Automatic pressure soybean milk machine and method for producing soybean milk

A soymilk machine and pressure technology, applied in dairy products, food preparation, beverage preparation devices, etc., can solve the problems of poor taste and complex structure of normal pressure cooking, and achieve the effect of simple technical realization and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

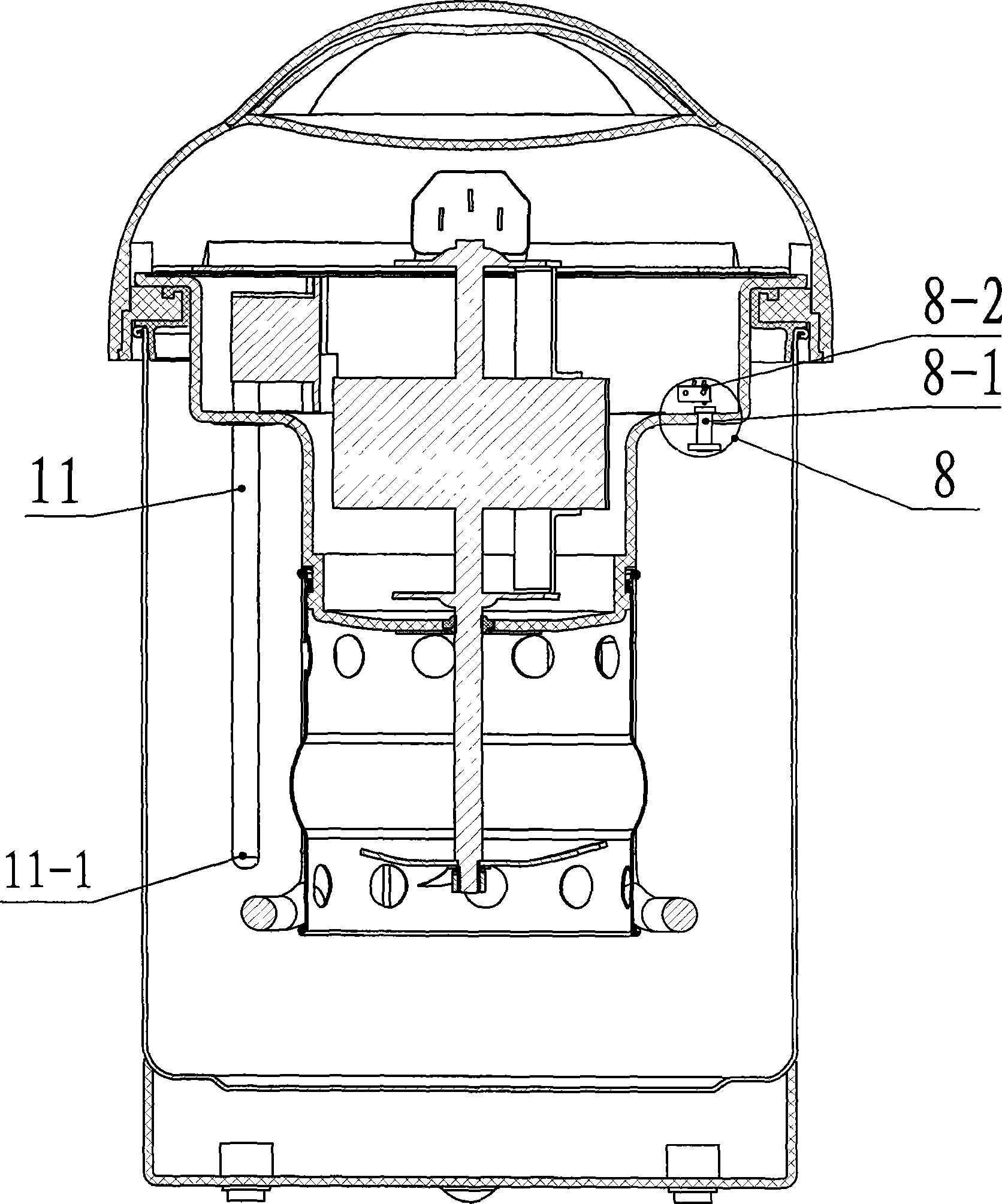

[0049] as attached figure 1 As shown, this automatic pressure soymilk machine is an embodiment of an upper-mounted motor, consisting of two parts: a machine base and a cup body;

[0050] The base part is composed of base 1, buckle teeth 2, sealing ring 3, cup cover 4, cup body 5, safety pressure relief device 6, motor 7, cutter 9, heating pipe 10, and temperature detector 11. An electric control circuit board (not described in detail) is arranged in the machine base 1 to be electrically connected to the motor 7, the heater 10, and the temperature detector 11 to realize various signal detection and circuit control. The machine base 1 can realize automatic pulping, Heating control, automatic induction chamber pressure function, over-pressure automatic pressure relief protection function; said machine base 1 is provided with a sealing ring 3, and the sealing ring 3 is between the cup cover 4 and the cup body 5, and the buckle tooth 2 will The cup cover 4 is fastened to the cup b...

Embodiment 2

[0052] Embodiment 2 is attached figure 2 As shown, the main structure and working principle of this automatic pressure soybean milk machine are basically the same as that of Embodiment 1, the difference is that the heater 10 of the second embodiment is a bottom-mounted heating plate, and the upper-mounted heating tube 10 is omitted.

Embodiment 3

[0053] Embodiment 3 is attached image 3 As shown, the main structure and working principle of this automatic pressure soybean milk machine are the same as those of the first embodiment, the main difference is that the third embodiment adds a pressure control switch 8, the pressure control switch 8 is a mechanical pressure control, When heating and pressurizing, the internal gas pressure begins to rise, and the air pressure pushes the push rod 8-1 upwards. When a certain pressure is reached, the push rod touches the switch 8-2 to disconnect the circuit connected to the switch, and the heater stops heating. Pressing up stops to realize automatic pressure control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com