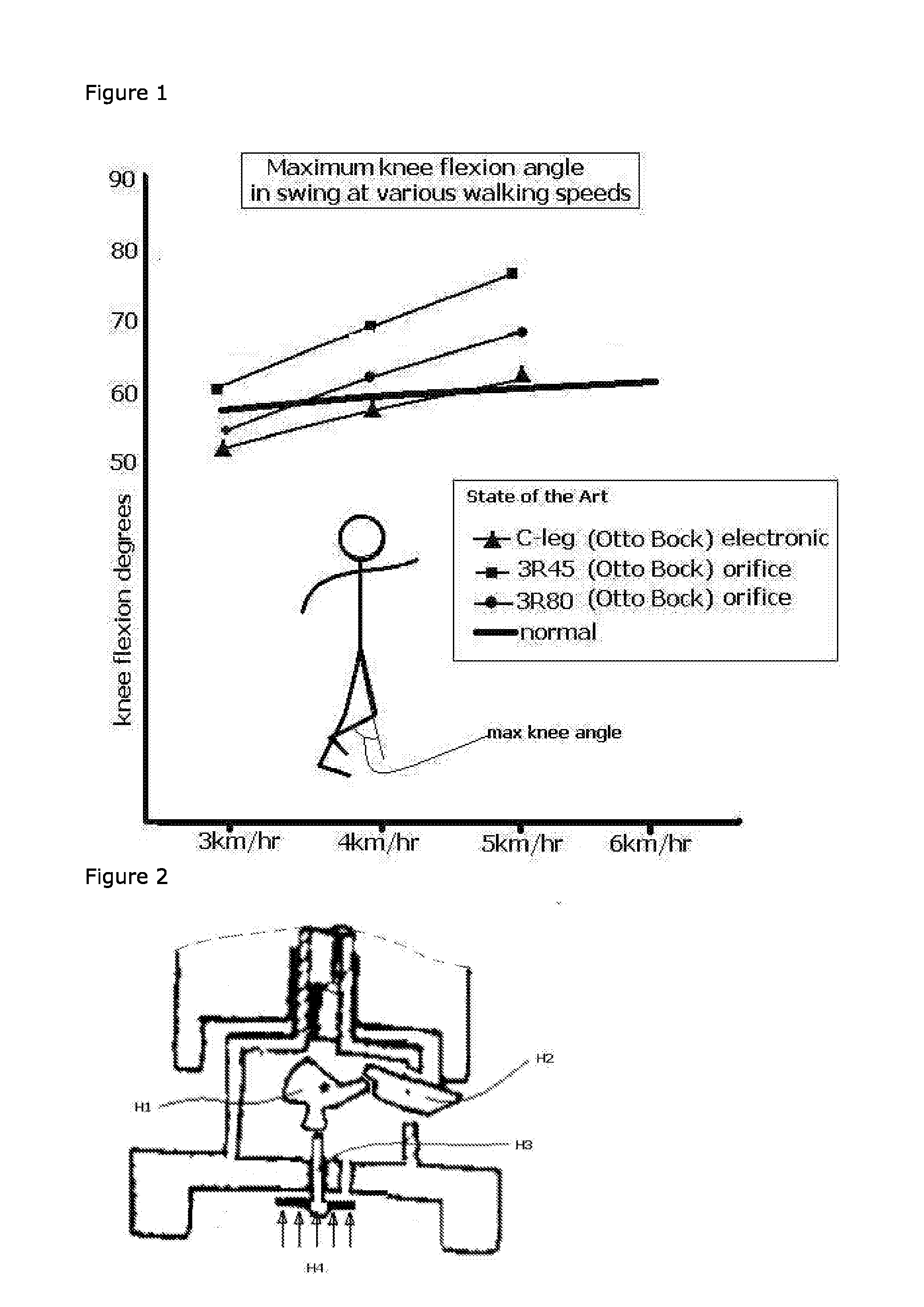

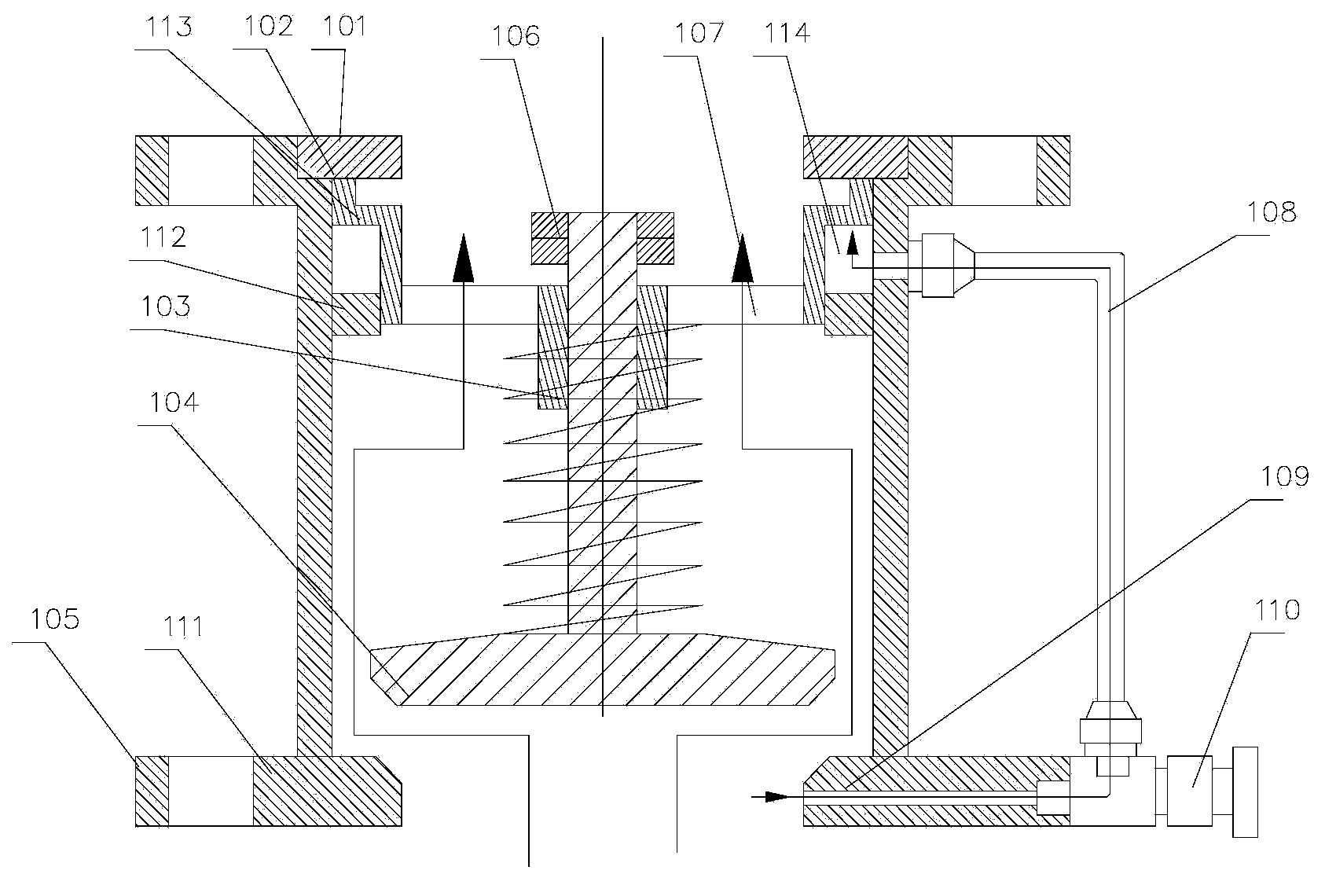

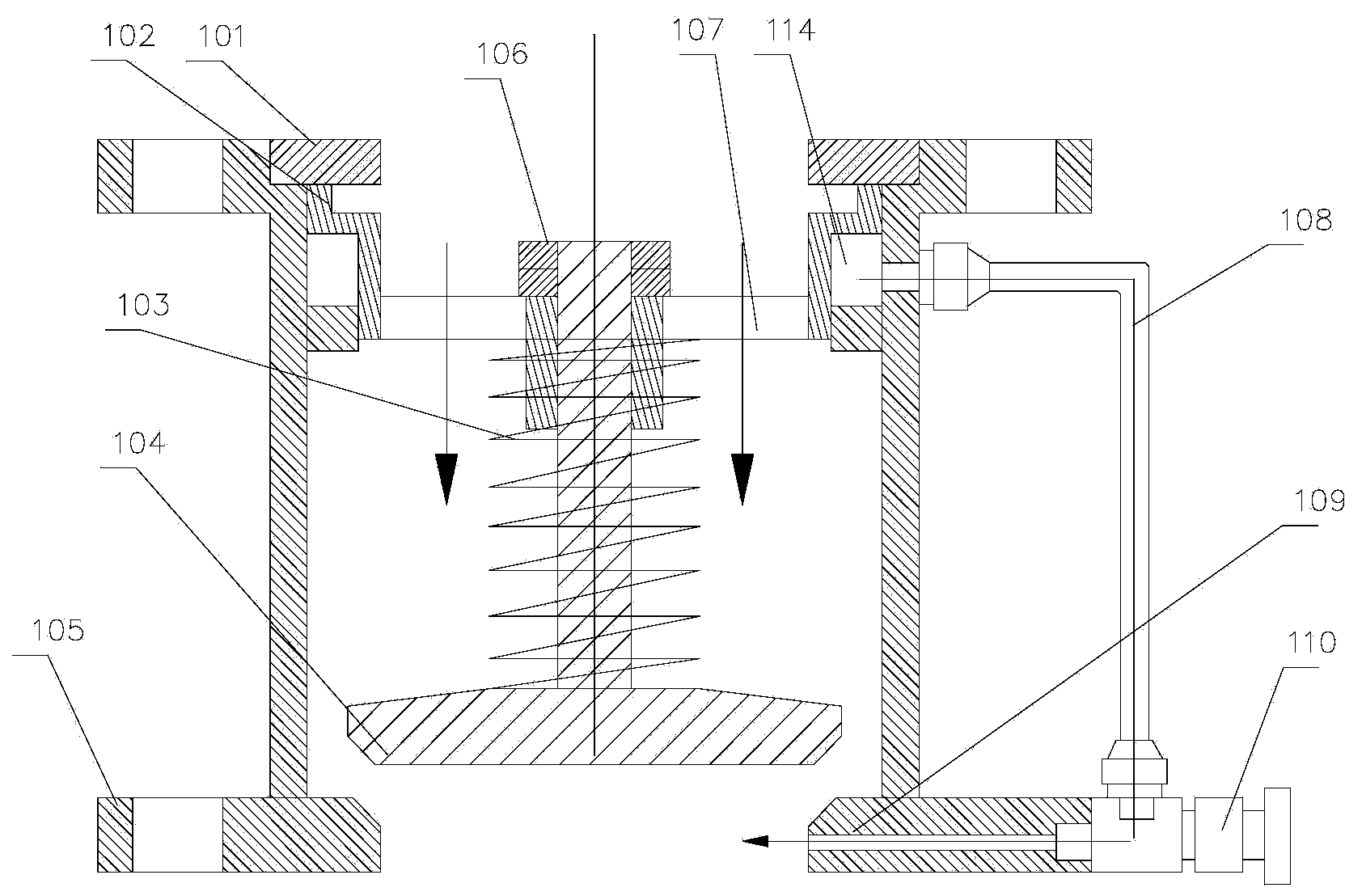

Prosthetic joints

The present invention relates to a prosthetic leg for those having a femoral amputee, namely those having an above the knee stump, where certain movements can be difficult to perform. Known prosthetic knee joints that are weight-activated cannot substantially assist short-stumped individuals. The weight placed on the toe will typically cause disengagement of any stance mode there otherwise might be. The invention provides a solution to the problems addressed above. The present invention seeks to provide an improved mechanically operated prosthesis for a femoral amputee. The invention also provides an improved electrically-operated prosthesis for a transfemoral amputee.

Owner:BOENDER JACOB QUINTUS LAURENCE ANTHONY +1

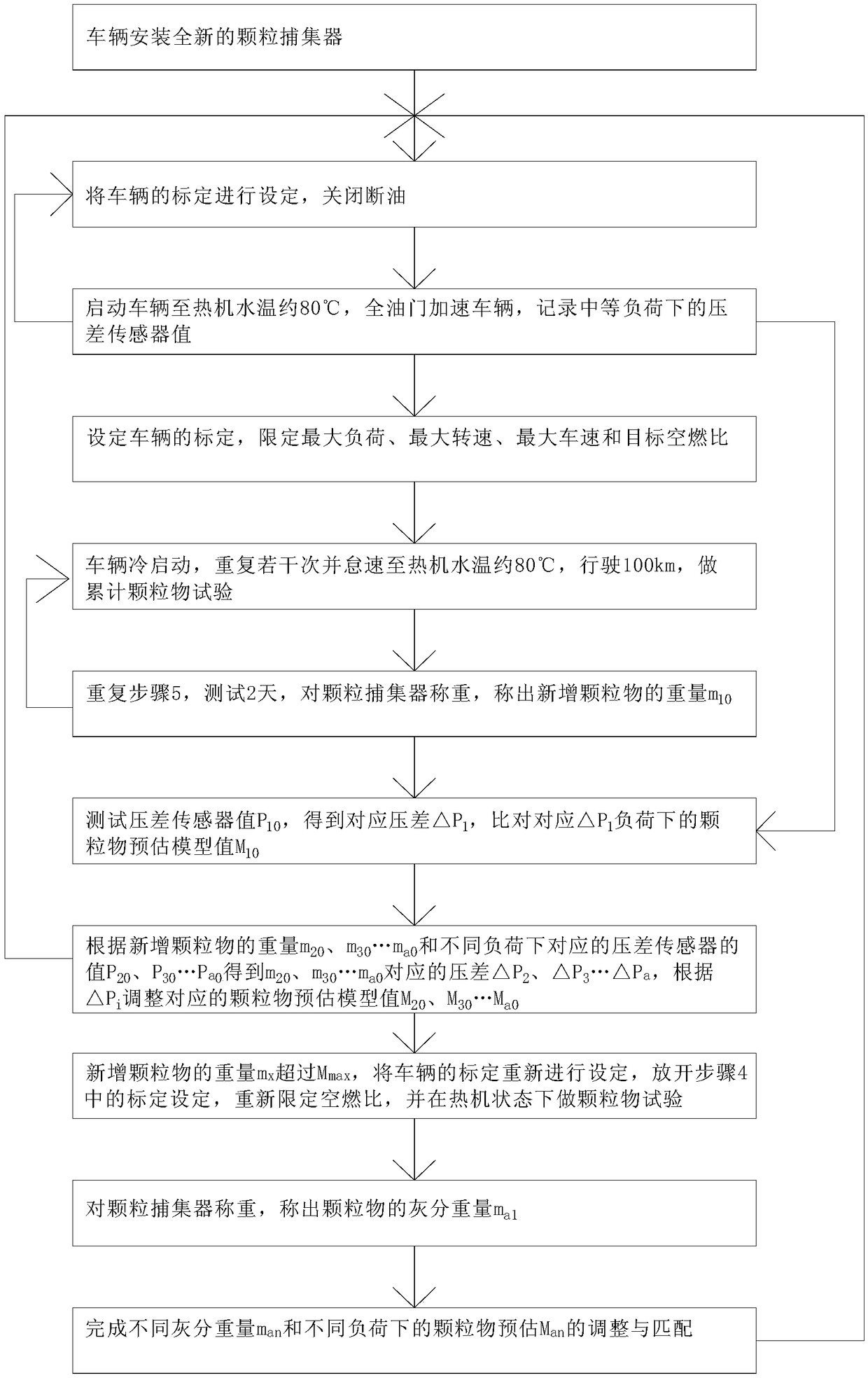

Calibration method of gasoline engine particulate matter model under low-temperature environment

ActiveCN108798851AExact matchPrecise adjustment and controlInternal combustion piston enginesExhaust treatment electric controlParticulatesGasoline

The invention discloses a calibration method of a gasoline engine particulate matter model under low-temperature environment. The method comprises the following steps that firstly, a brand-new particulate trap is arranged on a vehicle in a replacement manner; secondly, vehicle calibration is set; thirdly, a differential pressure transducer is started, and value of the differential pressure transducer is recorded; fourthly, vehicle calibration is set; fifthly, an accelerated accumulation particulate matter test is done; sixthly, the newly-added particulate matter is weighed; seventhly, particulate matter estimated model value is compared; eighthly, the steps from the second to the seventh are repeated, and the corresponding particulate matter estimated model value is adjusted; ninthly, whenthe weight of the newly-added particulate matter exceeds the active regeneration limit value of the particulate trap, the vehicle calibration is set again, and under the heat engine state, the particulate matter test is done; tenthly, the value of the differential pressure transducer and the particulate matter ash weight are recorded; eleventhly, the steps from the second to the tenth are repeated, and adjusting and matching of the particulate matter estimated model under different ash weights and different loads can be finished. Particulate matter model matching under the low-temperature environment can be achieved, and cost is reduced.

Owner:SAIC MOTOR

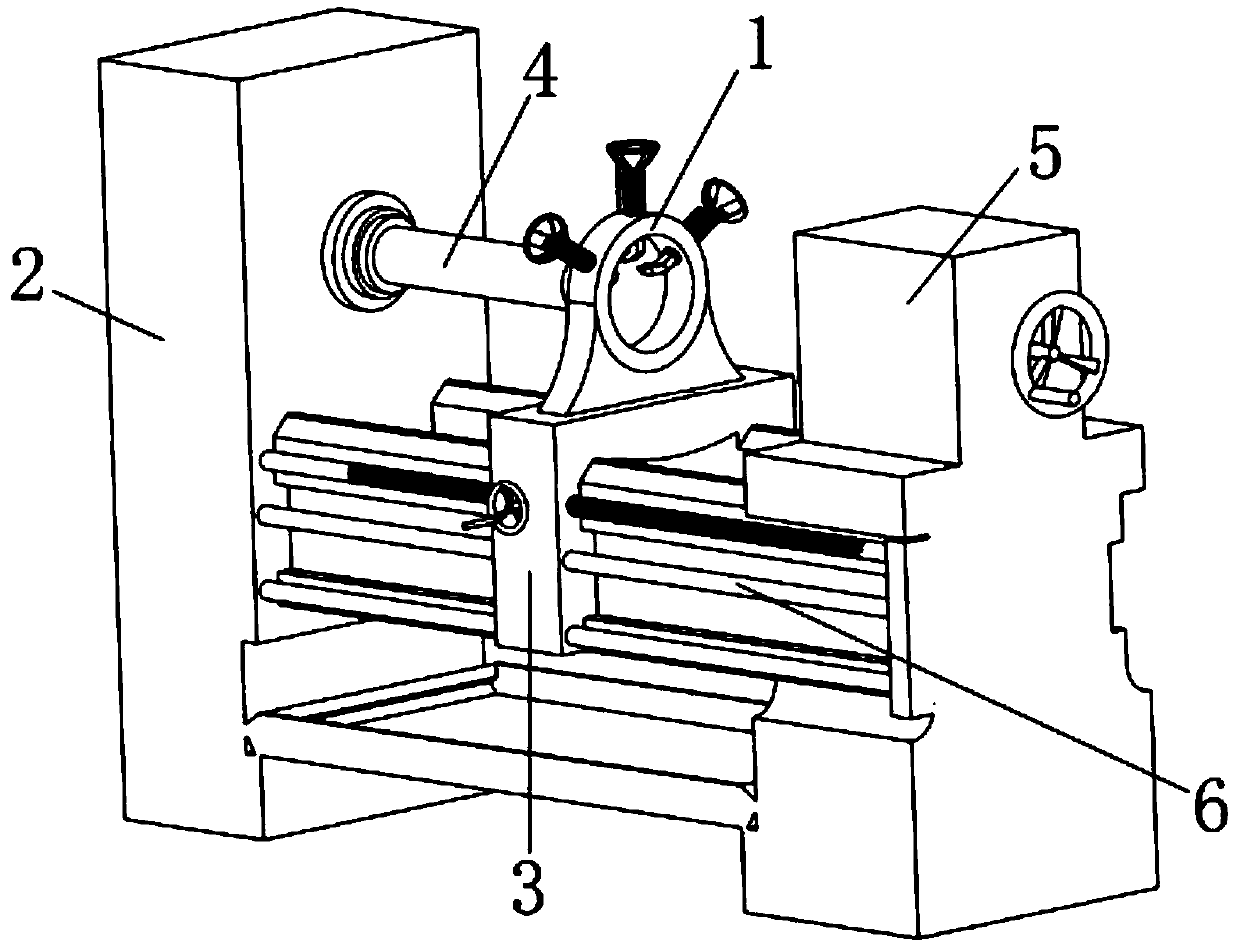

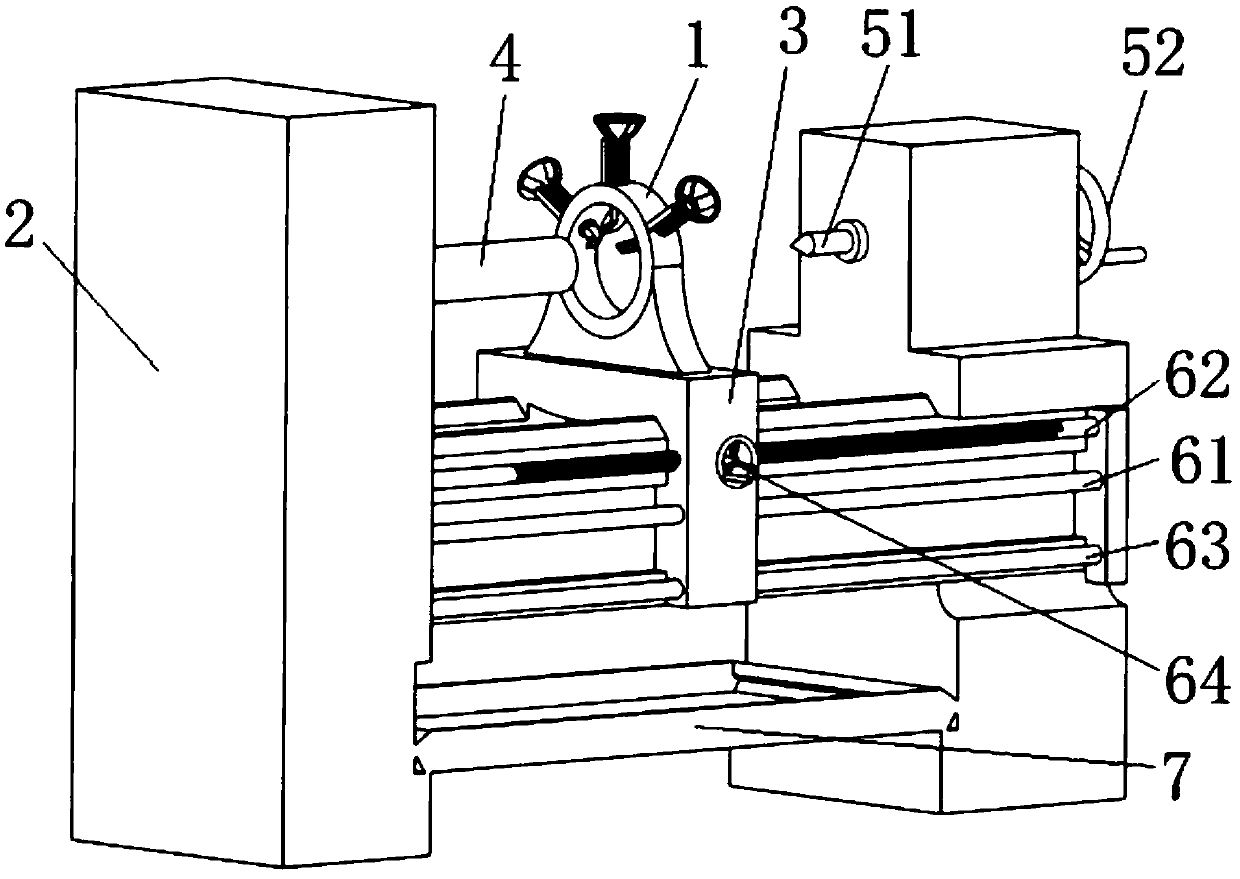

Multistage surface turning device

PendingCN109570529AIncrease productivityEasy to operateAuxillary equipmentTool holdersRadial positionEngineering

The invention relates to a multistage surface turning device. The multistage surface turning device comprises a tool, a lathe body used for installing the tool, a tool connecting piece connected withthe tool, a workpiece fixed to the lathe body, a tailstock which is used for coordinating with the lathe body to support the workpiece and a drive mechanism which is used for driving the tool to move.The tool comprises a guide rail, a support which is located on the guide rail and can slide along the guide rail, a tool rest which is installed on the support, at least two adjusting mechanisms which are arranged on the tool rest and tool bodies which are located at the ends of the adjusting mechanisms. The tool rest is in a ring shape and is internally provided with a through hole, and the workpiece penetrates through the through hole. According to the multistage surface turning device, by means of the at least two adjusting mechanisms different in radial position and the tool bodies, at least two stages of surface machining are achieved at the same time, multiple machining requirements of the workpiece surface are met at a time, the production efficiency is high, operation is convenient and rapid, and the production cost is saved.

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP +1

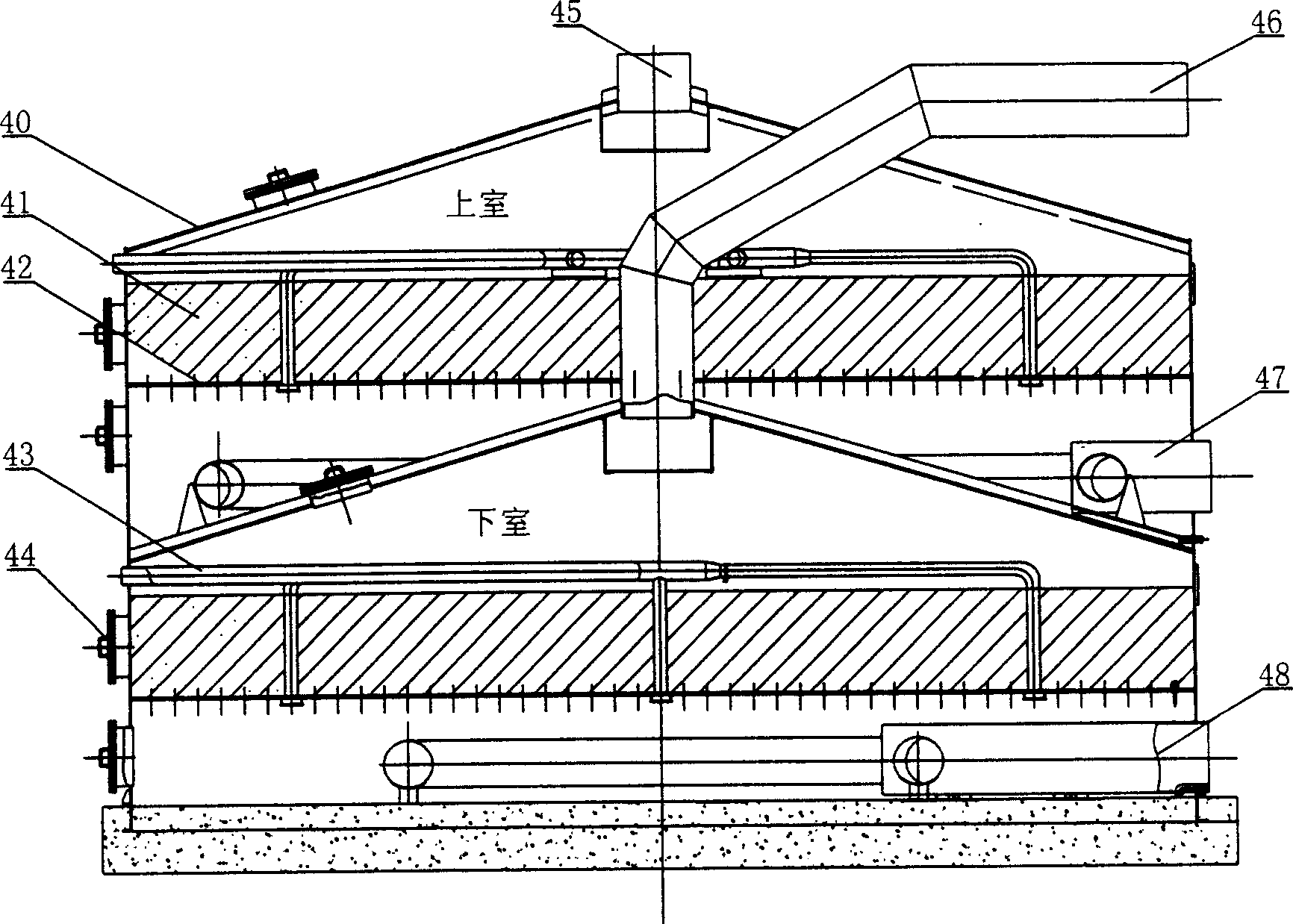

High-efficiency and energy-saving double suction fan

The invention discloses a high-efficiency and energy-saving double suction fan, which comprises an enclosure, a wind outlet, two wind inlets, a bidirectional air inlet impeller, a diffuser and air inlet prerotators, wherein air inlets are formed in the two sides of the bidirectional air inlet impeller; the air inlet prerotators are arranged on the two sides of the bidirectional air inlet impeller respectively; the wind inlets of the double suction fan are communicated with the air inlets in the same sides of the bidirectional air inlet impeller in an air flow adjustable way through the air inlet prerotators. According to the double suction fan, the structures of the air inlet prerotators are optimized, so that the flow can be more accurately adjusted and controlled through the air inlet prerotators, the energy loss is low, the working efficiency of the double suction fan is greatly improved, the overall axial size of the double suction fan can be greatly reduced under the condition of the same working capability, and the cost of the complete set is reduced.

Owner:苏州欧拉透平机械有限公司

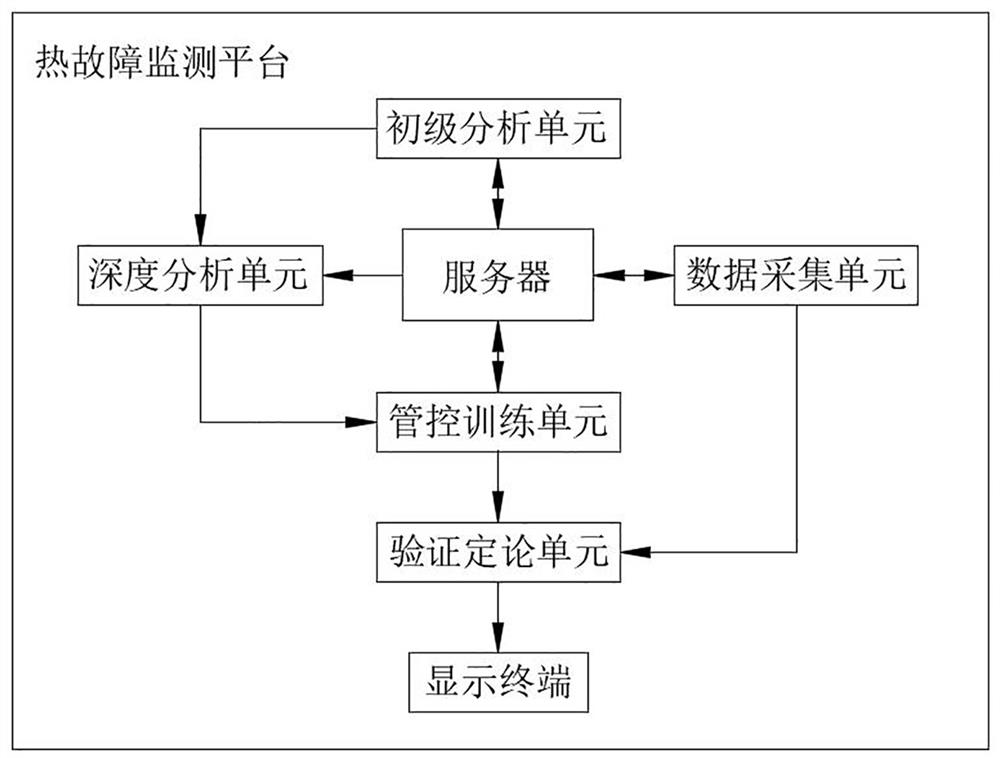

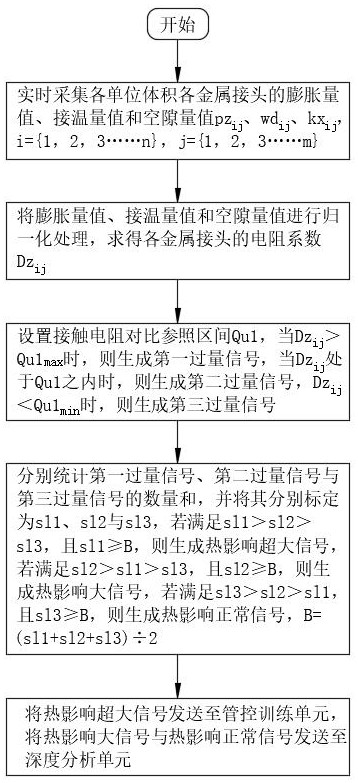

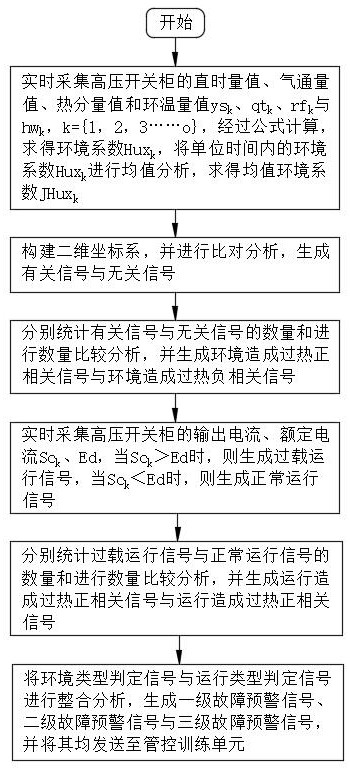

Fault monitoring system of wireless passive high-voltage switch cabinet

ActiveCN114740303AComprehensive and accurate overheating faultsClarify the failure levelCircuit arrangementsThermometer applicationsControl engineeringMonitoring system

The invention relates to the technical field of high-voltage switch cabinets, in particular to a fault monitoring system of a wireless passive high-voltage switch cabinet, and aims to solve the problems that in the conventional monitoring and analysis of overheating of the high-voltage switch cabinet, the monitoring and analysis mode has inaccuracy and one-sidedness; the fault monitoring system of the wireless passive high-voltage switch cabinet solves the problems that in the prior art, an overheat fault of the high-voltage switch cabinet is difficult to deeply and accurately analyze, stable operation of the high-voltage switch cabinet is difficult to guarantee, and power development is hindered in the prior art, and particularly discloses the fault monitoring system of the wireless passive high-voltage switch cabinet. Comprising a server, a data acquisition unit, a primary analysis unit, a deep analysis unit, a management and control training unit, a verification and deduction unit and a display terminal. According to the invention, the overheating fault of the high-voltage switch cabinet is accurately and comprehensively analyzed from different levels, and the high-voltage switch cabinet is subjected to regulation and control operation with corresponding intensity, so that the stable operation of the high-voltage switch cabinet is ensured while deep monitoring and accurate management and control of the overheating condition of the high-voltage switch cabinet are realized.

Owner:山东中安电力科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com