High-sensitivity flexible piezoresistive sensor based on MXene bionic skin structure

A piezoresistive sensor and skin structure technology, applied in the field of wearable electronics and new materials, can solve the problems of difficult wearability, poor light transmission, thick flexible piezoresistive sensor, etc., achieve good cycle stability and low cost , the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

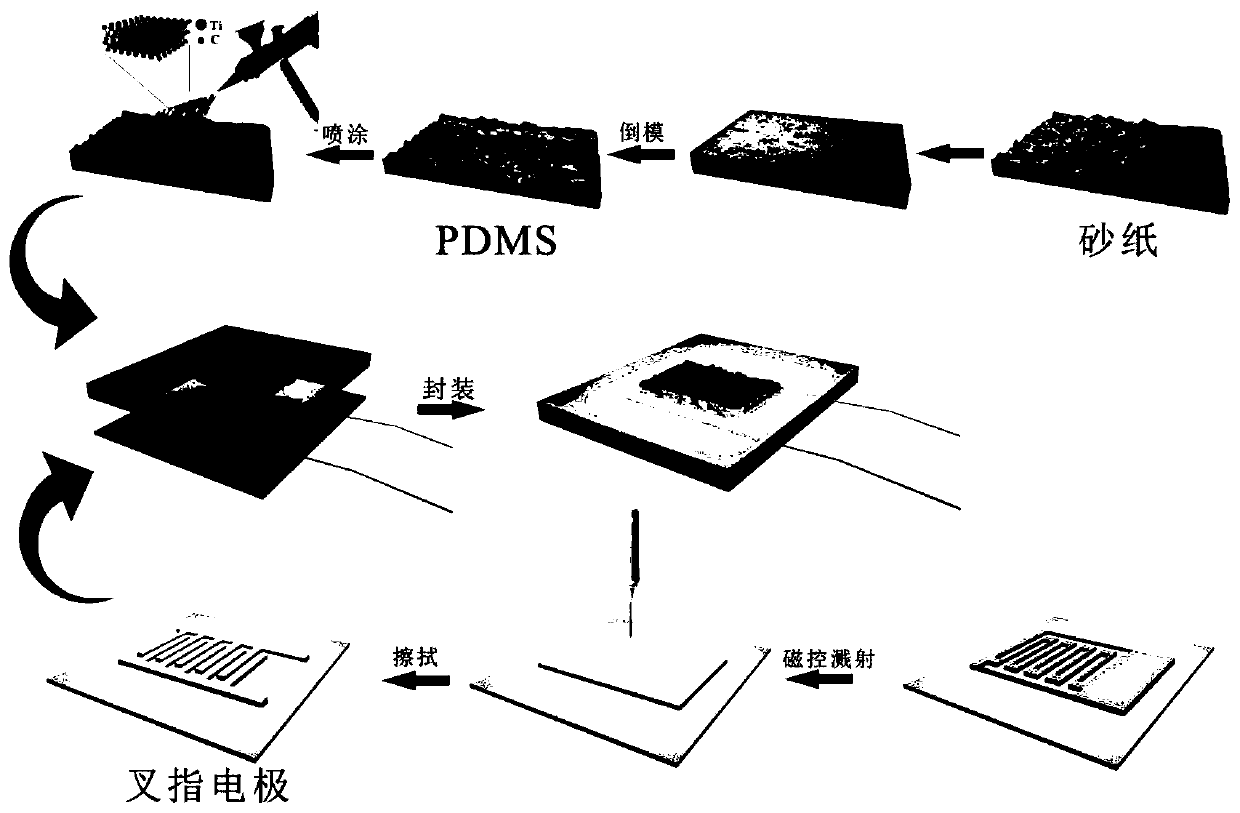

[0045] (3) Preparation of MXene-based silica gel biomimetic layer;

[0046] (4) Preparation of flexible interdigitated electrodes;

[0047] (5) Assembly of MXene-based biomimetic piezoresistive sensors.

Embodiment 1

[0049] In a preferred embodiment of the present invention, a method for preparing a high-sensitivity flexible piezoresistive sensor based on MXene material sandpaper bionic skin structure, the method comprises the following steps:

[0050] S1: The MAX phase was etched by chemical solution method, followed by centrifugal cleaning and low temperature ultrasonic to prepare MXene nanosheets.

[0051] The commercially available MAX phase precursor-Ti 3 AlC 2 , wet chemical etching was carried out at 35°C for 24 hours to obtain multilayer MXene; the etchant was centrifuged and washed 8 times repeatedly, and then sonicated for 40 minutes in an ice bath under the protection of an inert atmosphere (argon gas). After centrifugation for 1 hour under the conditions of a rotor radius of 7 cm, a rotating speed of 3500 r / min, and a lifting rate of 1 gear, the obtained upper liquid is MXene (i.e., Ti 3 C 2 T x nanosheet) colloidal solution; the average diameter of the MXene nanosheets is ...

Embodiment 2

[0062] In a preferred embodiment of the present invention, a method for preparing a high-sensitivity flexible piezoresistive sensor based on MXene material sandpaper bionic skin structure, the method comprises the following steps:

[0063] S1: The MAX phase was etched by chemical solution method, followed by centrifugal cleaning and low temperature ultrasonic to prepare MXene nanosheets.

[0064] The commercially available MAX phase precursor-Ti 3 AlC 2 , wet chemical etching was carried out at 35°C for 24h to obtain multilayer MXene; the etchant was centrifuged and washed 7 times repeatedly, and then ultrasonically treated for 1h under the protection of an ice bath and an inert atmosphere (argon gas). After centrifugation for 1 hour under the conditions of a rotor radius of 7 cm, a rotating speed of 3500 r / min, and a lifting rate of 1 gear, the obtained upper liquid is MXene (i.e., Ti 3 C 2 T x nanosheet) colloidal solution; the average diameter of the MXene nanosheets is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com