Self-lubricating polyethylene membrane

A polyethylene film, self-lubricating technology, applied in the field of flexible packaging film, can solve problems such as instability and inaccurate control of friction coefficient, and achieve the effects of accurate and stable friction coefficient, improved packaging production efficiency, and high film transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 1 part and 1.2 parts of LDPE and LLDPE for the outer layer; take 1 part of LDPE and LLDPE for the middle layer; take 1 part of LDPE for the inner layer, 1 part of LLDPE, 1.5 parts of MLLDPE, 0.015 parts of 10090-K, ABPE15N0 .1 part.

[0031] The proportioned materials are produced by multi-layer co-extrusion blow molding equipment according to the following procedures: feeding process, material plasticizing extrusion process, inflation traction process, air ring cooling process, herringbone splint process, traction roller traction process, Corona treatment process, film winding process:

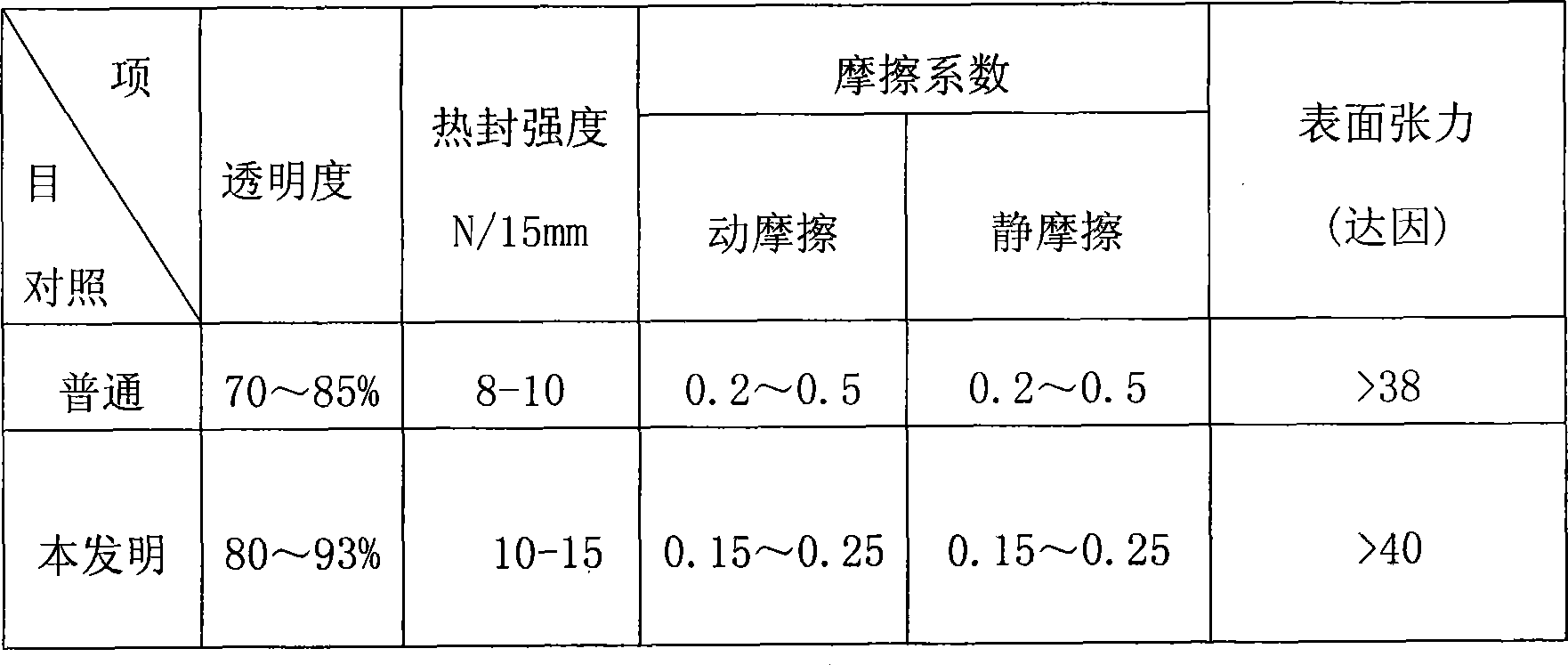

[0032] The properties of this film and ordinary polyethylene film are shown in the following table:

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com