Whisker composite material for reinforcing automobile brake friction and a method for producing the same

A technology for composite friction materials and automobile brakes, applied in the field of materials, can solve the problems of unreported basic magnesium sulfate whiskers, etc., and achieve the effects of abundant raw materials, low wear rate, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

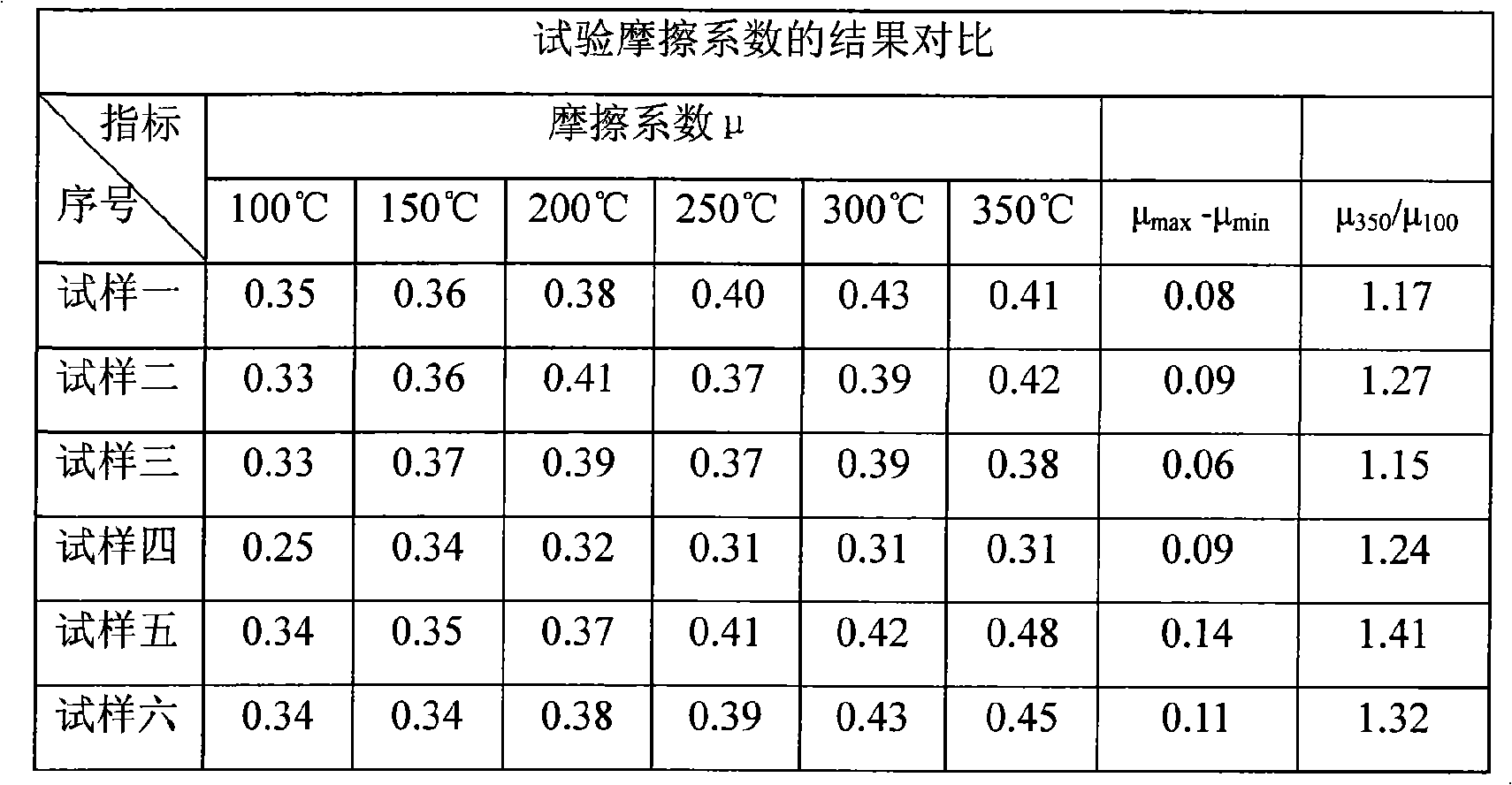

Examples

Embodiment 1

[0026] Embodiment 1 (preferred embodiment)

[0027] Take the following composition ratio: 40 parts of basic magnesium sulfate whiskers, 8 parts of pyrophyllite powder, 20 parts of phenolic resin, 12 parts of copper powder, 5 parts of graphite powder, 12 parts of aluminum oxide, and 2 parts of zinc stearate. Prepare the friction material according to the following process steps:

[0028] (a) Raw material pretreatment. Place the basic magnesium sulfate whiskers in an oven and dry at 100°C for 1 hour, and place other raw materials in an oven and dry at 80°C for 1 hour.

[0029](b) Take the dried filler, metal powder, phenolic resin and other raw materials in step (a) and put them into a mixer equipped with blades and horizontal ribs, stir and mix at a high speed of not less than 1000rpm for 3 minutes, and then add alkaline The magnesium sulfate whiskers were stirred for 3 minutes. The mixed material after stirring is cashmere-like, and the filler and resin powder are evenly di...

Embodiment 2

[0032] Embodiment 2 (preferred embodiment)

[0033] Take the following composition ratio: 35 parts of basic magnesium sulfate whiskers, 8 parts of pyrophyllite powder, 20 parts of phenolic resin, 12 parts of copper powder, 5 parts of graphite powder, 12 parts of aluminum oxide, and 2 parts of zinc stearate. Prepare the friction material according to the following process steps:

[0034] (a) Raw material pretreatment. Place the basic magnesium sulfate whiskers in an oven and dry at 80°C for 2 hours, and place other raw materials in an oven and dry at 80°C for 1 hour.

[0035] (b) Take the dried filler, metal powder, phenolic resin and other raw materials in step (a) and put them into a mixer equipped with blades and horizontal ribs, stir and mix at a high speed of not less than 1000rpm for 3 minutes, and then add alkaline The magnesium sulfate whiskers were stirred for 3 minutes. The mixed material after stirring is cashmere-like, and the filler and resin powder are evenly d...

Embodiment 3

[0038] Embodiment 3 (preferred embodiment)

[0039] Take the following composition ratio: 30 parts of basic magnesium sulfate whiskers, 15 parts of pyrophyllite powder, 18 parts of phenolic resin, 12 parts of copper powder, 10 parts of graphite powder, 12 parts of aluminum oxide, and 2 parts of zinc stearate. Prepare the friction material according to the following process steps:

[0040] (a) Raw material pretreatment. Place the basic magnesium sulfate whiskers in an oven and dry at 90°C for 1.5 hours, and place other raw materials in an oven and dry at 80°C for 1 hour.

[0041] (b) Take the dried filler, metal powder, phenolic resin and other raw materials in step (a) and put them into a mixer equipped with blades and horizontal ribs, stir and mix at a high speed of not less than 1000rpm for 3 minutes, and then add alkaline The magnesium sulfate whiskers were stirred for 3 minutes. The mixed material after stirring is cashmere-like, and the filler and resin powder are even...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com