Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

384 results about "Polyethylene membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-layer, microporous polyethylene membrane, and battery separator and battery using same

InactiveUS20090117453A1Improve balanceMaintain good propertiesSynthetic resin layered productsSecondary cellsPolymer scienceGlass transition

A multi-layer, microporous polyethylene membrane having at least three layers comprising (a) a first microporous layer amount of a polyethylene resin and constituting at least both surface layers, and (b) at least one second microporous layer made of a polyethylene resin, a heat-resistant resin having a melting point or glass transition temperature of 150° C. or higher and a filler, and sandwiched by both surface layers.

Owner:TORAY BATTERY SEPARATOR FILM

Polyethylene multilayer microporous membrane, battery separator using same, and battery

InactiveCN101208198AImprove permeabilityExcellent mechanical propertiesSynthetic resin layered productsSecondary cellsVitrificationSurface layer

A multi-layer, microporous polyethylene membrane having at least three layers comprising (a) a first microporous layer amount of a polyethylene resin and constituting at least both surface layers, and (b) at least one second microporous layer made of a polyethylene resin, a heat-resistant resin having a melting point or glass transition temperature of 150°C or higher and a filler, and sandwiched by both surface layers.

Owner:东丽东燃机能膜合同会社

High tear films from hafnocene catalyzed polyethylenes

InactiveUS20050058847A1Good orientationEasy to processSynthetic resin layered productsThin material handlingHafniumSecant modulus

A polyethylene film having a balance of improved physical and mechanical properties and a method for making the same are provided. In one aspect, the film includes a 1% secant modulus of greater than 25,000 psi, a dart impact resistance of greater than 500 g / mil, and a MD tear strength of greater than 500 g / mil. In one aspect, the method comprises reacting ethylene derived units and a comonomer in the presence of a hafnium-based metallocene at a temperature of from 70° C. and 90° C., an ethylene partial pressure of from 120 psia and 260 psia, and a comonomer to ethylene ratio of from 0.01 to 0.02 to produce an ethylene based polymer. The method further comprises extruding the ethylene based polymer at conditions sufficient to produce a polyethylene film comprising a secant modulus of greater than 25,000 psi, a dart impact resistance of greater than 500 g / mil, and a MD tear strength of greater than 500 g / mil.

Owner:UNIVATION TECH LLC

Polyethylene membrane

The invention relates to the technical field of high molecular material, in particular to a light weight polyethylene film. In order to solve the technical problem, the invention discloses the light weight polyethylene film which is prepared through the following raw materials by weight portion: 2 to 50 portions of polyethylene film composite parent material, and 50 to 98 portions of polyethylene, wherein the polyethylene film composite parent material is prepared through the following raw materials by weight portion: 80 to 100 portions of filler, 5 to 25 portions of polyolefin, 10 to 15 portions of poly-modifier, 11 to 15 portions of fatty acid, 2 to 8 portions of mineral oil, 2 to 3 portions of coupling agent, and 0.1 to 0.08 portions of crosslinking agent. The specific gravity of the light weight polyethylene film is between 0.8 and 0.95g / cm. The key physical properties of the light weight polyethylene film are not reduced while the cost of the finished product film is reduced simultaneously. The fracture elongation rate is more than or equal to 150 percent; the tensile property is more than or equal to 25MPa; and the thermal sealing strength is more than or equal to 6.0.

Owner:SHANGHAI RUNLONG PACKING

Production method of microporous polyethylene membrane and battery separator

InactiveUS20090269672A1Well-balanced permeability and mechanical propertyEasy to controlSemi-permeable membranesMembranesPolymer sciencePore diameter

A microporous polyethylene membrane having well-balanced permeability, mechanical properties, heat shrinkage resistance, compression resistance, electrolytic solution absorbability, shutdown properties and meltdown properties, with an average pore diameter changing in a thickness direction is produced by melt-blending a polyethylene resin and a membrane-forming solvent to prepare a solution A having a resin concentration of 25 to 50% by mass and a solution B having a resin concentration of 10 to 30% by mass, the resin concentration in the solution A being higher than that in the solution B, (a) simultaneously extruding the resin solutions A and B through a die, cooling the resultant extrudate to provide a gel-like sheet in which the resin solutions A and B are laminated, and removing the membrane-forming solvent from the gel-like sheet, or (b) extruding the resin solutions A and B through separate dies, removing the membrane-forming solvent from the resultant gel-like sheets A and B to form microporous polyethylene membranes A and B, and alternately laminating the microporous polyethylene membranes A and B, while easily controlling the average pore diameter distribution in the microporous polyethylene membrane in a thickness direction.

Owner:TORAY IND INC

Multi-layer, microporous polyethylene membrane, battery separator formed thereby and battery

ActiveUS20090148761A1Well-balanced resistanceFinal product manufactureSynthetic resin layered productsPolymer scienceGlass transition

A multi-layer, microporous polyethylene membrane comprising (a) a first microporous layer made of a polyethylene resin, and (b) a second microporous layer comprising a polyethylene resin, and a heat-resistant polymer having a melting point or a glass transition temperature of 170° C. or higher, the heat-resistant polymer being dispersed in the form of fine particles in the polyethylene resin, and the second microporous layer having pores containing fine particles of the heat-resistant polymer as nuclei from which the cleavage of polyethylene resin fibrils starts, the multi-layer microporous polyethylene membrane having well-balanced shutdown properties, meltdown properties, permeability, mechanical strength, heat shrinkage resistance and compression resistance.

Owner:TORAY IND INC

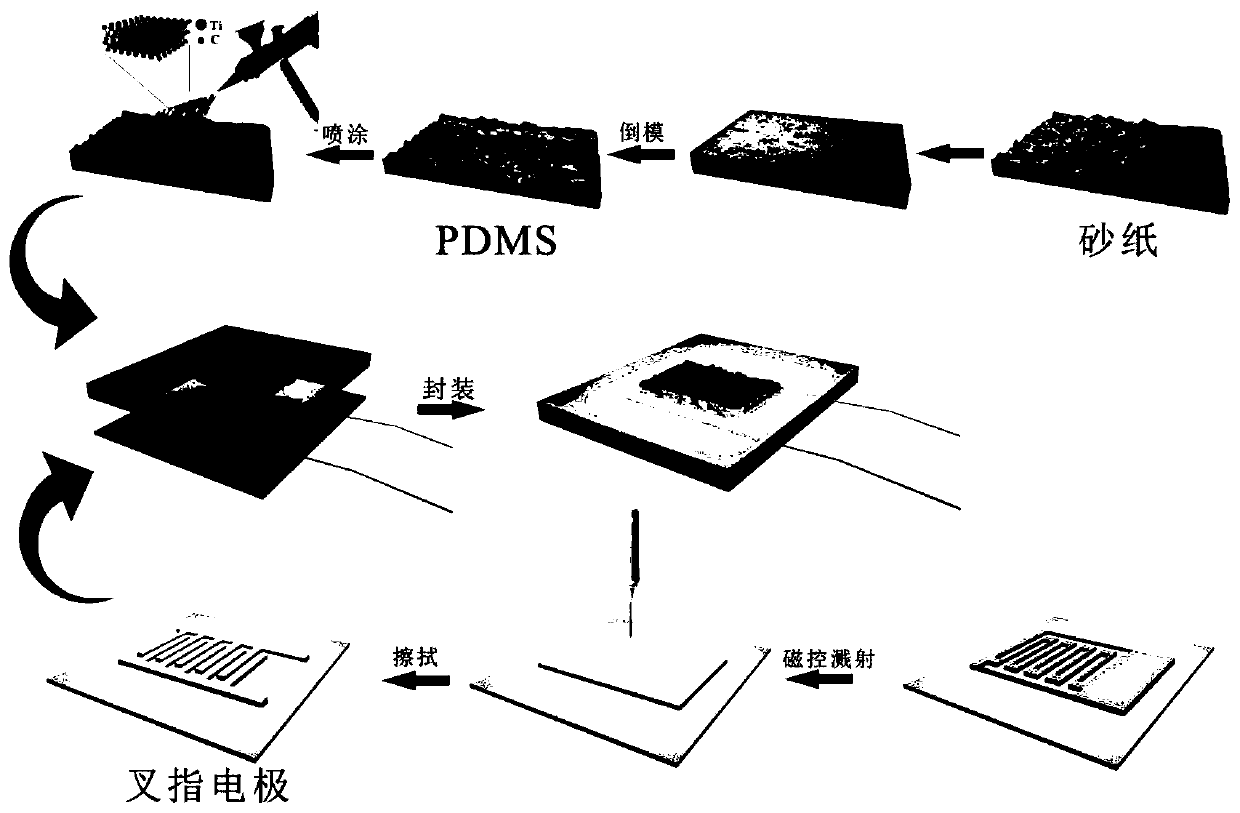

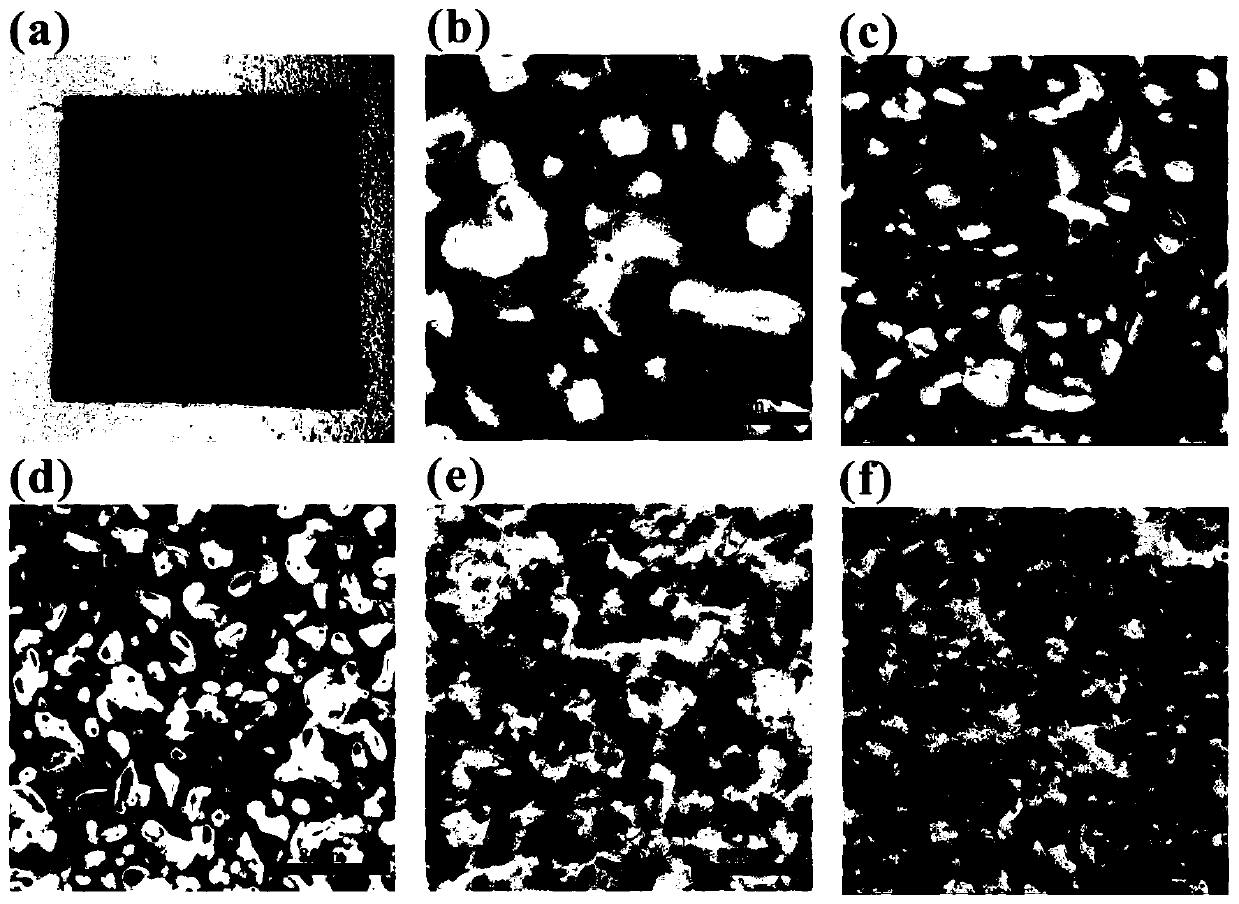

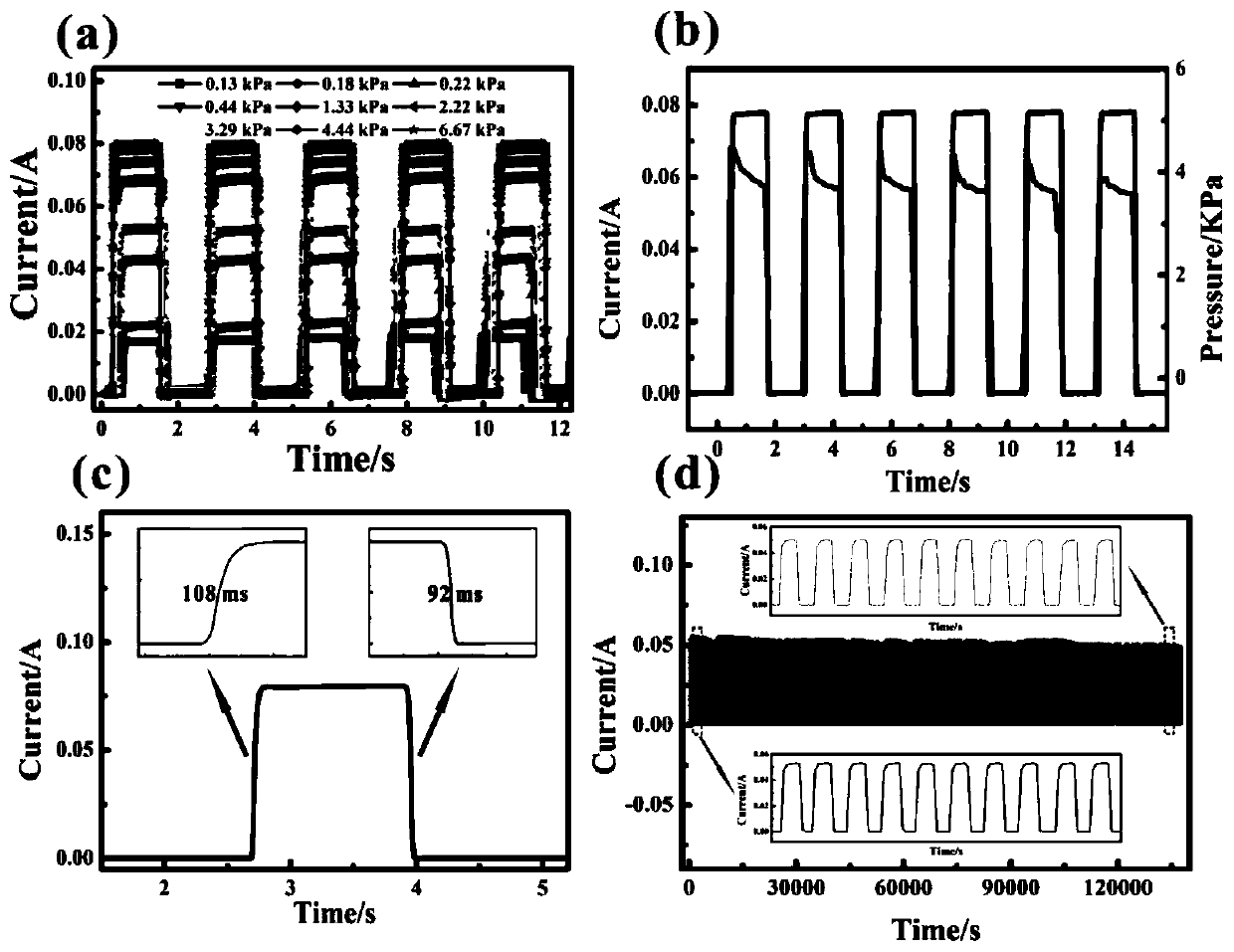

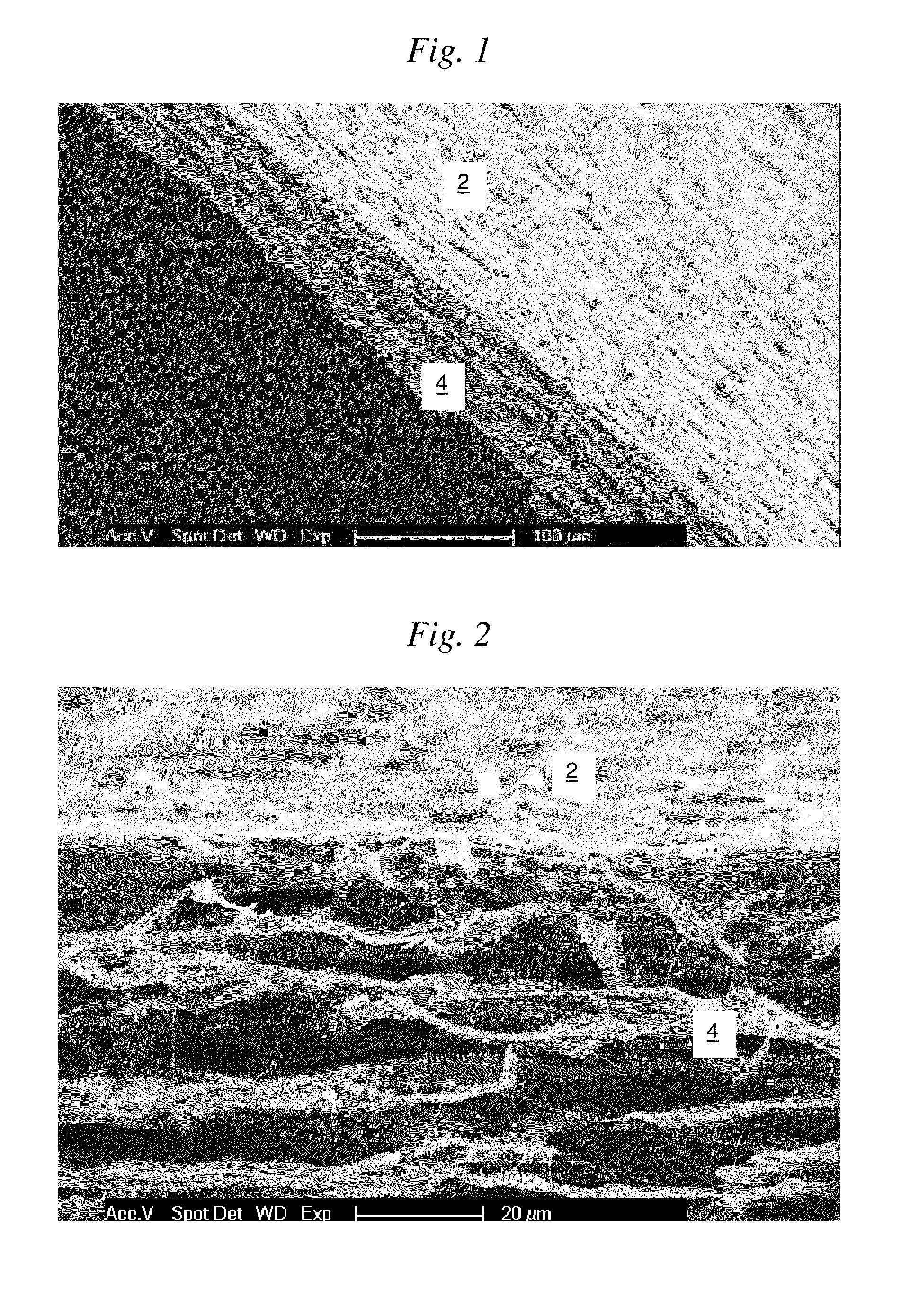

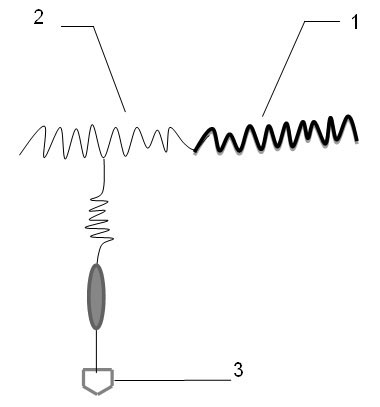

High-sensitivity flexible piezoresistive sensor based on MXene bionic skin structure

InactiveCN110579297AHigh sensitivityLow costFluid pressure measurement using ohmic-resistance variationForce measurementSputteringSilica gel

The invention discloses a high-sensitivity flexible piezoresistive sensor based on an MXene bionic skin structure. The high-sensitivity flexible piezoresistive sensor comprises a flexible interdigitalelectrode layer, an MXene-based silica gel bionic layer and a packaging layer; the MXene-based silica gel bionic layer is prepared by obtaining a film with a bionic skin structure through silica gelimpression abrasive paper and then coating the bionic film with the film; the flexible interdigital electrode layer is obtained through ink-jet printing and magnetron sputtering; the MXene-based silica gel bionic layer is in direct contact with an electrode area to form a loop; and the packaging material is preferably a polyethylene film. The flexible pressure-sensitive sensor provided by the invention has extremely high sensitivity, low detection limit, short response time and high stability, and shows great application potential in practical application of electronic skin, wearable electronic devices and the like. The sensor solves the problems that an existing MXene-based piezoresistive sensor is complex in preparation process and difficult to have high sensitivity and stability at thesame time.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

Microporous polyethylene membrane, its production method and battery separator

InactiveUS20100151310A1High electrolytic solution absorption speedAir permeability littleMembranesSemi-permeable membranesPore diameterSolvent

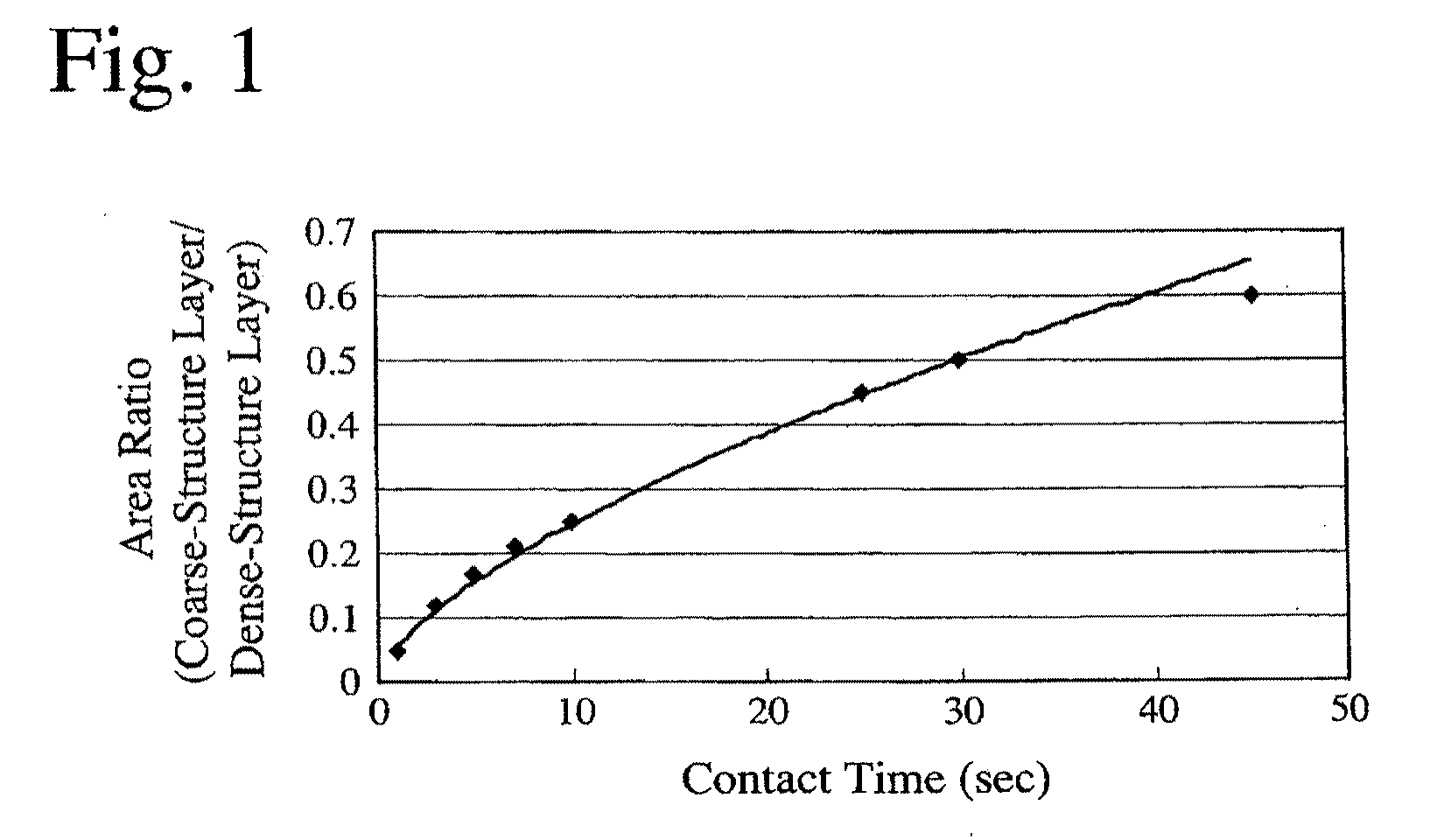

A microporous polyethylene membrane made of a polyethylene resin comprising 15% or less by mass of ultra-high-molecular-weight polyethylene having a mass-average molecular weight of 1×106 or more, which is constituted by a dense-structure layer having an average pore diameter of 0.01 to 0.05 μm, and a coarse-structure layer formed on at least one surface and having an average pore diameter 1.2-fold to 5.0-fold of that of the dense-structure layer, has a high electrolytic solution absorption speed with thickness and air permeability little changing when compressed. Such a microporous polyethylene membrane is produced by extruding a melt blend of the above polyethylene resin and a membrane-forming solvent through a die, cooling the resultant extrudate with a temperature distribution in a thickness direction to provide a gel-like sheet, stretching the gel-like sheet at a temperature from the crystal dispersion temperature of the polyethylene resin +10° C. to the crystal dispersion temperature +30° C., removing the membrane-forming solvent, and stretching the membrane again to 1.05-fold to 1.45-fold.

Owner:TORAY BATTERY SEPARATOR FILM

Polyethylene microporous membrane, process for production thereof, and battery separator

InactiveCN101233176AImprove breathabilityImprove featuresCell component detailsPolymer sciencePore diameter

PROBLEM TO BE SOLVED: To provide a microporous polyethylene membrane exhibiting little change in thickness and air permeability during compression and having a rapid electrolyte-absorption rate, and to provide its production method and a battery separator formed by such microporous polyethylene membrane.SOLUTION: The microporous polyethylene membrane is made of a polyethylene resin comprising ≤15 mass% of ultra-high molecular weight polyethylene having a mass-average molecular weight of ≥1 x 10<SP POS="POST">6< / SP>. The microporous polyethylene membrane is a single film that has a densely-structured layer comprising an average pore diameter of 0.01-0.05 μm and a coarsely-structured layer having an average pore diameter larger by 1.2-5.0 times than that of the densely-structured layer, both structured layers being adjacent to each other in a thickness direction, wherein a coarsely-structured layer is formed at least on one surface.

Owner:TONEN CHEM CORP

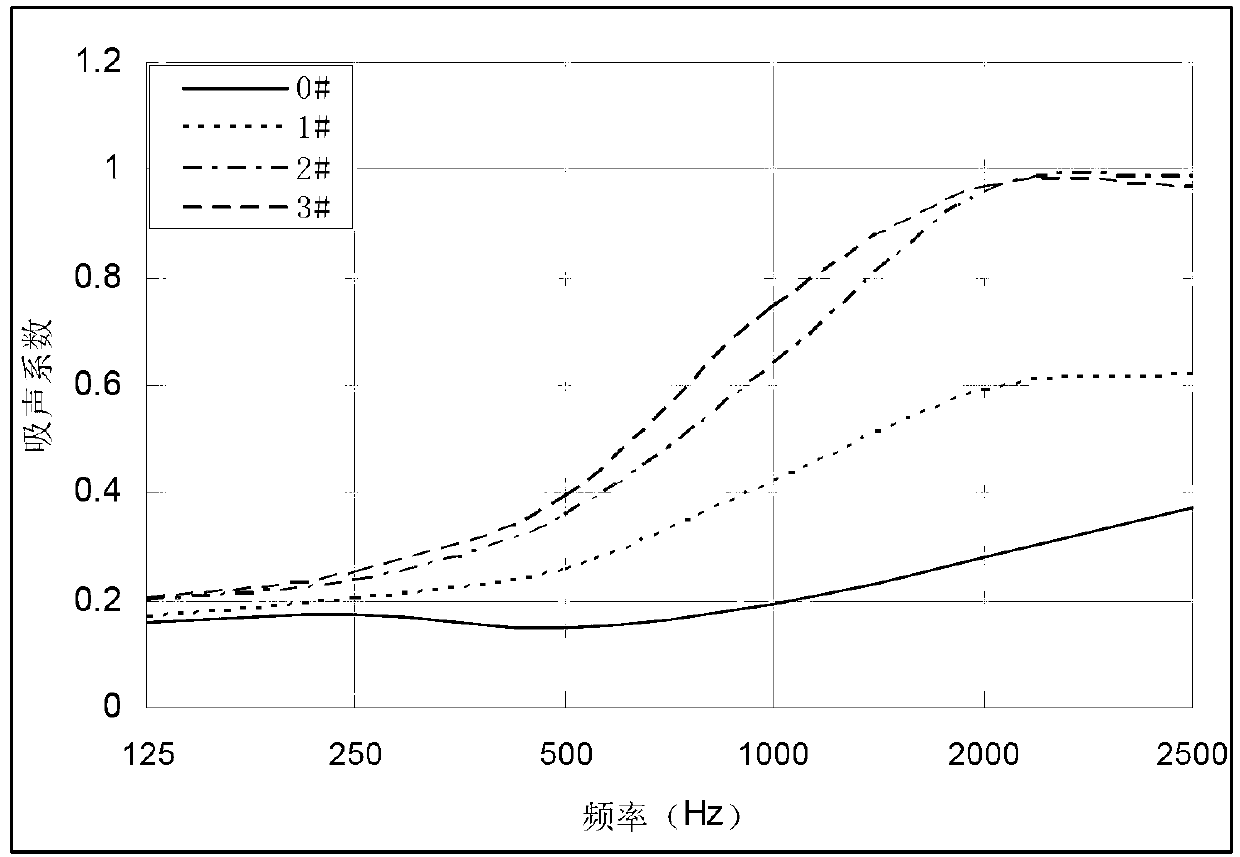

Low-frequency sound absorption needling non-woven composite materials and preparation method thereof and application thereof

InactiveCN103106898AImproved sound absorptionImprove sound absorptionSound proofingSound producing devicesKapok fiberEconomic benefits

The invention relates to low-frequency sound absorption needling non-woven composite materials and a preparation method of the low-frequency sound absorption needling non-woven composite materials and application of the low-frequency sound absorption needling non-woven composite materials. The composite materials comprise kapok fibers or hollow Dacron non-woven fabric and polyethylene films. The preparation method comprises: mixing, opening, carding and meshing are conducted to 60%-90% kapok fibers and 40%-10% hollow Dacron non-woven fabric according to mass percent; a fiber mesh is inputted in a needling machine so as to conduct needling reinforcement, the fiber mesh is reeled and cut off so as to obtain kapok or hollow Dacron needle non-woven fabric; the polyethylene films in 0.06mm-0.10mm are smoothly placed on one side of the needle non-woven fiber mesh, and are composited, taken out and cooled, and then the low-frequency sound absorption needling non-woven composite materials are obtained. The composite materials can be applied to the field of automotive trim, construction, high-speed rail and the like. The sound absorption materials have the advantages of being light in weight, simple in operation of the preparation method, good in economic benefit and suitable for industrial production.

Owner:DONGHUA UNIV

Polyethylene membrane composite master batch

The invention relates to the technical field of high molecular material, in particular to a polyethylene film composite parent material. The invention discloses the polyethylene film composite parent material which is prepared through the following raw materials by weight portion: 80 to 100 portions of filler, 5 to 25 portions of polyolefin, 10 to 15 portions of poly-modifier, 11 to 15 portions of fatty acid, 2 to 8 portions of mineral oil, 2 to 3 portions of coupling agent, and 0.1 to 0.08 portion of crosslinking agent. The specific gravity of the light weight polyethylene film prepared from the polyethylene film composite parent material is between 0.8 and 0.95g / cm<3>. The key physical properties of the light weight polyethylene film are not reduced while the cost of the finished product film is reduced simultaneously. The fracture elongation rate is more than or equal to 150 percent; the tensile property is more than or equal to 25MPa; and the thermal sealing strength is more than or equal to 6.0.

Owner:SHANGHAI RUNLONG PACKING

Microporous polyethylene membranes having low fusing temperatures

InactiveUS6168858B1High porosityRelation between porousness and fuse effect can be better improvedPrimary cell maintainance/servicingLayered productsPolymer chemistryPolyethylene membrane

A polyethylene microporous film which is composed of a linear copolymeric polyethylene having a melt index (MI) of less than 0.1 and a propylene unit content of 0.1 to 4 mol % and which has a fuse temperature of less than 136° C. A polyethylene microporous film which is composed of a mixture of a linear copolymeric polyethylene having a melt index (MI) of less than 0.1 and a propylene unit content of 0.1 to 4 mol % and a high density polyethylene having a comonomer unit content of less than 0.1 mol %, said mixture having a weight average molecular weight of 250,000 to 700,000 and a propylene unit content of 0.1 to 4 mol %, and which has a fuse temperature of less than 136° C.

Owner:ASAHI KASEI KK

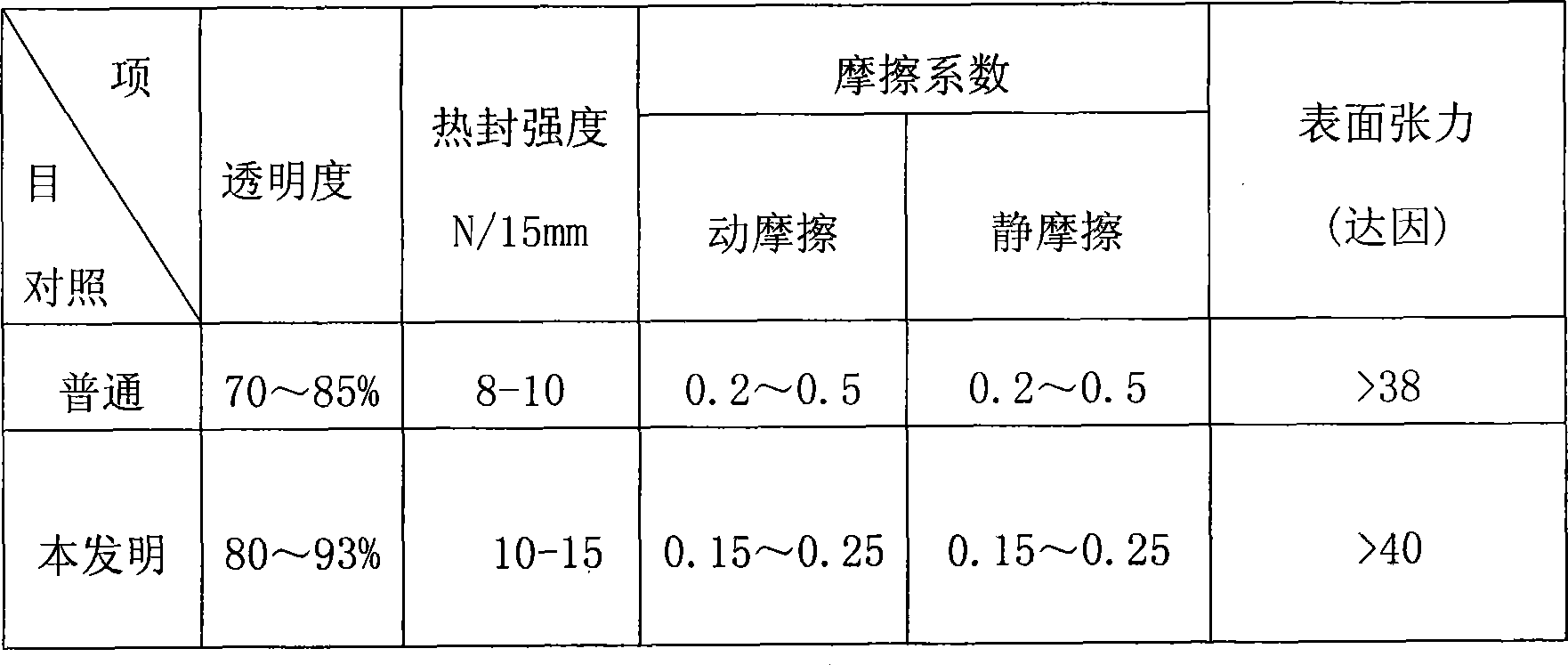

Self-lubricating polyethylene membrane

InactiveCN101475074AMechanical supporting adaptability is strongIncrease productivityFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention discloses a self-lubricating polyethylene membrane. The membrane consists of an outer layer, an intermediate layer and an inner layer, wherein the outer layer contains low density polyethylene and linear low density polyethylene with a weight ratio of 1:0.5-2; the intermediate layer contains low density polyethylene and linear low density polyethylene with a weight ratio of 1:0.5-5; and the inner layer contains low density polyethylene, linear low density polyethylene, metallocene linear low density polyethylene, a slipping agent and an auxiliary agent with a weight ratio of 1:0.5-2:1-2:0.01-0.02:0.05-0.2. Compared with the prior art, the self-lubricating polyethylene membrane has precise and stable friction coefficient and good transparency and lustrousness, and can realize matched packaging effect with a quick automatic packaging machine.

Owner:HUANGSHAN YONGJIA GRP

Multi-layer, microporous polyethylene membrane, its production method, and battery separator

ActiveUS20090117455A1Well-balanced mechanical strengthWell-balanced permeabilitySemi-permeable membranesMembranesPolymer scienceHigh density

A multi-layer, microporous polyethylene membrane having at least two layers, which comprises (a) a microporous polyethylene resin layer A comprising high-density polyethylene A having 0.2 or more terminal vinyl groups per 10,000 carbon atoms when measured by infrared spectroscopy, and (b) a microporous polyethylene resin layer B comprising high-density polyethylene B having less than 0.2 terminal vinyl groups per 10,000 carbon atoms when measured by infrared spectroscopy, has well-balanced permeability, mechanical strength, heat shrinkage resistance, shutdown properties, meltdown properties and oxidation resistance.

Owner:TORAY IND INC

Polyethylene film resistant to high-temperature steaming and production process of polyethylene film

ActiveCN107283980AHigh mechanical strengthHigh hot viscosityLamination ancillary operationsSynthetic resin layered productsComposite filmPolymer science

The invention provides a polyethylene film resistant to high-temperature steaming and a production process of the polyethylene film. The polyethylene film comprises a corona layer, a middle layer and a heat sealing layer, wherein raw materials of the corona layer, the middle layer and the heat sealing layer comprise metallocene medium-density polyethylene and metallocene high-density polyethylene independently; the difference between the vicat softening point and the melting point of each of metallocene medium-density polyethylene and metallocene high-density polyethylene does not exceed 10 DEG C. The polyethylene film has high mechanical strength, excellent optical performance, low-temperature freezing performance, high heat-sealing strength, high thermo-viscous force, a wide heat-sealing window, low odor, resistance to steaming for 30 min at the temperature of 121 DEG C and other excellent performance and can be used as an inner material of a composite film resistant to high-temperature steaming.

Owner:永新股份(黄山)包装有限公司

Polyethylene membrane and method of its production

ActiveUS20100313753A1Reduce total pressure lossReduce use costCombination devicesSemi-permeable membranesHEPAFiltration

The invention relates to a porous membrane having a particle filtration value of at least 10 under U.S. Military Standard MIL-STD-282 (1956), where the porous membrane is a polyethylene membrane. The membranes according to the invention are particularly useful for filters such as ASHRAE filters, HEPA filters and ULPA filters for example in heating, ventilating, respirators and air conditioning applications.

Owner:LYDALL SOLUTECH

High-temperature steaming resistant and easy-uncovered composite film and manufacturing method thereof

InactiveCN108099303AHigh transparencyMeet safety requirementsSynthetic resin layered productsLaminationComposite filmPolypropylene

The invention discloses a high-temperature steaming resistant and easy-uncovered composite film. The film comprises a surface layer, a barrier layer and a heat sealing layer arranged in sequence; thesurface layer is a single-layer structure or two-layer composite structure or a three-layer composite structure, and comprises a PET film, a nylon film or a polypropylene film; the barrier layer is aluminum foil or aluminized PET; and the heat sealing layer is an inorganic filler modified polyethylene film. The invention also discloses a manufacturing method of the high-temperature steaming resistant and easy-uncovered composite film. The film of the invention can be subjected to high-temperature steaming sterilization, has good transparency, a wide heat sealing window, stable heat sealing strength and excellent uncovering property, and can meet safety performance requirements of medical packaging. After reaching the heat sealing window, the film of the invention does not cause dead sealing compared with a conventional film.

Owner:JIANGYIN BAOBO PACKING

Antifogging agent composition and transparent antifogging window membrane formed therefrom

ActiveCN102627880AGood anti-fog durabilityEasy to prepareOther chemical processesFilm/foil adhesivesPolyesterPolymer science

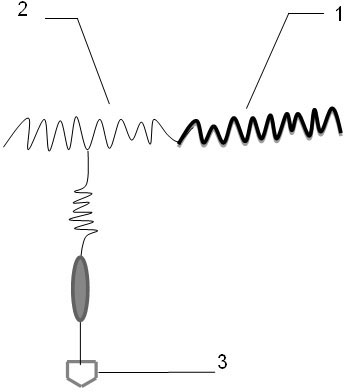

The invention relates to an antifogging agent composition and a transparent antifogging window membrane formed from the composition. The antifogging agent composition consists of 9-14wt% of hydrophilic resin, 55-76wt% of propylene glycol methyl ether, 3-10wt% of dimethyl methylamine, 1-5wt% of triethylenediamine, 1-5wt% of a levelling agent, 5-26wt% of isopropanol, and 5-24wt% of ethanol. The antifogging window membrane is composed of an antifogging agent coating (1), a transparent polyester membrane or transparent polyethylene membrane base material (2), an acrylic adhesive layer (3) and a release membrane (4), and all layers are integrated. The antifogging agent coating (1) is formed by the antifogging agent composition, while the acrylic adhesive layer (3) is formed by a mixture of an acrylic adhesive, a curing agent, toluene and butanone. The transparent antifogging window membrane has effective antifogging function and high light transmittance, as well as a protection effect.

Owner:CHANGZHOU SANYOU DISSAN PROTECTIVE MATERIAL MFG

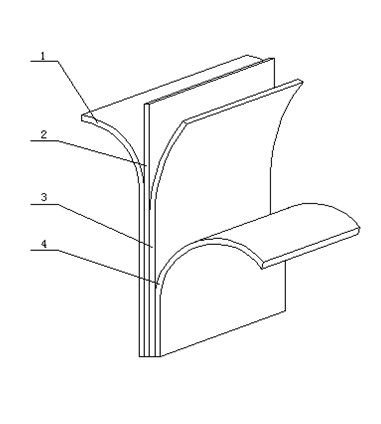

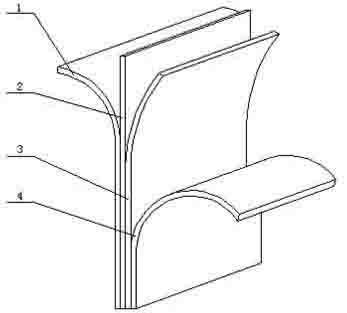

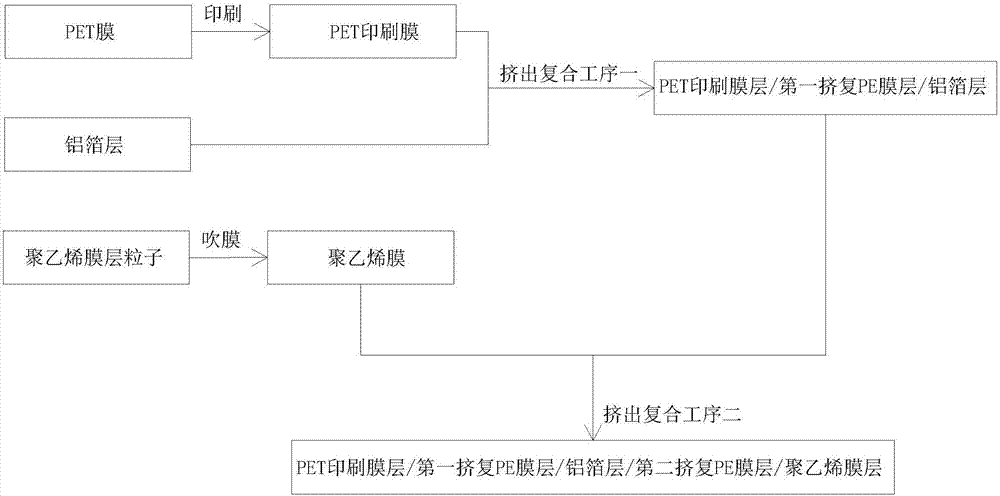

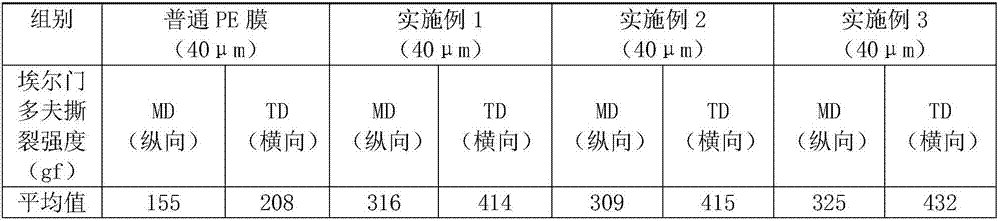

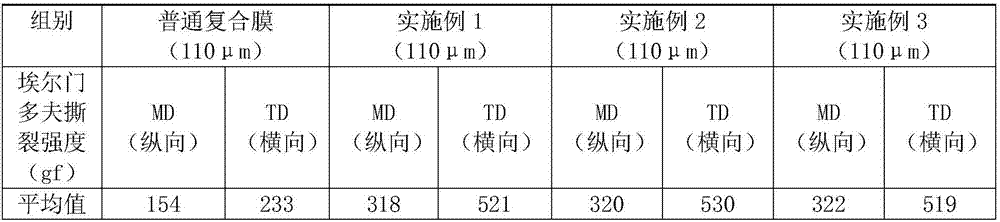

Tear-resistant polyethylene film, composite membrane and preparation method thereof

ActiveCN107323053AHigh peel strengthHigh heat sealing strengthFlexible coversWrappersTear resistanceAluminum foil

The invention relates to a tear-resistant polyethylene film, a composite membrane and a preparation method thereof. The polyethylene film comprises a corona layer, a middle layer and a heat sealing layer, wherein the corona layer and the middle layer are each composed of first metallocene PE, octa-carbon LLDPE and processing aids, and the heat sealing layer is composed of the first metallocene PE, second metallocene PE, silicone, a slipping agent and an opening agent. The composite membrane is formed by a PET printing membrane layer, a first extruded PE membrane layer, an aluminum foil layer, a second extruded PE membrane layer and a polyethylene membrane layer which are sequentially fitted in the membrane layer thickness direction; the extruded PE membrane layer comprises a first adhesive layer in fit with the aluminum foil layer and a second adhesive layer in fit with the PET printing membrane layer or the polyethylene membrane layer, wherein the first adhesive layer is composed of third metallocene PE and adhesive resin, and the second adhesive layer is composed of the third metallocene PE and color master batch. The polyethylene film and the composite membrane disclosed by the invention have higher tear resistance strength. In addition, the composite membrane has excellent humidity resistance property.

Owner:HUANGSHAN NOVEL

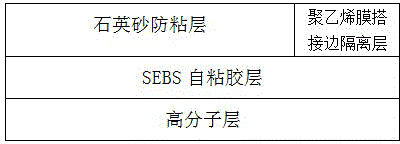

Macromolecular self-adhesive glue film coiled material adopting SEBS self-adhesive glue as self-adhesive layer and production method of macromolecular self-adhesive glue film coiled material

InactiveCN104441816APrevent channelingHigh tensile strengthSynthetic resin layered productsAdhesivesElastomerPolymer science

The invention discloses a macromolecular self-adhesive glue film coiled material adopting SEBS self-adhesive glue as a self-adhesive layer and a production method of the macromolecular self-adhesive glue film coiled material. The coiled material comprises a macromolecular layer, an SEBS self-adhesive glue layer, a quartz sand anti-sticking layer and a polyethylene film overlap edge isolation layer, wherein the tensile strength of the macromolecular self-adhesive glue film coiled material is more than 800N / 50mm, the right-angled tearing strength of the macromolecular self-adhesive glue film coiled material is more than 80N / mm, the shear strength between two coiled materials is more than 550N / 50mm, the macromolecular layer is made of a polyolefins synthesized macromolecular waterproof coiled material, and the SEBS self-adhesive glue layer is prepared by adopting the following raw materials in parts by weight: 5 to 10 parts of SEBS elastomer, 25 to 30 parts of rubber, 35 parts of tackifying resin, 10 parts of a softening agent, 0.3 to 0.5 part of an antioxidant 1010 and 0.3 to 0.5 part of a light stabilizer 770. The product of the macromolecular self-adhesive glue film coiled material has the advantages of simplicity in construction, low requirement for the construction environment, less construction time and low construction cost and also has the advantages of high shear strength, high tensile strength and good waterproof effect.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL

Photoresponse block liquid crystal polymer with crosslinkable property and preparation method thereof

The invention provides a photoresponse block liquid crystal polymer with crosslinkable property and a preparation method thereof. The preparation method of the photoresponse block liquid crystal polymer is not limited by the dimension of a liquid crystal box, thereby being simpler and easier to operate on the aspect of the processing forming of the photoresponse block liquid crystal polymer; and in addition, the invention is not only beneficial to the preparation of large-size membranous materials, but also easy to realize the composite processing with flexible membranes, i.e. polyethylene membranes and the like, greatly enhances the mechanical property of the materials and is beneficial to the development of the photoresponse block liquid crystal polymer as an all-optical driving flexible device.

Owner:FUDAN UNIV

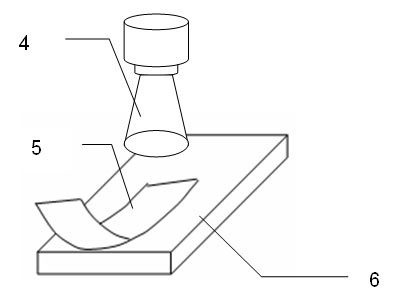

Fabricating method of air vent vehicle body paste

ActiveCN101581061AEasy constructionThe picture is flat and beautifulSpecial visual effect coatingsMechanical working/deformationLiquid statePulp and paper industry

The invention relates to a fabricating method of air vent vehicle body paste, which mainly comprises the following steps: putting base paper on a membrane pouring machine frame; pouring a polyethylene membrane on the base paper at high temperature to form membrane poured paper; extruding leather patterns with regular tongues on the membrane poured paper to form embossing membrane poured paper; coating liquid organic silicone on the embossing membrane poured paper, making embossing release paper; coating glue water on the embossing release paper after being coated with the silicone; drying the embossing release paper after being coated with the glue water through an oven; jointing a PVC membrane on the embossing release paper through a cooling and jointing roll; and rolling, cutting and packaging after the jointing. The air vent vehicle body paste fabricated by the method can guide gathered air without air bubbles through leather patterned tongues during jointing and using, is convenient for construction, and is flat and beautiful in pictures.

Owner:SHANGHAI NAR INDAL

Microporous polyethylene membrane, its production method, and battery separator

ActiveUS20090269656A1Excellent electrolytic solution absorbabilitySmall air permeability changeMembranesSemi-permeable membranesPolymer sciencePore diameter

A microporous polyethylene membrane made of a polyethylene resin having a ratio (mass-average molecular weight / number-average molecular weight) of 5 to 300 and comprising 1% or more by mass of ultra-high-molecular-weight polyethylene having a mass-average molecular weight of 7×105 or more, the microporous polyethylene membrane comprising (a) a coarse-structure layer having an average pore diameter of more than 0.04 μm, which is formed on at least one surface, and (b) a dense-structure layer having an average pore diameter of 0.04 μm or less, an area ratio of the coarse-structure layer to the dense-structure layer in a membrane cross section being 0.1 to 0.8.

Owner:TORAY IND INC

Method for producing multi-layer, microporous polyolefin membrane

ActiveUS20090134538A1Well-balanced permeabilityWell-balanced mechanical strengthLamination ancillary operationsSynthetic resin layered productsPolyolefinPolymer science

A multi-layer, microporous polyolefin membrane comprising a polypropylene layer and a polyethylene resin layer and having well-balanced permeability, mechanical strength, heat shrinkage resistance, shutdown properties and meltdown properties can be obtained by (1) forming a sheet comprising a gel-like polypropylene layer containing a membrane-forming solvent or a polypropylene layer containing no membrane-forming solvent and a gel-like polyethylene resin layer containing a membrane-forming solvent, stretching the sheet at two-stage temperatures, and then removing the membrane-forming solvent, or (2) forming a gel-like polypropylene sheet containing a membrane-forming solvent or a polypropylene sheet containing no membrane-forming solvent, and a gel-like polyethylene resin sheet containing a membrane-forming solvent, stretching them at two-stage temperatures, removing the membrane-forming solvent, and then laminating the resultant microporous polypropylene membrane and the resultant microporous polyethylene membrane.

Owner:TORAY IND INC

Preparation method of calcium carbonate-filled high-performance degradable polyethylene film

A preparation method of a calcium carbonate-filled high-performance degradable polyethylene film comprises the following steps: 1, drying calcium carbonate; 2, fully mixing dried calcium carbonate with a coupling agent according to a mass ratio of 100:0.5-3; 3, fully mixing high density polyethylene, EVA and calcium carbonate obtained in step 2; 4, adding a photodegradation agent to a mixture obtained in step 3, and uniformly mixing; 5, adding a mixture obtained in step 4 to an extruder, and carrying out fusing extrusion and granulation; and 6, adding granules obtained in step 5 to a film blowing machine, and carrying out blow molding to form the film. The polyethylene film prepared in the invention has the advantages of low cost, good mechanical performances, high tensile strength and elongation at break, degradability and environmental protection.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Preparation method of standard sample for specific migration quantity detection on restricted substances in polyethylene film

ActiveCN103900879AStrong designability of ingredientsImprove uniformityPreparing sample for investigationBlow moldingPhysical chemistry

The invention provides a preparation method of a standard sample for the specific migration quantity detection on restricted substances in a polyethylene film. The preparation method comprises the following steps: uniformly mixing specific migration substances and a blow molding grade polyethylene resin raw material, and manufacturing master batches by using a double-screw extruder; then mixing the master batches and the polyethylene resin raw material in a set proportion, regulating the pulling speed by using a blow molding machine to obtain the polyethylene film with a certain thickness, and carrying out series treatment on the film to obtain the standard sample. The standard sample has the good uniformity and stability, can be used for comparing interlaboratory specific migration quantity detection data of the restricted substances in the polyethylene film, verifying the accuracy of the method, calibrating test instruments, controlling the quality and assessing test results. The preparation method is low in material cost and simple; the obtained standard sample is a material standard sample, is uniform and stable, and is easy to store.

Owner:INSPECTION & QUARANTINE TESTING CENT OF HEBEI ENTRY EXIT INSPECTION & QUARANTINE BUREAU

Modified asphalt waterproof membrane

InactiveCN107189756AReduce orderReduce clumpingNon-macromolecular adhesive additivesOil/fat/wax adhesivesElastomerPolyester

The invention discloses a modified asphalt waterproof coiled material, which comprises a base layer B, an upper surface layer A bonded to the base layer B, and a lower surface layer C bonded under the base layer B, wherein the upper surface layer A and the base layer B are , and the base layer B and the lower surface layer C are bonded with each other by elastomer modified asphalt, the base layer B is made of glass fiber film, the upper surface layer A is made of polyethylene film, high temperature resistant polyester film or fine sand, and the lower layer The surface layer C is made of polyethylene film; the elastomer modified asphalt is prepared according to the following steps: after carbon nanotubes are hydroxylated, then acidified to obtain the second material; MAH-g-SBS is mixed with the second material and then ultrasonically Disperse and age to obtain carbon nanotube-modified SBS; after heating the asphalt, add carbon nanotube-modified SBS, nano-zinc oxide and other materials in sequence, and continue to heat up to obtain a mixed material; after the mixed material is oxidized and polished, then add talc powder to obtain elastomer-modified asphalt.

Owner:湖北永阳材料股份有限公司

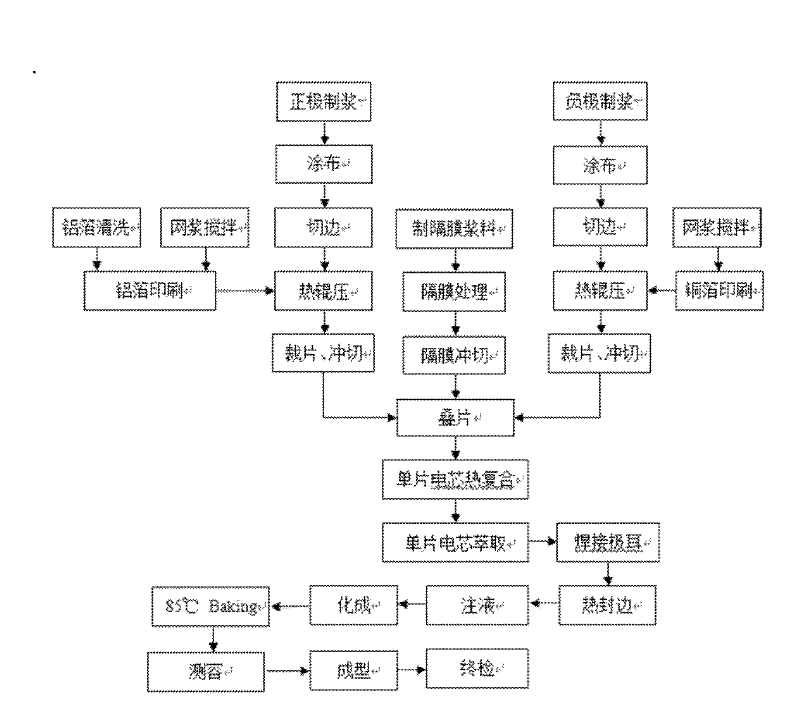

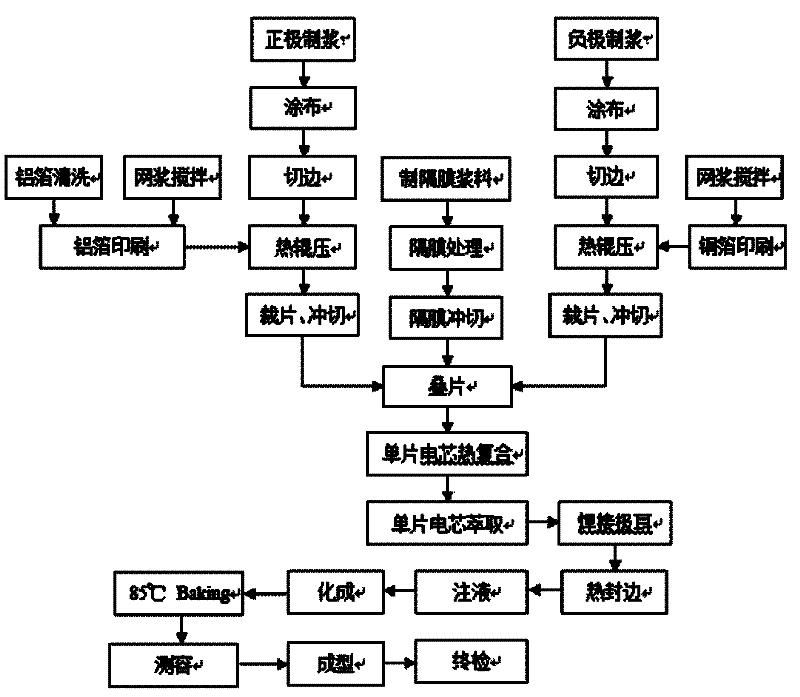

Gel-state polymer lithium ion battery suitable for high-temperature and low-temperature environment and preparation method thereof

InactiveCN102347511AReduce the diffusion distanceAchieving Low Temperature Discharge PerformanceFinal product manufactureCell electrodesElectrolytic agentElectrical battery

The invention relates to a polymer lithium ion battery and a preparation method thereof. The polymer lithium ion battery is manufactured by that anode and cathode pole pieces manufactured by the Bellcore technology and a diaphragm are overlaid into a battery cell, and then the battery cell is extracted, welded, packaged and reduced. The active material of the anode pole piece is LiCoO2 of which the D50 is 5-10mu m; the active material of the cathode pole piece is graphite; the diaphragm is a polyethylene film made with a dry method; and high-temperature and low-temperature electrolyte is prepared by evenly mixing electrolyte salt, organic solvent and additive. In the preparation method, the anode and cathode pole pieces and the diaphragm are overlaid into the battery cell; the battery cell is put in a flexible package film after being extracted, welded and packaged; the three edges of the flexible package film are sealed; the high-temperature and low-temperature electrolyte is injected into the battery cell; the fourth edge of the film is sealed in a vacuum packaging mode; and the reduction technology is carried out. Compared with the prior art, the preparation method has the characteristic that the low-temperature discharging performance of the battery is realized.

Owner:龙能新能源科技(深圳)股份有限公司

Material special for preparing lithium ion battery diaphragm and preparation method thereof

The invention relates to a material special for preparing a lithium ion battery diaphragm and a preparation method thereof. The material consists of the following components in part by weight: 62.5 to 86 parts of polyethylene, 0.5 to 1.5 parts of di-tert-butyl peroxide, 3 to 5 parts of vinyl triethoxy silane, 10 to 30 parts of titanium dioxide whiskers and 0.5 to 1 part of antioxidant. The preparation method comprises the following steps of: mixing the polyethylene, the di-tert-butyl peroxide, the antioxidant and the vinyl triethoxy silane, performing melt blending by using a double-screw extruder and performing an in-situ grafting reaction to obtain silane-grafted polyethylene; and stirring and blending the silane-grafted polyethylene and the titanium dioxide whiskers to obtain the material special for preparing the lithium ion battery diaphragm. The vinyl triethoxy silane is grafted on a polyethylene molecular chain and an ethyoxyl silane group can further react with the titanium dioxide whiskers so that a cross-linking reaction is realized in an entire membrane system and the intensity of a polyethylene membrane is enhanced.

Owner:SOUTH CHINA UNIV OF TECH

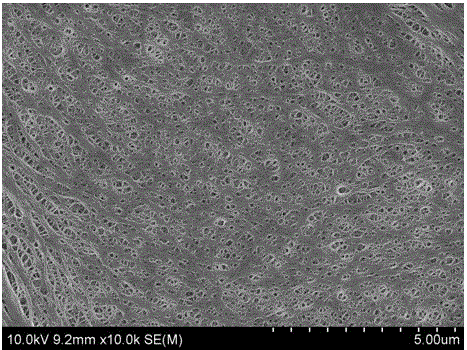

Formation method of nano coating of lithium ion battery membrane

ActiveCN107180938AOutstanding FeaturesHighlight significant progressSecondary cellsCell component detailsCoated membraneAdhesive

The invention discloses a formation method of a nano coating of a lithium ion battery membrane. The formation method comprises the following steps: (1) dissolving an aqueous adhesive and an additive into de-ionized water and stirring for 3h to obtain an aqueous adhesive mixed solution; (2) adding an inorganic material nano-sol into the aqueous adhesive mixed solution; continually stirring for 2h and standing for 1h to obtain aqueous nano coating paint; (3) putting a polyethylene membrane into a plasma treatment device for treating, so as to primarily improve the surface of the membrane; then coating the surface of the lithium ion battery membrane and the surface of a three-dimensional pore channel with the aqueous nano coating paint; drying the coated membrane in the air for 10min and then transferring the membrane into a drying box at 40 DEG C; drying to obtain the lithium ion battery membrane modified by a nano inorganic coating. The battery membrane disclosed by the invention can be used for modifying the surface of the membrane and the pore channel under the condition that the thickness of the membrane is not increased; the speed of ions penetrating through the membrane is improved, and the ion conductivity and the lithium-ion transference number of the membrane are improved; when the modified membrane is used for assembling a battery, the circulating performance of the battery is remarkably improved.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com