Preparation process for additive-free dried yoghourt and yoghourt powder

A technology for yogurt powder and yogurt, which is applied to the production process of yogurt powder and the field of additive-free dried yogurt, can solve the problems of inconvenience, large waste of yak milk, incomplete convenience and reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Attached picture

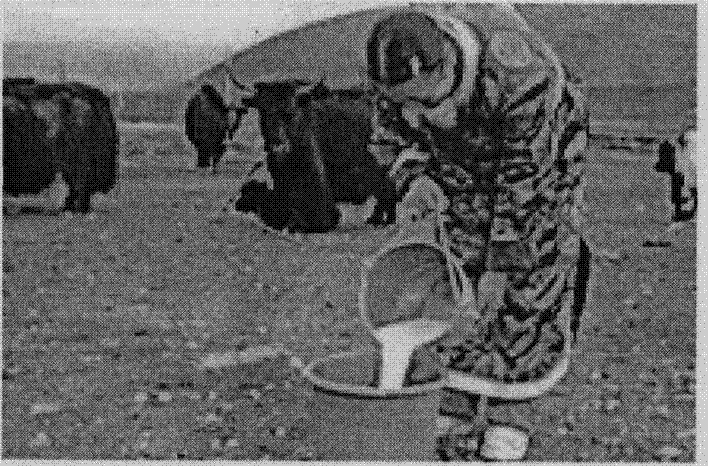

[0038] 1. Milking yak milk ( figure 1 ), and collect yak milk in a bucket ( figure 2 )

[0039] 2. Filter the yak milk in the bucket with fine gauze cloth, heat it to 30°C-40°C, pour it into the milk fat (ghee) separator ( image 3 ), the left basin is the milk from which part of the milk fat (ghee) has been separated, and the right basin is milk fat (ghee). After the liquid ghee is cooled and solidified, it becomes solid ghee.

[0040] 3. Stir and heat the separated yak milk to 50°C-60°C (heated by an artificial firewood cooker, heated to 50°C in summer and 60°C in winter; electric heating can also be used) - pour the hot milk into In the heat preservation container, stir and cool down to 38°C-42°C, and add 5%-10% yak milk acid water reserved for the first time in time (yak acid water has the effect of lactic acid bacteria, which can ferment fresh milk into yogurt), Quickly mix the hot milk and yogurt water evenly, seal it in time, and ferment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com