Friction material, organic carbon-ceramic brake pad for light-weight carbon-ceramic plate prepared from friction material, as well as preparation method and application thereof

A friction material and lightweight technology, applied in the field of brake materials, can solve the problems of poor matching of lightweight carbon-ceramic brake discs, and achieve the effects of lightweight, improved friction noise and good workmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

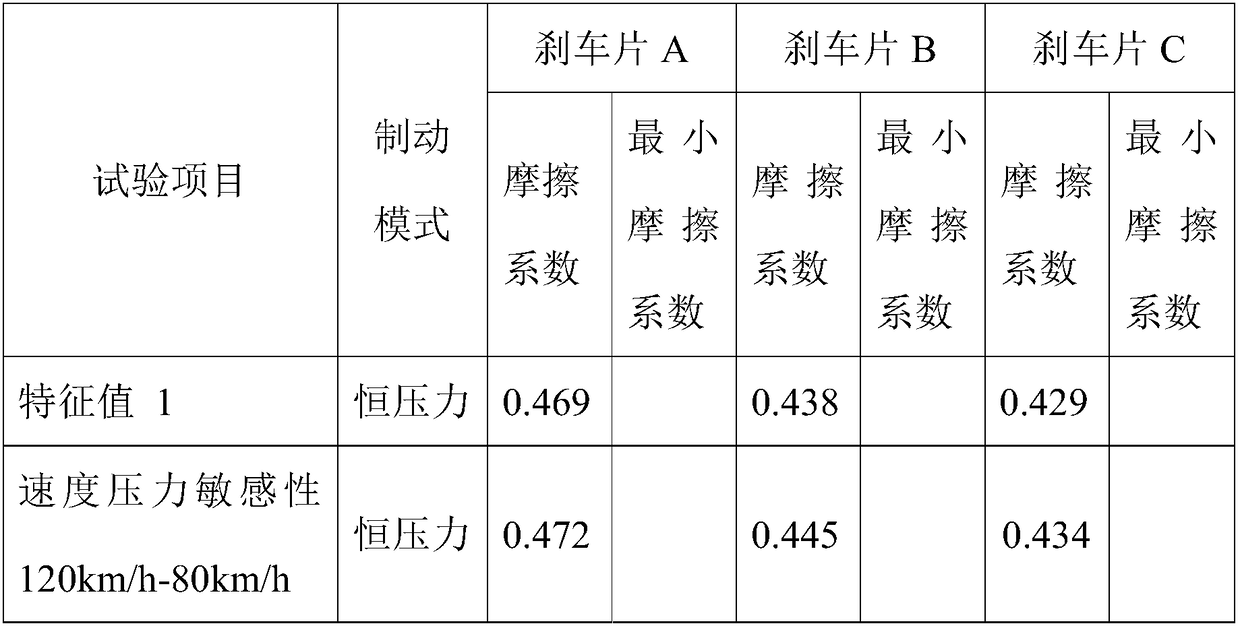

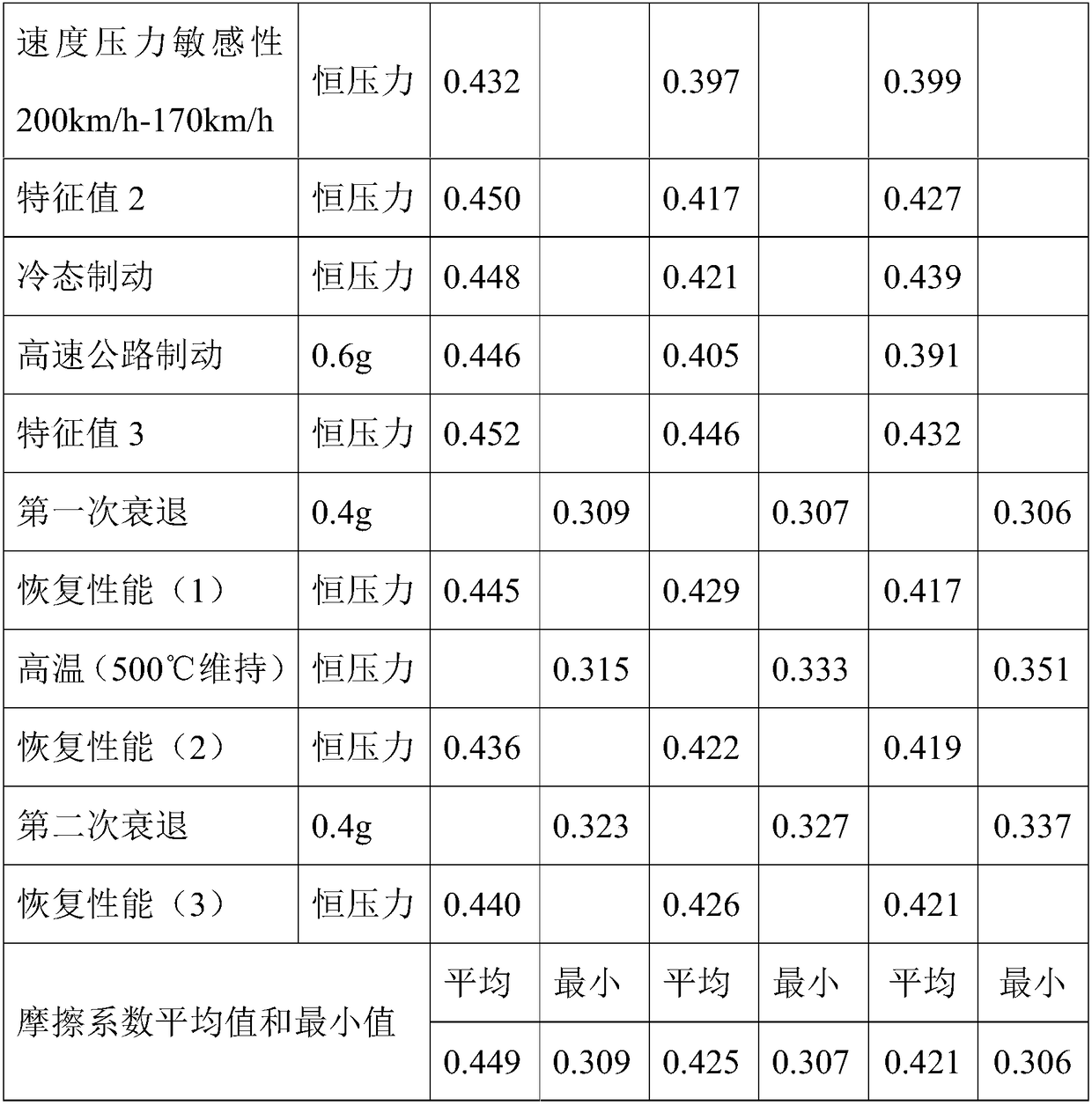

Embodiment 1

[0028] This embodiment provides an organic carbon-ceramic brake pad for lightweight carbon-ceramic discs. The friction material includes the following raw materials in parts by weight: 2 parts of basalt fiber, 15 parts of steel fiber, 5 parts of mineral fiber, and 12 parts of boron phenolic resin. 10 parts, 10 parts of elastic particles, 6 parts of cashew oil friction powder, 20 parts of precipitated barium sulfate, 3 parts of acrylic fiber, 2 parts of silicon carbide, 6 parts of diatomaceous earth, and 12 parts of glass microspheres.

[0029] Prepare according to the steps of the following preparation method according to the above proportioning ratio:

[0030] (1) Mixing step, accurately weigh each component, and mix for 40 minutes;

[0031] (2) pressing step, steel back and mixed material are placed in the mould, 15Mpa is pressed 350s to become blank;

[0032] (3) In the curing step, the pressed blank is heated to 190° C. for 8 hours to obtain the final brake pad A.

Embodiment 2

[0034] This embodiment provides an organic carbon-ceramic brake pad for lightweight carbon-ceramic discs. The friction material includes the following raw materials in parts by weight: 4 parts of basalt fiber, 10 parts of steel fiber, 10 parts of mineral fiber, boron phenolic resin 8 parts, 5 parts of elastic particles, 10 parts of cashew oil friction powder, 10 parts of precipitated barium sulfate, 1 part of acrylic fiber, 4 parts of silicon carbide, 11 parts of diatomaceous earth, 9 parts of glass microspheres.

[0035] Prepare according to above-mentioned proportioning with following preparation method:

[0036] (1) Mixing step, accurately weigh each component, and mix for 60 minutes;

[0037] (2) pressing step, the steel back and the mixed material are placed in the mould, and 20Mpa is pressed for 420s to become a blank;

[0038] (3) In the curing step, the pressed blank is heated to 220° C. for 12 hours to be cured to obtain a brake pad B.

Embodiment 3

[0040] This embodiment provides an organic carbon-ceramic brake pad for lightweight carbon-ceramic discs. The friction material includes the following raw materials in parts by weight: 4 parts of basalt fiber, 13 parts of steel fiber, 8 parts of mineral fiber, boron phenolic resin 10 parts, 7 parts of elastic particles, 8 parts of cashew oil friction powder, 15 parts of precipitated barium sulfate, 2 parts of acrylic fiber, 3 parts of silicon carbide, 9 parts of diatomaceous earth, 11 parts of glass microspheres.

[0041]Prepare according to above-mentioned proportioning with following preparation method:

[0042] (1) Mixing step, accurately weigh each component, and mix for 45 minutes;

[0043] (2) pressing step, the steel back and the mixed material are placed in the mould, and 18Mpa is pressed for 380s to become a blank;

[0044] (3) In the curing step, the pressed blank is heated to 210° C. for 10 h to prepare the brake pad C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com