Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

436results about How to "Reduce stuck" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

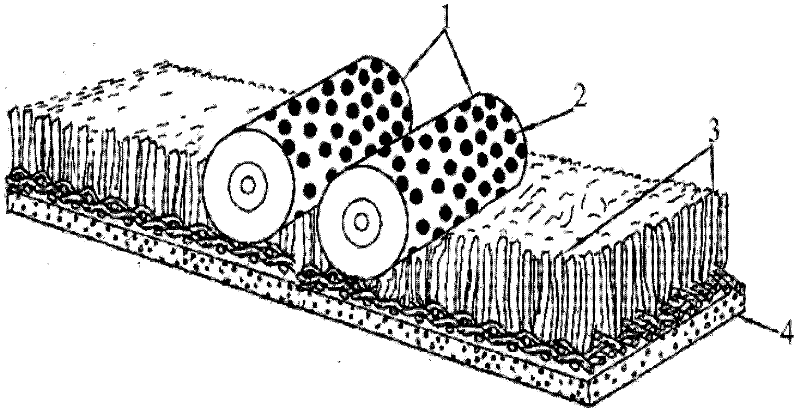

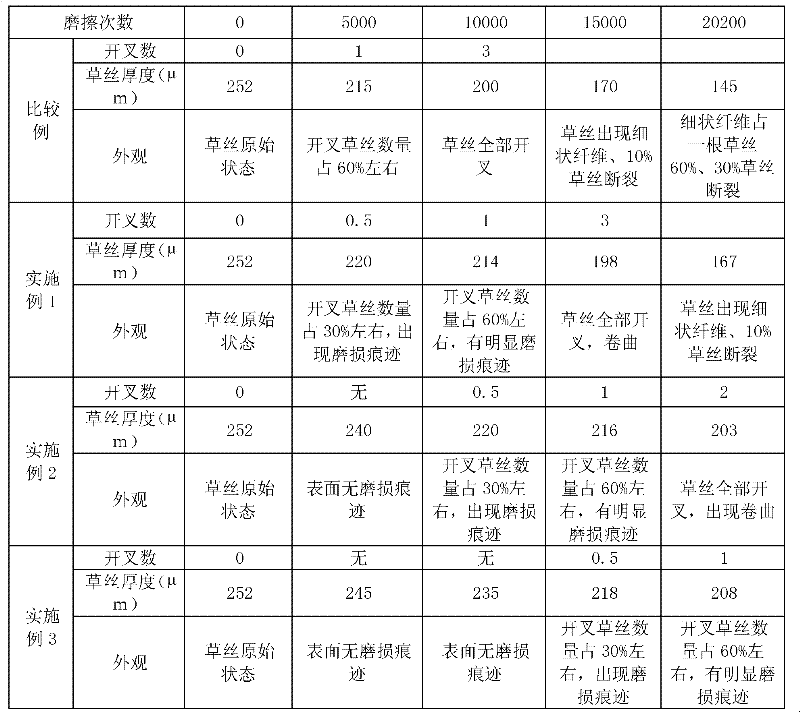

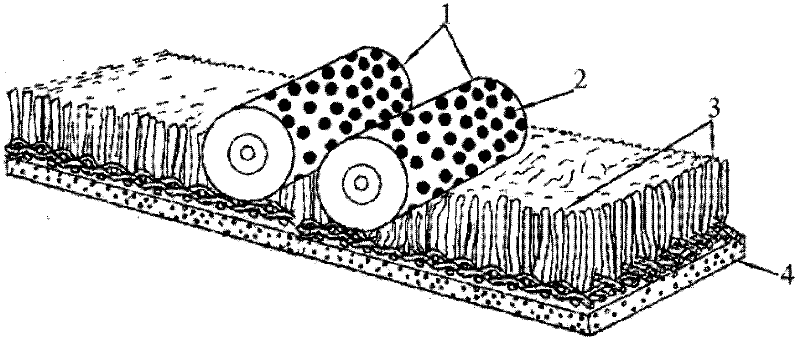

Wear-resistant artificial turf fiber

ActiveCN102493011AReduce wear rateImprove wear resistanceArtificial filament heat treatmentGround pavingsMasterbatchFiber

The invention relates to a wear-resistant artificial turf fiber made of the following raw materials by weight: 60 to 95 parts of matrix resin, 1 to 10 parts of wear-resistant masterbatch, 1 to 10 parts of color masterbatch, and 2 to 5 parts of age resister; and the wear-resistant masterbatch contains silicone powder. The wear-resistant artificial turf fiber has a greatly improved wear resisting property, thereby being suitable for places such as schools and the like where the wear-resistant artificial turf fiber is required to be used frequently for a long time. The wear-resistant artificial turf fiber has the advantages that the preparation method is simple; and the cost is low.

Owner:TAISHAN SPORTS IND GRP +1

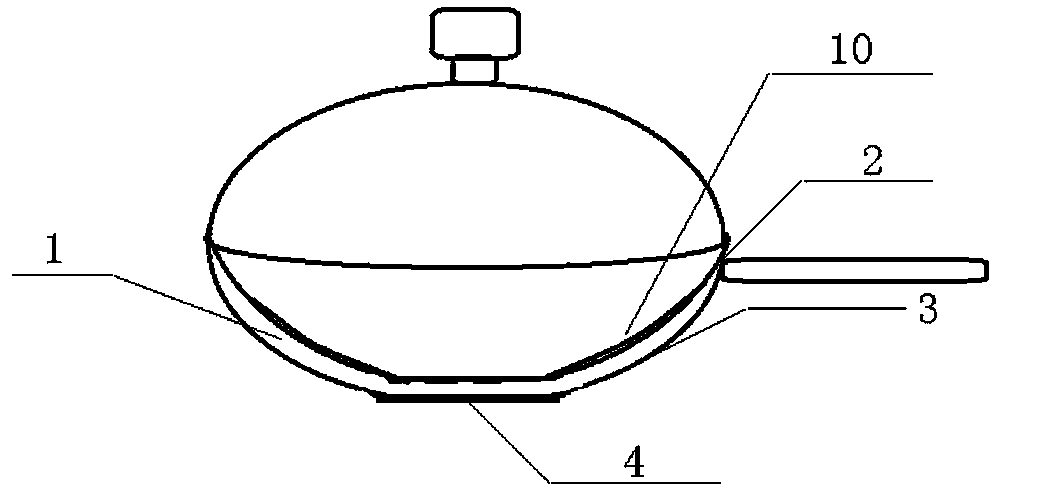

Novel composite cooker and manufacturing method thereof

The invention provides a novel composite cooker which comprises a cooker body with the thickness of 1.5 mm-5.0 mm. The thickness of the cooker wall is successively and progressively decreased by the 2 mm-3 mm space from the upper portion of the plane of a cooker bottom to the edge of the cooker wall. The cooker body comprises an inner layer cooker body and an outer layer cooker body, the inner layer cooker body is made of one of iron, iron-base alloy, stainless steel, titanium and titanium alloy, the outer layer cooker body is made of aluminum alloy or pure aluminum or AZ31B magnesium alloy or magnesium alloy, and a magnetic conduction energy storage layer is pressed on the outer surface of the outer layer cooker body. The materials of the inner surface of the cooker is healthful and sanitary, the heat conduction performance of the outer surface of the cooker is good, the outer surface is light in material, the magnetic conduction energy storage layer is arranged on the outer portion of the cooker bottom, the heat collection effect of the cooker bottom is increased, cooking energy consumption is reduced, and the application range of the cooker is expanded. The invention further provides a manufacturing method of the novel composite cooker. The method is easy to operate, saves materials, reduces cost, and is convenient to implement and beneficial to industrialization of the novel composite cooker.

Owner:WUYI RUIPU KITCHENWARE CO LTD

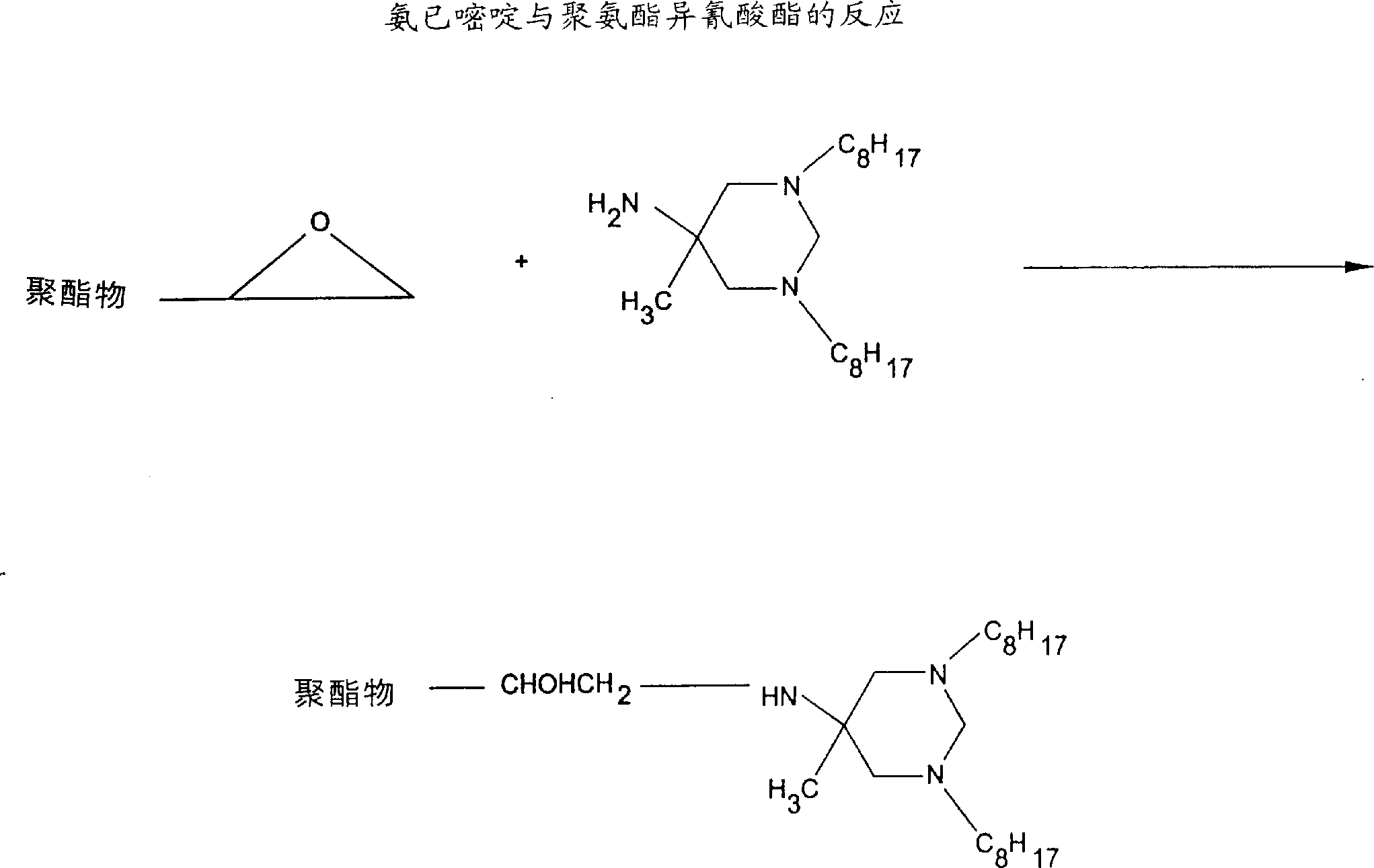

Biodegradable coated compound fertilizer and preparation method thereof

The invention relates to a coated compound fertilizer, in particular to a totally biodegradable coated compound fertilizer and a preparation method thereof. The coated compound fertilizer consists of a coated layer and a compound fertilizer core. The main body of the coated layer is polylactic acid and / or polybutylene succinate. The coating process adopts fluidized bed spraying-coated technology, and comprises the following steps: dissolving polylactic acid and / or polybutylene succinate in trichloromethane, adding carboxymethylcellulose, urease and / or nitrification inhibitor, organic and / or inorganic conditioner in the solution, spraying and coating the surfaces of the fluidized compound fertilizer granules after uniformly mixing the mixture under the stirring of a stirrer to form the uniform and complete organic polymeric membrane layer. The process has the advantages of easy implementation, and capacity of effectively slowing down the release of the fertilizer nutrient to the outside and the conversion rate of nitrogen in soils, effectively controlling the release and conversion of the fertilizer nutrient in soils, and reducing the pressure on environment caused by the rapid release of nutrient. The coated material can be totally biodegradable, and the degradation products have no secondary pollution to the environment.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

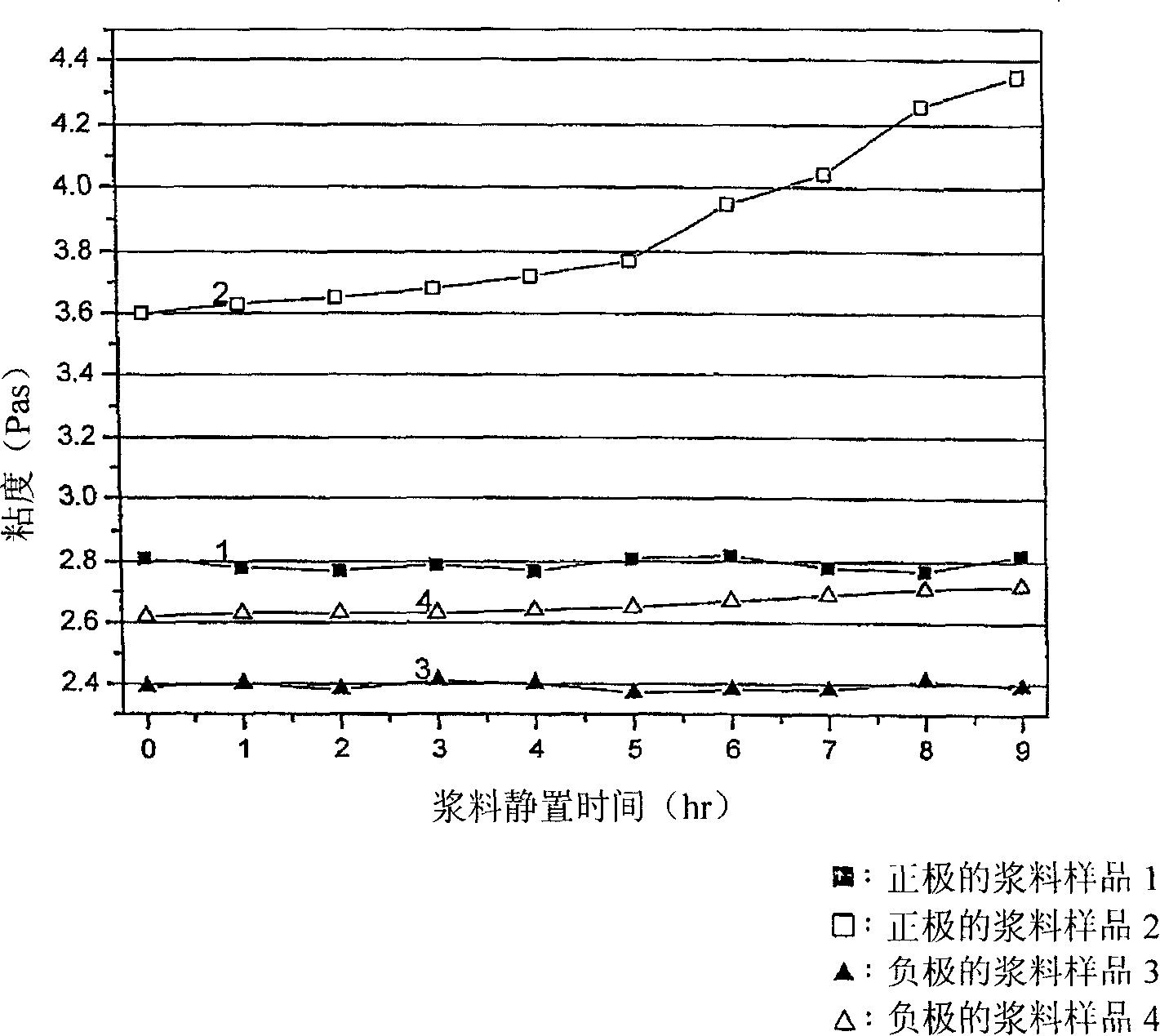

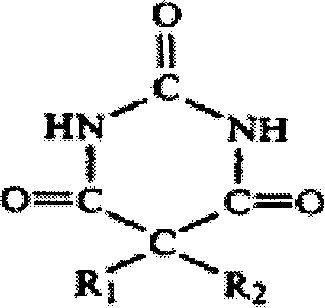

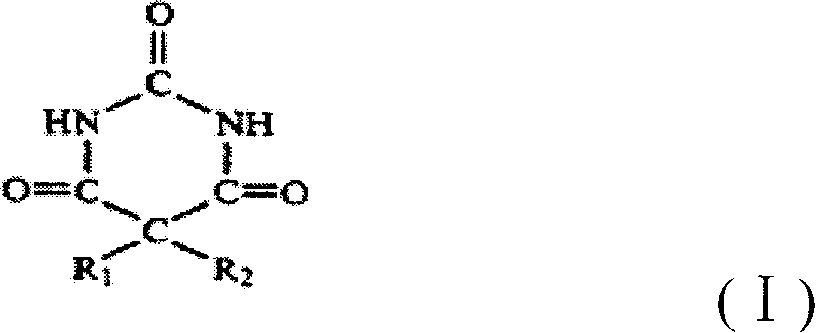

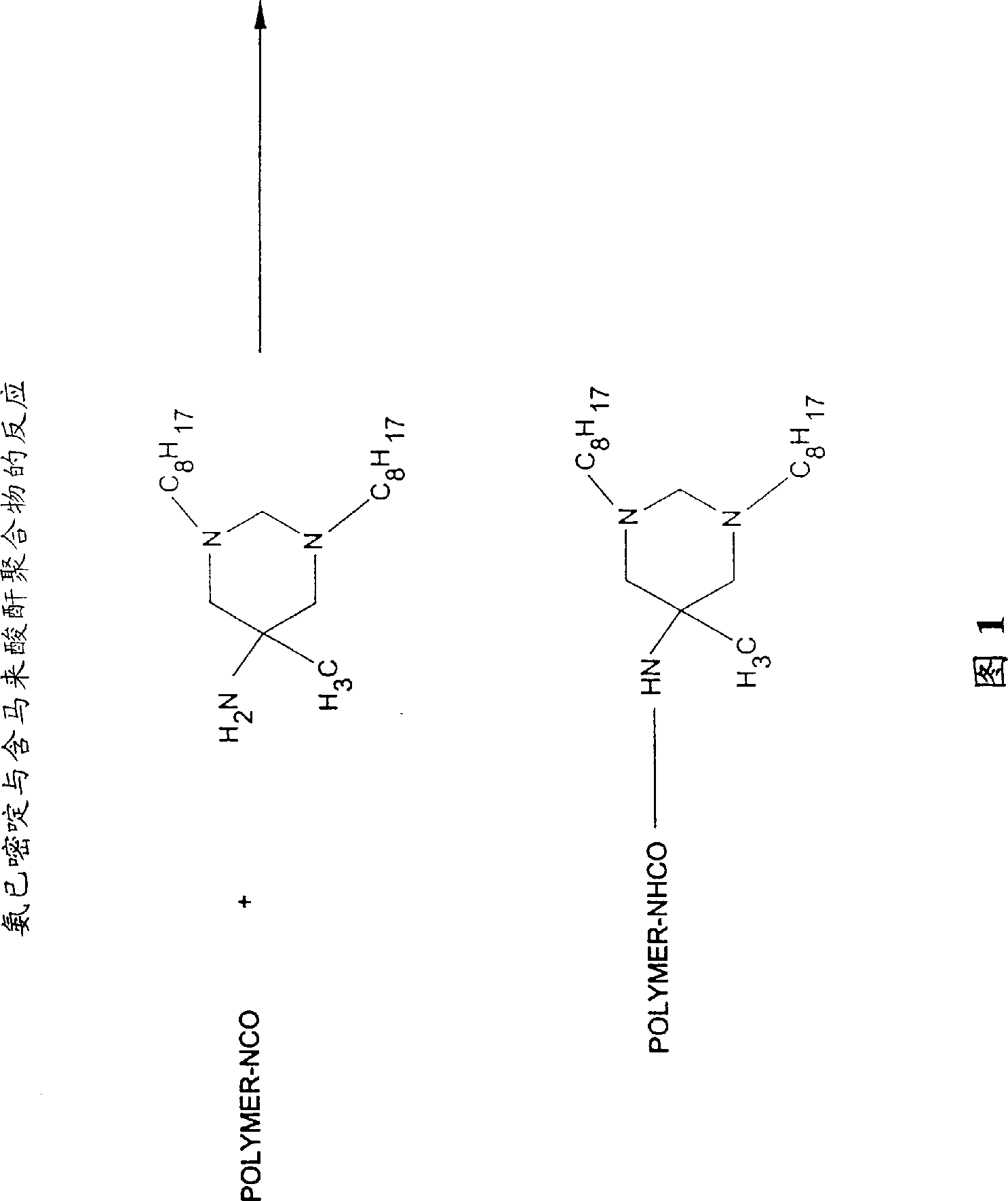

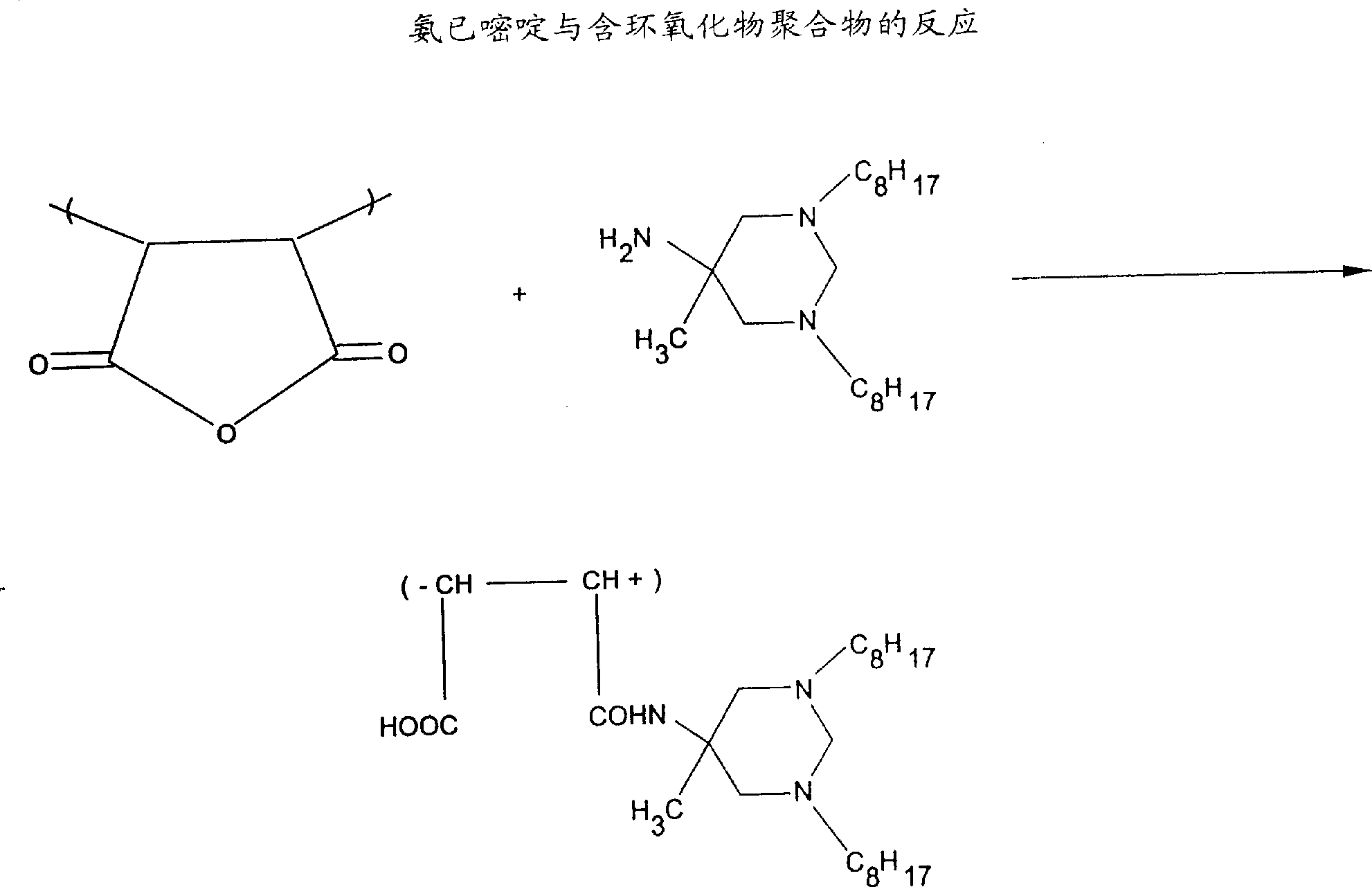

Battery electrode paste compound containing modified maleimide

ActiveCN101212052AReduce stuckGood storage stabilityCell electrodesAcid polymer adhesivesDendrimerSolvent

The invention discloses an electrode paste compound of a battery containing modified maleimide, which comprises electrode active material, conductive additive, agglutinate and modified maleimide dispersing agent. The modified maleimide acting as the dispersing agent in the compound has a dendrimer-like hyperbranched structure and can form a stable complex compound with the electrode active material such as metal oxide, improve the dispersion of the paste solution, reduce the viscosity of the paste, and maintain the stability of the viscosity for a long term. Besides, due to excellent compatibility of the modified maleimide and the electrode paste solvent, the stability in storing the paste can be improved. In addition, through stable bonds formed by the modified maleimide and a current collecting substrate of the electrode, the adhesive force between an electrode membrane and the current collecting substrate can be increased, and the cycle life of the battery product can be prolonged.

Owner:IND TECH RES INST

Biodegradable coated carbamide and preparation method thereof

InactiveCN101723751AReduce releaseReduce rateUrea compound fertilisersFertilizer mixturesCoated ureaNitrification inhibitors

The invention relates to coated carbamide, in particular to a totally biodegradable coated carbamide and a preparation method thereof. The coated carbamide consists of a coated layer and a carbamide core. The main body of the coated layer is polylactic acid and / or polybutylene succinate. The coating process adopts fluidized bed spraying-coated technology, and comprises the following steps: dissolving polylactic acid and / or polybutylene succinate in trichloromethane, adding carboxymethylcellulose, organic and / or inorganic conditioner, urease and / or nitrification inhibitor in the solution, spraying and coating the surfaces of the fluidized carbamide after uniformly mixing the mixture under the stirring of a stirrer to form the uniform and complete organic polymeric membrane layer. The process has the advantages of easy implementation, and capacity of effectively slowing down the release of the nutrient to the outside and the conversion rate of nitrogen in soils, effectively controlling the release of the nitrogen nutrient in soils, and reducing the pressure on environment caused by the rapid release of nutrient. The coated material can be totally biodegradable, and the degradation products have no secondary pollution to the environment.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

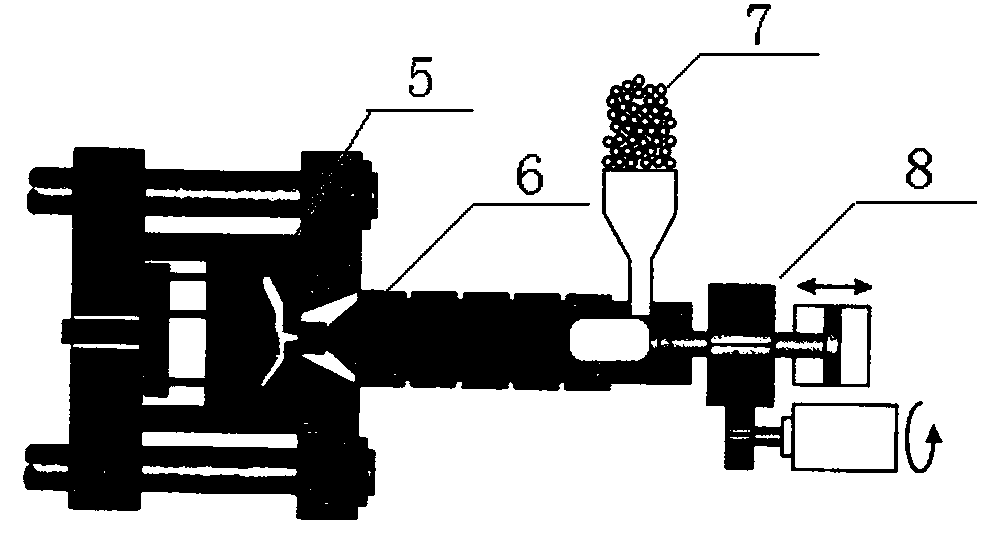

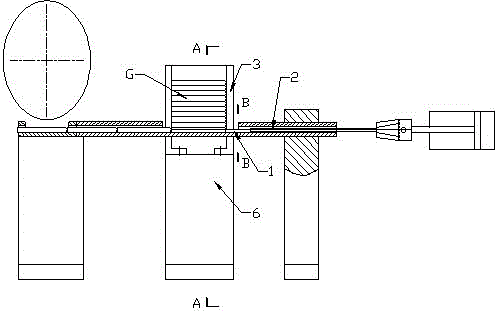

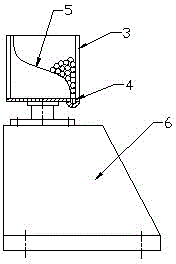

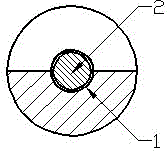

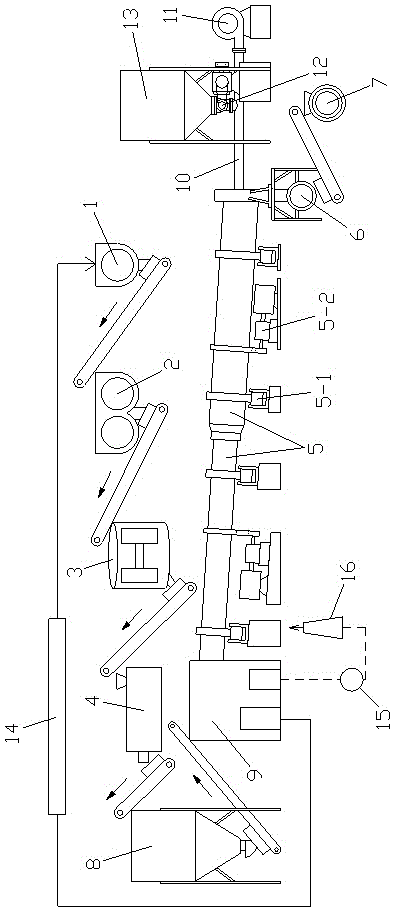

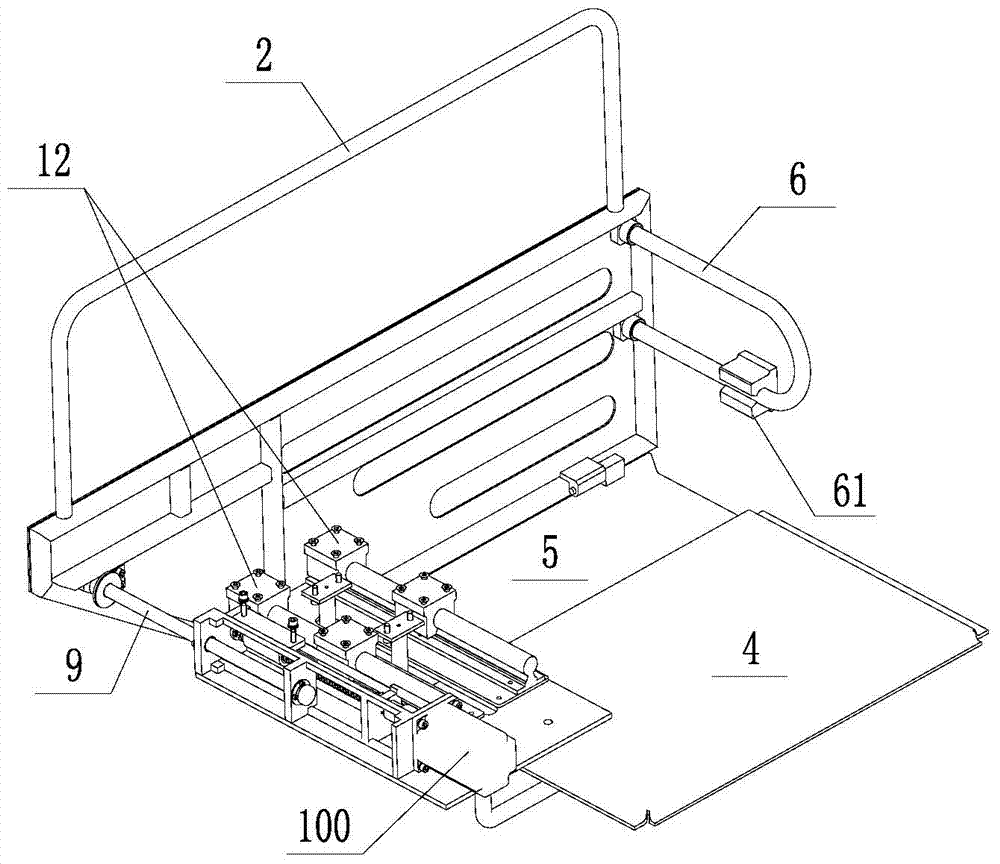

Feed device of minor-diameter rodlike workpiece processing equipment

ActiveCN102873614AStable outputSmall diameterGrinding machine componentsGrinding machinesEngineeringUltimate tensile strength

The invention relates to a feed device of minor-diameter rodlike workpiece processing equipment. The feed device comprises a horizontal feed channel, the front end of which is connected with a part of a cutting device; a pushing mandril which is driven by a power unit and can axially move in the feed channel is arranged at the rear section of the feed channel; a feed box is arranged above the feed channel; a discharge port which directly faces the feed channel is arranged at the bottom of the feed box and rodlike workpieces can pass through the discharge port one by one; a guide slope which enables the rodlike workpieces to roll to the discharge port under the actions of gravities is arranged inside the feed box; and the feed box is installed on a vibrating device and can vibrate up and down along with the vibrating device. The feed device has the advantages that: 1, with the feed device, the workpieces with small diameter and light weight can be discharged successfully, clamping stagnation is reduced, and the movement reliability is improved; 2, the strength of the pushing mandril and the structural strength of the entire guide structure are improved, and the fault of breakage of a small-size pushing mandril is reduced.

Owner:丹阳市盛力机械有限公司

Novel self-lubricating polymer composite material and its prepn process

The present invention relates to novel self-lubricating polymer composite material and its preparation process. The novel self-lubricating polymer composite material is prepared with calcium carbonate whisker in 10-25 weight portions, PTFE in 10 weight portions and polyether ether ketone in 65-80 weight portions; and the preparation process includes the following steps: drying the said materials at 130-150 deg.c and mixing through high speed stirring in a stirrer; melting the mixture in a hot pressing mold pressurizing at 20 MPa to form, maintaining for 8-10 min, cooling inside the die to 100 deg.c, demolding, cooling to room temperature, and maintaining at 250 deg.c of 1 hr. The present invention has calcium carbonate whisker to strengthen polyether ether ketone, PTFE as antifriction agent, and the cooperation of polyether ether ketone, PTFE and calcium carbonate whisker to result in self lubricating, reduced friction and raised wear resistance.

Owner:FUZHOU UNIV

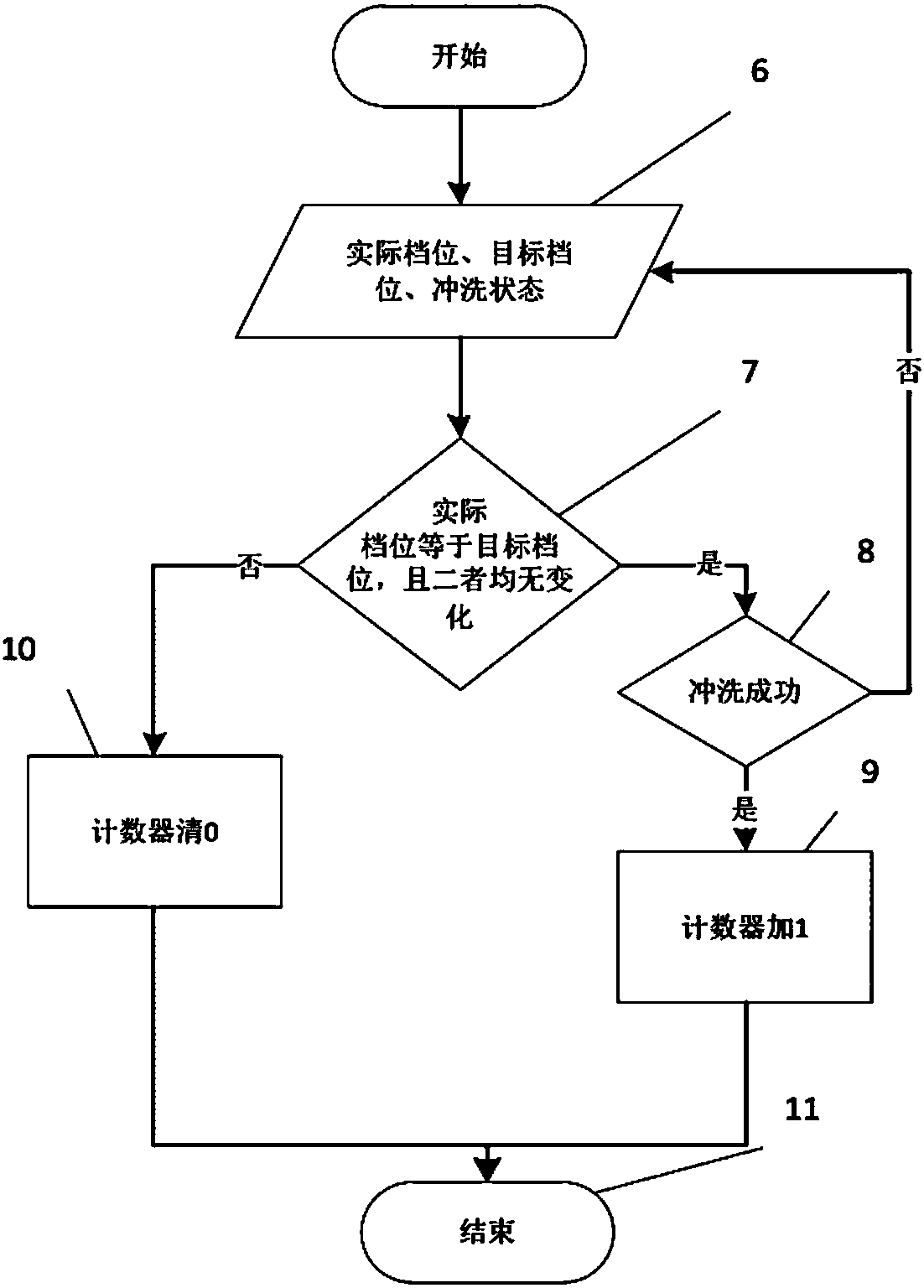

Flushing control method and system for solenoid valves of wet type dual clutch transmission clutch

ActiveCN107701720AReduce stuckPlay a preventive roleClutchesGearing controlSolenoid valveControl theory

The invention discloses a flushing control method and system for solenoid valves of a wet type dual clutch transmission clutch. The transport condition of a vehicle is detected, and state judgment iscarried out in real time; when the vehicle is normally driven, impulse type flushing is carried out on the solenoid valve of a clutch which does not work; and when the solenoid valve is blocked and apressure difference failure, vehicle limping or a parking state are given out, impulse type flushing is carried out on the broken clutch solenoid valve, when impulse type flushing cannot eliminate theblocking failure, impulse type flushing is carried out on the solenoid valves of the two clutches at the same time in a parked state, and therefore automatic recovery of the solenoid valve state is achieved. By means of the flushing control method and system, the cleanliness of the solenoid valves can be guaranteed, a transmission failure is prevented, and the probability of the transmission failure is reduced; and the service life of the transmission is prolonged, and the maintaining cost and the using cost are saved.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

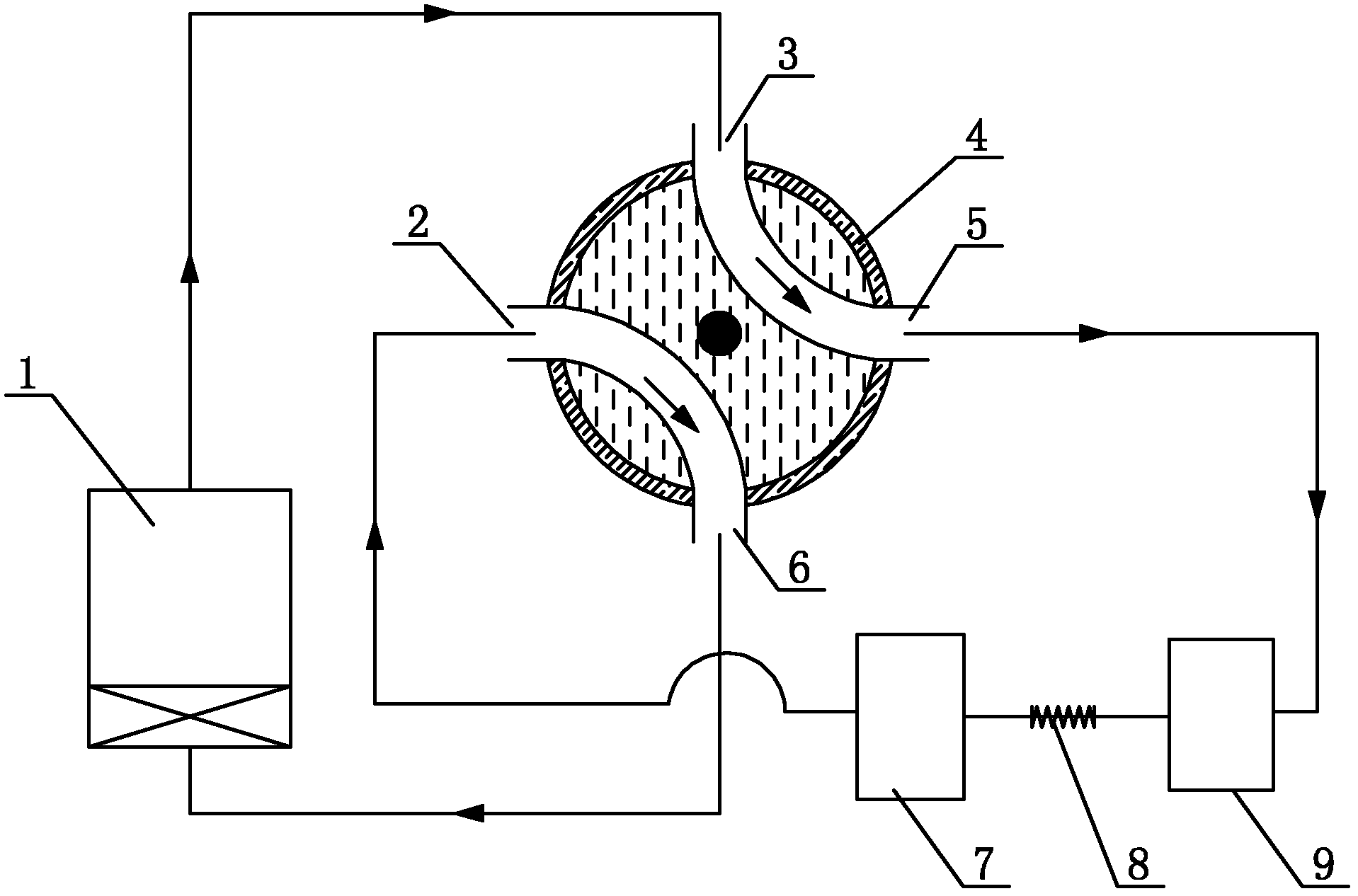

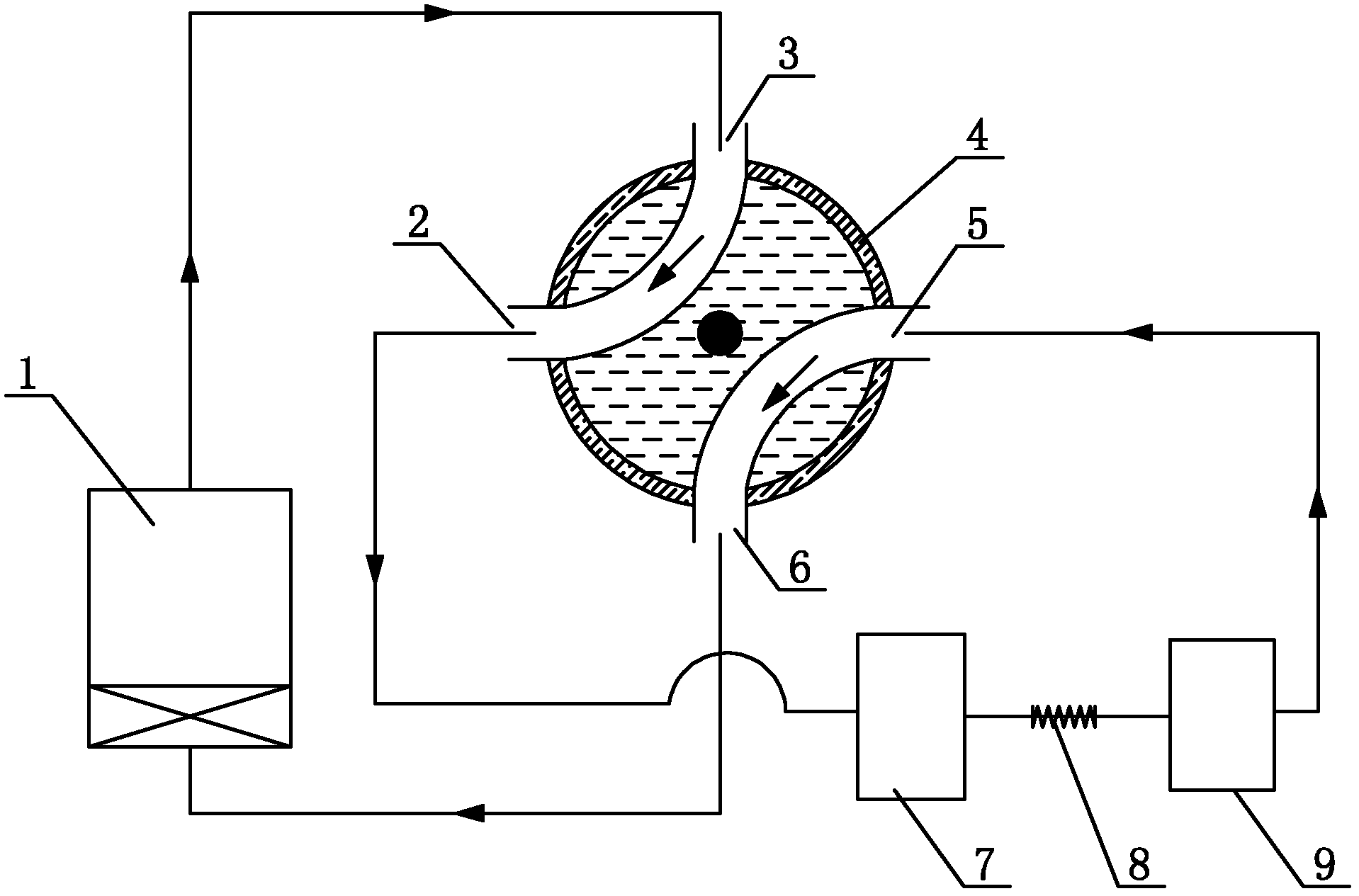

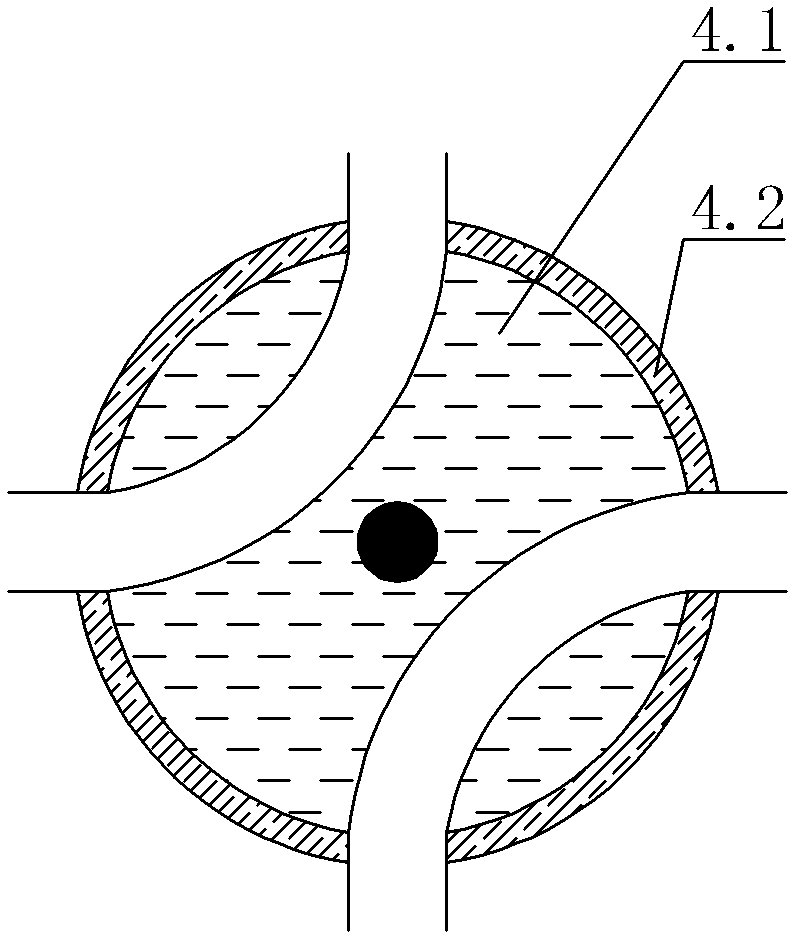

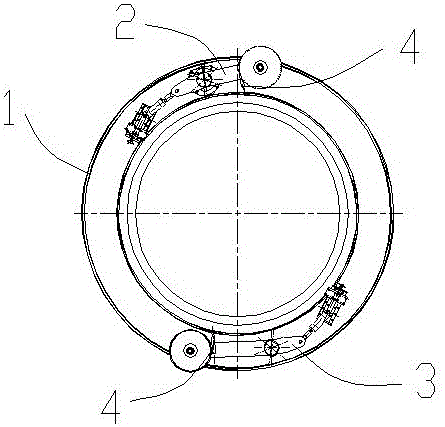

Four-way valve for Carnot cycle system

A four-way valve for a Carnot cycle system comprises a four-way valve body consisting of a valve body and a columnar valve spool. The four-way valve body is connected with an air conditioner through a pipeline, mutually symmetric channels are arranged inside the valve spool and penetrate through the surface of the valve spool, the valve body is provided with more than one through hole corresponding to the channels, and the diameter of each through hole is as same as that of an opening of each channel. A refrigerating state and a heating state are switched only by using a steeping motor for driving the valve spool and the valve body to be in running fit, modes can be switched by means of short-time electrification during running, and the valve can be kept continuing running in the original mode after power is cut off. Besides, the valve spool is hermetically connected with the inner surface of the valve body, so that tightness of the four-way valve is improved, and back flowing is prevented. The shortcomings of complicated structure, difficulty in manufacture, poor reliability and the like of a traditional four-way valve are overcome. The four-way valve has the advantages of simple and reasonable structure, high energy efficiency ratio, high control precision and short staring time, and is convenient for popularization and application.

Owner:MIDEA GRP CO LTD

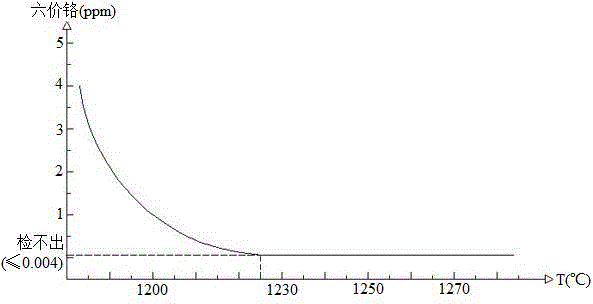

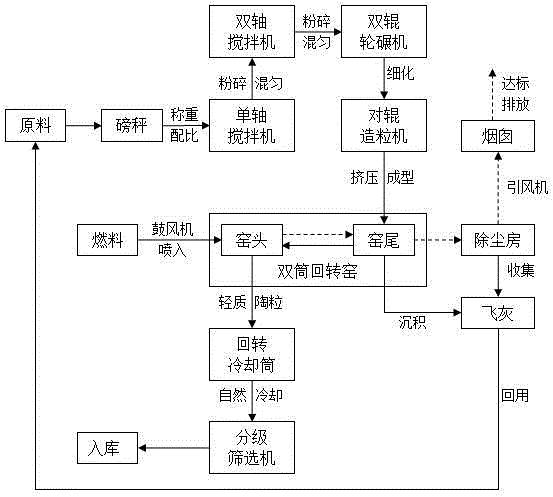

Method for preparing light ceramisite by means of chromium-containing sludge

ActiveCN105347837AEvenly heatedReduce adhesionCeramic materials productionCeramicwareClay soilRotary kiln

The invention relates to a method for preparing light ceramisite by means of chromium-containing sludge. The method comprises the following steps that 1, raw materials are supplied by weight; 2, the chromium-containing sludge is ground to 150-200 meshes in a wet mode, municipal sludge, decomposed rock, sludge and clay or kaolin are ground to 100-150 meshes in a dry mode, anthracite is ground to 100-150 meshes in a drying mode, and ferric oxide or hematite is ground to 100-150 meshes in a dry mode; 3, all the raw materials are mixed evenly; 4, the mixed materials are deep refined and then extruded into raw ceramisite through a granulating machine; 5, the raw ceramisite is preheated and calcined into light ceramisite through a double-barrel rotary kiln, and after discharging and cooling are performed, the finished light ceramisite is obtained. According to the method, the chromium-containing sludge generated through leather production is effectively utilized, toxin removing is thorough, the reliability is achieved, the technology is simple, the sludge consumption is large, heavy metal pollutants can be simultaneously treated, the production cost is low, and the prepared ceramisite can be reused in construction industry.

Owner:ZHANGZHOU WEISHUI SOLID WASTE DISPOSAL CO LTD

Method for preparing light ceramisite by means of electroplating sludge

ActiveCN105347838AReduce crackingReduce stuckCeramic materials productionCeramicwareSludgeKaolin clay

The invention relates to a method for preparing light ceramisite by means of electroplating sludge. The method comprises the following steps that 1, raw materials are supplied by weight; 2, the electroplating sludge is ground to 150-200 meshes in a wet mode, municipal sludge, decomposed rock, sludge and clay or kaolin are ground to 100-150 meshes in a dry mode, anthracite is ground to 100-150 meshes in a drying mode, and ferric oxide or hematite is ground to 100-150 meshes in a dry mode; 3, all the raw materials are mixed evenly; 4, the mixed materials are deep refined and then extruded into raw ceramisite through a granulating machine; 5, the raw ceramisite is preheated and calcined into light ceramisite through a double-barrel rotary kiln, and after discharging and cooling are performed, the finished light ceramisite is obtained. According to the method, the electroplating sludge is effectively utilized, toxin removing is thorough, the reliability is achieved, the technology is simple, the sludge consumption is large, heavy metal pollutants can be simultaneously treated, the production cost is low, and the prepared ceramisite can be reused in construction industry.

Owner:ZHANGZHOU WEISHUI SOLID WASTE DISPOSAL CO LTD

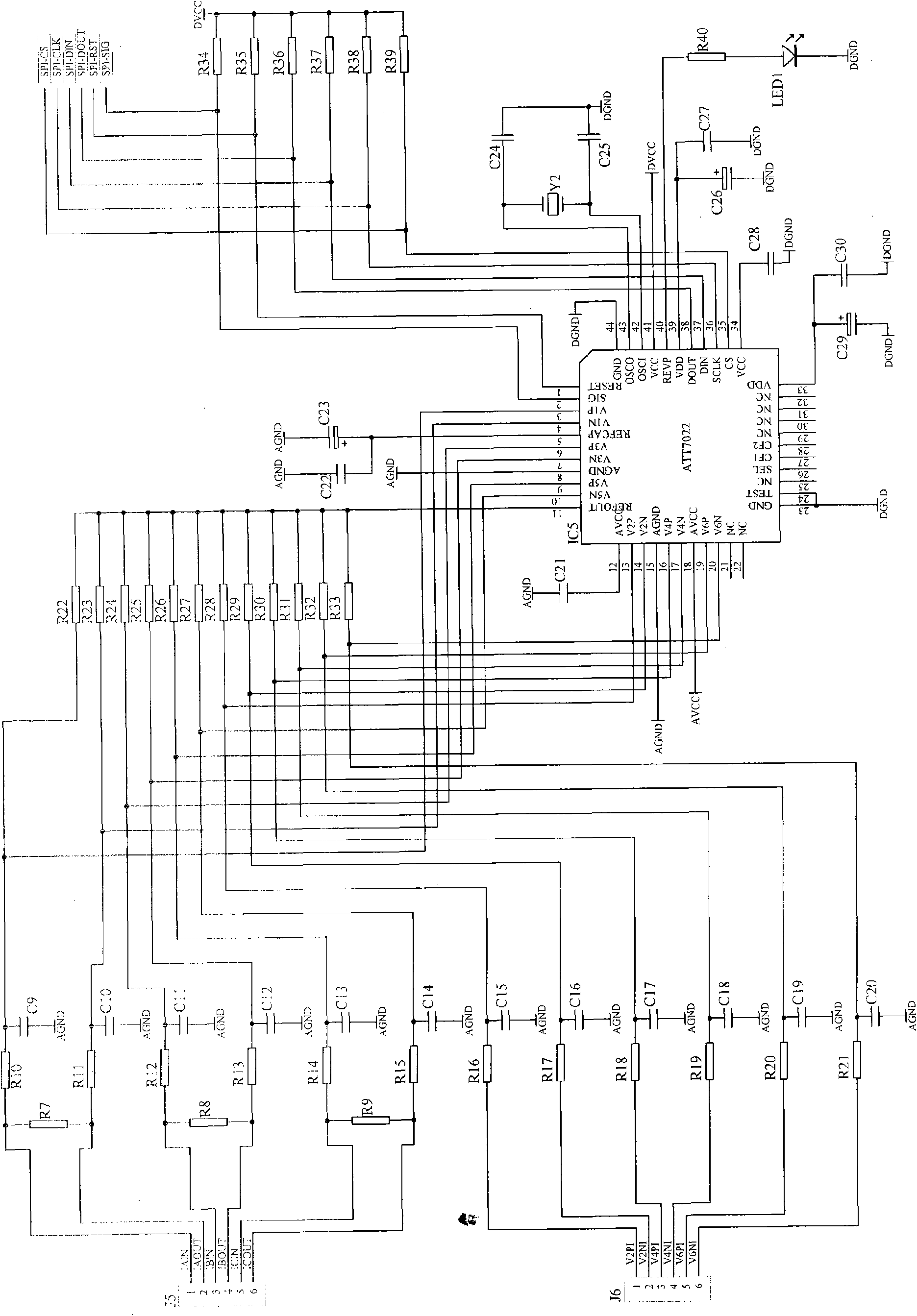

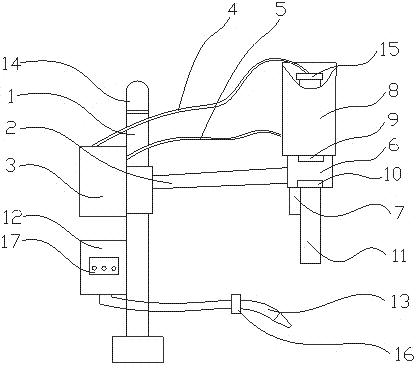

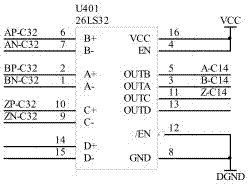

Intelligent monitoring device for screw pump well

InactiveCN101539135AMonitor work dataExtended service lifeFlexible member pumpsElectric controllersClosed loopEngineering

The invention relates to an intelligent monitoring device for a screw pump well, which is a high-performance industrial control device combined with optical, mechanical and electronic integration and electronic information and communication technology, and is mainly used for intelligently monitoring oil extraction of the screw pump well in oil field. The intelligent monitoring device mainly comprises a light current part and a strong current part, and is characterized in that the intelligent monitoring device takes connection of parts such as a sensor capable of measuring dynamic liquid level of the screw pump well on line, a sensor capable of measuring the torque and axial force of the screw pump well on line, a sensor capable of measuring electricity using parameters such as running current constantly and a remote wireless communication device and the like with a CPU as a core to realize the effective measurement and intelligent closed-loop control of the screw pump well. The intelligent monitoring device can avoid pump burning phenomenon of a screw pump caused by evacuation through accurate measurement and effective monitoring and dispatching, scientifically make a hot washing system according to wax deposition cause and the like to avoid phenomena such as rod breakage and the like, find eccentric wear problem in time to prolong pump detection cycle, and optimize design of the screw pump well to reasonably determine working parameters and reduce potential safety hazard and the like.

Owner:王洪亮 +1

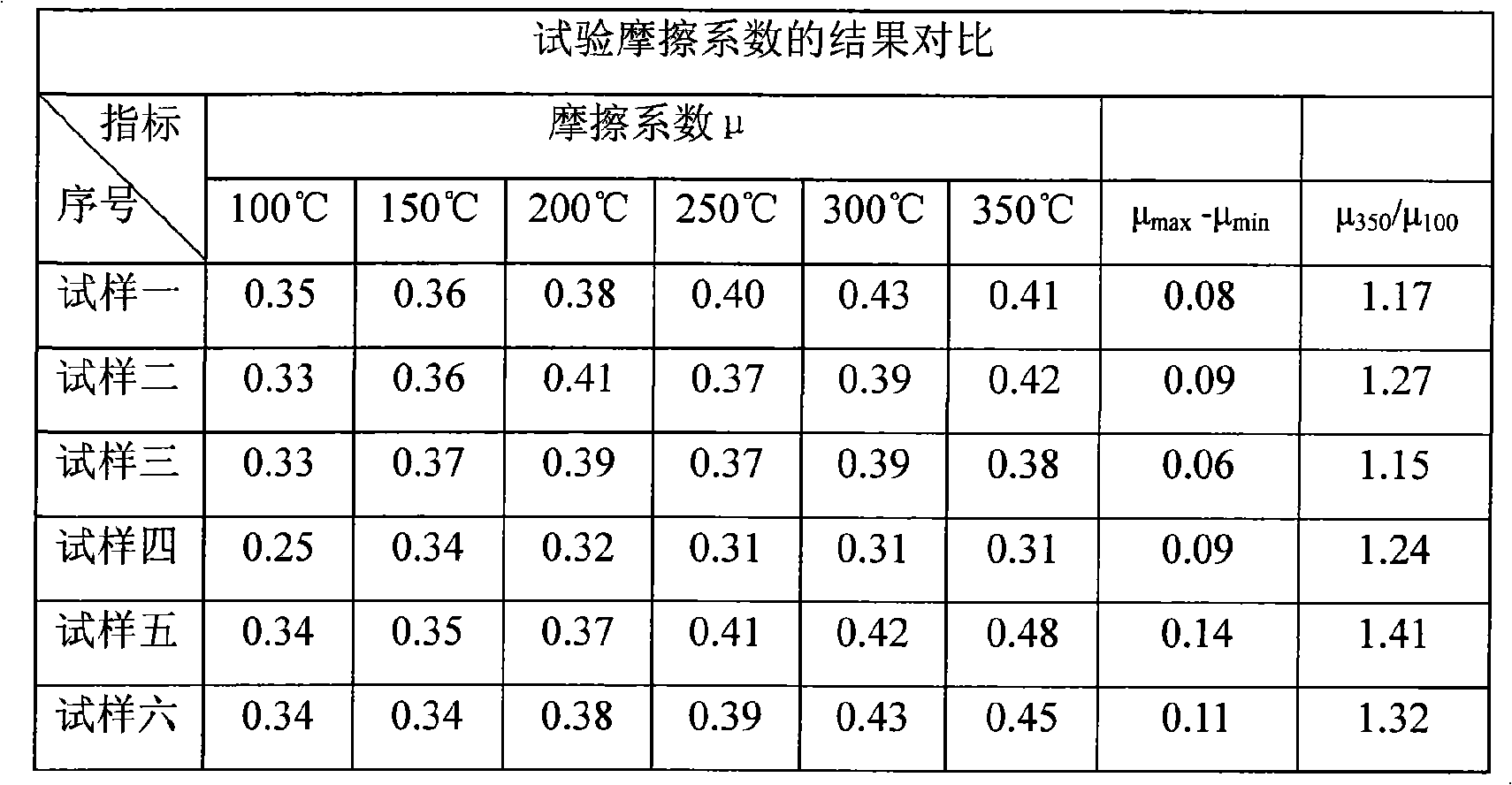

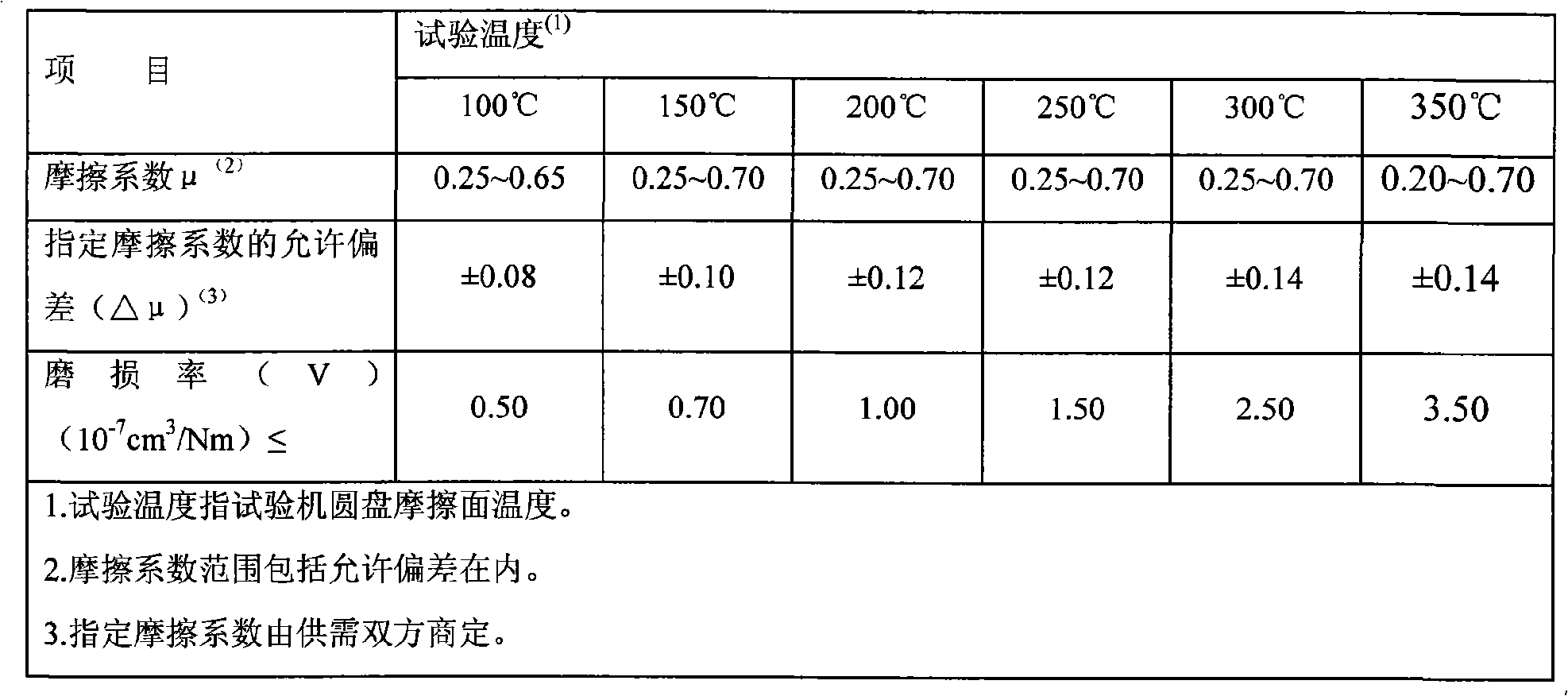

Vehicle braking composite material reinforced by confusion of natural fiber and crystal whisker and preparing method thereof

InactiveCN101514251AStable coefficient of frictionReduce wear rateFriction liningPyrophylliteConfusion

The present invention provides a vehicle braking composite material reinforced by confusion of natural fiber and crystal whisker and preparing method thereof. The raw materials of composite friction material is composed of bamboo fiber, phenolic resin, magnesium sulfate crystal whisker, steel fiber, copper powder, graphite dust, pyrophyllite powder, aluminum oxide, iron oxide, barium sulfate and zinc stearate. The preparing method comprises the following steps: preprocessing the raw materials, mixing the raw materials, hot pressing shaping and heat processing. The invention uses the bamboo fiber with low cost for reinforcing the phenolic resin. The proper amount of wear-increasing agent, anti-wear agent and filling agent for exerting the cooperative coupling function among the substrate, the fiber / crystal whisker and filling agent, thereby obtaining the novel vehicle braking composite material which has the advantages of stable friction coefficient under different temperatures, low wear rate, high heat fading resistance, excellent braking effect, shock absorbing, noise reduction and low cost.

Owner:FUZHOU UNIV

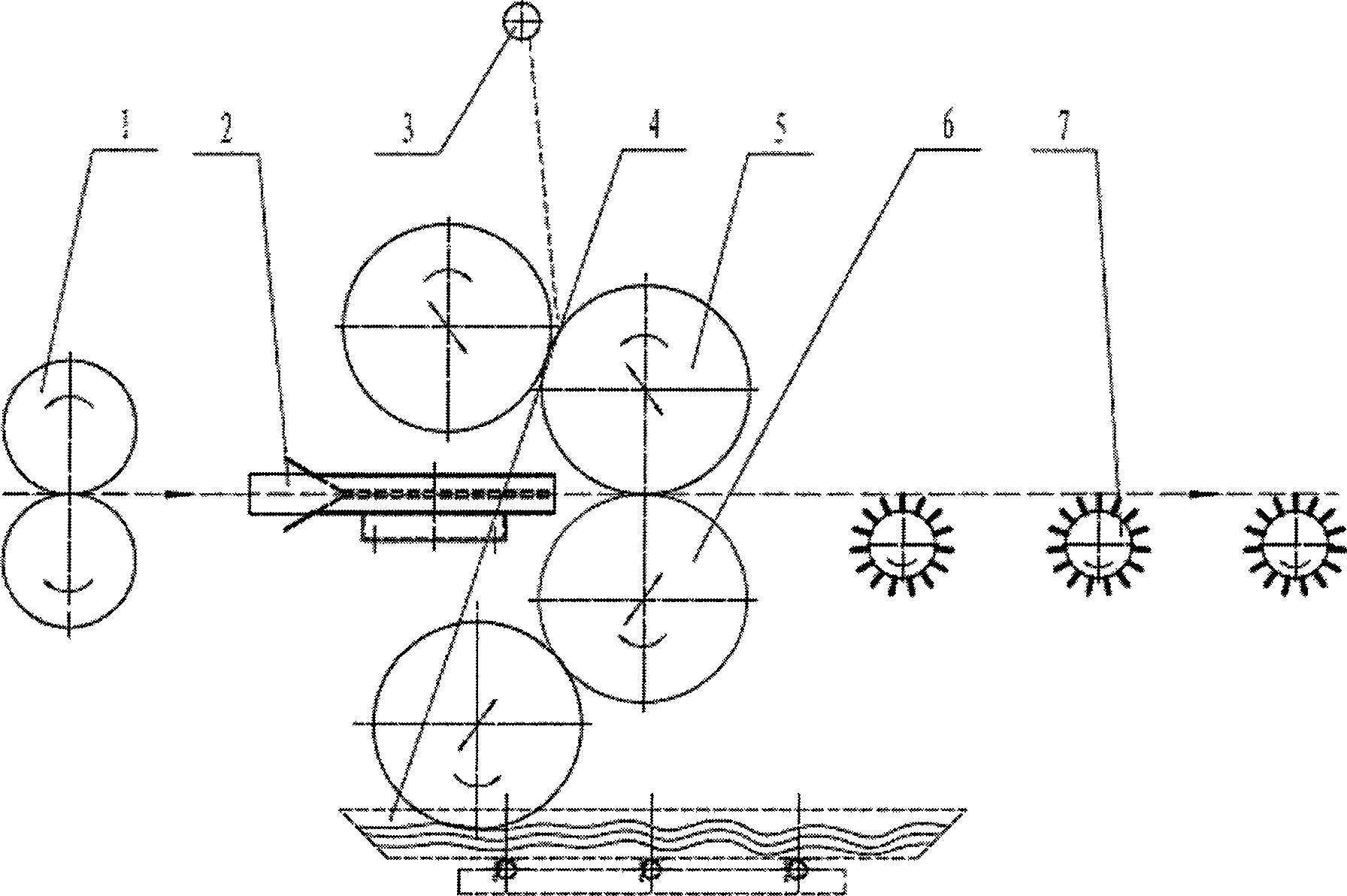

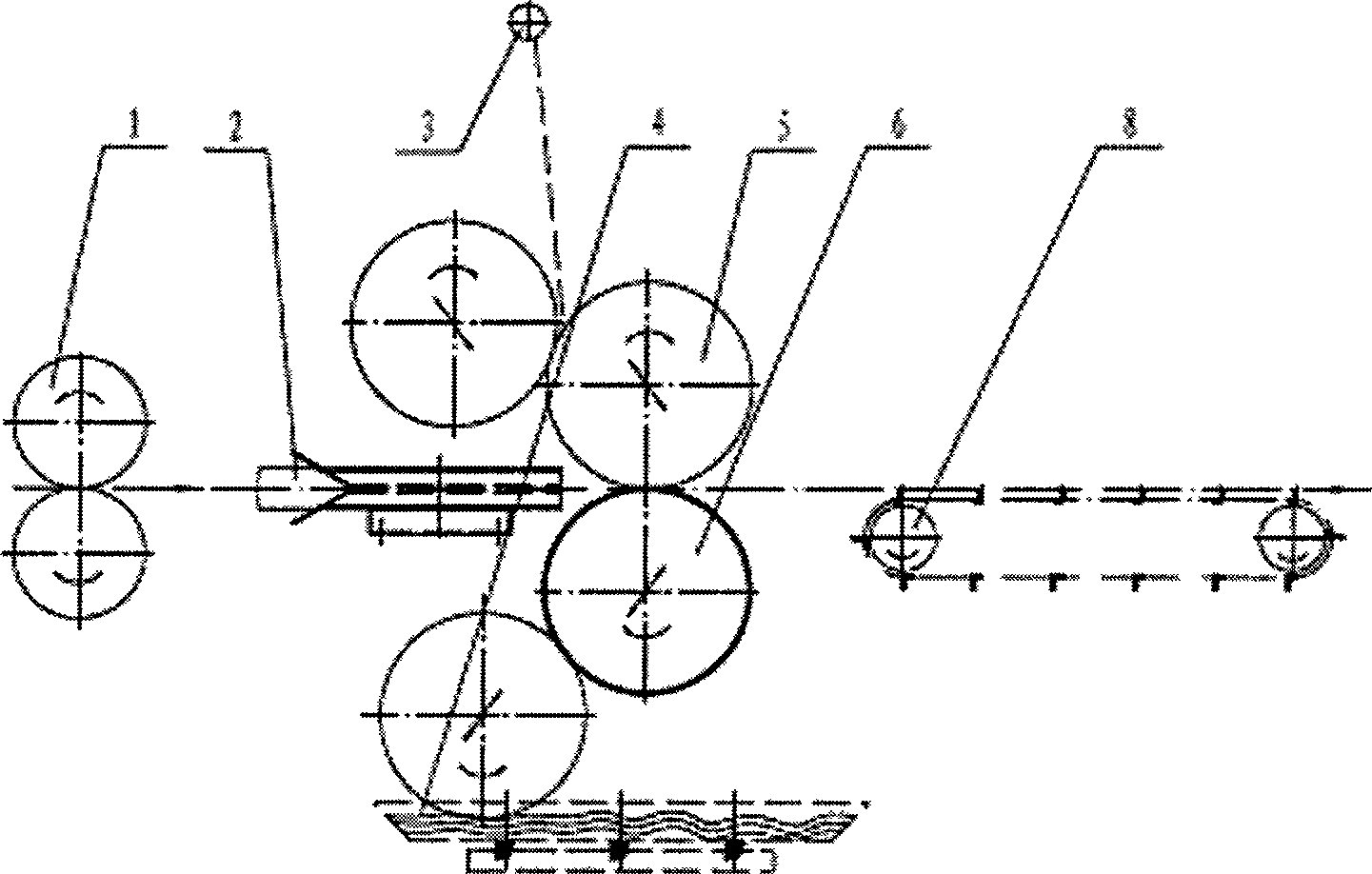

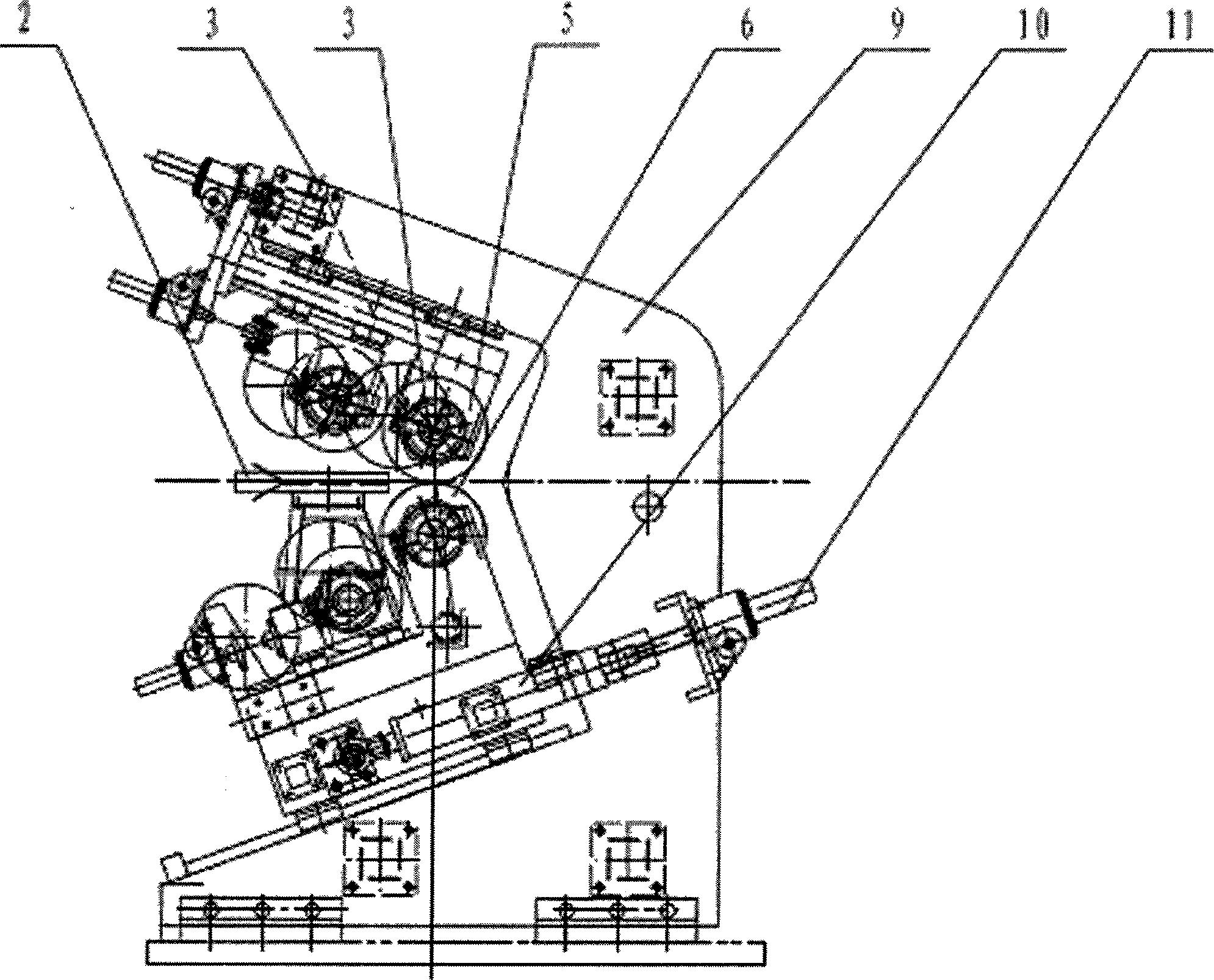

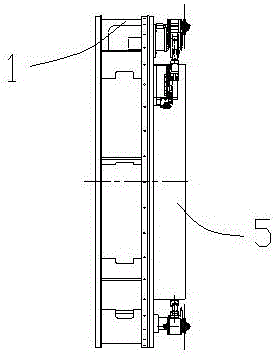

Single sheet type sheet metal roll coating mechanism

InactiveCN101474607AQuality improvementEasy curingLiquid surface applicatorsCoatingsSheet steelLacquer

The invention provides a single metal sheet roller coating mechanism, which is applicable to coating of chemical coatings. The invention is characterized in that the roller coating mechanism consists of a pair of pinch rolls 1, a material guiding section 2, a single-sheet roller coater, a pin-wheel-type conveyer 7 or a chain-type conveyer 8. An electric appliance is used to control synchronization of speed of the adopted pinch rolls 1, the single-sheet roller coater, the pin-wheel-type conveyer 7 or the chain-type conveyer 8, thereby ensuring coating quality. Inlet of the material guiding section 2 is provided with a horn-mouth-type structure, so as to facilitate leading in of steel plates; the material guiding section 2 and the steel plate can contact in a rolling way or a sliding way. The incoming materials can be carried by a lacquer disc or be sprayed by a spray nozzle on a spray tube. Each roller can be adjusted jointly or individually. A lower rolling system 6 can be rapidly adjusted by an oil cylinder. Such a structure mode can realize double-surface coating, thereby reducing material sticking to the maximum. Synchronization of front and rear conveying can ensure coating quality, save time and improve production efficiency.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH

Biostatic coatings for reduction and prevention of bacterial adhesion

InactiveCN1282216AReduce coefficient of frictionNo reduction in antimicrobial propertiesBiocideAntifouling/underwater paintsThiolBacterial Adhesions

The present invention relates to biostatic compositions, as well as coatings and methods for preparing biostatic articles using the same. The compositions contain a hydrophilic polymer possessing a functional group which covalently bonds to an amine, thiol, carboxyl, or hydroxyl active group of an antimicrobial agent. The functional group is capable of reacting with and covalently bonding to an antimicrobial agent without effectively reducing antimicrobial property of the antimicrobial agent below its capability of acting as a biostatic agent and without releasing the antimicrobial agent into a solution.

Owner:海德罗默公司

Automatic locking device for bolt and control method of automatic locking device

PendingCN107538209AImprove work efficiencyImprove locking qualityMetal working apparatusFastening meansConstant speedServo drive

The invention provides an automatic locking device for a bolt and a control method of the automatic locking device. The automatic locking device for the bolt comprises a supporting column, a supporting arm, a servo driver, a motor encoder wire, a motor power wire, a speed reducer, a position sensor, a servo motor, torque sensors, a connector, an anaerobic adhesive storage device and an anaerobic adhesive dropper. The control method comprises the following steps that 1, the servo driver is used for slowly driving the servo motor and the speed reducer to accelerate so that the connector can be driven to normally lock the bolt into a part, and the connector rotates at a constant speed; and 2, when the bolt is close to the locking position, the servo motor starts to decelerate, and the servo motor stops rotating when the torque values fed back by the torque sensors reach a set torque value. According to the automatic locking device for the bolt and the control method of the automatic locking device, the position sensor is arranged to judge whether the bolt is installed in place or not and whether the blot is inclined or not; the anaerobic adhesive dropper is arranged so that manual control over the extrusion amount of the anaerobic adhesive can be avoided; and the working efficiency of the locking of the bolt is improved, and the assembling quality is improved.

Owner:广州市韦德电气机械有限公司

Reinforced anti-adhesion composite gel, preparation method and application

ActiveCN101869727AHigh strengthProlong the degradation time in vivoSurgeryPolyelectrolytePolysaccharide

The invention relates to the field of biological medicinal materials, and discloses a reinforced anti-adhesion composite gel. The reinforced anti-adhesion composite gel comprises the following components in mass / volume ratio: 0.01 to 8 percent of polysaccharide with anionic groups, 0.0000001 to 1 percent of functional polypeptide with positive charge groups, and 0.05 to 5 percent of polysaccharide with cationic groups or cationic polymerized polypeptide or mixture of the two in any ratio. The invention also provides a preparation method for the reinforced anti-adhesion composite gel. The reinforced anti-adhesion composite gel can effectively reduce the occurrence of adhesion by adding the anti-adhesion functional polypeptide with polyelectrolyte interaction and the polysaccharide with cationic groups and / or cationic polymerized polypeptide into materials.

Owner:SUZHOU BOCHUANG TONGKANG PHARM TECH CO LTD

Method for solving tree control node quantity restriction

ActiveCN105468365ABreak outAvoid stickingExecution for user interfacesOperational systemParallel computing

The invention discloses a method for solving tree control node quantity restriction. Node data is asynchronously loaded in batches to improve a tree control node data loading success rate and reduce a series of faults caused by the data loading failure of the tree control node data; the node data of a visible region is dynamically loaded, the node data of an invisible region can be removed, so that consumption on the memory of an operating system, a CPU (Central Processing Unit) and the like by the tree control can be effectively lowered, the resource use ratio of the operating system is improved, and the problem that an interface is stuck and the like since the tree control excessively consumes the resources of the operating system is solved so as to fundamentally break through the node quantity restriction by the tree control.

Owner:XIAMEN YAXON NETWORKS CO LTD

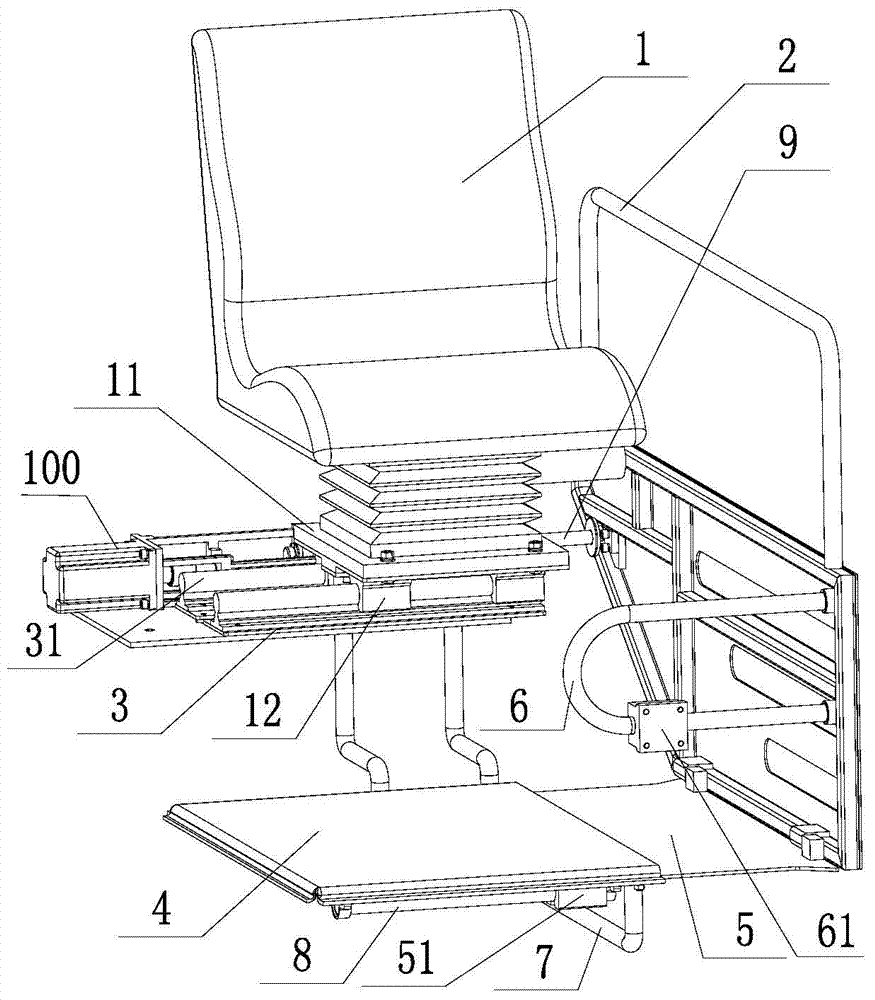

Mobile seat of engineering machinery, and paver

The invention discloses a mobile seat of engineering machinery, and a paver. The mobile seat comprises a seat body (1), a pedal, a side handrail (2) and a seat support table (3), wherein the seat body is arranged on the seat support table in a sliding manner; the pedal comprises a fixed pedal (4) and a movable pedal (5) which stretches from middle part to outward or shrinks inwards; the movable pedal is respectively connected with the side handrail and the seat body to achieve integral movement; the fixed pedal and the seat support table are respectively arranged on a rack of a main machine, wherein the seat body can achieve the integral movement together with the pedal and the side handrail. The integral movement brings about relatively comfortable and humanized feeling to an operator, the waste motion of the operator on the pedal is reduced, and the observation operation and the like can be conveniently complemented by of the operator by the overall seat. The overall seat is arranged on the rack of the main machine through two parts, namely the fixed pedal and the seat support table, so that a relatively large amount of support is brought about to the seat, and the structure is relatively firm and relatively stable, the seat is relatively balanced in stress during sliding, the clamping stagnation is reduced, and the seat is relatively smooth to move.

Owner:ZOOMLION HEAVY IND CO LTD

Plastic pipe following copying double-cutting device

InactiveCN106272621ASolve for ellipticitySolve the problem that the roundness deviation is too large and cannot be cutMetal working apparatusControl systemEngineering

The invention discloses a plastic pipe following copying double-cutting device and aims at solving the problems that in the producing process of a large-caliber plastic pipe, because large deviations of roundness and ovality exist, a single tool can not cut, an end face is coked, the tool is clamped and broken, and cuttings are sucked to a neck mold by a ventilating device to affect inner wall quality. The plastic pipe following copying double-cutting device comprises a cutting machine rotary disc and a hydraulic controlling and module controlling system and is characterized in that a copying saw blade cutting device and a copying blade cutting device are arranged on the cutting machine rotary disc; copying displacement sensing devices are arranged on the copying saw blade cutting device and the copying blade cutting device correspondingly; and when a cutting signal for a pipe product is obtained, the cutting devices cut the pipe in a following copying mode according to actual outer circle outline signals detected by the copying displacement sensing devices. The plastic pipe following copying double-cutting device achieves equal-thickness cutting in any state, avoids cutting accumulation at the neck mold, and achieves a multifunctional cutting mode.

Owner:ZHEJIANG SHUANGLIN PLASTIC MACHINERY

Whisker reinforced resin-base composite friction material and its prepn process

The present invention relates to whisker reinforced resin-base composite friction material and its preparation process. The whisker reinforced resin-base composite friction material is prepared with calcium carbonate whisker in 5-30 weight portions and polyether ether ketone in 70-95 weight portions; and the preparation process includes the following steps: drying calcium carbonate whisker and polyether ether ketone at 130-150 deg.c for 3-5 hr, mixing through high speed stirring in a stirrer for 8-10 min, melting the mixture in a hot die at 380-390 deg.c, pressurizing at 20 MPa to form, maintaining for 8-10 min, cooling inside the die to 100 deg.c, demolding, cooling to room temperature, and maintaining at 250 deg.c of 1 hr to obtain the product. The calcium carbonate whisker reinforced polyether ether ketone composite friction material has low friction coefficient, low wear rate, high bearing capacity, low cost and other advantages.

Owner:FUZHOU UNIVERSITY

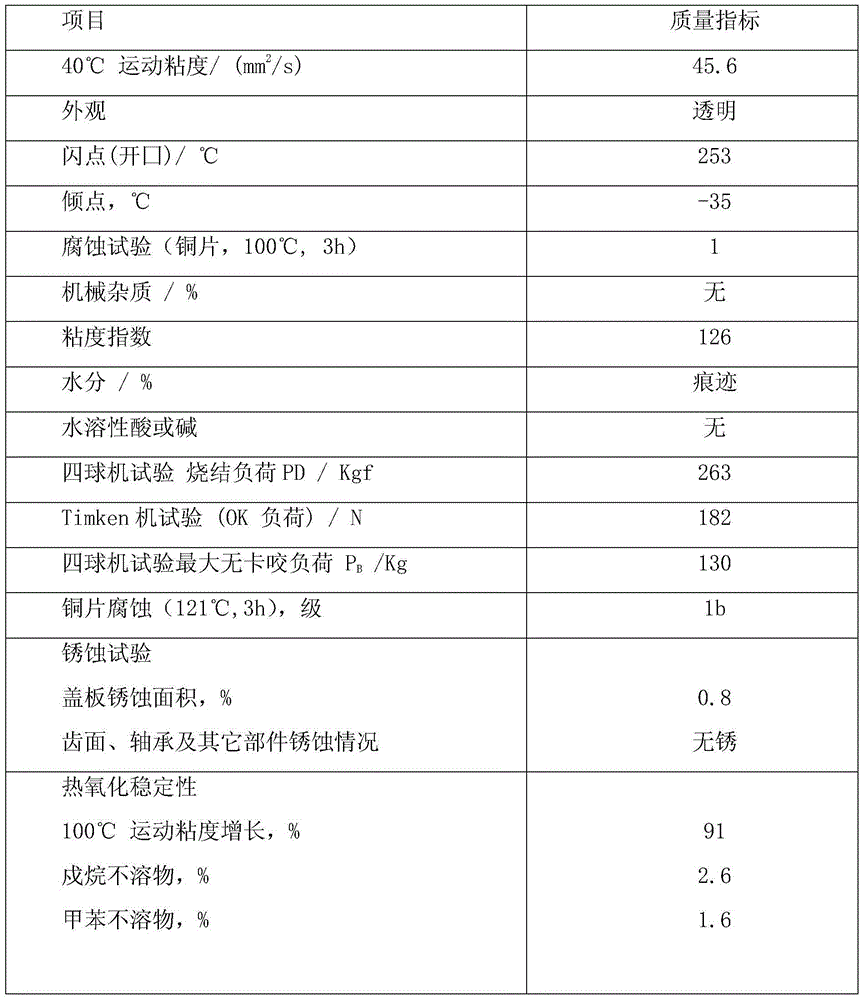

Lubricant composition used in electric mechanical transmission device

InactiveCN104450071AMeet lubricitySatisfy coolingLubricant compositionAntioxidantOxidation resistant

The invention discloses a lubricant composition used in an electric mechanical transmission device. The lubricant composition is prepared from a complex of trimellitate and poly-alpha-olefin serving as base oil as well as a plurality of composite additives comprising a rust inhibitor, an antioxidant, an oiliness agent, an anti-wear agent, a metal deactivator, a friction modifier, an anti-foaming agent, an oxidation-resistant and corrosion-resistant agent, a detergent and a dispersing agent. The lubricant composition disclosed by the invention has excellent detergency and dispersibility, cooling property, lubricating property, sealing property, friction property, rust-inhibiting property, corrosion resistance and extreme pressure anti-wear property; by the lubricant composition, a layer of uniform and continuous oil film having a certain thickness is easily formed in a movement friction pair, the coefficient of friction in the movement is decreased, the carrying capacity is increased and the phenomenon of adhesion of transmission members and vibration and noise are reduced.

Owner:GUANGXI UNIV

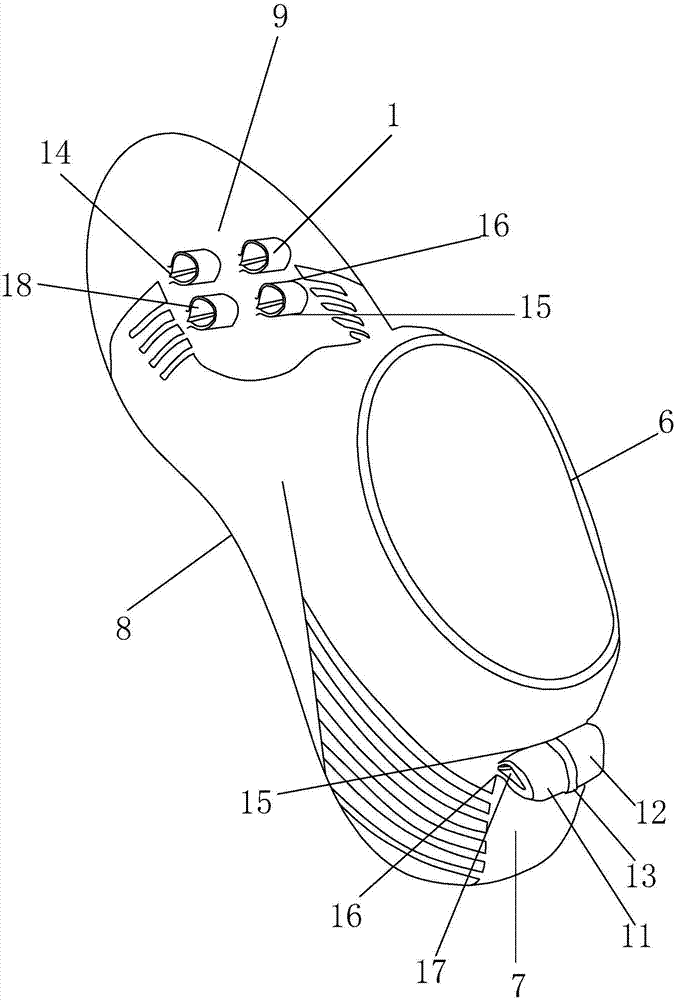

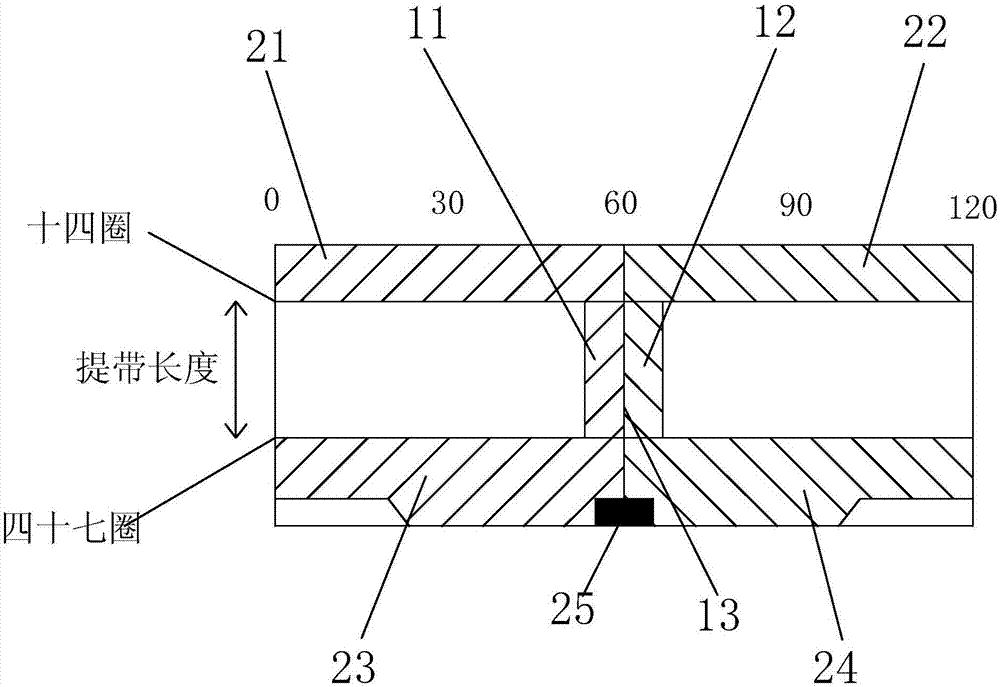

Knitted integrated shoe with knitted tapes and knitting technology of shoe

ActiveCN107348601AReduce stuckReduced processing performanceTextile/flexible product manufactureUpperHeel strikeEngineering

The invention discloses a knitted integrated shoe with knitted tapes. The knitted integrated shoe comprises a shoe body knitted integrally through a hosiery machine. The shoe body is provided with a tube body with an opening, and the shoe body comprises a rib top part, a heelpiece part, a vamp part and a shoe sole part. The knitted integrated shoe is characterized by comprising the knitted tapes, wherein the knitted tapes and the shoe body are integrally knitted and formed. The direction where the shoe body corresponds to the toe position and the direction where the shoe body corresponds to the heel position correspond to the forward direction and the backward direction respectively; the direction where the shoe body corresponds to the rib top part and the direction where the shoe body corresponds to the heel position correspond to the upward direction and the downward direction respectively; the initial knitting end of each knitted tape is set as the first end, the knitting finishing end is the second end, and the first end and the second end of each knitted tape are arranged in the forward and backward directions or in the upward and downward directions; a tape lifting hole is formed by each knitted tape and the shoe body, and a knitting seam between the first end and the second end is formed by the shoe body and the corresponding knitted tape. The knitted lifting tapes and the vamp are well bonded, the firmness is good, and the production efficiency is high. The invention further provides a knitting technology of the knitted integrated shoe with the knitted tapes. The making efficiency of the knitted tapes is improved.

Owner:SINCETECH FUJIAN TECH CO LTD

Whisker composite material for reinforcing automobile brake friction and a method for producing the same

The invention provides a whisker composite material for reinforcing automobile brake friction and a method for producing the same, wherein the composite friction material consists of basic magneislum whisker, pyrophyllite power, phenol resin, copper powder, graphite powder, aluminium oxide and zine stearate, as raw materials; the producing method comprises raw material pretreatment, raw material mixing, hot press molding and cooling. The invention achieves the phenol resin reinforcement by the basic magneislum whisker [MgSO4.5MgO.8H2O] with excellent low cost, selects the pyrophyllite [Al4Si8O20OH4] as the filler for the assorted fiber brake friction material, the concerted coupling function of a substrate, the whister and the filler can be exerted according to the addition of a friction reinforcing agent, and an antiwear agent, thereby the novel automobile brake composite material has advantages of good heat resistance, moderate coefficient of friction, small wear rate, well heat fade resistance, good brake effect and low cost.

Owner:FUZHOU UNIV

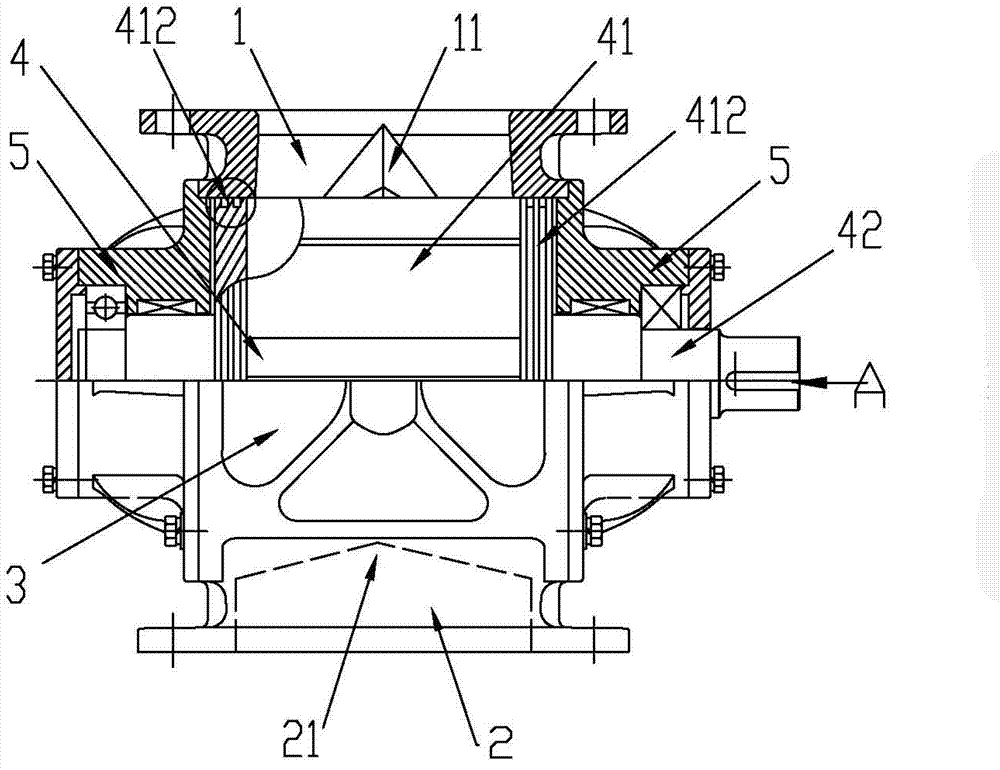

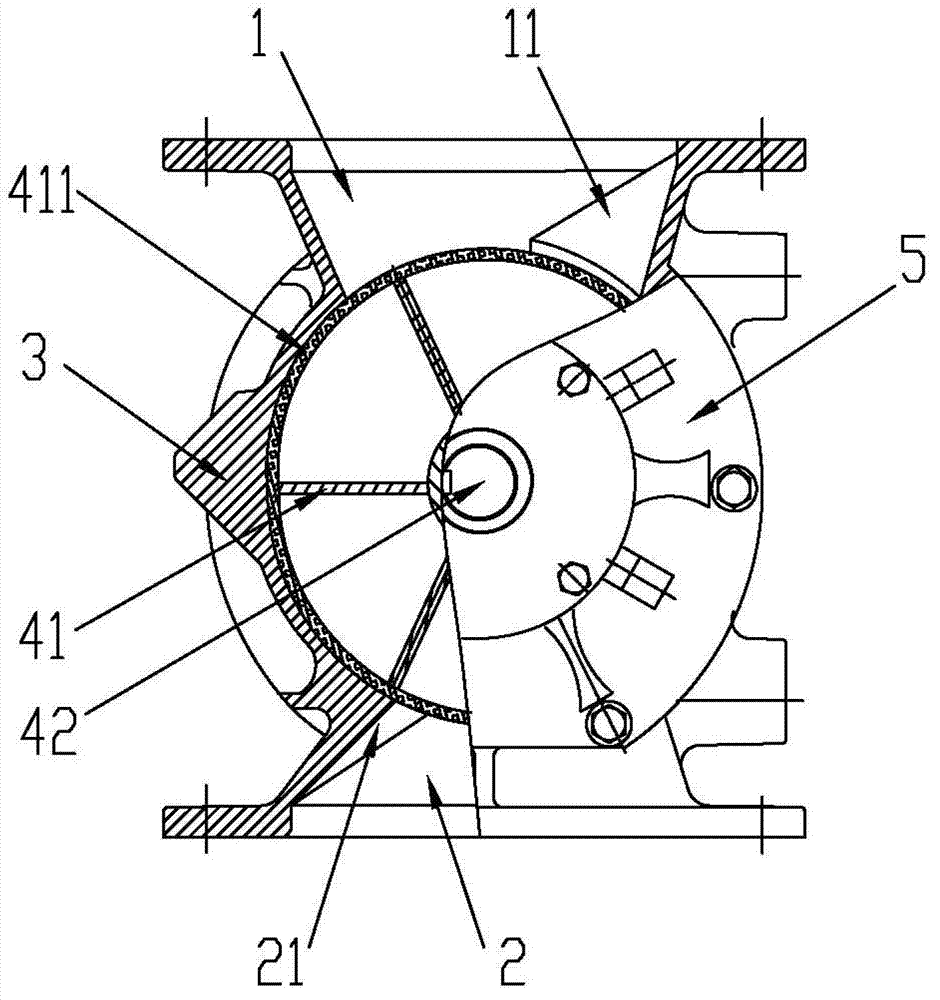

Emulsifying machine

The invention relates to an emulsifying machine which comprises a motor, a connecting body, a cavity, a discharge outlet and a feed inlet, wherein the cavity is internally provided with a fixed gear and a moving gear driven by a spindle of the motor, and the fixed gear and the moving gear are mutually engaged; 2-6 rows of annularly distributed rectangular teeth are arranged on the end faces of the moving gear and the fixed gear, and the gap between each row of adjacent rectangular teeth is 30-50mm; the rectangular teeth of the moving gear and the rectangular teeth of the fixed gear are just inserted into the gaps of the adjacent rows of teeth of each other, and the fixed gear and the moving gear are coaxial; and the cavity is internally provided with 2-5 sets of fixed gears and moving gears which are mutually engaged. The emulsifying machine has good emulsifying effect, smooth surfaces of generated carriers and adhesion phenomenon reduction.

Owner:张再明

Electroconductive rubber composition

ActiveCN100999607ANo sticky feelingAdhesion susceptibilityCarbon-silicon compound conductorsPolymer scienceGraphite

The aim of the invention is to provide a silastic composition which has excellent processability and excellent conductivity. The conductive silastic composition is characterized in that the composition is obtained by mixing organopolysiloxzane base polymer, solidifying agent and black pigment, as black carbon, the BET specific surface area is 50-200m<2> / g, DBP oil absorption volume is 120-280ml / 100g, and the graphite interlaminar distance representing the graphitizing degree is 0.346-0.349.

Owner:SHIN ETSU CHEM IND CO LTD

Catalyst carrier for olefin polymerization, catalyst for olefin polymerization and preparation methods and application of catalyst carrier and catalyst

The invention relates to the field of olefin polymerization, and discloses a catalyst carrier for olefin polymerization, a catalyst for olefin polymerization and preparation methods and application of the catalyst carrier and the catalyst. The preparation method of the catalyst carrier for olefin polymerization comprises the steps that (1) magnesium halide shown in the general formula MgXY, an alcohol compound shown in the general formula R1OH and an optional inert liquid medium are in contact to form emulsion; and (2) the emulsion obtained in the step (1) and an ethylene oxide compound shown in the general formula (I) are subject to contact reacting according to the flow ratio being (1.5-6):1. By means of the method, the catalyst carrier which is used for olefin polymerization and is better in feature, high in yield and low in production cost can be obtained under the condition that a surface active agent is not needed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Plastic blend friction material and preparation method thereof

The invention discloses a plastic blend friction material which is prepared from the following raw materials in parts by weight: 37-40 parts of melamine, 50-60 parts of 37-40% formalin, 4-6 parts of bentonite, 0.7-1 part of copper 8-hydroxyquinoline, 0.1-0.2 part of nonyl phenol, 10-16 parts of liquid ethylene propylene diene monomer rubber, 0.2-0.4 part of sp80, 3-4 parts of epoxy octyl stearate, 140-170 parts of polyvinyl chloride, 6-8 parts of ethyl orthosilicate, 0.2-0.3 part of triethanolamine, 0.3-0.5 part of alkylphenol polyoxyethylene, 2-3 parts of dialkyl pentasulfide RC2540, 1-2 parts of potassium hexatitanate whisker, 0.3-1 part of titanate coupling agent kt105, 0.1-0.2 part of lithium naphthenate, 0.6-1 part of butyl tin mercaptide, 1-2 parts of ammonium polyphosphate, 1-2 parts of citric acid and 0.01-0.02 part of 1,3,5-trimethylbenzene. The plastic blend friction material has the advantages of high temperature friction resistance, favorable comprehensive properties and high stability.

Owner:来安县隆华摩擦材料有限公司

Wear-resistant rotary feeder with labyrinth seal structures on rotor end surface

The invention discloses a wear-resistant rotary feeder with labyrinth seal structures on a rotor end surface. The wear-resistant rotary feeder comprises a feed port, a discharge port, a housing and a rotor transversely arranged inside the housing, wherein end covers are arranged at both ends of the housing; the end covers are fixed on both sides of the housing through bolts; a wear-resistant coating is coated on the surface of the inner wall of the housing; the rotor comprises an impeller and a rotating shaft; the rotating shaft is arranged at the central part of the impeller; a wear-resistant layer is arranged at the contact excircle part of the impeller and material in a surfacing manner; the labyrinth seal structures are arranged at both ends of the impeller; and a wear-resistant layer is also arranged at the contact excircle part of each labyrinth seal structure and the material in a surfacing manner. The wear-resistant rotary feeder solves the problems that the rotor end surface is poor in sealing, the rotor end surface is serious in inverted ventilation, the wear resistance is poor, the service life is short and the material is easy to shear when an ordinary rotary feeder is used under wear working condition. The wear-resistant rotary feeder has the advantages of being good in blocking prevention, resistant to wear abrasion, resistant to medium pressure, and the like.

Owner:SHANDONG ZHANGQIU BLOWER

Morinda citrifolia-based oral care compositions and methods

InactiveCN1859852AReduce inflammationHigh densityCosmetic preparationsToilet preparationsDental plaque induced gingivitisMedicine

Methods and formulations that utilize components of the Indian Mulberry plant, scientifically known as Morinda citrifolia L., to treat one or more oral and dental disorders, including periodontal diseases such as gingivitis and periodontitis, tooth decay, halitosis, and other mouth disorders and irritations.

Owner:MORINDA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com