High-performance ternary compound brake pad

A ternary composite and brake pad technology, applied in the field of auto parts, can solve the problems of easy brittle cracking of corners, high wear resistance, poor thermal conductivity, etc., and achieve the effects of strong temperature resistance, long service life and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

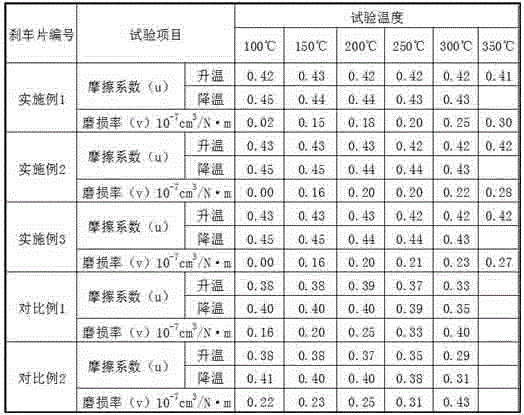

specific Embodiment 1

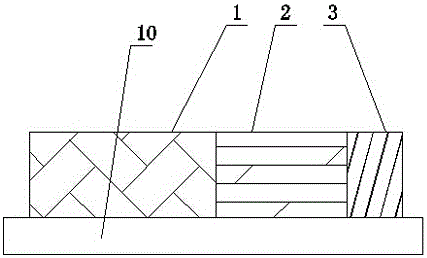

[0013] Specific embodiment one: as figure 1 As shown, the high-performance ternary composite brake pad includes a steel back 10 and a brake pad body, which is characterized in that the brake pad body is composed of a pre-friction area 1, a main friction area 2, and a heat dissipation area 3 in parallel.

[0014] Among them, the pre-friction area consists of 8 parts of basalt fiber (1000 grams per part, the same below), 7 parts of boron phenolic resin, 7 parts of ceramic fiber, 8 parts of polyacrylonitrile preoxidized fiber, 6 parts of nitrile rubber, and 15 parts of calcium sulfate whisker. 15 parts of barite, 5.5 parts of flake graphite, 6 parts of cashew oil friction powder, and 5 parts of zircon powder;

[0015] The main friction zone is made of the following component proportions in parts by weight:

[0016] The main friction area consists of 9 parts of PROMAXON®-D calcium silicate particles, 5 parts of fused magnesia, 0.2 parts of fused zirconia, 4 parts of aramid fiber,...

specific Embodiment 2

[0019] Specific embodiment two: as figure 1 As shown, the high-performance ternary composite brake pad includes steel, 10, and a brake pad body, which is characterized in that the brake pad body is composed of a pre-friction area 1, a main friction area 2, and a heat dissipation area 3; the pre-friction area is made of basalt 10 parts of fiber, 8 parts of boron phenolic resin, 8 parts of ceramic fiber, 15 parts of polyacrylonitrile preoxidized fiber, 10 parts of nitrile rubber, 17 parts of calcium sulfate whisker, 17 parts of barite, 7 parts of flake graphite, cashew nut oil Composed of 8 parts of friction powder and 8 parts of zircon powder;

[0020] The main friction area consists of 10 parts of PROMAXON®-D calcium silicate particles, 6 parts of fused magnesia, 0.3 parts of fused zirconia, 6 parts of aramid fiber, 10 parts of ceramic fiber, 2.5 parts of tire powder, and 6 parts of expanded vermiculite , 6 parts of potassium titanate whiskers, 7 parts of flake graphite, 8 pa...

specific Embodiment 3

[0023] Specific embodiment three: as figure 1 As shown, the high-performance ternary composite brake pad includes a steel back 10 and a brake pad body, which is characterized in that the brake pad body is composed of a pre-friction area 1, a main friction area 2, and a heat dissipation area 3; the pre-friction area is made of basalt 9 parts of fiber, 8 parts of boron phenolic resin, 7.5 parts of ceramic fiber, 14 parts of polyacrylonitrile preoxidized fiber, 7 parts of nitrile rubber, 16 parts of calcium sulfate whisker, 16 parts of barite, 6 parts of flake graphite, cashew nut oil Composed of 7 parts of friction powder and 6 parts of zircon powder;

[0024] The main friction area consists of 10 parts of PROMAXON®-D calcium silicate particles, 5.5 parts of fused magnesia, 0.23 parts of fused zirconia, 5 parts of aramid fiber, 9 parts of ceramic fiber, 2.2 parts of tire powder, and 5.2 parts of expanded vermiculite , 4 parts of potassium titanate whiskers, 6 parts of flake gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com