Emulsifying machine

A technology of emulsifying machine and fixed gear, applied in the field of emulsifying machine, can solve the problem of uneven distribution of carrier particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

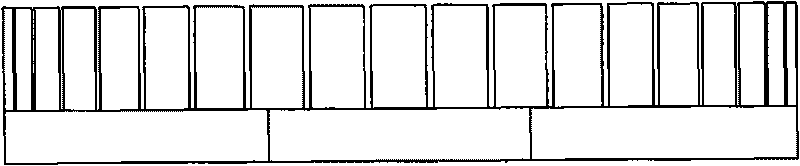

[0014] Such as figure 1 As shown, an emulsifying machine includes a motor 1, a connecting body 2, a cavity 3, a discharge port 4 and a feed port 7, a fixed gear 6 is installed inside the cavity 3, and a movable gear 5 driven by the motor main shaft, The fixed gear 6 and the movable gear 5 mesh with each other, and the end faces of the movable gear 5 and the fixed gear 6 have 2 to 6 rows of circularly arranged rectangular teeth, and the gap between adjacent rectangular teeth of each row is 30 ~50mm, the rectangular teeth of the movable gear 5 and the rectangular teeth of the fixed gear 6 are just inserted into the gaps between adjacent tooth rows of the other side, and the two gears are coaxial.

[0015] There are 2 to 5 groups of fixed gears 6 and movable gears 5 meshing with each other inside the cavity 3 .

[0016] Due to the change of the tooth shape, the flow channel is narrowed and the residence time between the teeth is prolonged, so as to achieve the effect of uniform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com