Macromolecular self-adhesive glue film coiled material adopting SEBS self-adhesive glue as self-adhesive layer and production method of macromolecular self-adhesive glue film coiled material

A technology of self-adhesive film and production method, which is applied in the field of building waterproof materials, can solve the problems of many processes required for the construction of ordinary coils, poor adhesion between the coil and the base layer, and increased construction costs, so as to improve the self-waterproof function. , Significant waterproof effect, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

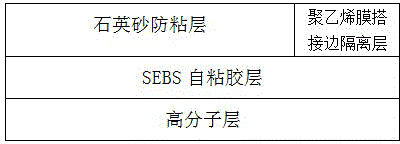

Image

Examples

Embodiment 1

[0033] 1. Preparation of SEBS self-adhesive

[0034] Stir 5kg of SEBS elastomer, 25kg of butyl (IIR) rubber, 35kg of terpene resin and 10kg of naphthenic oil for rubber at 190-200°C for 2 hours. After swelling and stirring evenly, add 0.3kg of Stir the mixture of antioxidant 1010 and 0.3kg of light stabilizer 770 evenly to obtain a uniform and stable viscous SEBS self-adhesive liquid, which is cooled to 165-170°C for use.

[0035] 2. Preparation of Polymer Layer

[0036] The polyolefin synthetic polymer waterproof membrane is processed by an extruder and a calender to produce a homogeneous polymer membrane.

[0037] 3. Preparation of SEBS self-adhesive layer

[0038] The SEBS self-adhesive adhesive is evenly coated on the surface of the polymer coil by an automatic adhesive coating machine, and the thickness of the self-adhesive adhesive layer is 0.25mm.

[0039] 4. Preparation of anti-sticking layer of quartz sand

[0040] Evenly coat the quartz sand on the surface of the...

Embodiment 2

[0044] 1. Preparation of SEBS self-adhesive

[0045] Stir 7kg of SEBS elastomer, 27kg of butyl (IIR) rubber, 35kg of terpene resin and 10kg of naphthenic oil for rubber at 190-200°C for 2 hours. After swelling and stirring evenly, add 0.4kg of Stir the mixture of antioxidant 1010 and 0.4kg of light stabilizer 770 evenly to obtain a uniform and stable viscous SEBS self-adhesive liquid, which is cooled to 165-170°C for use.

[0046] 2. Preparation of Polymer Layer

[0047] The polyolefin synthetic polymer waterproof membrane is processed by an extruder and a calender to produce a homogeneous polymer membrane.

[0048] 3. Preparation of SEBS self-adhesive layer

[0049] The SEBS self-adhesive adhesive is evenly coated on the surface of the polymer coil by an automatic adhesive coating machine, and the thickness of the self-adhesive adhesive layer is 0.27mm.

[0050] 4. Preparation of anti-sticking layer of quartz sand

[0051] Evenly coat the quartz sand on the surface of the...

Embodiment 3

[0055] 1. Preparation of SEBS self-adhesive

[0056] Stir 10kg of SEBS elastomer, 30kg of butyl (IIR) rubber, 35kg of terpene resin and 10kg of naphthenic oil for rubber at 190-200°C for 2 hours. After swelling and stirring evenly, add 0.3kg of The mixture of antioxidant 1010 and light stabilizer 770 with a weight ratio of 1:1.2 is stirred evenly to obtain a uniform and stable viscous SEBS self-adhesive liquid, which is cooled to 165-170°C for use.

[0057] 2. Preparation of Polymer Layer

[0058] The polyolefin synthetic polymer waterproof membrane is processed by an extruder and a calender to produce a homogeneous polymer membrane.

[0059] 3. Preparation of SEBS self-adhesive layer

[0060] The SEBS self-adhesive adhesive is evenly coated on the surface of the polymer coil by an automatic adhesive coating machine, and the thickness of the self-adhesive adhesive layer is 0.30mm.

[0061] 4. Preparation of anti-sticking layer of quartz sand

[0062]Evenly coat the quartz ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com