Backflow blocking valve

A backflow and valve body technology, applied in the field of check valves and valves, can solve the problems of inability to provide valve mold blanks, large check valve valve bodies, and expensive models, so as to facilitate the selection of new models and replacement of damaged valves. Quick, simple-to-build effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

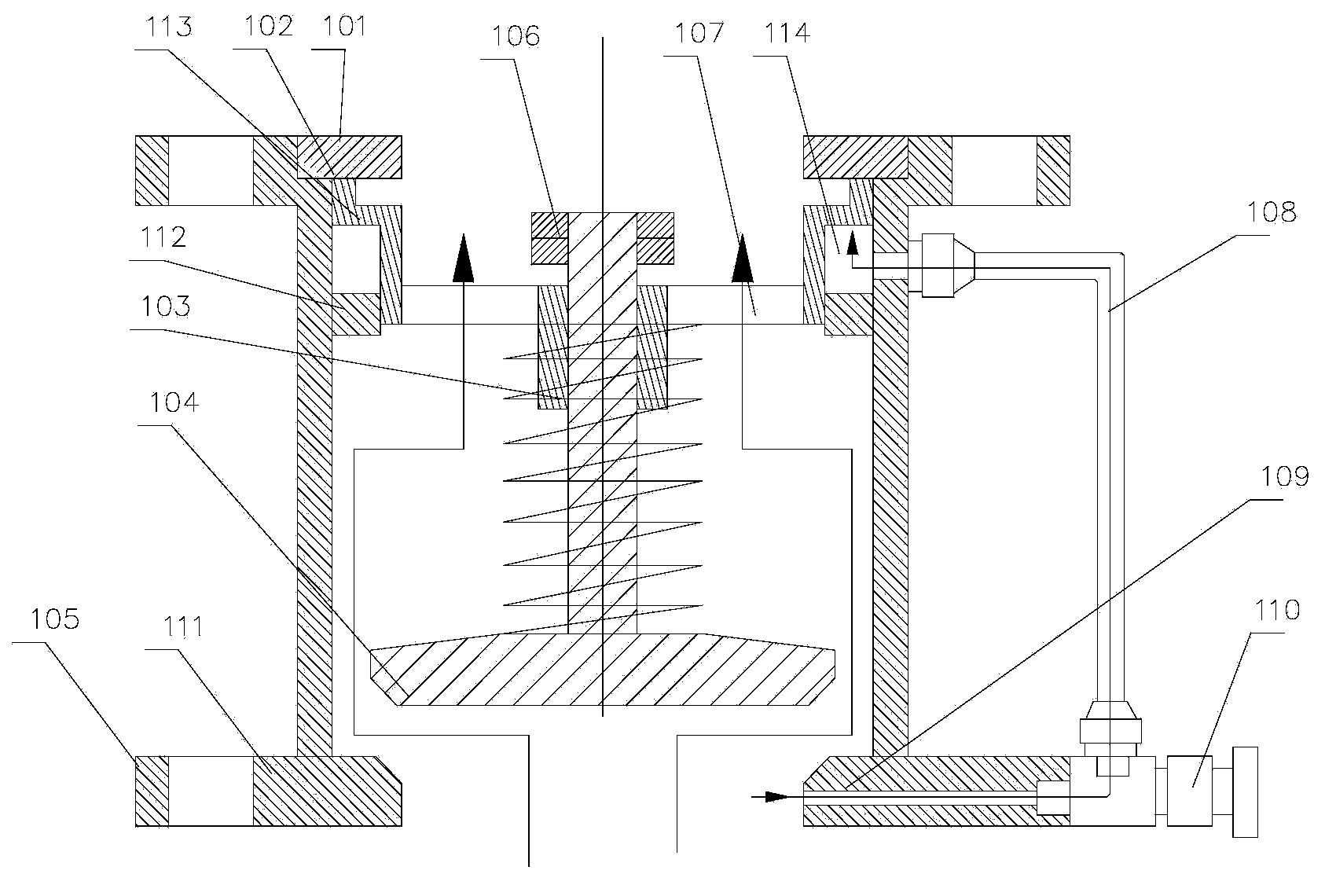

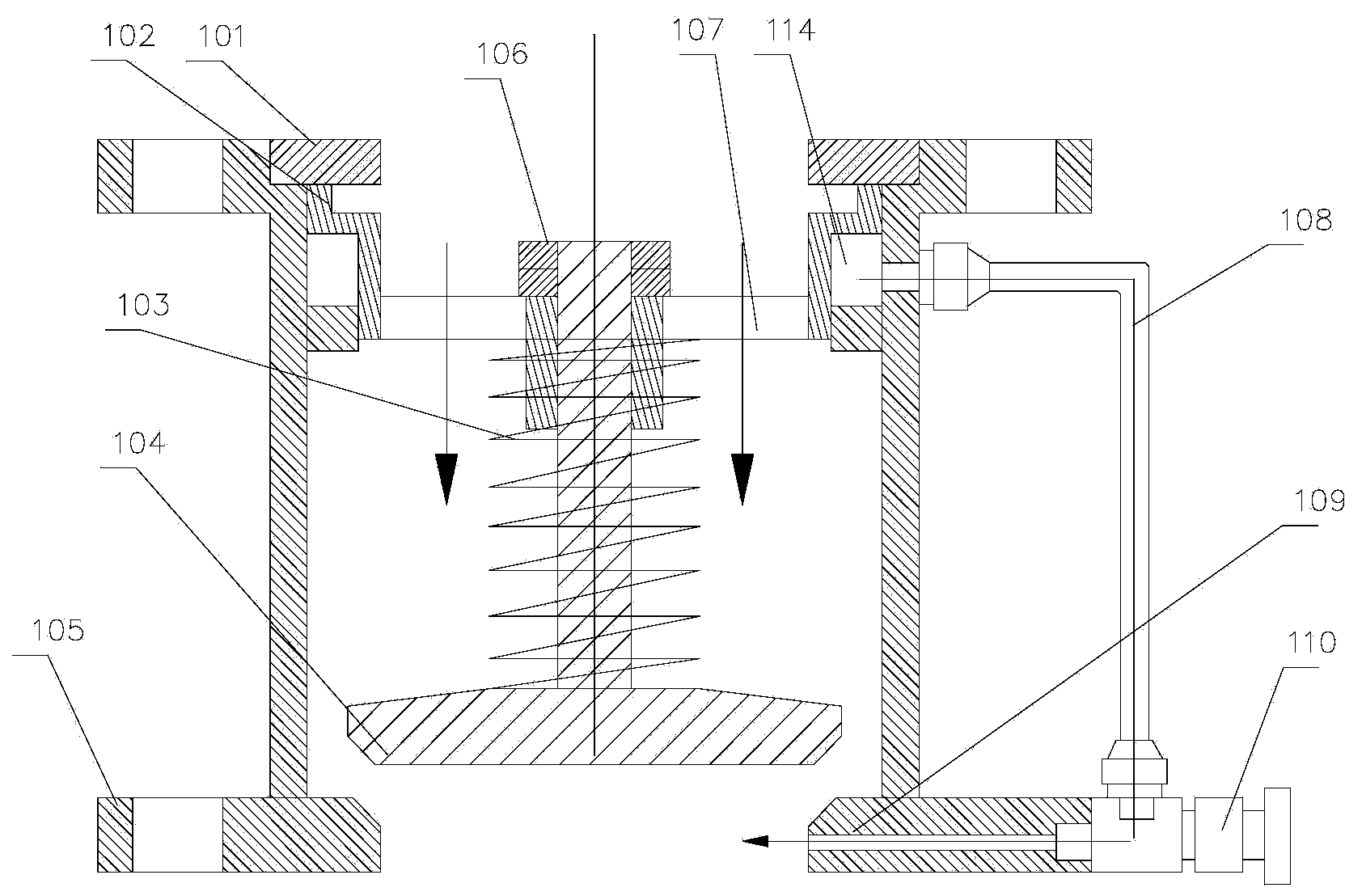

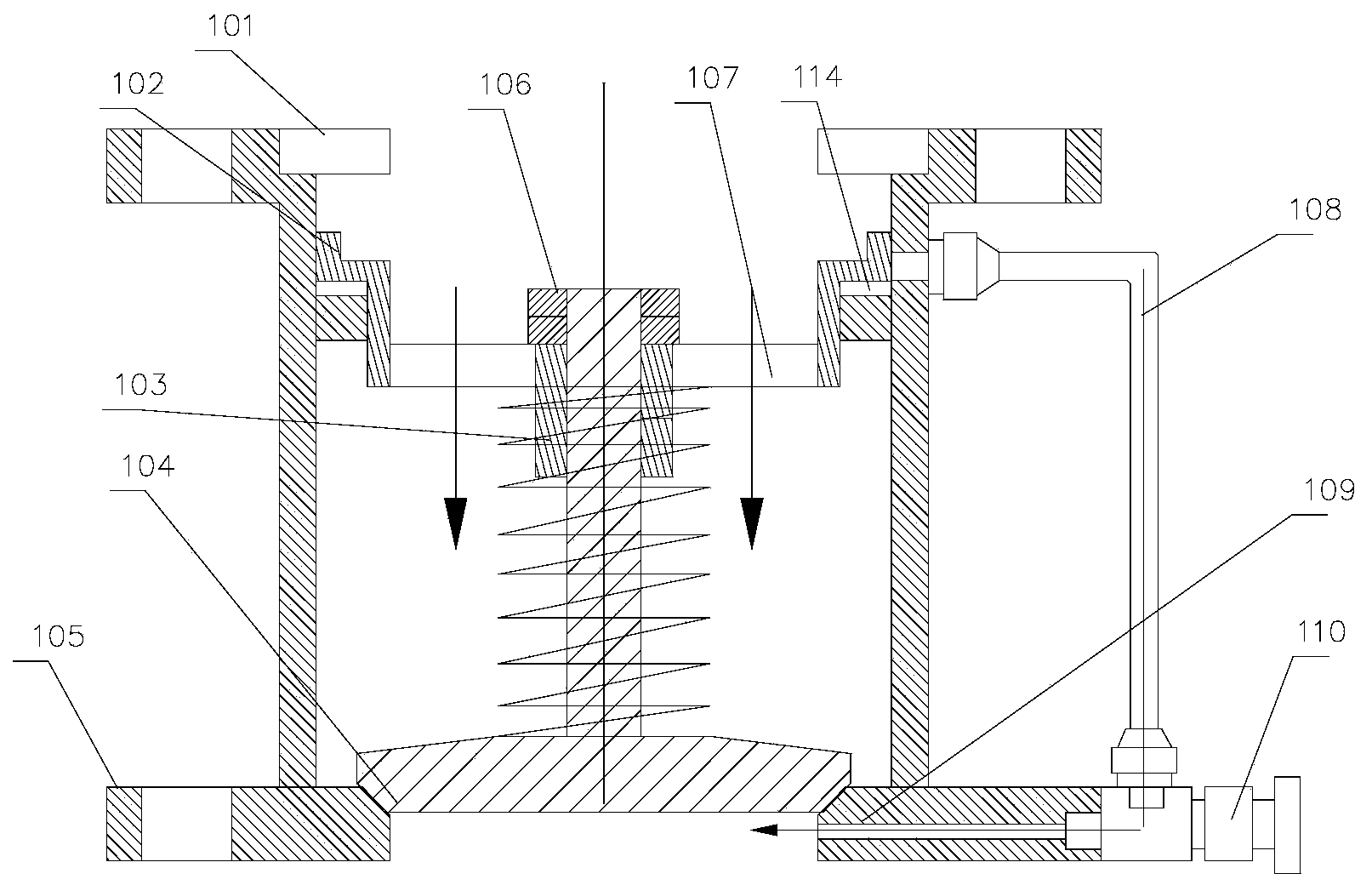

[0047] Such as Figure 1~3 Shown is an embodiment of the backflow prevention valve of the present invention. As a basic form, it includes a valve body 105, the inside of which is a valve cavity that can accommodate fluid, and the valve body 105 has a first limit end in the liquid inlet direction and a second limit end in the liquid outlet direction , the main body of the valve cavity formed between the first limiting end and the second limiting end is equipped with an auxiliary piston 102, a valve stem and a stopper that can slide in the axial direction, and the auxiliary piston 102 is connected with the valve inner cavity There is a liquid storage space between the walls that can accommodate the fluid to be delivered. When liquid is injected into the liquid storage space, the volume of the liquid storage space will increase due to the increase in pressure. On the contrary, the volume will decrease. When the volume of the liquid storage space When increasing, the auxiliary pi...

Embodiment 2

[0055] Such as Figure 4~6 Shown is another embodiment of the backflow prevention valve of the present invention. As a basic form, it includes a valve body 205, the inside of which is a valve cavity that can accommodate fluid, and the valve body 205 has a first limit end in the liquid inlet direction and a second limit end in the liquid outlet direction , the main body of the valve cavity formed between the first limit end and the second limit end is equipped with an auxiliary piston 202, a valve stem 209 and a stopper that can slide in the axial direction, and the auxiliary piston and the inner cavity of the valve Between the walls there is a reservoir space 214 which can contain the fluid to be delivered. When the volume of the liquid storage space increases, the auxiliary piston is in the open position due to the pressure of the liquid in the liquid storage space, and when the volume of the liquid storage space decreases, the auxiliary piston is in the closed state due to ...

Embodiment 3

[0061] Such as Figure 7-9 Shown is another embodiment of the backflow prevention valve of the present invention. As a basic form, it includes a valve body 305, inside the valve body is a valve cavity that can accommodate fluid, and the valve body 305 has a first limit end in the liquid inlet direction and a second limit end in the liquid outlet direction , the main body of the valve cavity formed between the first limit end and the second limit end is equipped with an auxiliary piston 302, a valve stem 309 and a stopper that can slide in the axial direction, and the auxiliary piston and the inner cavity of the valve body Between the walls there is a reservoir space 314 which can accommodate the fluid to be delivered. When the volume of the liquid storage space increases, the auxiliary piston is in the open position due to the pressure of the liquid in the liquid storage space, and when the volume of the liquid storage space decreases, the auxiliary piston is in the closed po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com