Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Moderate coefficient of friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

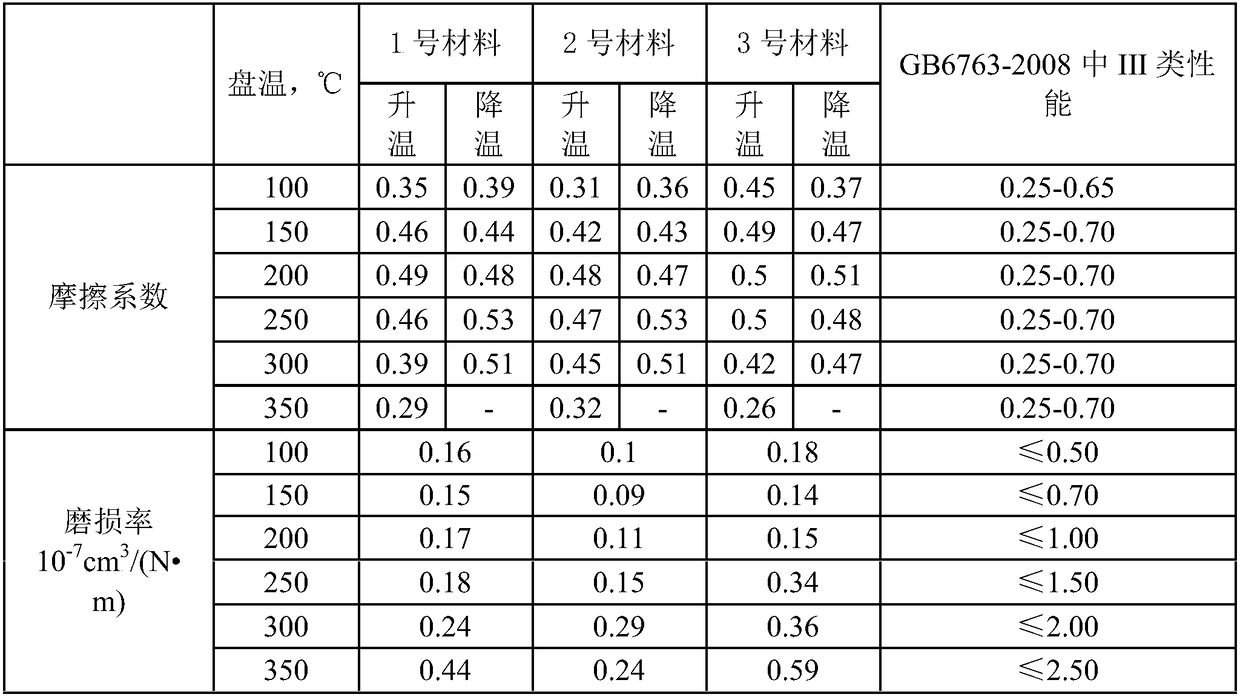

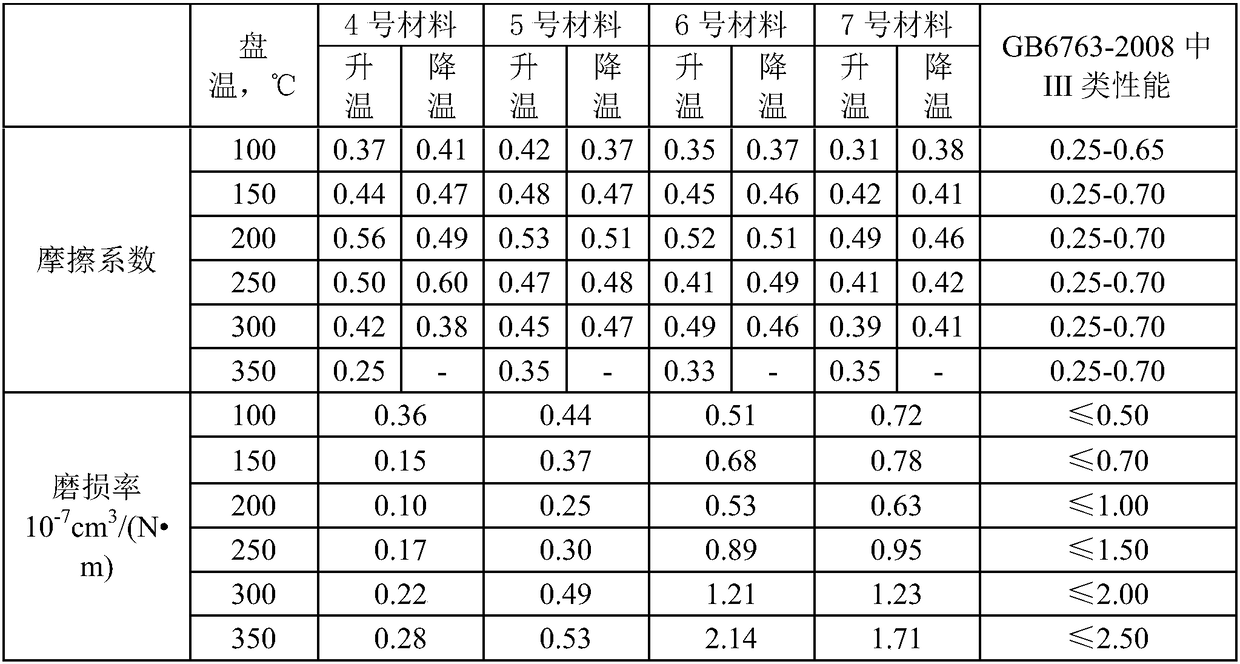

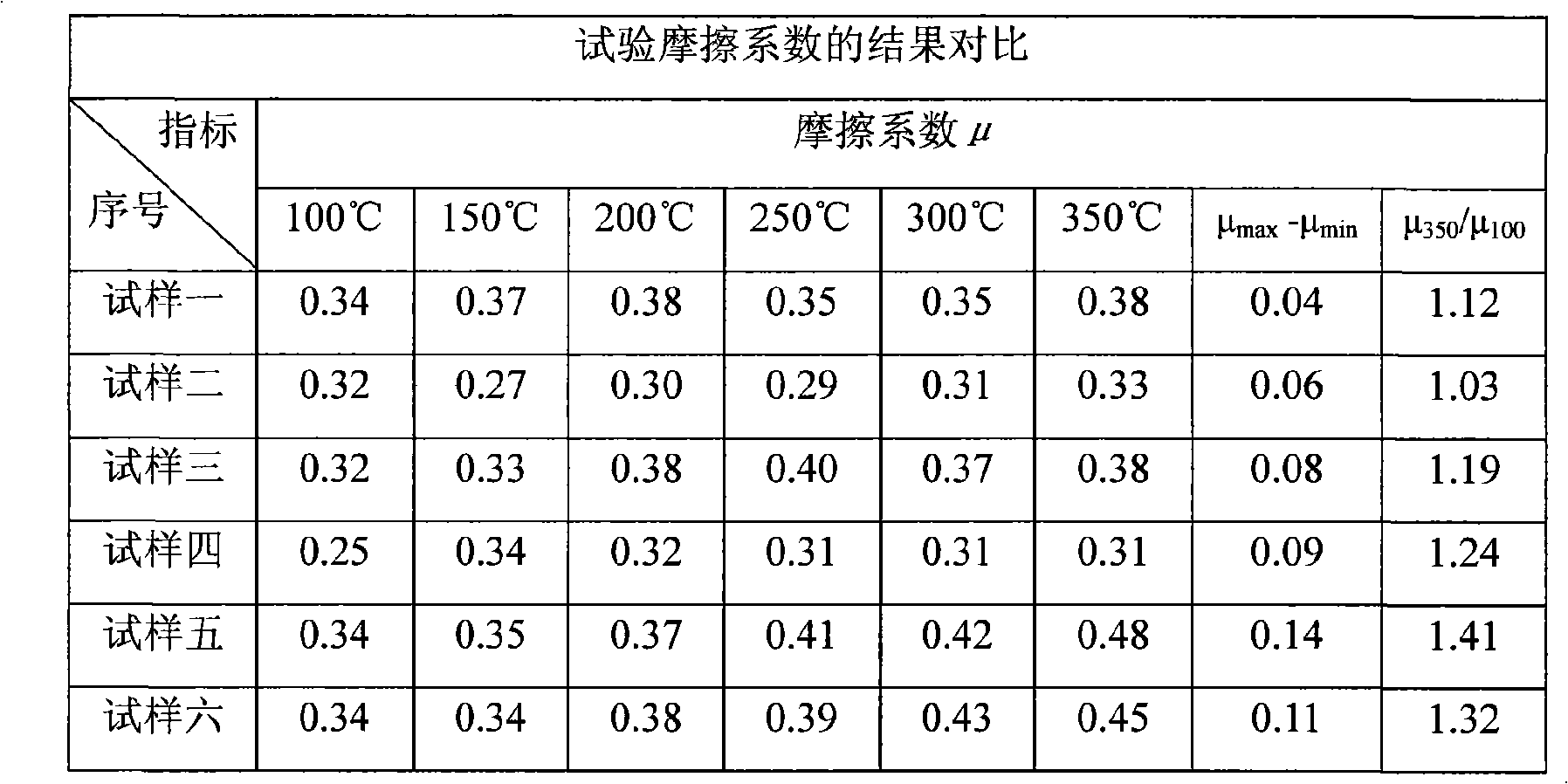

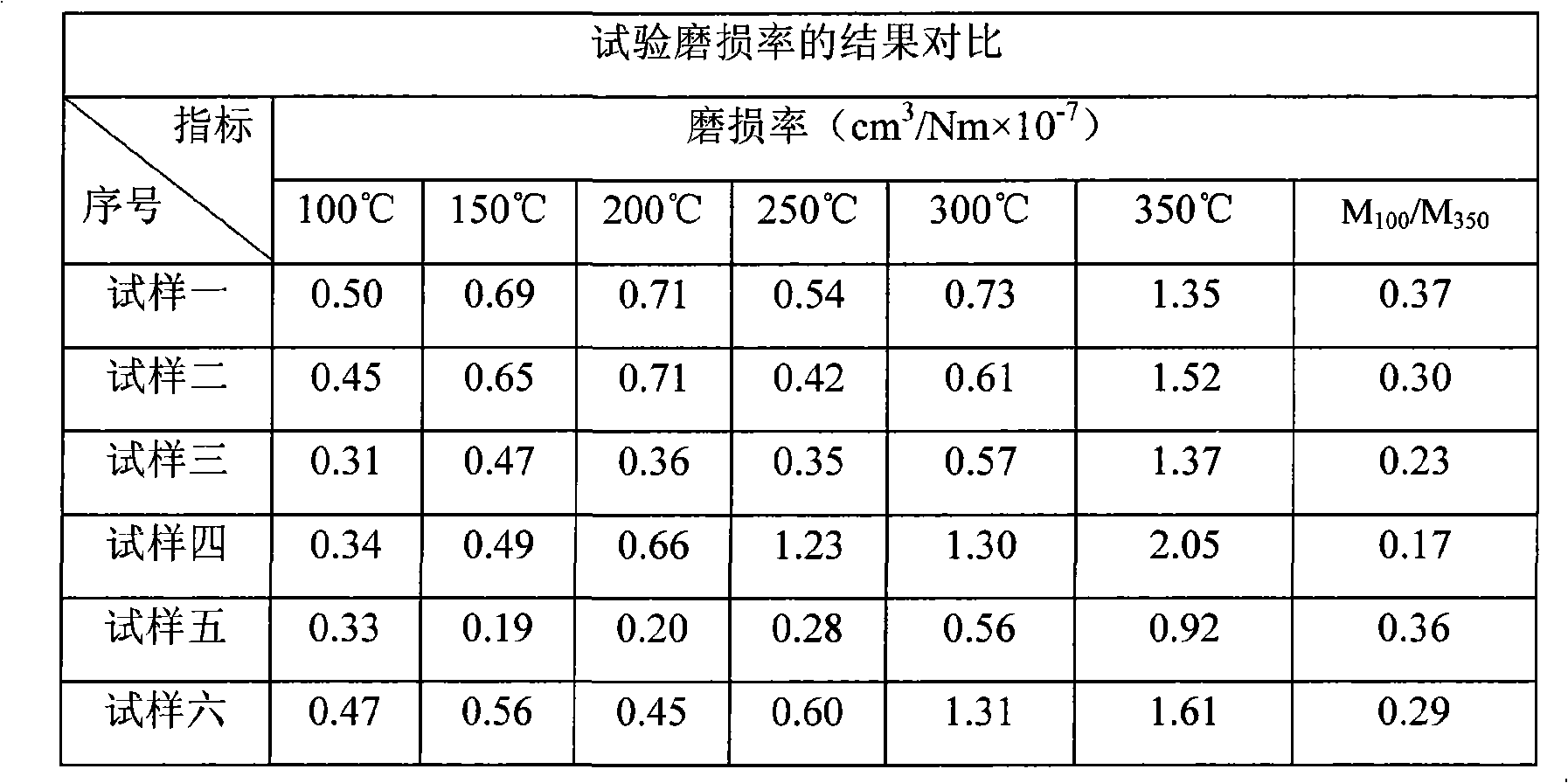

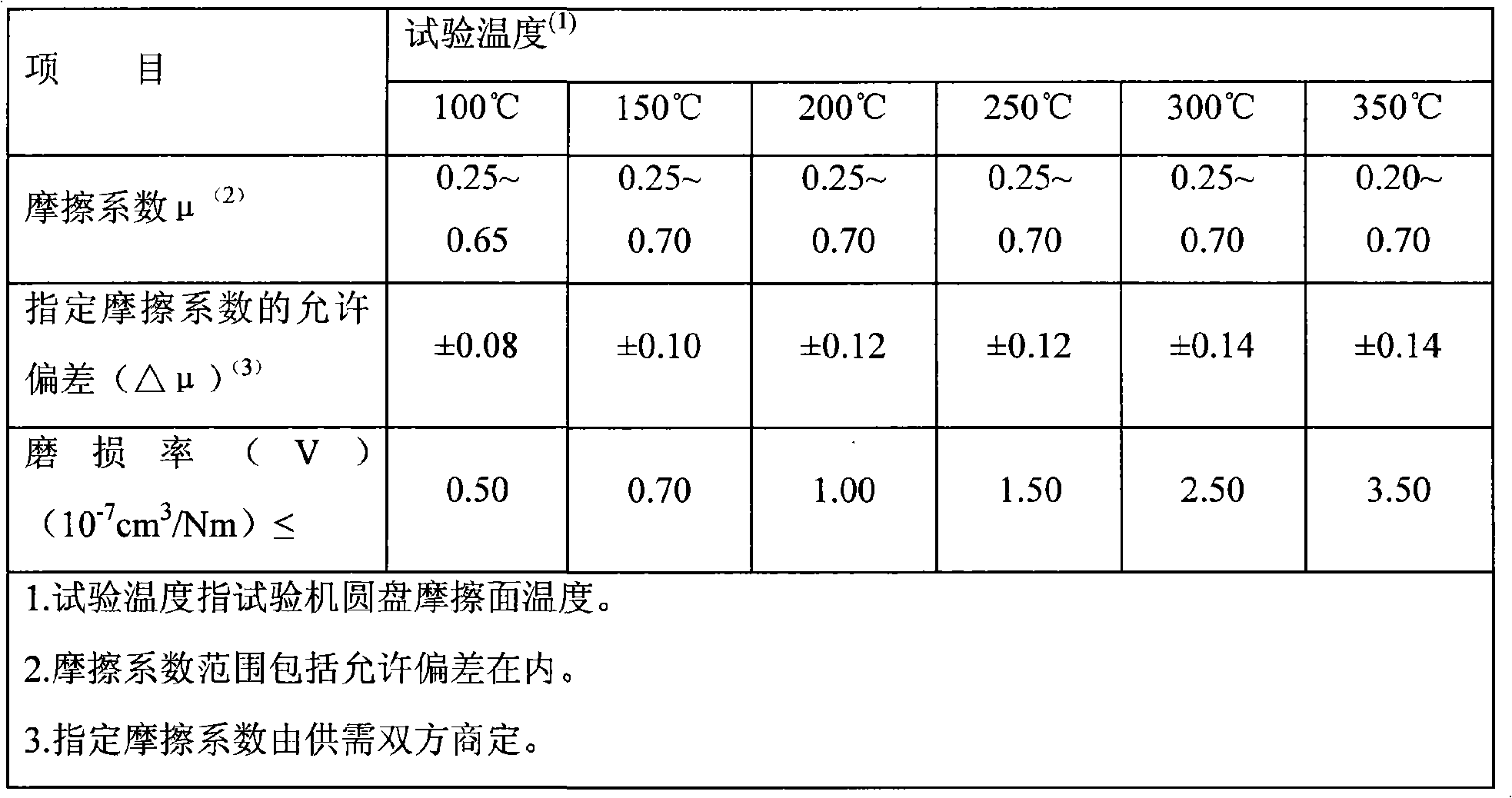

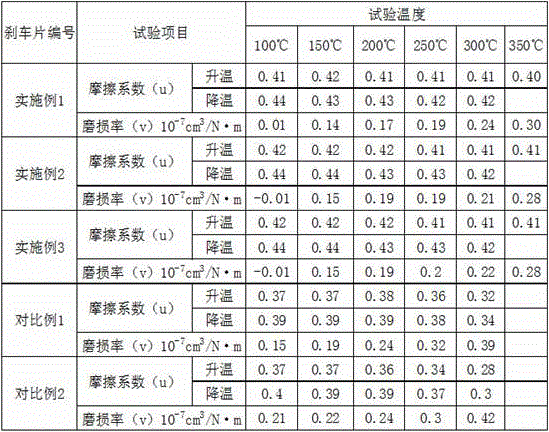

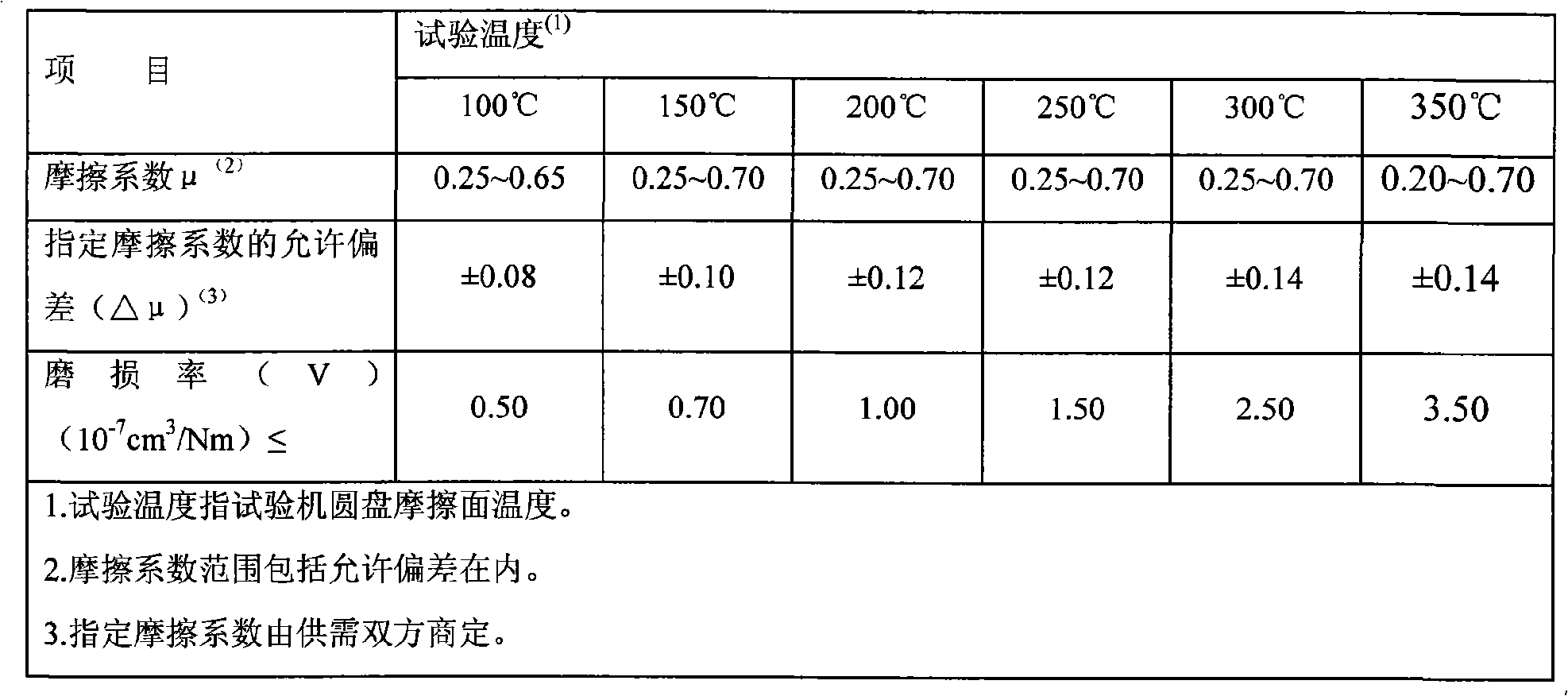

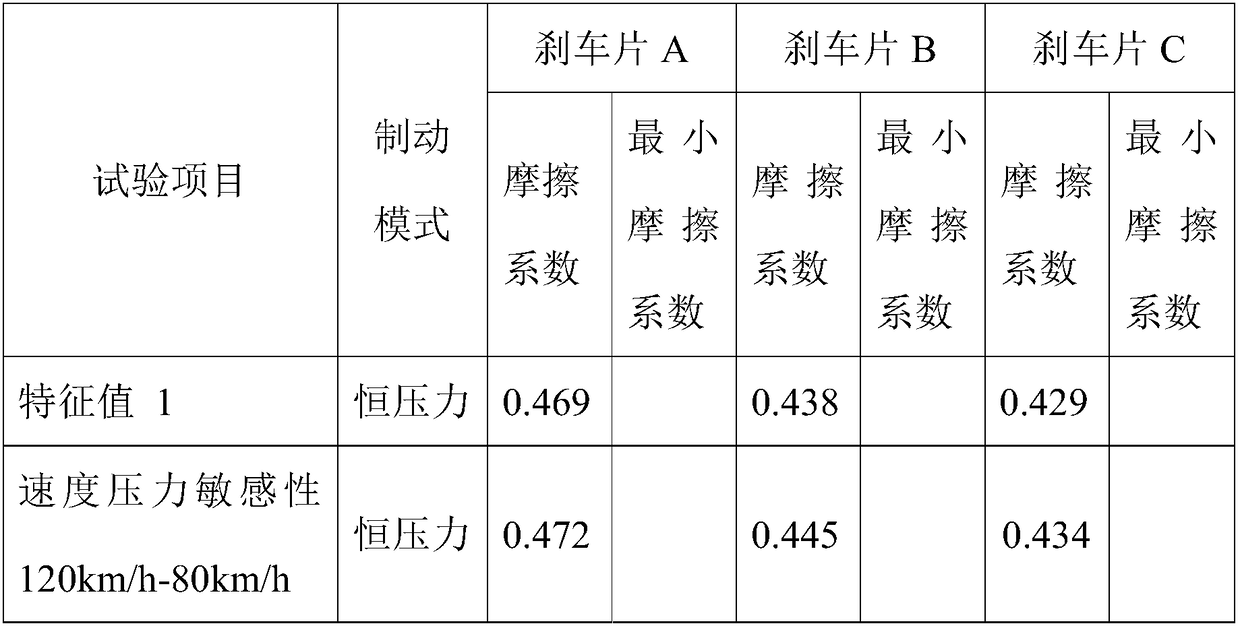

Ceramic-based friction material and method for preparing same

ActiveCN101831273AGood friction performanceModerate coefficient of frictionOther chemical processesFriction liningFrictional coefficientHot press

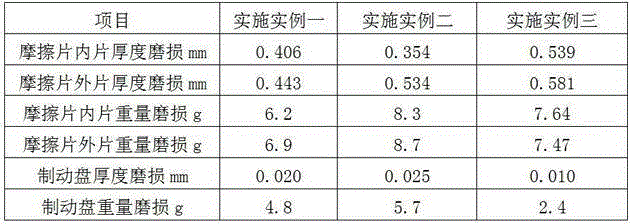

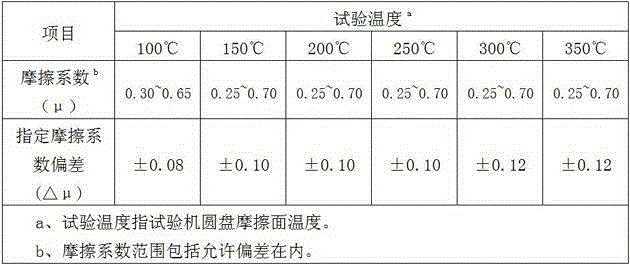

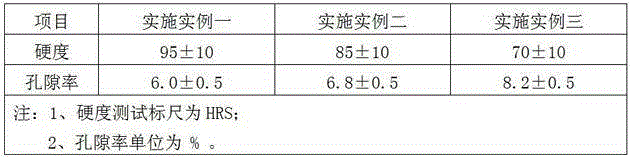

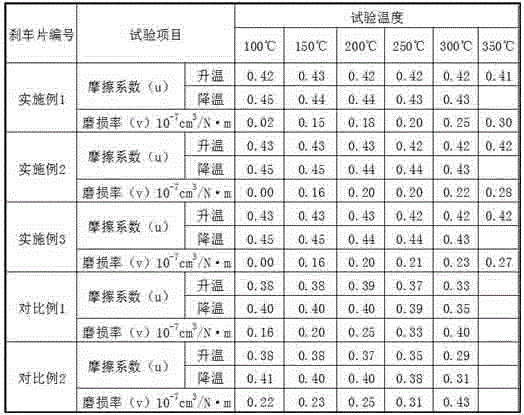

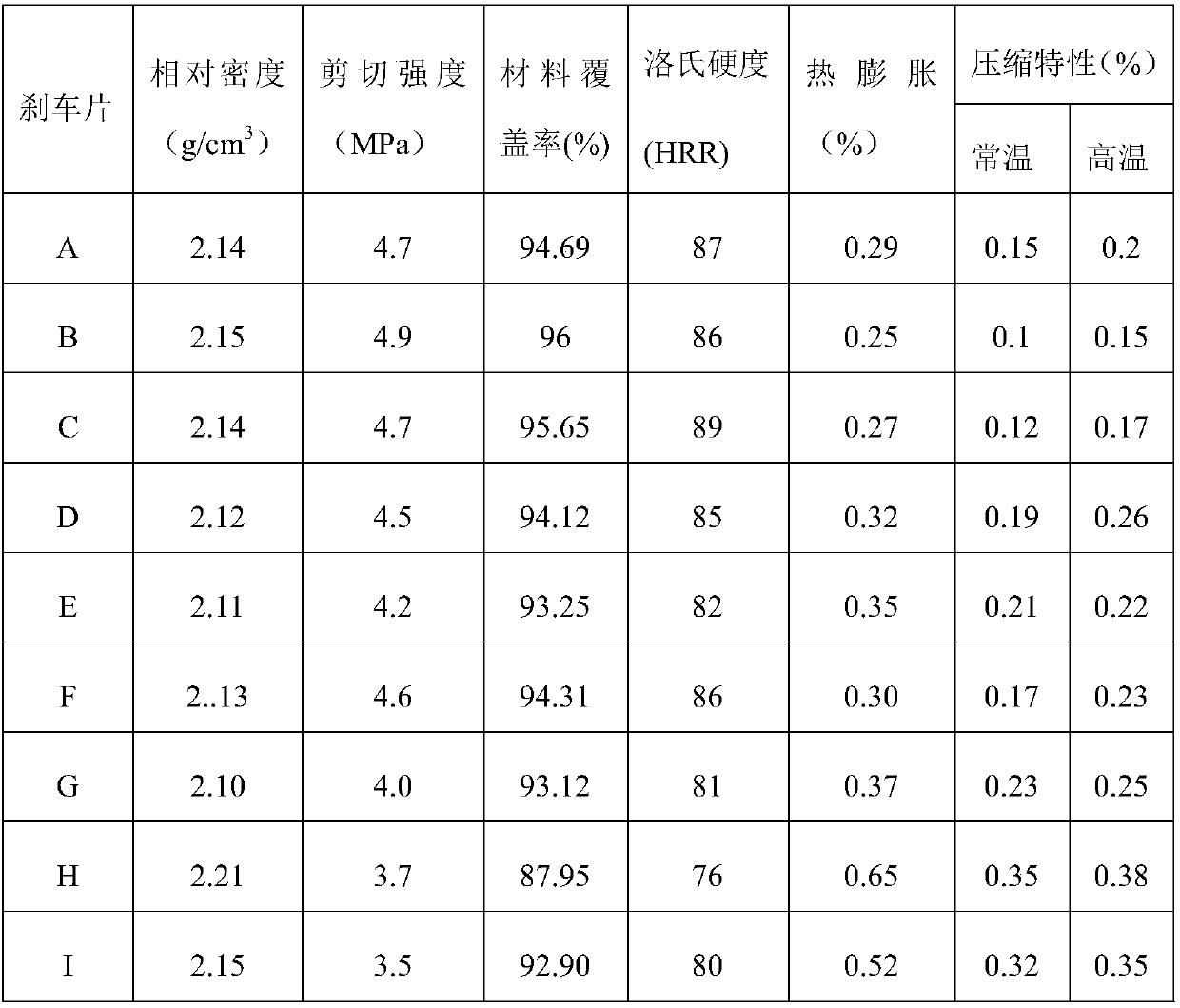

The invention discloses a ceramic-based friction material and a method for preparing the same. The ceramic-based friction material consists of the following raw materials in part by weight: 6 to 8 parts of thermal plasticity phenolic resin or modifier thereof, 7 to 8 parts of potassium titanate whisker, 5 to 6 parts of attapulgite clay, 3 to 4 parts of expanded vermiculite, 4 to 5 parts of butyronitrile rubber powder, 4 to 5 parts of chromite powder, 12 to 13 parts of ceramic fiber, 3 to 4 parts of powdered coke, 14 to 15 parts of barium sulfate, 5 to 6 parts of artificial graphite, 9 to 10 parts of scale graphite, 7 to 8 parts of organic rubbing powder, 3 to 4 parts of sericite, 0.5 to 1 part of aluminum oxide, 3 to 4 parts of copper fiber, 3 to 4 parts of coloring agent and 0.5 to 1 part of organic fiber. The preparation method comprises the following steps of: material blending, cold press moulding, hot press moulding, polishing and curing treatment. The ceramic-based friction material has the advantages of high and stable frictional property, suitable frictional coefficient, low wear rate, low hardness, no damage to friction coupling materials, low braking noise, and extremelylow environmental pollution; and in use, the ceramic-based friction material has the advantages of smooth braking, gentleness, comfortability, safety and reliability.

Owner:YUTIAN COUNTY JUNDA AUTOMOBILE PARTS MFG CO LTD

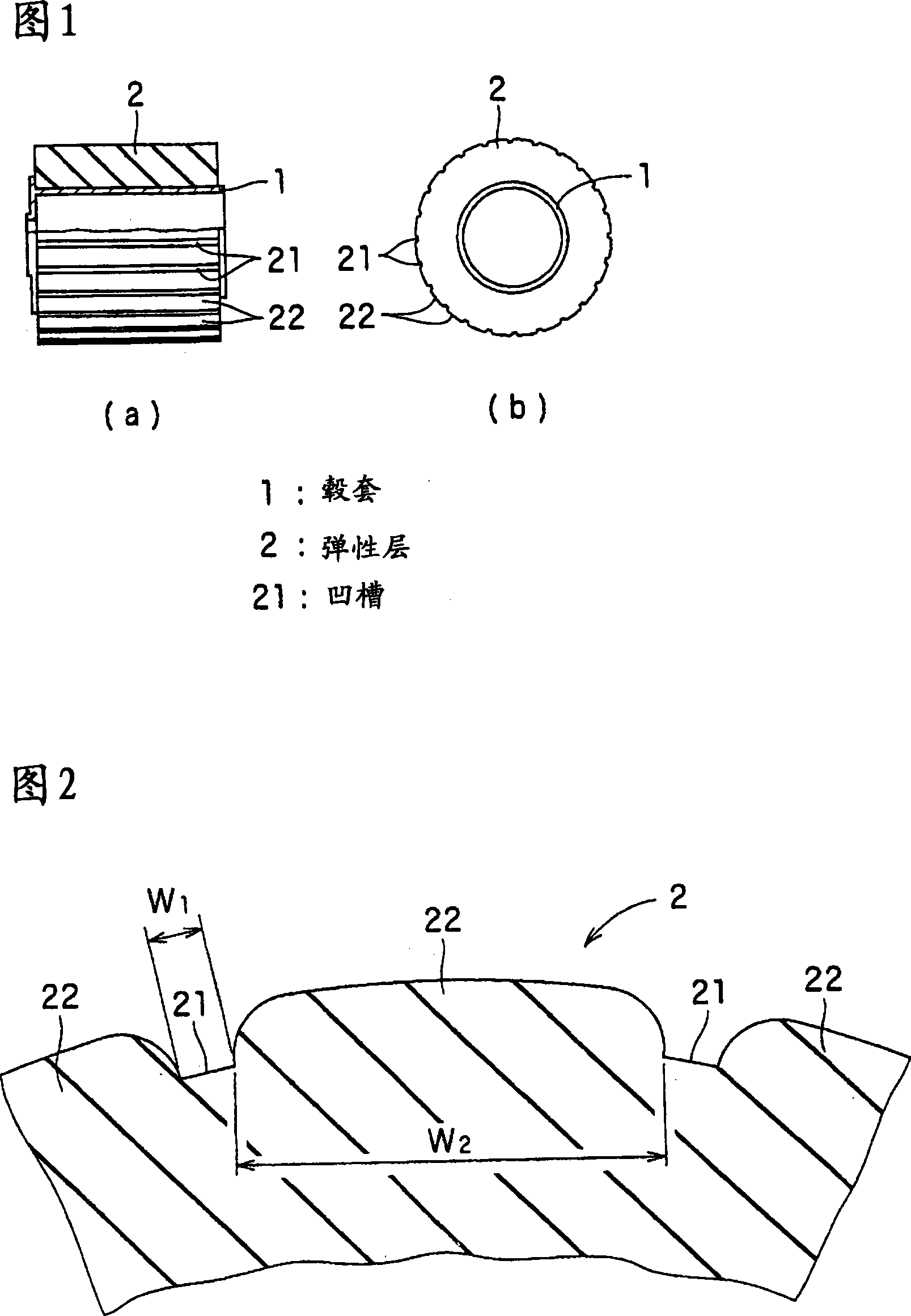

Member for office machines

InactiveUS6273415B1Process stabilityIncrease coefficient of frictionOther printing apparatusArticle feedersPaper sheetEngineering

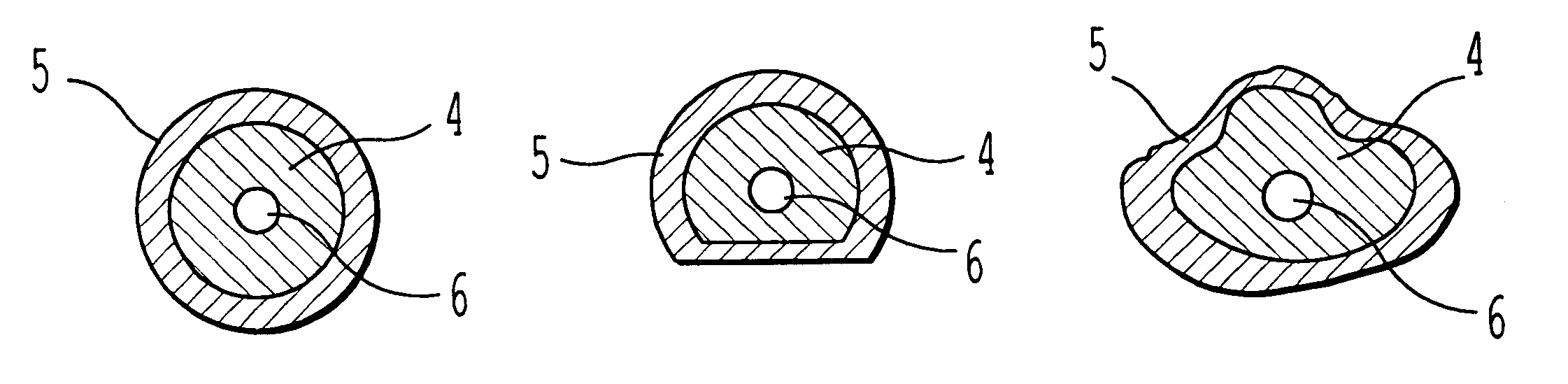

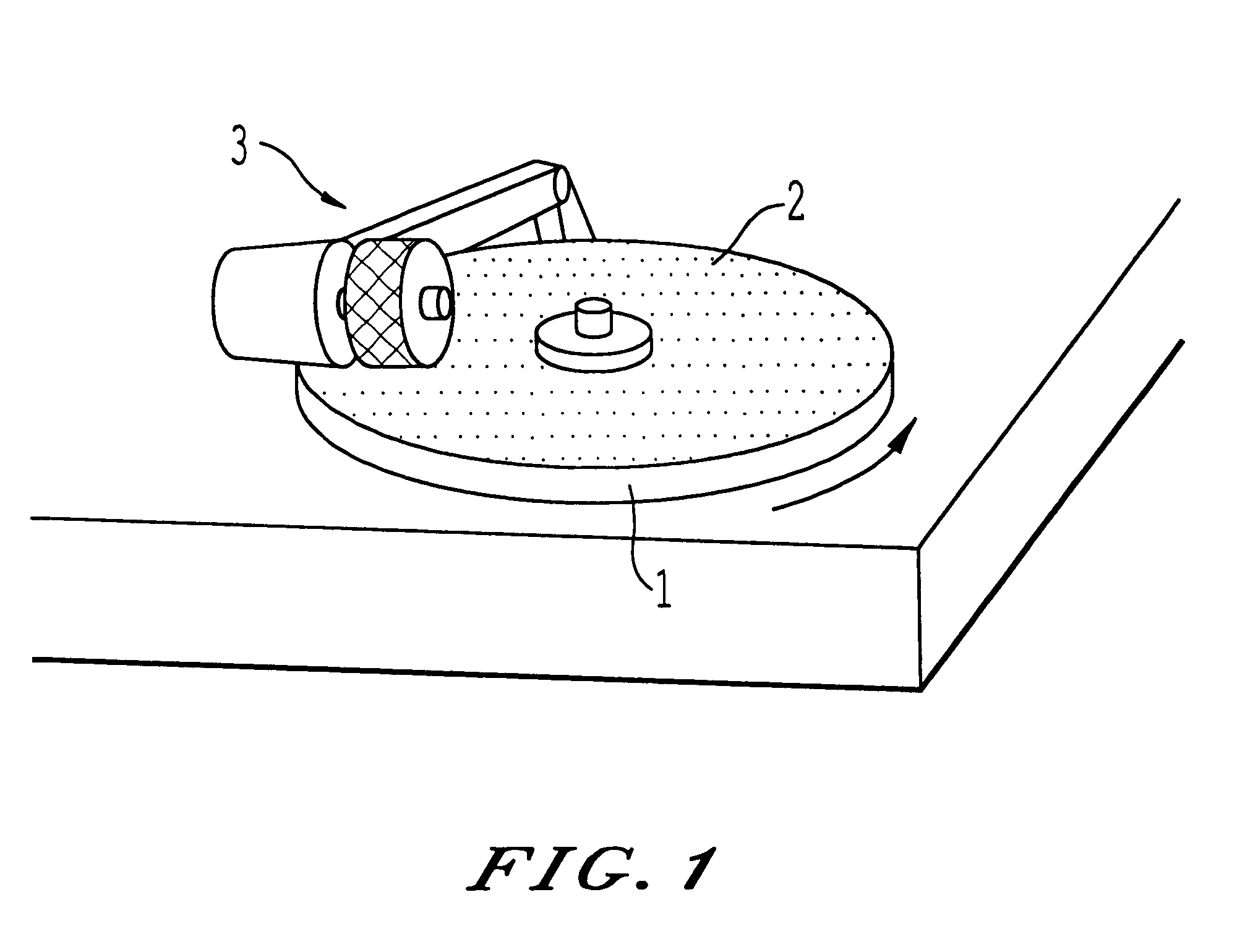

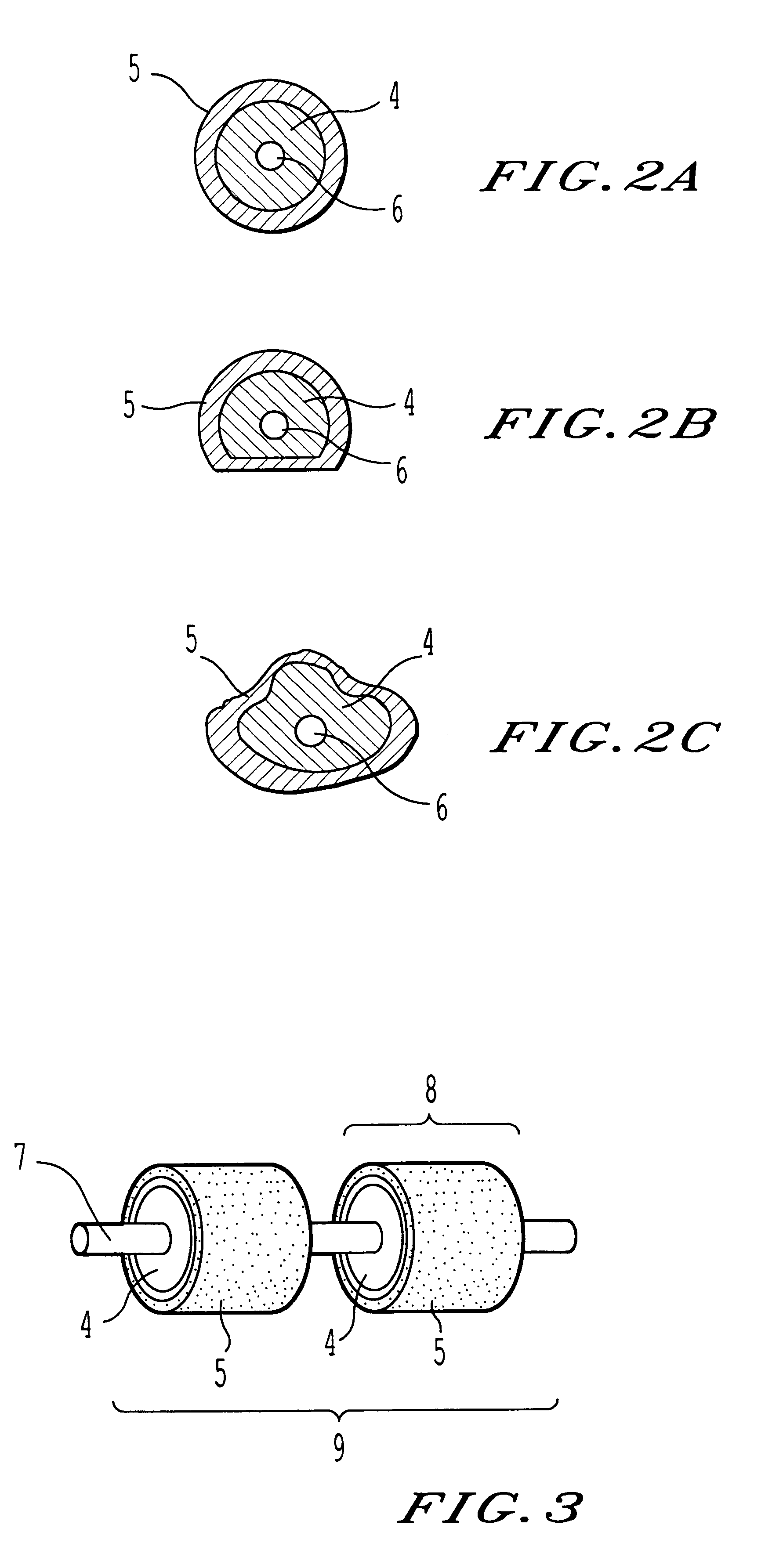

There is disclosed a member for office machines which comprises a core body and an annular elastic body installed on the peripheral surface thereof, wherein the expansion rate of the annular elastic body E(%) falls within the range of 5 to 30%, when expressed by the formulawherein d1 in mm is the diameter of the core body, or a longest value in the cross-section of the core body in the shape of a roller or odd-shape; and d2 in mm is the inside diameter in mm of the annular elastic body before being installed on the peripheral surface of the core body. The member for office machines enables stable and steady paper sheet feeding, when used as a paper feeding member in electrophotographic equipment and electrostatic recording equipment, and equipment having a variety of paper feeding mechanisms such as ink-jet printers, automatic teller machines (ATM), money exchange machines, counting machines, automatic vending machines and cash dispensers (CD).

Owner:BRIDGESTONE CORP

Environmental protection type friction material with less metal used for automobile brake block and preparation method thereof

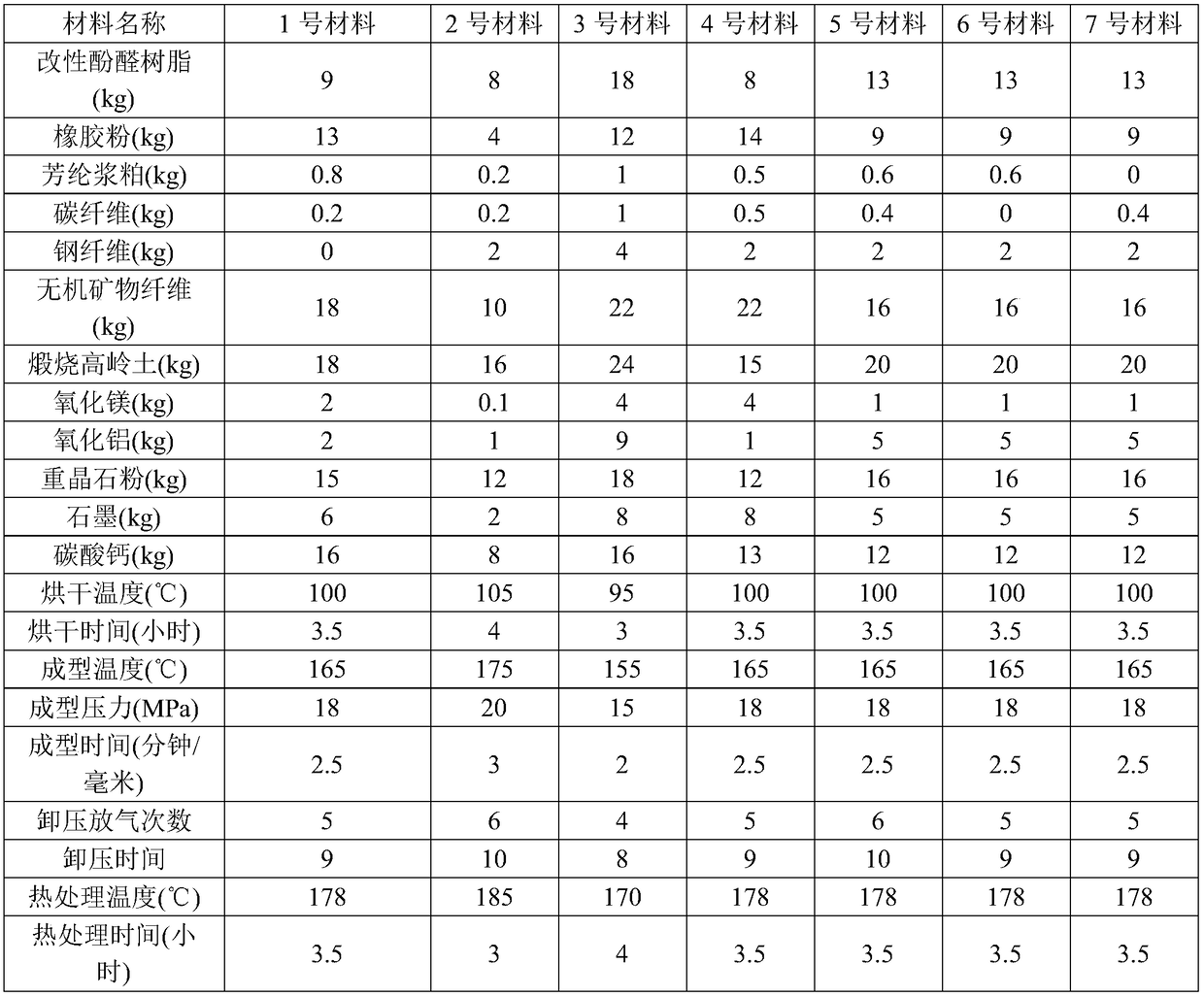

ActiveCN108728041AAvoid damageModerate coefficient of frictionOther chemical processesFriction liningFiberLow noise

An environmental protection type friction material with less metal used for automobile brake block is prepared with the following raw materials in parts by weight: 8-18 parts of modified phenolic resin, 4-14 parts of rubber powder, 0.2-1 part of PPTA-pulp, 0.2-1 part of carbon fiber, 0-4 parts of steel fiber, 10-22 parts of mineral fiber, 16-24 parts of calcined kaolin, 0.1-4 parts of magnesium oxide, 1-9 parts of aluminum oxide, 12-18 parts of barite powder, 2-8 parts of graphite, and 8-16 parts of calcium carbonate, the invention adopts the above technology and has the following advantages:1, the environmental protection friction material with less metal used for the automobile brake block has no asbestos, no sulfide, no copper and no other harmful heavy metal components, which is environmentally friendly; 2. with the co-action of each component, the invention has appropriate friction coefficient, high heat-resistance, low wear rate, low noise, less damage to coupled parts, rust resistance and other performances; 3, the preparation technology provided by the invention is simple, which is applicable for industrial production and has significant economic and social benefits.

Owner:QILU UNIV OF TECH

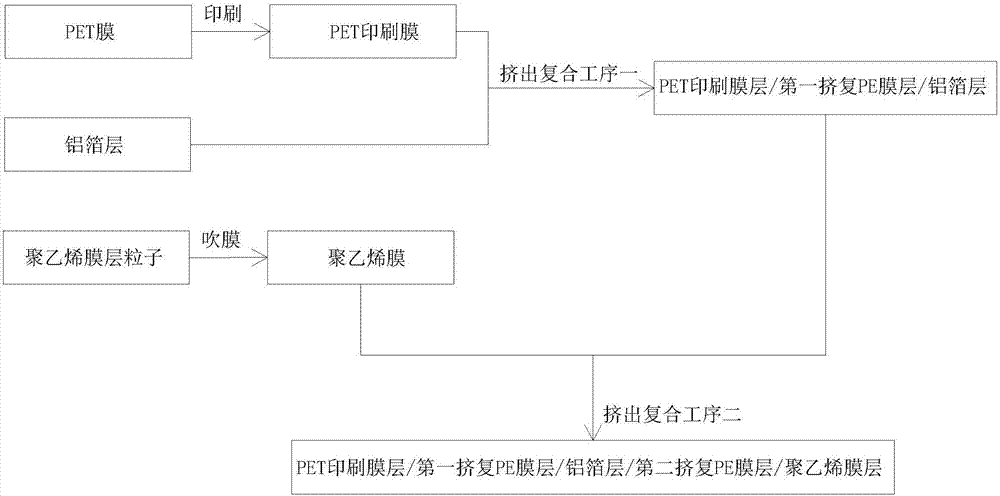

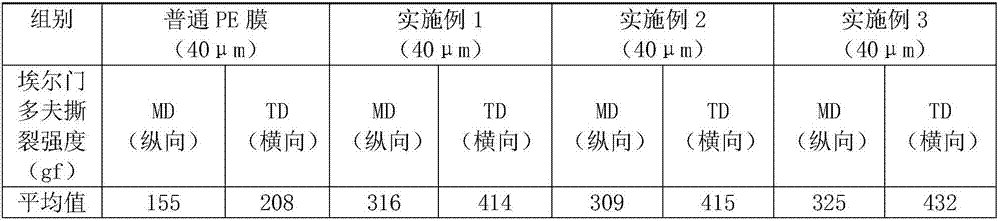

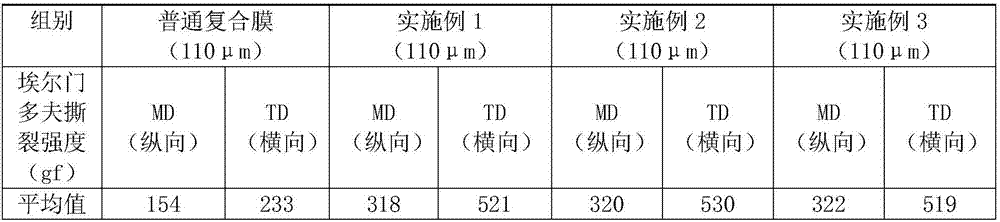

Tear-resistant polyethylene film, composite membrane and preparation method thereof

ActiveCN107323053AHigh peel strengthHigh heat sealing strengthFlexible coversWrappersTear resistanceAluminum foil

The invention relates to a tear-resistant polyethylene film, a composite membrane and a preparation method thereof. The polyethylene film comprises a corona layer, a middle layer and a heat sealing layer, wherein the corona layer and the middle layer are each composed of first metallocene PE, octa-carbon LLDPE and processing aids, and the heat sealing layer is composed of the first metallocene PE, second metallocene PE, silicone, a slipping agent and an opening agent. The composite membrane is formed by a PET printing membrane layer, a first extruded PE membrane layer, an aluminum foil layer, a second extruded PE membrane layer and a polyethylene membrane layer which are sequentially fitted in the membrane layer thickness direction; the extruded PE membrane layer comprises a first adhesive layer in fit with the aluminum foil layer and a second adhesive layer in fit with the PET printing membrane layer or the polyethylene membrane layer, wherein the first adhesive layer is composed of third metallocene PE and adhesive resin, and the second adhesive layer is composed of the third metallocene PE and color master batch. The polyethylene film and the composite membrane disclosed by the invention have higher tear resistance strength. In addition, the composite membrane has excellent humidity resistance property.

Owner:HUANGSHAN NOVEL

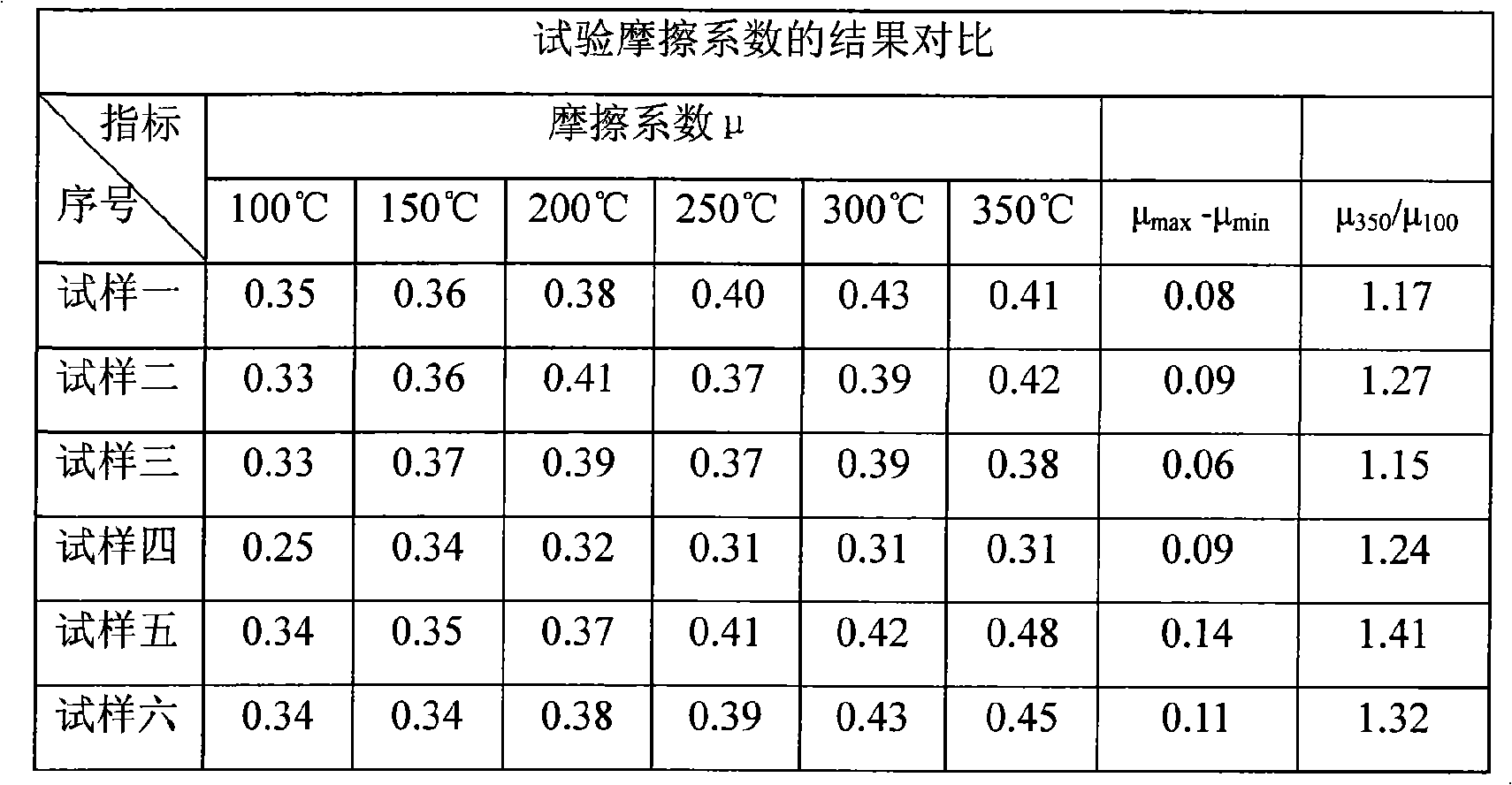

Vehicle braking composite material reinforced by confusion of natural fiber and crystal whisker and preparing method thereof

InactiveCN101514251AStable coefficient of frictionReduce wear rateFriction liningPyrophylliteConfusion

The present invention provides a vehicle braking composite material reinforced by confusion of natural fiber and crystal whisker and preparing method thereof. The raw materials of composite friction material is composed of bamboo fiber, phenolic resin, magnesium sulfate crystal whisker, steel fiber, copper powder, graphite dust, pyrophyllite powder, aluminum oxide, iron oxide, barium sulfate and zinc stearate. The preparing method comprises the following steps: preprocessing the raw materials, mixing the raw materials, hot pressing shaping and heat processing. The invention uses the bamboo fiber with low cost for reinforcing the phenolic resin. The proper amount of wear-increasing agent, anti-wear agent and filling agent for exerting the cooperative coupling function among the substrate, the fiber / crystal whisker and filling agent, thereby obtaining the novel vehicle braking composite material which has the advantages of stable friction coefficient under different temperatures, low wear rate, high heat fading resistance, excellent braking effect, shock absorbing, noise reduction and low cost.

Owner:FUZHOU UNIV

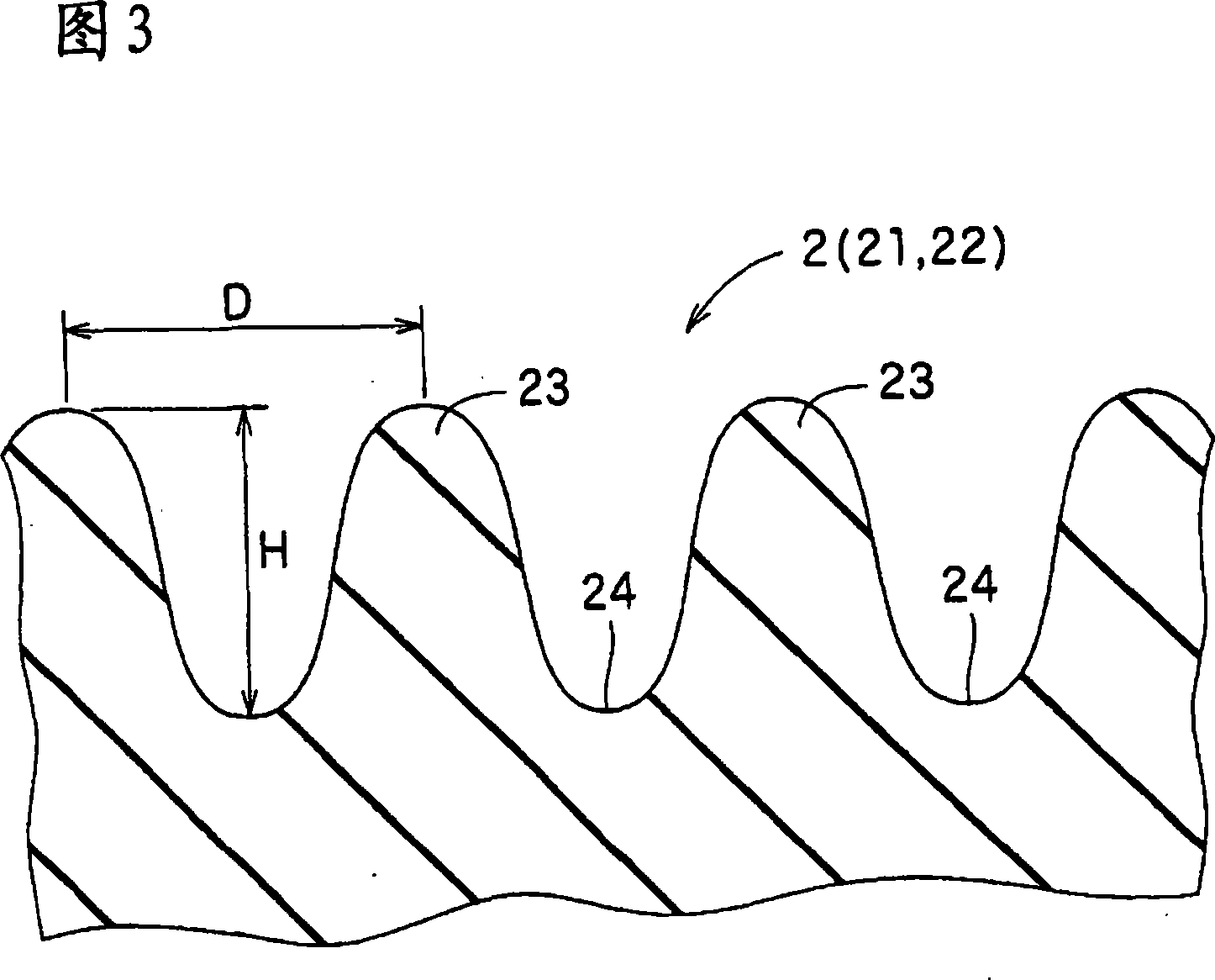

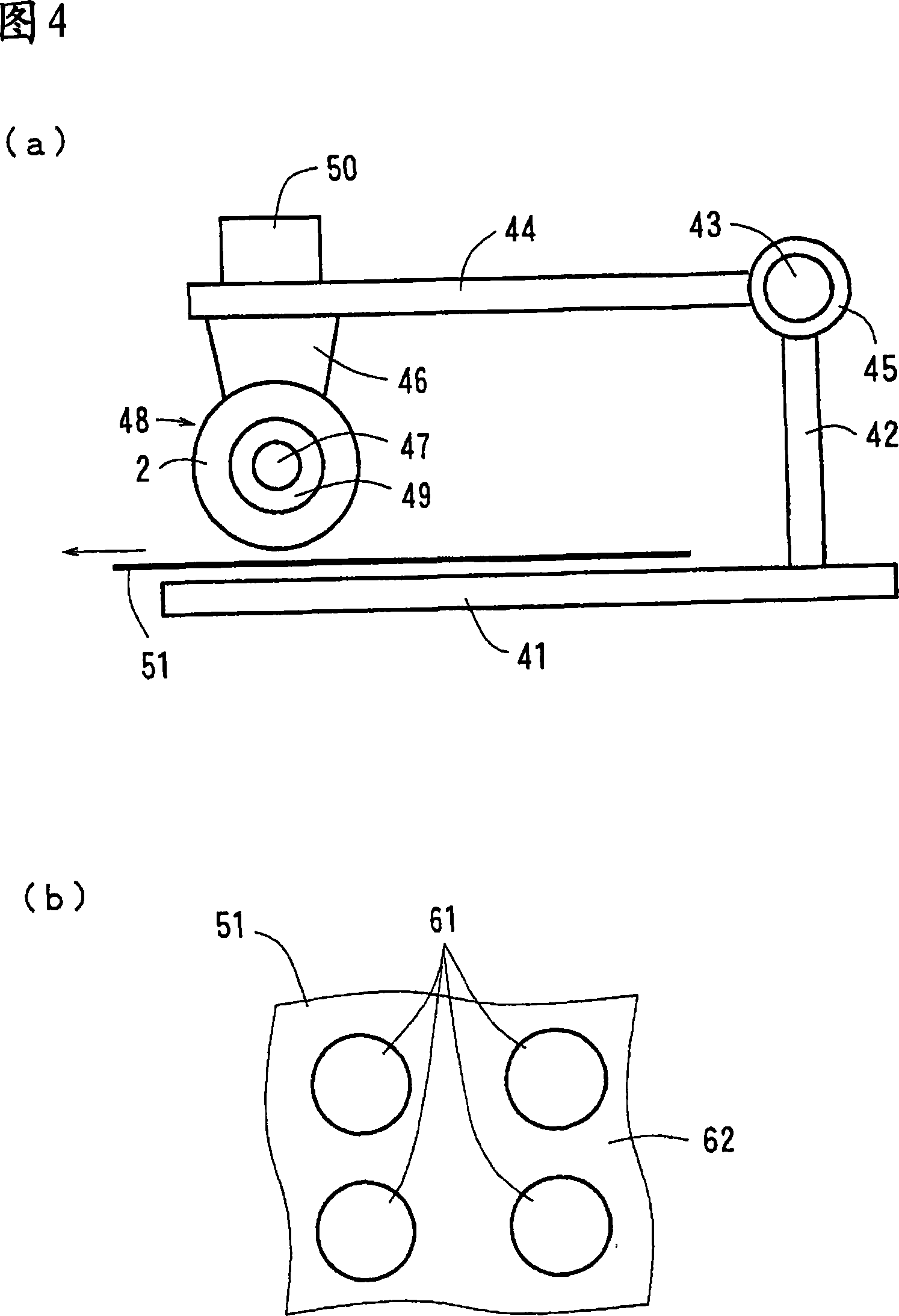

Sheet feed roller and method of manufacturing the same

InactiveCN101139048AImprove delivery capacityLong lastingElectrographic process apparatusOther printing apparatusPaper sheetEngineering

A sheet feed roller, prolonging sustainability of sheet feeding capability in the presence of paper powders, comprises a hub, an elastic layer 2 provided on an outer peripheral surface of the hub and circumferentially-spaced axially-extending plural grooves 21 on the outer peripheral surface of the elastic layer. A textured surface comprising mountain and valley portions is formed on the outer peripheral surface of the elastic layer 2, this textured surface being on the wall and bottom surfaces of the grooves 21 as well as on the surface of the portions 22 between the grooves. A ratio of a total area of the bottom surfaces of the grooves to a total area of the outer peripheral surface of the elastic layer except for the grooves is 10 % to 20 %.

Owner:TOKAI RUBBER IND LTD

Composite brake pad with stable performance

InactiveCN106674883AHigh strengthStrong temperature resistanceFriction liningActuatorsFriction effectEngineering

The invention discloses a composite brake pad with stable performance. A brake pad body consists of a pre-friction region, a main friction region and a heat dissipation region, wherein the pre-friction region has a proper friction coefficient, is high in braking performance and cannot scratch a brake flange; the pre-friction region is located at the forefront part of the brake pad body, can form an excellent friction layer and a transfer film through wear to a certain extent, and achieves a good pre-friction effect, so that a foundation is laid for efficient work of the main friction region; the main friction region is compounded by various new fiber materials; the multiple new fiber materials can complement the respective performance shortcomings and also carry out mutual traction action to generate high performance. In a braking process, the highest temperature can be up to 380 DEG C, the friction coefficient and the wear rate of the brake pad cannot be changed, and no cracks appear under sudden braking; the heat dissipation region carries out reasonable matching on various components to ensure that the advantages of all the materials can be fully developed in a friction material, is high in temperature resistance, high in thermal stability and relatively low in heat conductivity, and meets the technical requirements of high wear resistance, high speed and safety of the brake pad.

Owner:摩擦一号汽车科技(仙桃)有限公司

Whisker composite material for reinforcing automobile brake friction and a method for producing the same

The invention provides a whisker composite material for reinforcing automobile brake friction and a method for producing the same, wherein the composite friction material consists of basic magneislum whisker, pyrophyllite power, phenol resin, copper powder, graphite powder, aluminium oxide and zine stearate, as raw materials; the producing method comprises raw material pretreatment, raw material mixing, hot press molding and cooling. The invention achieves the phenol resin reinforcement by the basic magneislum whisker [MgSO4.5MgO.8H2O] with excellent low cost, selects the pyrophyllite [Al4Si8O20OH4] as the filler for the assorted fiber brake friction material, the concerted coupling function of a substrate, the whister and the filler can be exerted according to the addition of a friction reinforcing agent, and an antiwear agent, thereby the novel automobile brake composite material has advantages of good heat resistance, moderate coefficient of friction, small wear rate, well heat fade resistance, good brake effect and low cost.

Owner:FUZHOU UNIV

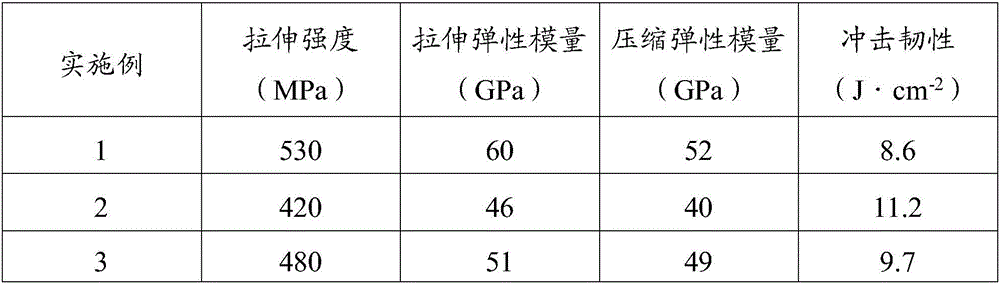

Hybrid fiber reinforced polypropylene composite material

InactiveCN106397973AIncrease surface tensionImprove interface compatibilityGlass fiberPolypropylene composites

The invention discloses a hybrid fiber reinforced polypropylene composite material. The hybrid fiber reinforced polypropylene composite material comprises, by mass, 10 to 30% of glass fiber, 10 to 50% of carbon fiber, 2 to 5% of aramid fiber, 5 to 15% of bamboo fiber, 5 to 25% of basic magnesium sulfate whisker, 10 to 30% of polypropylene, 2 to 5% of a functional polypropylene copolymer, 3 to 6% of epoxy resin, 2 to 8% of a binder, and 5 to 30% of a filler. According to a preparation method, the self-made functional polypropylene copolymer is added as a high molecular surfactant, so that the surface tension of the hybrid fiber reinforced polypropylene composite material is increased obviously, and interfacial compatibility of polypropylene resin with glass fiber is improved; the hybrid fiber reinforced polypropylene composite material possesses relatively high elasticity modulus, tensile strength, and toughness; and material application range is widened.

Owner:JIANGSU SHENXIANG ELECTROMECHANICAL

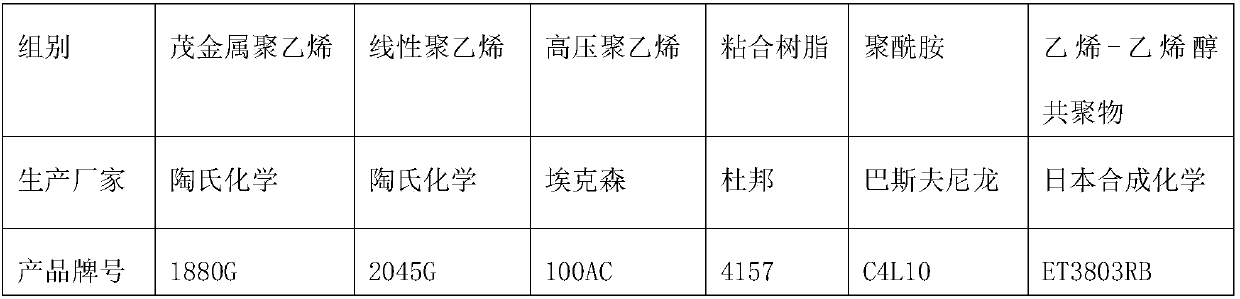

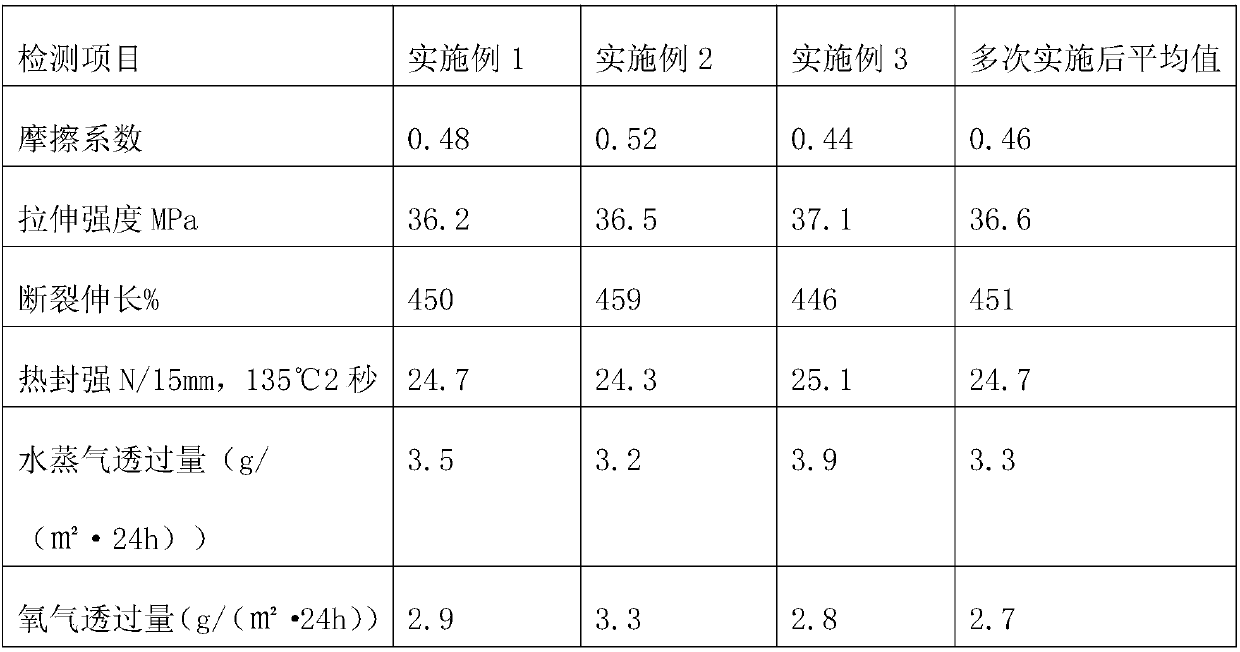

Easy-cutting nylon EVOH high-barrier film and production method thereof

InactiveCN107745561AStrong anti-pollutionGood sealingSynthetic resin layered productsLaminationPolyamideEngineering

The present invention relates to an easy-cutting nylon EVOH high-barrier film and a production method thereof. The nylon EVOH high-barrier film comprises a first PE film layer, a first adhesion film layer, a first PA film layer, a middle EVOH film layer, a second PA film layer, a second adhesion film layer and a second PE film layer, wherein the first PE film layer, the first adhesion film layer,the first PA film layer, the middle EVOH film layer, the second PA film layer, the second adhesion film layer and the second PE film layer sequentially contact and are molded through co-extrusion, thefirst PE film layer and the second PE film layer comprise metallocene polyethylene, linear polyethylene and high-pressure polyethylene, the first adhesion film layer and the second adhesion film layer comprise an adhesion resin, the first PA film layer and the second PA film layer comprise polyamide, and the middle EVOH film layer comprises an ethylene-vinyl alcohol copolymer. According to the present invention, the materials of each film layer are added to the material cylinder of a seven-layer co-extrusion film blasting machine, and melting, co-extrusion, film blasting and cooling shaping are performed to obtain the easy-cutting nylon EVOH high-barrier film; and the obtained easy-cutting nylon EVOH high-barrier film has advantages of extremely high barrier performance, excellent heat sealing performance and moderate friction coefficient, cannot produce adhesion and slipping during being cut, and is suitable for a high-speed packaging production line.

Owner:HUANGSHAN NOVEL

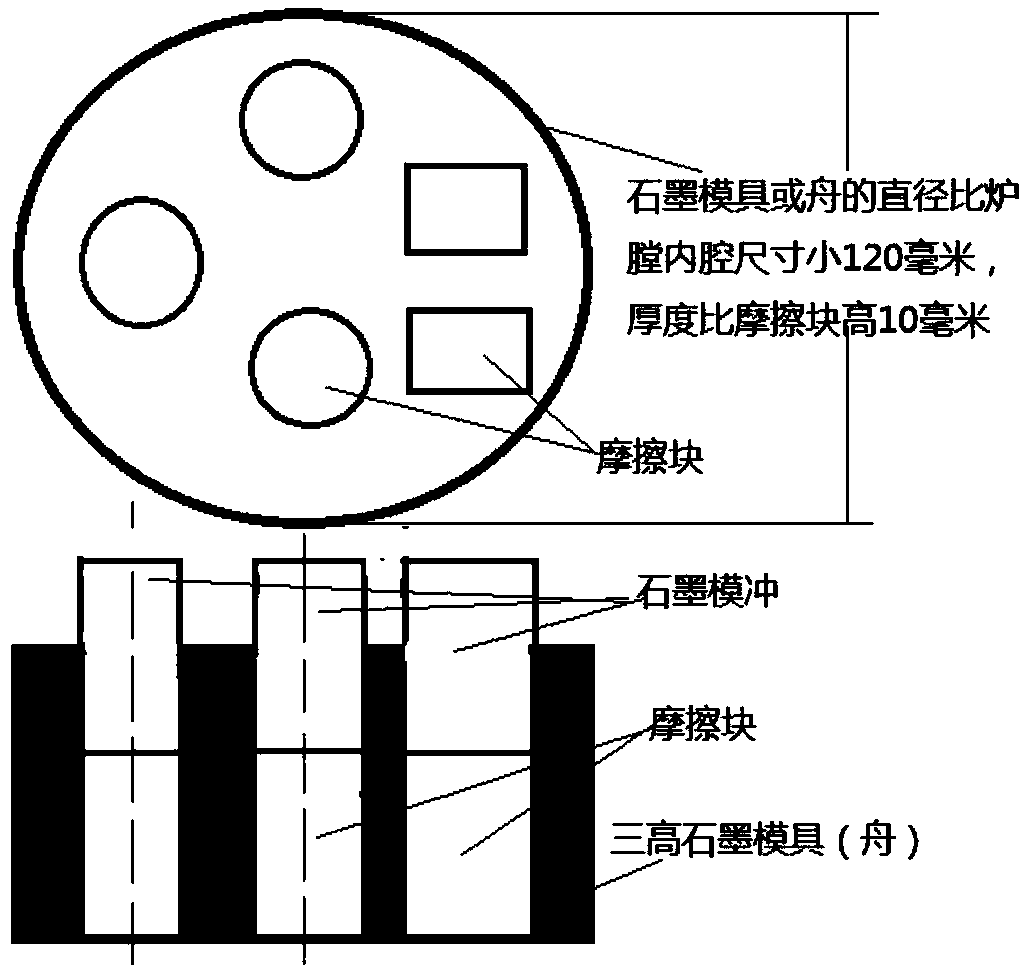

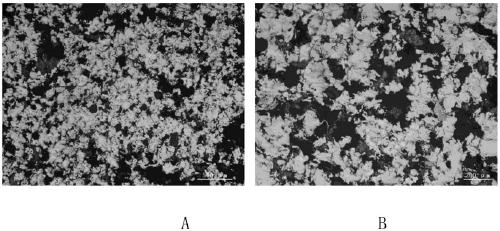

Preparation method of iron-copper based composite friction materials

ActiveCN109139755AStrong shear resistanceHigh strengthOther chemical processesFriction liningFiberCarbon fibers

Provided is a preparation method of iron-copper based composite friction materials. After raw materials are burdened and mixed, a mixture is obtained after being subjected to cold pressing and then subjected to high-temperature hot pressing and sintering, and the mixture is subjected to compression moulding forming through the pressure intensity of 450-550 MPa; and a pressed blank is put into a heating furnace and is subjected to pressure sintering under the nitrogen protection atmosphere, and the sintering process includes the steps that heat is preserved for 2-3 hours under the pressure of 2.5-2.8 MPa at 1000 DEG C and the billet is cooled along with the furnace. The friction materials are obtained through high-temperature hot pressing and sintering after cold pressing, the respective advantages of iron and copper are played, at the same time, carbon fibers with high specific modulus and high specific strength are applied into the iron-copper based composite friction materials, the strength of a matrix is enhanced, the impact toughness is improved, the brake noise is reduced, the friction coefficient is proper, and high-temperature abrasion resistance is good.

Owner:滁州欧瑞斯机车部件有限公司

Electrophoresis coating technique for fasteners

InactiveCN101387003AImprove corrosion resistanceAppropriate coefficient of frictionElectrophoretic coatingsLiquid temperatureChemistry

The present invention discloses a process for electrophoretic painting of a fastener, which comprises the following; firstly, a step of phosphatization of zinc series, in which the phosphatization is carried out in a phosphatization tank at a temperature of between 30 and 40 DEG C for 3 to 5 minutes, and the sample piece is subjected to ceaseless shaking, washing, drying for 20 minutes at a temperature between 80 and 100 DEG C; secondly, a step of cathodic electrophoresis, in which the cathodic electrophoresis is carried out in an electrophoresis tank, the tank liquid temperature is between 28 and 32 DEG C, the electrophoresis time is between 2 and 3 minutes and the painting voltage is between 140 and 180 volt, and water washing is adopted; thirdly, a step of drying, in which the surface is dried for 40 minutes at a temperature of between 170 and 180 DEG C. The process solves the problem of processing main Cr6+ pollution in the most universal fastener surface treatment (zinc plating+passivation process, Dacro coating process, darkening process, and the like). The cathodic electrophoretic painting process adopted by the fastener is a novel technology, which improves the corrosion resistance of the fastener and has capacity of protecting environment as well. The composite cost of the process is lower than that of the barrel plating.

Owner:CHINA FIRST AUTOMOBILE

Safety type friction material having high cleaning performance and friction plate preparation method

InactiveCN105400493AGuaranteed flatnessReduce porosityOther chemical processesFriction liningFiberActivated carbon

The invention aims to provide a friction material having high cleaning performance while having high friction coefficient and safety performance and a friction plate preparation method. The friction material comprises, by weight percentage, 4-10% of resin, 6-10% of coke dust, 0.5-5% of nitrile powder, 1-8% of tire powder, 1-4% of corundum, 9-20% of graphite, 1-3% of iron black, 1-3% of activated carbon, 2-5% of friction powder, 20-30% of fiber and 30-55% of packing. The method for preparing a friction plate by utilizing the materials comprises a step (1) of mixing the materials: manufacturing a friction material mixed material; a step (2) of performing prepressing: preforming the mixed material; a step (3) of performing hot pressing: placing pressed blank in a die to undergo hot pressing, and performing interval exhaust-gas disposal; a step (4) of performing heat treatment: performing constant-speed warming and thermal insulation in a graded manner from room temperature to 185 DEG C; and a step (5) of performing size processing. The friction material is applied to the field of friction materials.

Owner:ZHUHAI HUALI FRICTION MATERIAL

Yaw brake block material for wind driven generator and preparing method of yaw brake block material

InactiveCN108561467AMeet the requirements of yaw low speed brakingMeet environmental protection requirementsOther chemical processesFriction liningWind drivenLow speed

The invention discloses a yaw brake block material for a wind driven generator. The yaw brake block material comprises components including, by mass, 8-12 parts of boron modified phenolic resin, 0.5-3parts of nitrile rubber modified phenolic resin, 25-35 parts of calcium sulfate crystal whiskers, 8-12 parts of aramid pulp, 2-8 parts of aluminum oxide, 3-5 parts of graphite, 10-15 parts of vermiculite, 2-5 parts of zinc oxide, 1-3 parts of nanosilicon dioxide and 2-5 parts of barite. The invention further discloses a preparing method of the material. A yaw brake block does not contain metal and heavy metal compounds, the environmental requirement is met, the yaw brake block material has the advantages of appropriate and stable friction coefficients, the high compressive strength, the low brake noise, the long service life and the low manufacturing cost, and the requirement for the yaw low-speed braking of the wind driven generator can be sufficiently met.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

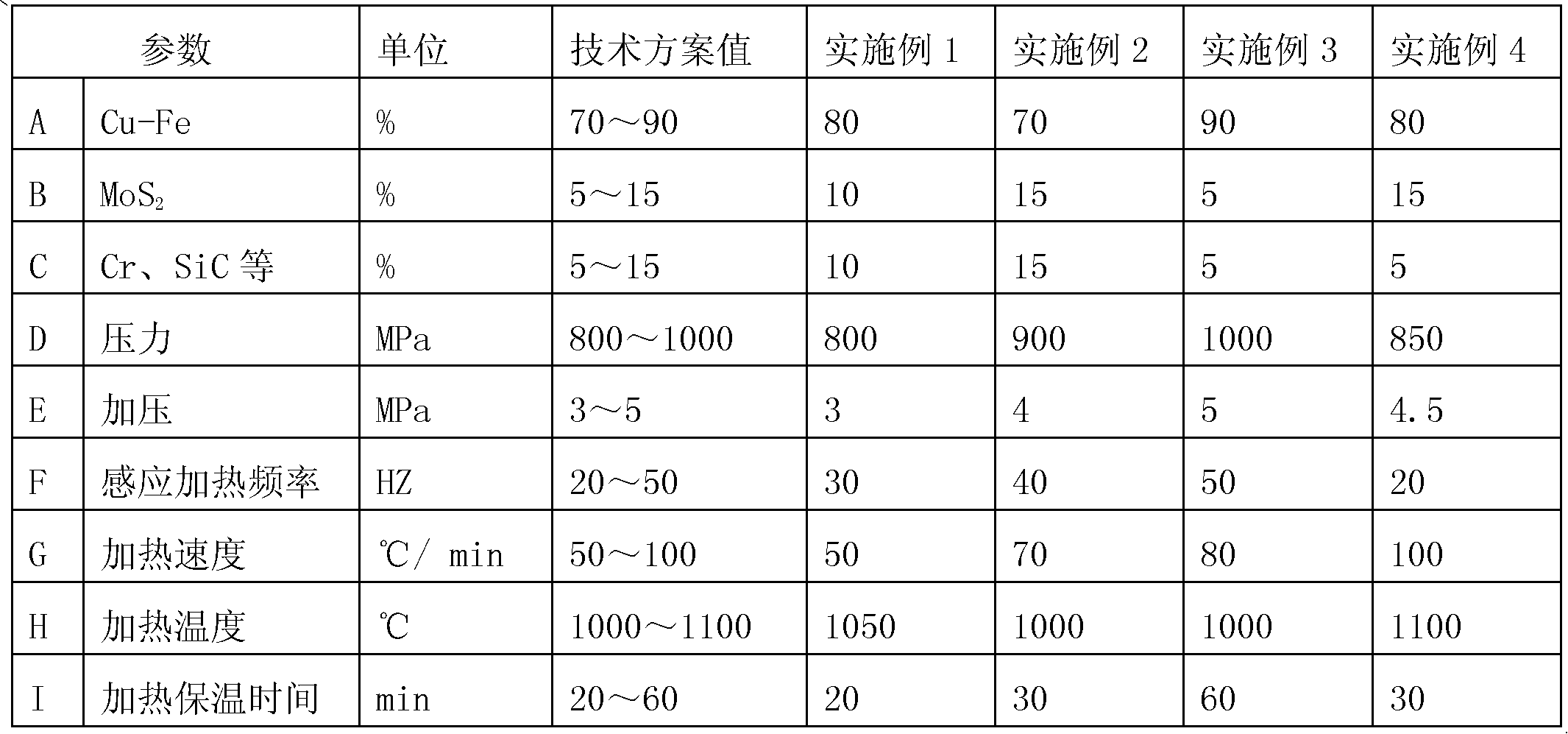

Preparation method of brake molybdenum disulfide-Cu-Fe radical friction material

InactiveCN102002623AModerate coefficient of frictionReduce wear rateFriction liningLubricationMolybdenum disulfide

The invention relates to a preparation method of a brake molybdenum disulfide-Cu-Fe radical friction material, which takes a Cu-Fe radical alloy as a substrate added with a lubricating component of MoS2, a friction component of SiC and alloy components of Mn and Cr to prepare the brake molybdenum disulfide-Cu-Fe radical friction material and comprises the technological steps of: 1. selecting the original auxiliary powder material; 2. proportioning according to the weight; 3. mechanically stirring and uniformly mixing; 4. pressing into a cylindrical pressed shape; 5. placing the pressed shape into a stainless steel container and filling protective gas of hydrogen into a stainless steel container; 6. placing the container into an intermediate-frequency induction heating coil to be heated, stopping heating after heating and preserving the temperature, and cooling to room temperature along a furnace; 7. taking out a sample to be dried after ultrasonic cleaning; and 8. detecting the property of the sample. The synthesis method of sampling induction heating sintering and burning reactions has the advantage that the prepared molybdenum disulfide-Cu-Fe radical friction material with good brake performance has the characteristics of self-lubrication, moderate frictional factor and less wear rate.

Owner:DALIAN UNIVERSITY

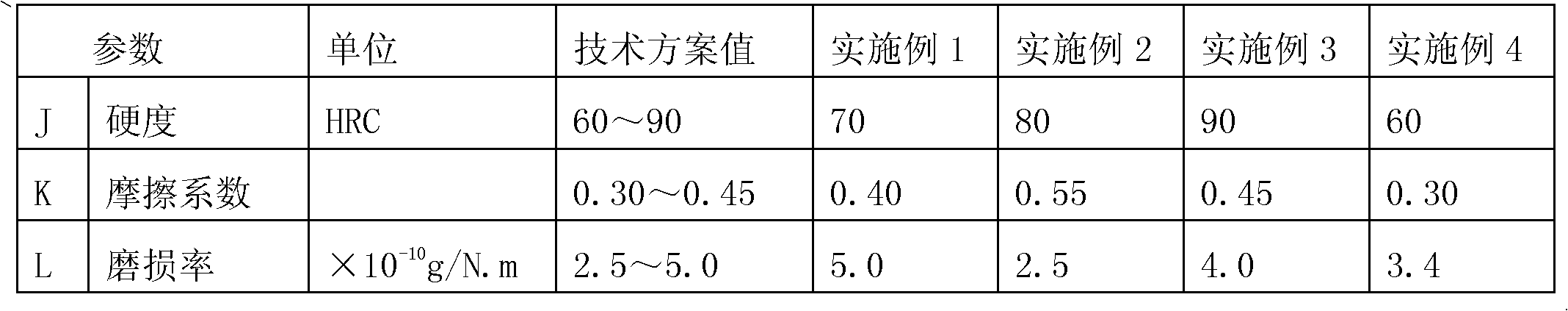

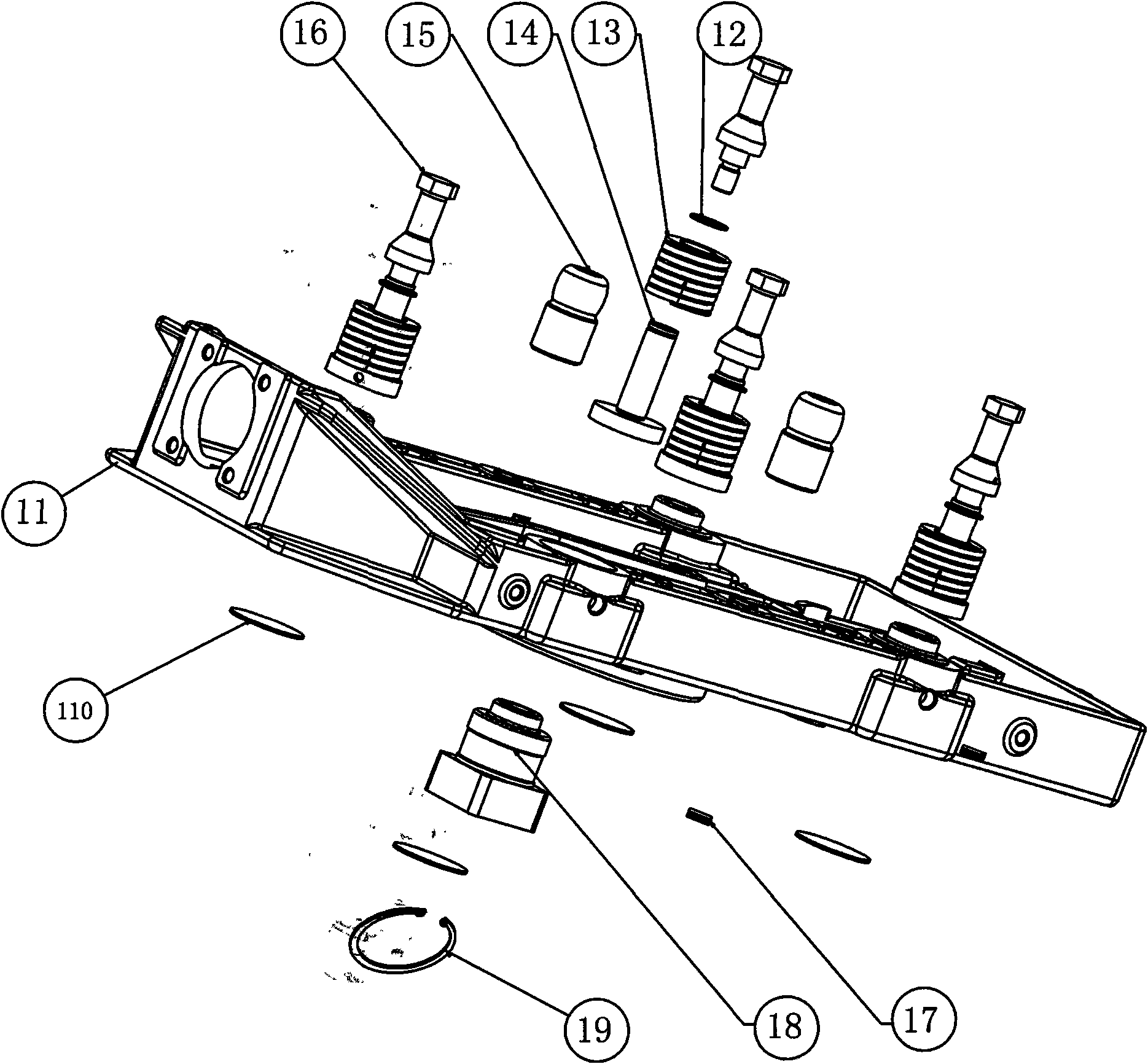

Automatic test device used for testing uniformity of antenna radiation field

ActiveCN107121600AEnvironmental factors are smallAvoid impact on test accuracyAntenna radiation diagramsStructural engineeringMechanical engineering

The invention discloses an automatic test device used for testing the uniformity of an antenna radiation field. The device comprises a regular geometric frame and a support bar separated from the geometric frame. The geometric frame is provided with a number of positioning bars capable of moving along the inner frame of the geometric frame. Each positioning bar is directed to the center of the geometric frame and is capable of telescoping. One end of the support bar is perpendicular to the cross section of the geometric frame and is directed to the center of the geometric frame. Probes are used for testing the antenna radiation field are arranged on one end of the support bar and the positioning bars. The automatic test device provided by the invention has the advantages of clever design, simple structure, easy operation, convenient use, low cost of making and maintaining, outstanding substantive characteristics and remarkable progress, and is suitable for large-scale application in the fields of antenna measurement and electromagnetic waves.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

High-performance ternary compound brake pad

ActiveCN105909706AModerate coefficient of frictionImprove wear resistanceFriction liningActuatorsFiberFully developed

Provided is a high-performance ternary compound brake pad. A brake pad body is formed by a pre-friction region, a main friction region, and a heat radiation region. The pre-friction region has a proper friction coefficient, and brake performance is good and does not scratch a brake disc. The pre-friction region is on the forefront of the brake pad body, and through certain degree abrasion, an excellent frictional layer and a transfer film are formed, so as to play good pre-friction role, and lays foundation for high-efficiency operation of the main friction region. The main friction region is composited by a plurality of kinds of new fiber materials, and the materials make up defects of respective performance and have high performance caused by mutual dragging effect. In a brake process, highest temperature reaches 380 DEG, and the brake pad would not change the friction coefficient and wear rate, and the brake pad would not have cracks when the brake is slammed. The heat radiation region ensures advantages of each material to be fully developed in the friction material through rational matching of various components. The temperature resistance of the heat radiation region is good, and the heat radiation region has good heat stability and relatively low heat conduction force, and satisfies technical requirements of high wear resistance, high speed, and safety of the brake pad.

Owner:摩擦一号制动科技(仙桃)有限公司

Dry cleaning agent for cleaning kitchens and hand oil stains

InactiveCN102242019AVersatileQuick decontaminationInorganic/elemental detergent compounding agentsCosmetic preparationsSolventDry cleaning agent

The invention provides a dry cleaning agent for cleaning kitchens and hand oil stains. The dry cleaning agent comprises the following components in parts by weight: 4-6 parts of expanded perlite, 1-3 parts of diatomite, 1-3 parts of bentonite, 1-3 parts of coral powder, 2-4 parts of anion active agent, 2-4 parts of nonionic active agent, 0.5-1 part of solvent, 1-3 parts of humectant, 0.5-1 part of foamer, 1-3 parts of disinfectant, 1-3 parts of emollient, 0.03-0.05 part of spice and the balance of purified water. The dry cleaning agent is prepared by the following steps: putting the expanded perlite, diatomite, bentonite and coral powder in a container; mixing and stirring the nonionic active agent, anion active agent, solvent, an addition agent, humectant, foamer, an anti-precipitation agent, disinfectant, emollient and spice in water through using a reaction kettle; pouring the solution into the container for soaking; and then until the solution is absorbed after 10-14 hours, forming water-containing semisolid particles, inspecting and then packaging. The dry cleaning agent has the advantages of no toxicity, no harm, no pollution and no residue, and meets environmentally-friendly and water-saving requirements.

Owner:王银河

Friction material, carbon ceramic brake pad formed through preparing of friction material and preparing method of carbon ceramic brake pad

InactiveCN107725648AIncrease temperatureReduce wearOther chemical processesBraking membersFailure causesSilicon dioxide

The invention belongs to the technical field of brake materials, and particularly relates to a friction material, a carbon ceramic brake pad formed through preparing of the friction material, and a preparing method of the carbon ceramic brake pad. The friction material comprises, by weight, 8-16 parts of carbon ceramic fiber, 1-6 parts of steel fiber, 3-12 parts of mineral fiber, 8-16 parts of chemigum modified phenolic resin, 5-11 parts of powder chemigum, 4-11 parts of petroleum coke, 9-22 parts of barium sulfate, 1-5 parts of polyacrylonitrile fiber, 6-16 parts of heavy magnesium oxide, 4-12 parts of kaolin and 2-8 parts of silicon dioxide. The above raw materials are mixed to form the mixture and placed into a die to be pressed and cured into a blank, the blank is heated and cured, andthe carbon ceramic brake pad is obtained. The brake pad has the beneficial effects of being small in abrasion thickness and long in service life; the tolerable temperature of the friction material ishigh, the problem of brake failures caused by the high brake pad temperature during frequent braking is solved, and the driving safety is ensured.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

Process for producing formaldehyde-removing solid wood flooring

ActiveCN101804654BEasy surface modificationReduce energy consumptionLiquid surface applicatorsWood veneer joiningSolid woodPulp and paper industry

The invention relates to a process for producing formaldehyde-removing solid wood flooring. The process comprises the following steps of: processing a surface board, processing a core board, processing a base board, glue pressing and compounding, fine processing, coating the surface, and forming the finished product. The process has the advantages of strong natural visual sensation, comfortable foot sensation, good material quality, easy processing, cyclic utilization, good geothermy adaptability, strong stability, more simple and convenient construction and installation, excellent environmental performance, great increase of comprehensive utilization ratio of timbers and special effects on adsorbing and degrading free formaldehyde in indoor air.

Owner:临江市宝健木业有限责任公司

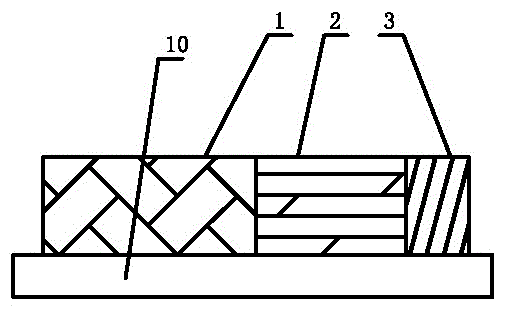

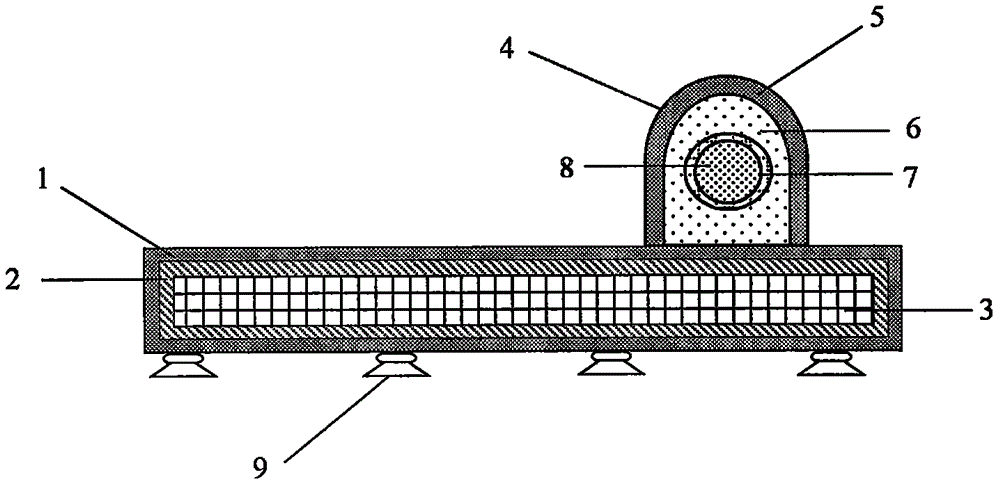

Environment friendly mouse mat for computer

InactiveCN105700717AWide variety of sourcesLow priceInput/output processes for data processingFiberCarbon fibers

The invention relates to an environment friendly mouse mat for a computer. The mouse mat is composed of a corn fiber shell fabric layer 1, a waterproof layer 2, a support layer 3 and a wrist support part 4. The corn fiber fabric layer 1 is a fabric material and is formed by interweaving warp and weft yarns; the warp yarns are formed by blending corn fibers and anion fibers; the weft yarns are formed by blending the corn fibers and bamboo carbon fibers; the mass percents of the fibers are as follows: 81%-91% of corn fibers, 3%-8% of anion fibers and 5%-12% of bamboo carbon fibers; the linear density of the warp yarns is 12-21 tex; and the linear density of the weft yarns is 12-21 tex. The mouse mat provided by the invention has the advantages that the mouse mat has various healthcare functions; the use performance of the mouse mat can be improved; the mouse mat is green and environment friendly and is low in cost; after the mouse mat is used for a long time, the mouse mat is still smooth without oil dirt and blocking feeling; the original hand feeling and performance are kept after the mouse mat is washed for many times; and the service life is long.

Owner:耿翠英

Friction material, organic carbon ceramic brake pad prepared from friction material and used for abrasion-resistant coating braking disc, and preparation method and application of organic carbon ceramic brake pad

ActiveCN109555802AHigh strengthImproved resistance to heat fadingOther chemical processesFriction liningCarbon fibersNew energy

The invention relates to the technical field of brake materials, in particular to a friction material, an organic carbon ceramic brake pad prepared from the friction material and used for an abrasion-resistant coating braking disc, and a preparation method and application of the organic carbon ceramic brake pad. The friction material is prepared from the following raw materials in parts by weight:3-5 parts of carbon fibers, 10-15 parts of steel fibers, 5-10 parts of mineral fibers, 8-12 parts of modified phenolic resin, 5-10 parts of powdered nitrile rubber, 6-10 parts of cashew nut oil frictional powder, 10-20 parts of precipitated barium sulfate, 1-3 parts of acrylic fibers, 2-4 parts of silicon carbide, 5-10 parts of soft kaolin and 9-12 parts of zirconium silicate. The preparation method of the organic carbon ceramic brake pad comprises the steps of pressing, solidifying and forming. The organic carbon ceramic brake pad for the abrasion-resistant coating braking disc is stable instructure, good in heat resistance and friction performance, simple in preparation process and short in preparation period, the matching property between the organic carbon ceramic brake pad and the abrasion-resistant coating braking disc is good, an abrasion-resistant friction pair is made of the organic carbon ceramic brake pad and the abrasion-resistant coating braking disc, and the service life of the braking disc of an automobile, or a new energy vehicle or a bullet train can be effectively prolonged.

Owner:BEIJING TIANRENDAOHE NEW MATERIAL CO LTD

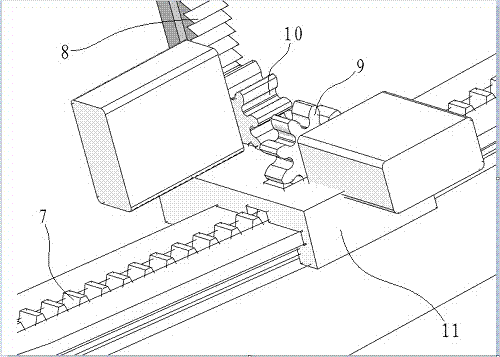

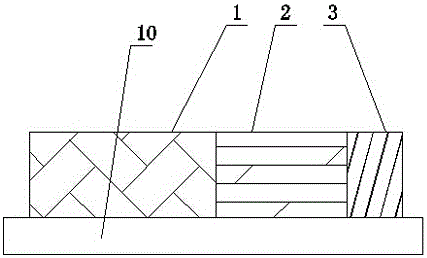

Sliding mechanism controlling ladle molten steel casting flow rate

InactiveCN101569928AEasy to useExtended service lifeMelt-holding vesselsHydraulic cylinderMechanical equipment

The invention relates to smelting mechanical equipment. A sliding mechanism controlling ladle molten steel casting flow rate comprises a main frame, a slide block and a support, wherein the slide block is matched with and slide-mounted in a slide block frame of the support on the lower end of the main frame; frame bodies on two sides of the splicing surface of the main frame and the support are respectively provided with positioning mechanism which are matched with each other; the main frame, the slide block and the support are connected into a whole through elastic tension elements; two sides inside the slide block frame of the support are symmetrically provided with two guide rails respectively; a pulley intermediate steel sheet is arranged in the middle of two guide rails on each side; one corresponding end of the guide rails on two sides is provided with a pulley stopper; after the pulley on the other end of the slide block pushed by a pushing rod of an external hydraulic cylinder drops on the position of the pulley stopper, the pulley on the end is just in the pulley intermediate steel sheet. The pin slide board can be changed and operated conveniently, is better matched with the requirement of ladle continuous casting, improves the safety use coefficient and service life of the sliding mechanism, and is beneficial to new technology of steel-making continuous casting.

Owner:河南省伯马股份有限公司

Novel flaky environment-friendly brass scrap and preparation method thereof

InactiveCN106947882AReduce contentLow costTransportation and packagingMetal-working apparatusAlloyCrusher

The invention belongs to the technical field of friction materials, and particularly relates to a novel flaky environment-friendly brass scrap and a preparation method thereof. The novel flaky environment-friendly brass scrap comprises, by weight, 55%-59% of copper, 0.32%-0.4% of aluminum, 200-500ppm of lead, and the balance zinc. The preparation method includes the steps that after all the components are put into a pure high-temperature electric resistance furnace to be heated and molten in proportion, the components are cast into an alloy bar through a horizontal continuous casting method; and then the alloy bar is crushed to be in the shape of flakes of different sizes through a blade-type crusher, and accordingly the flaky environment-friendly brass scrap can be obtained. According to the novel flaky environment-friendly brass scrap and the preparation method thereof, the strength, hardness and plasticity of brass can be improved through the aluminum, and the working condition design requirements of the friction materials are met; the content of the lead and the content of the copper are lowered in the novel flaky environment-friendly brass scrap, a proper amount of the aluminum is added, and therefore the effects of environmental protection and cost reducing are achieved under the premise that mass production can be guaranteed; the brass scrap is flaky, so that the contact area is effectively increased, the binding force is high, the friction coefficient is proper, and abrasion is small; and the novel flaky environment-friendly brass scrap can be widely applied to raw materials of the friction materials like a brake pad.

Owner:江苏新冠制动科技有限公司

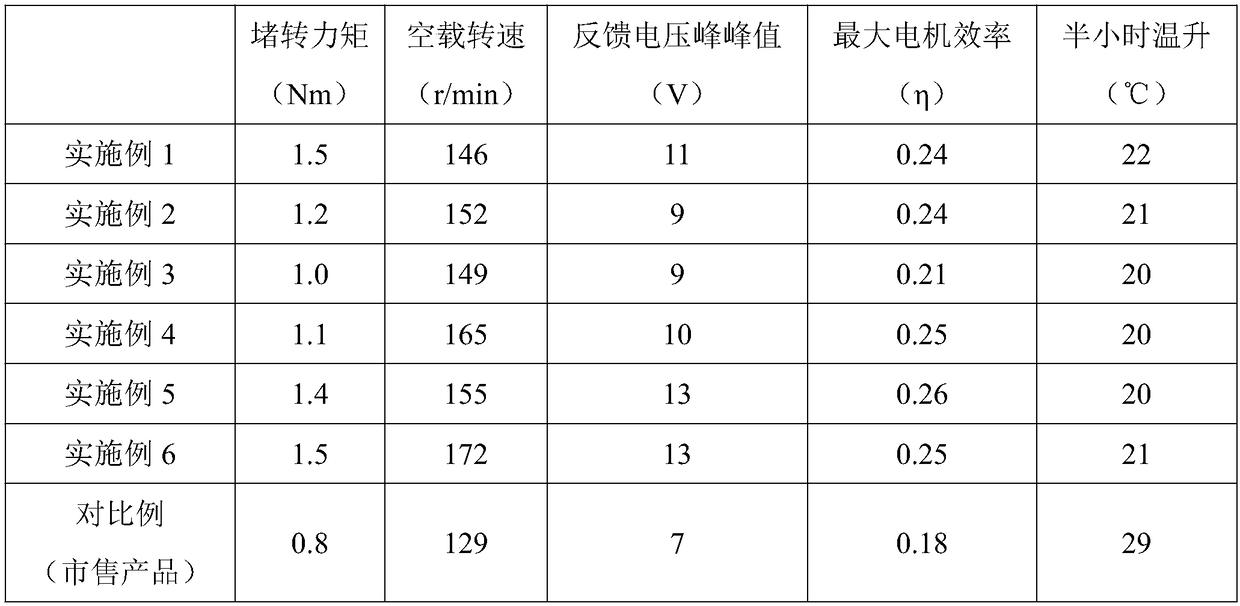

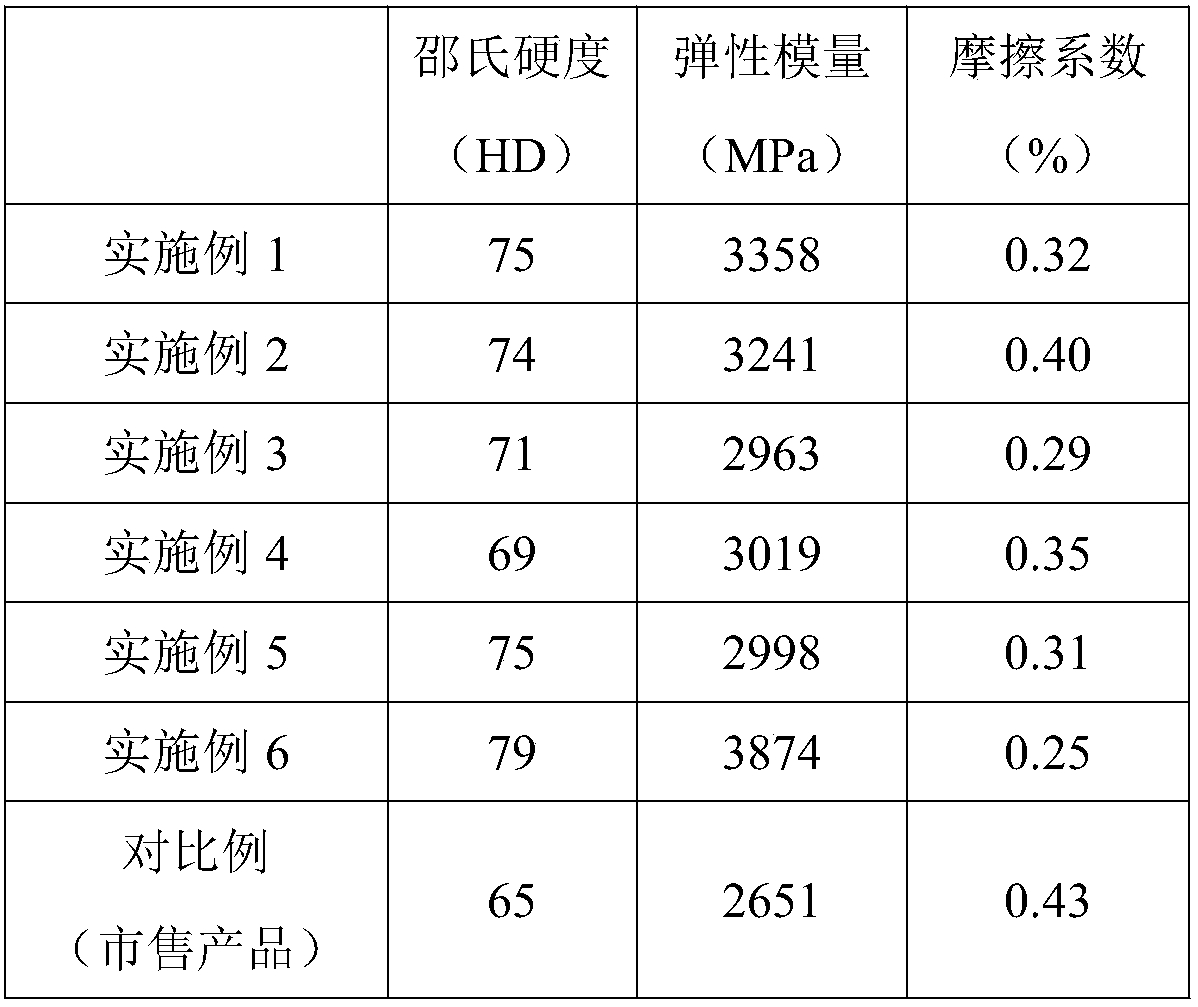

Preparation method for polyetheretherketone composite ultrasonic motor alloy friction material

InactiveCN108219359AGuaranteed dimensional stabilityEasy to scratchPoly ether ether ketoneWear resistant

The invention belongs to the field of polymer materials, and particularly relates to a preparation method for a polyetheretherketone composite ultrasonic motor alloy friction material. In order to achieve a friction material with high stalling torque and capability of stably operating, a matrix material formula is designed, the influences of different contents of polyetheretherketone, polybenzoate, polytetrafluoroethylene, nano silica and molybdenum disulfide on the stalling torque, no-load speed, motor efficiency, thermal conductivity, mechanical properties and frictional property of a motorare studied, ultimately, a wear-resistant material formula with excellent properties is obtained, and the high-property wear-resistant material is prepared.

Owner:YIBIN TIANYUAN GRP CO LTD

Friction material, organic carbon-ceramic brake pad for light-weight carbon-ceramic plate prepared from friction material, as well as preparation method and application thereof

InactiveCN109404450AImprove strengthHigh strengthOther chemical processesFriction liningTotal organic carbonBasalt fiber

The invention relates to the technical field of brake materials, in particular to a friction material, an organic carbon-ceramic brake pad for a light-weight carbon-ceramic plate prepared from the friction material, as well as a preparation method and application thereof. The organic carbon-ceramic brake pad for the light-weight carbon-ceramic plate is prepared from the following raw materials including, by weight, 2 to 4 parts of basalt fiber, 10 to 15 parts of steel fiber, 5 to 10 parts of mineral fiber, 8 to 12 parts of phenolic resin, 5 to 10 parts of elastic particles, 6 to 10 parts of cashew nut oil friction powder, 10 to 20 parts of precipitated barium sulphate, 1 to 3 parts of acrylic fiber, 2 to 4 parts of silicon carbide, 6 to 11 parts of kieselguhr and 9 to 12 parts of glass beads. The preparation method is pressing and thermosetting forming. The organic carbon-ceramic brake pad for the light-weight carbon-ceramic plate provided by the invention is stable in structure, goodin heat resistance and friction performance, simple in preparation process, and short in preparation period, and has good compatibility with the light-weight carbon-ceramic plate and good practicability so as to form a light-weight friction pair, so that the light weight of a vehicle can be effectively realized.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

Preparation method of titanium-containing antifouling wear-resistant bionic paint coating for mineral processing shakers

InactiveCN109836962AWith anti-scaling functionImprove corrosion resistanceNatural rubber coatingsAnti-corrosive paintsWear resistantLacquer

The invention discloses a preparation method of a titanium-containing antifouling wear-resistant bionic paint coating for mineral processing shakers. The bionic paint coating has excellent resistanceto fouling, wear and corrosion, has the basic characteristics of a raw lacquer, has no anaphylactic reaction effects on human bodies during construction, does not reduce the mineral processing efficiency under raw lacquer conditions, and prolong the repairing period. The bionic paint coating concretely comprises, by weight, 25-60 parts of resin, 5-20 parts of bionic paint resin, 5-20 parts of a titanium nano-polymer, 10-30 parts of a wear-resistant filler, 3-10 parts of a special nanometer metal oxide, a curing agent accounting for 15-30% of the weight of the resin, 1.5-3 parts of an assistant, 0.5-2 parts of an anti-settling agent and 15-40 parts of a mixed solvent. The bionic paint coating is suitable for protecting tin, copper and gold mineral processing shakers.

Owner:朱兰芬

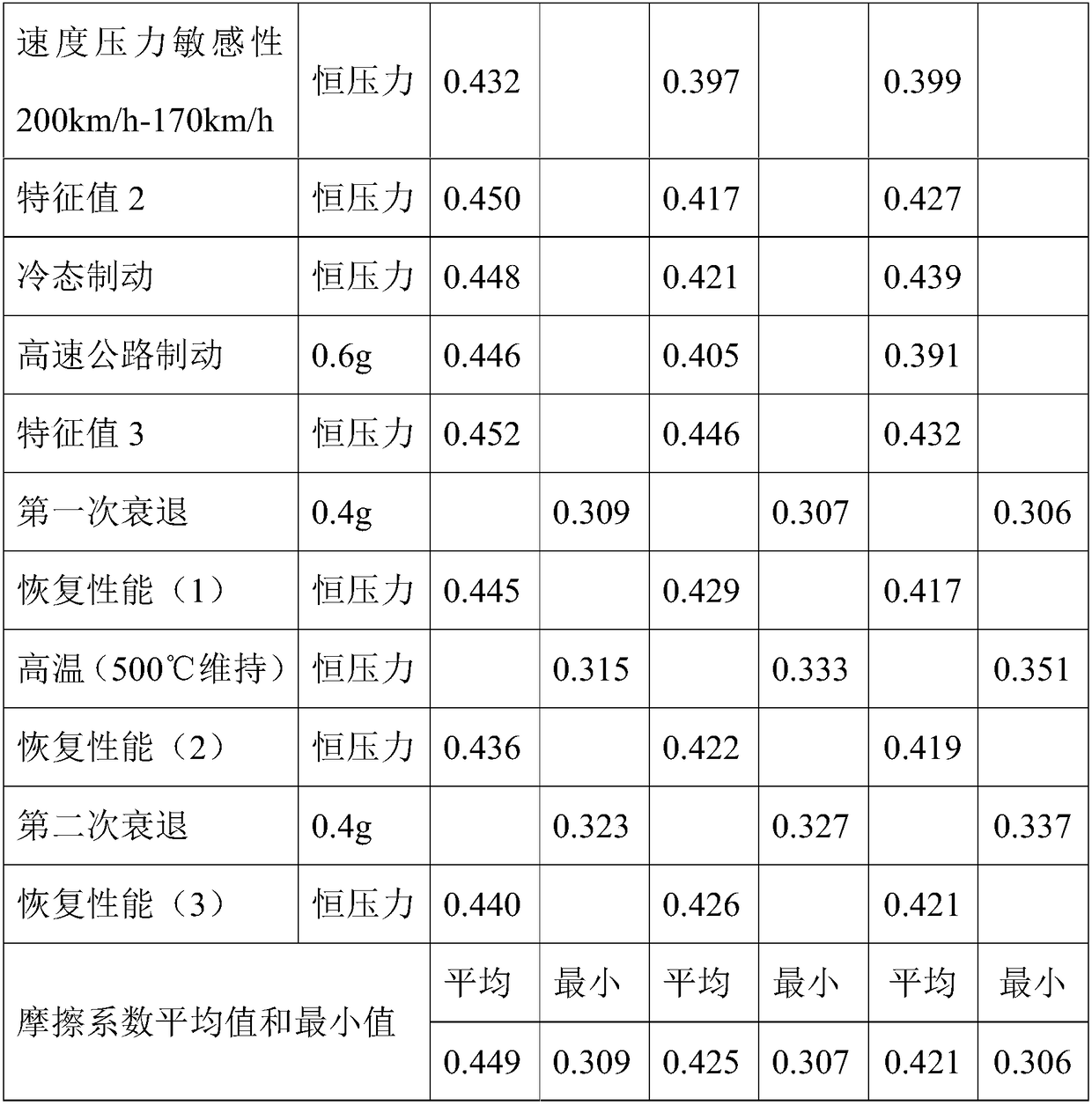

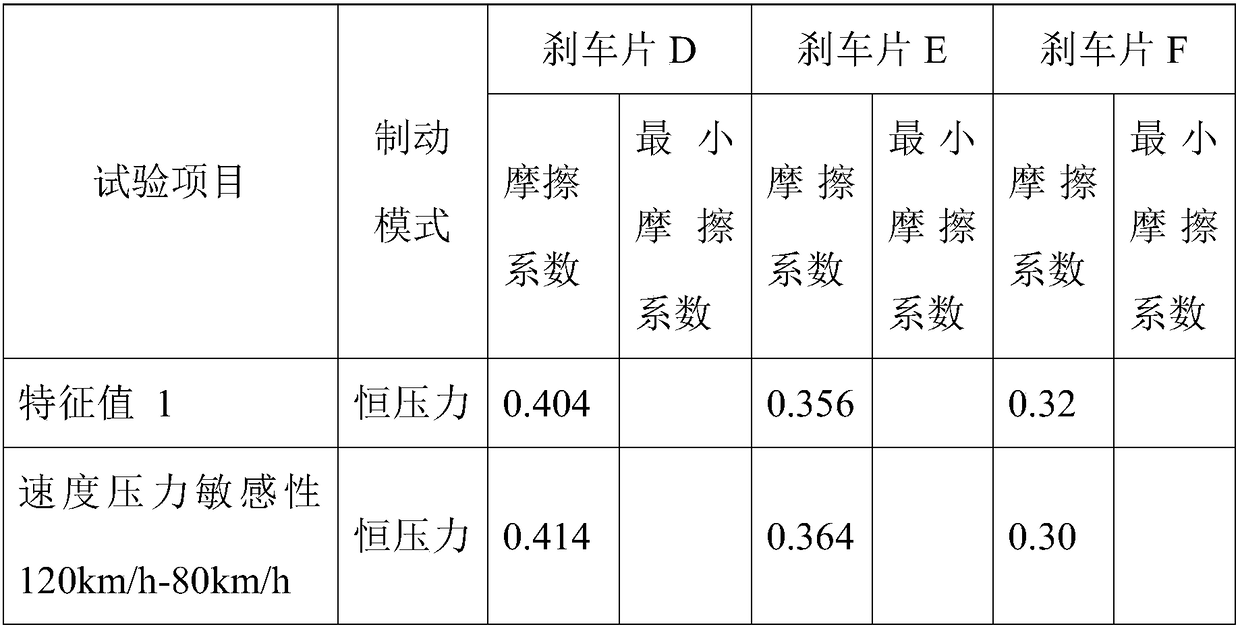

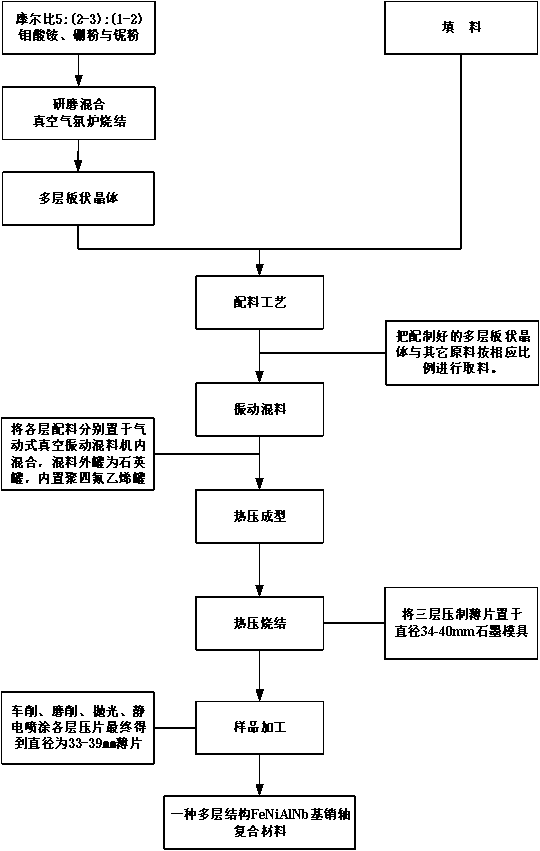

Tribological design and preparation method of FeNiAlNb-based pin shaft multilayer composite structure material

ActiveCN110626016AImprove tribological propertiesModerate coefficient of frictionLamination ancillary operationsLaminationAlloyThermal stability

The invention discloses a tribological design and preparation method of an FeNiAlNb-based pin shaft multilayer composite structure material. A FeNiAlNb matrix, an antifriction agent, an anti-wear agent and a reinforcing agent are adopted as the components, a multi-element tabular crystal is prepared, by means of each layer material component design and computation, vibration mixing, hot press molding, multi-layer structure compounding and subsequent machining procedures, the FeNiAlNb-based pin shaft multilayer composite structure material can be prepared. Through reasonable design and optimalproportioning of the matrix alloy, the antifriction agent, the anti-wear agent and the reinforcing agent on a friction film, a bearing transition layer and a matrix bearing layer, the material utilization rate is improved, the production cost is reduced, and the FeNiAlNb-based pin shaft multilayer composite structure material can meet the friction and wear properties under high-low temperature andhigh-load working conditions while having excellent thermal stability and mechanical properties, and also significantly enhances the use precision and service life of the pin shaft on the premise ofobviously improving the connection strength and bearing capacity of the pin shaft.

Owner:ANYANG INST OF TECH

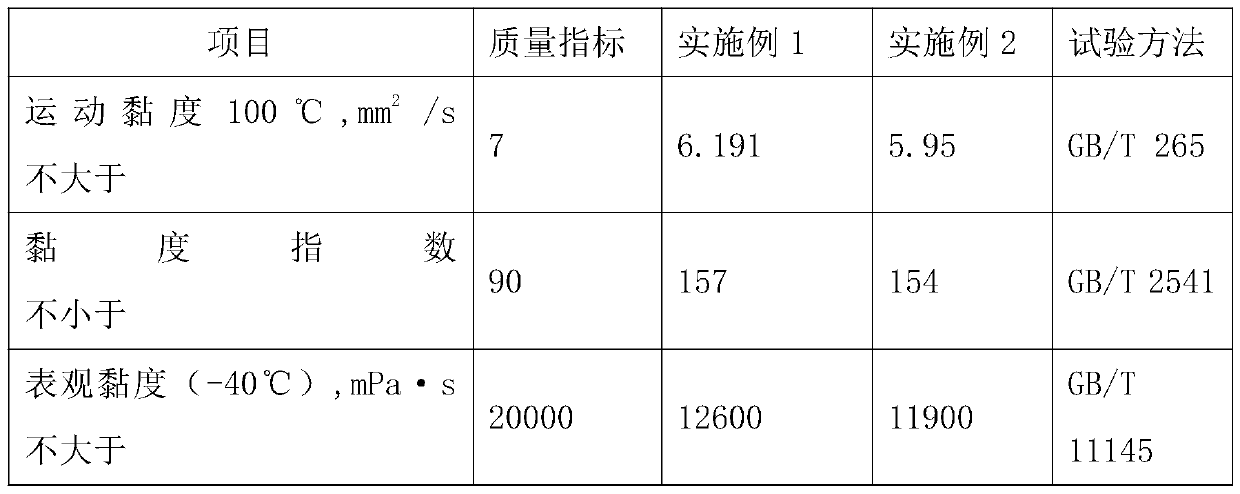

Lubricating oil specially used for hybrid electric vehicle transmission

InactiveCN109705959AImprove insulation performanceGood wear protectionLubricant compositionClutchElectric vehicle

The invention relates to the field of lubricating oil and especially relates to lubricating oil specially used for a hybrid electric vehicle transmission. The lubricating oil includes, by mass, 87.7-89.7 parts of base oil Yubase 4, 0.5 parts of an additive LK1-300, 1.0-3.0 parts of an additive LK12-095 and 8.8 parts of an additive LK4165B, wherein the total mass part of the base oil Yubase 4, theadditive LK1-300, the additive LK12-095 and the additive LK4165B is 100 parts. The lubricating oil has high insulation performance, excellent abrasion protective capability and excellent temperature increase character. The lubricating oil also can supply a proper friction coefficient to clutches.

Owner:山东莱克科技有限公司

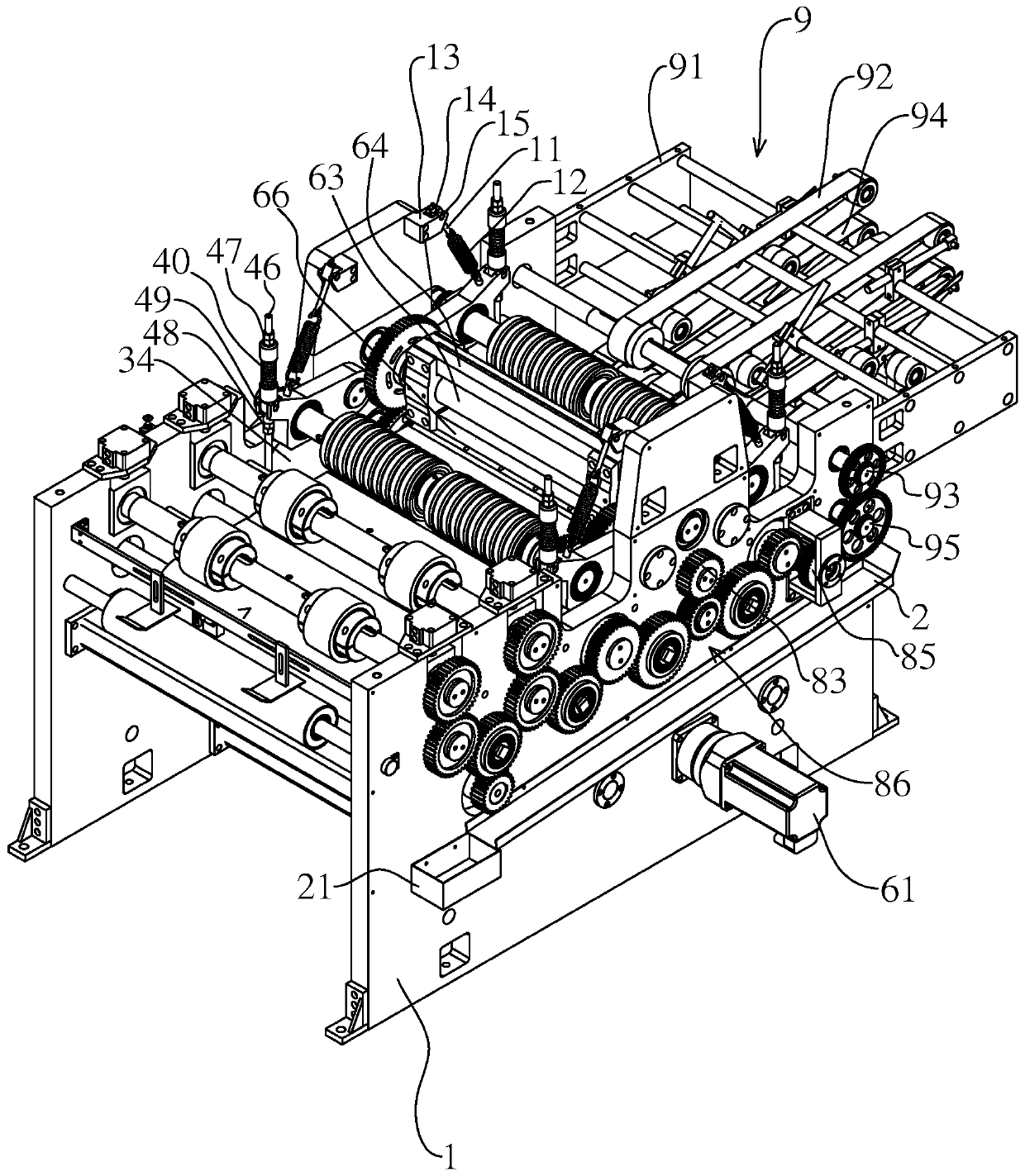

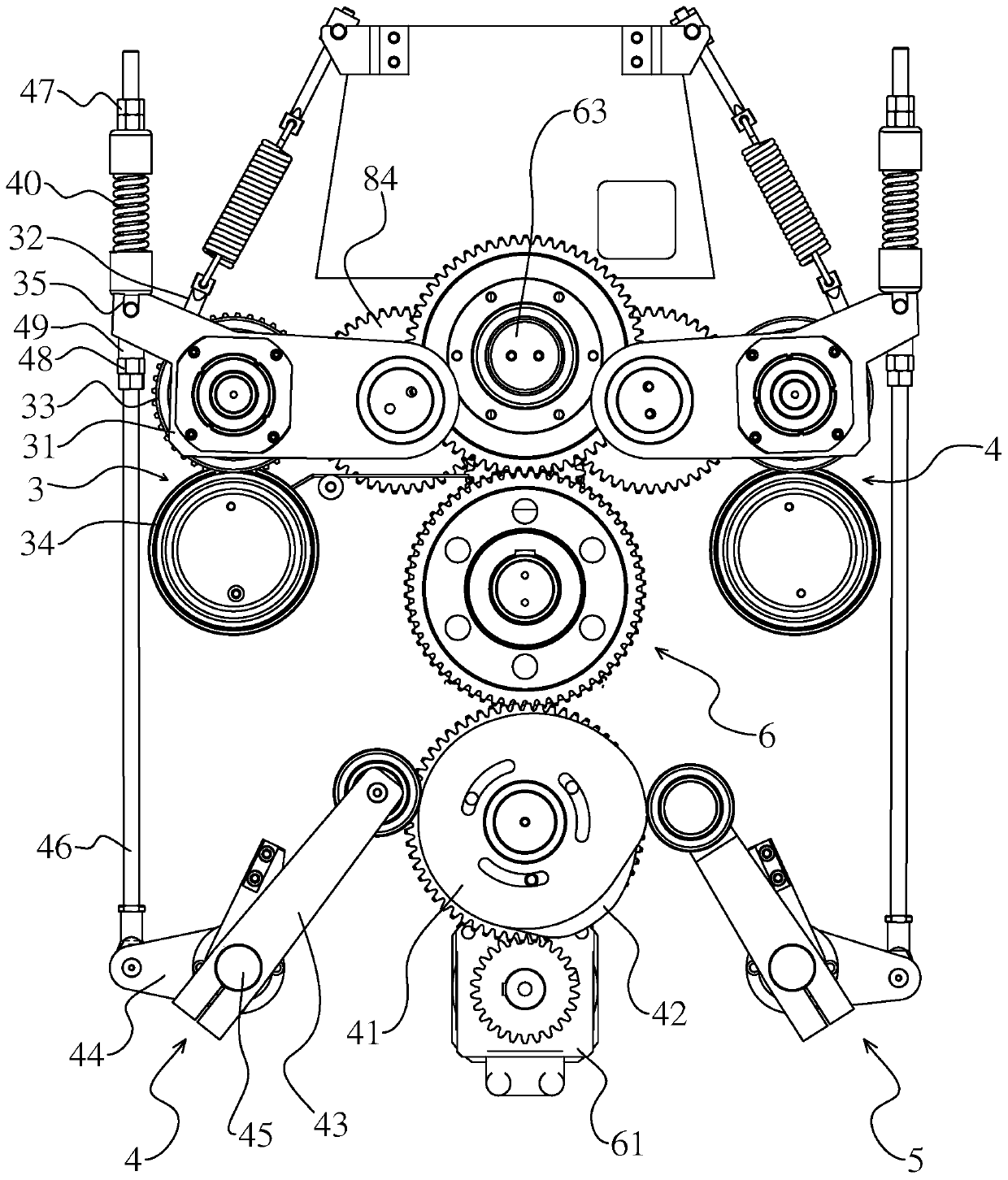

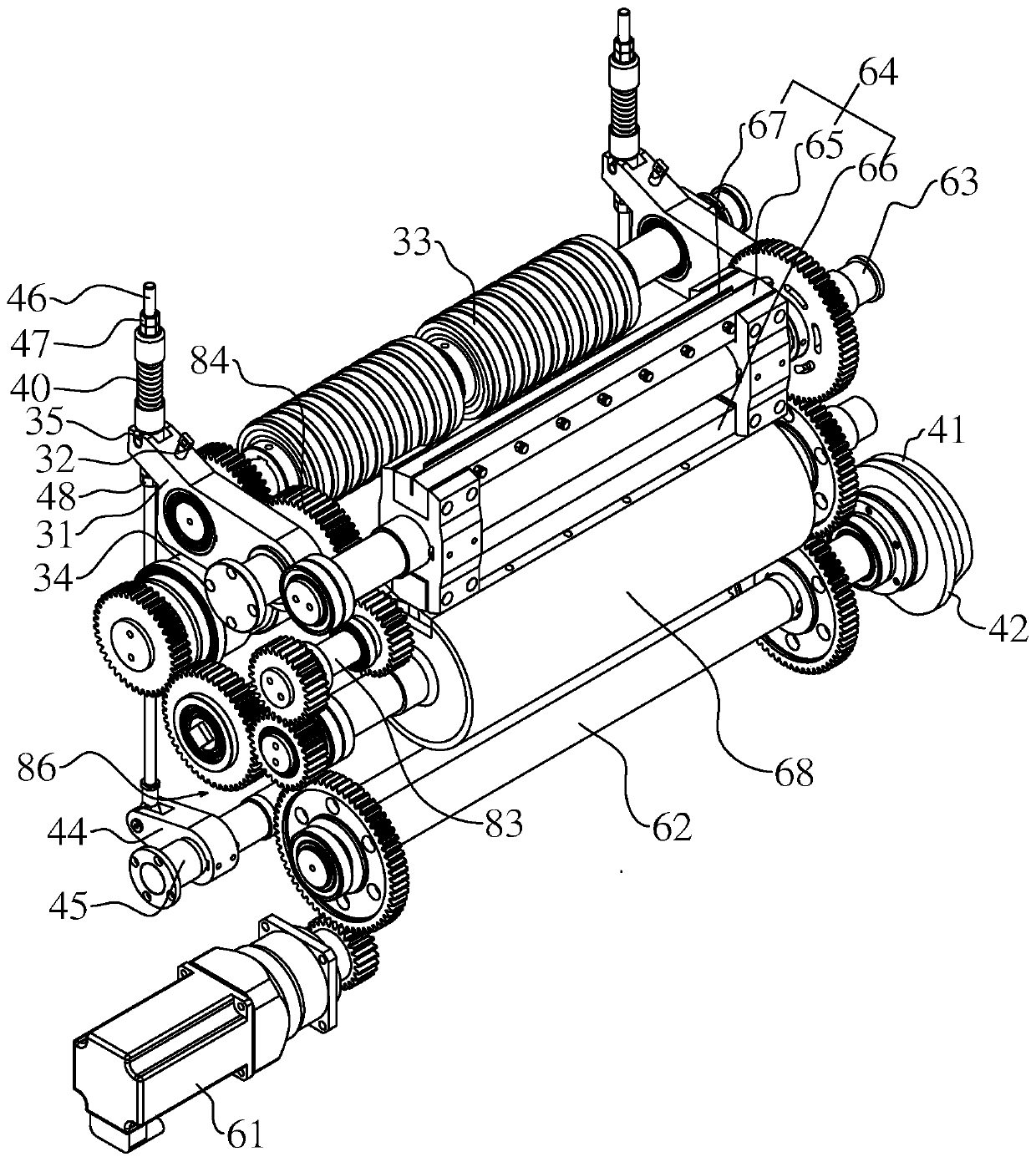

Paper bag barrel pull-apart device of barrel-making machine

ActiveCN111531962AGuaranteed accuracyTransmission speed does not affectBag making operationsPaper-makingPaper sheetElectrical and Electronics engineering

The invention relates to a paper bag barrel pull-apart device of a barrel making machine. The paper bag barrel pull-apart device comprises a rack, and further comprises a front pull-apart mechanism and a rear pull-apart mechanism which are arranged on the rack; each of the front pull-apart mechanism and the rear pull-apart mechanism comprises a lower pull-apart part, an upper pull-apart part and amaterial breaking swing arm; the two ends of each lower pull-apart part are rotationally installed on the rack, two material breaking swing arms are arranged and one end of each material breaking swing arm is rotationally installed on the rack, and the upper pull-apart part is rotationally installed between the material breaking swing arms and located at the ends, opposite to the rack, of the material breaking swing arms; the rack is provided with a transmission assembly for driving the lower pull-apart parts and the upper pull-apart parts to rotate, and the conveying speed of the lower pull-apart part and the upper pull-apart part in the front pull-apart mechanism is smaller than that of the lower pull-apart part and the upper pull-apart part in the rear pull-apart mechanism; and the rack is further provided with a reciprocating mechanism for driving the front pull-apart mechanism and the rear pull-apart mechanism to synchronously press down and lift up, so that the influence on thetraction accuracy of the strip-shaped paper in the pull-apart process is reduced.

Owner:FOSHAN TECON PACKAGE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com