Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Soft braking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

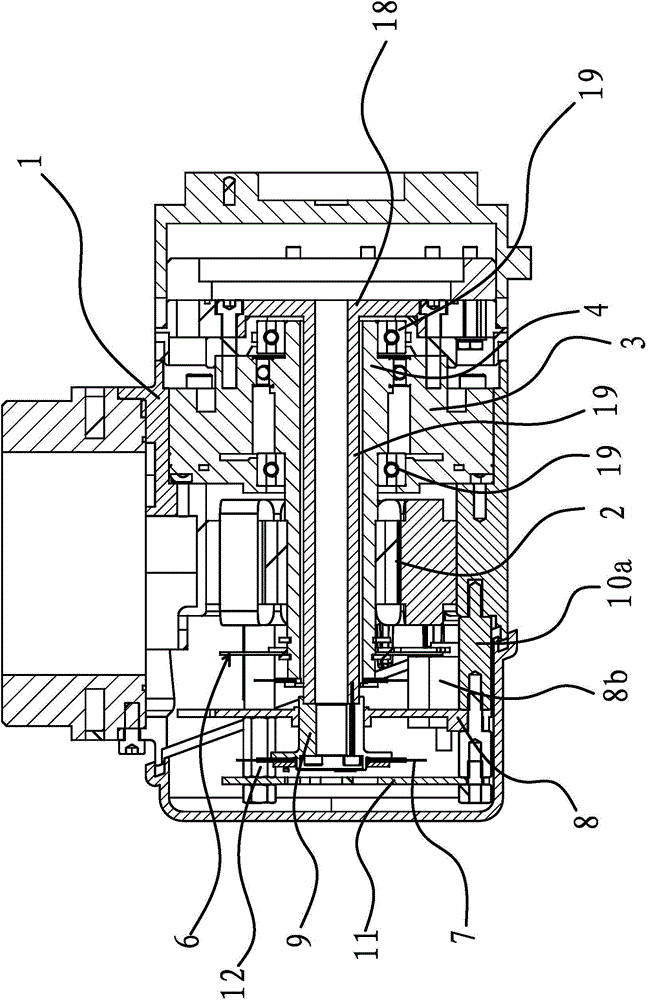

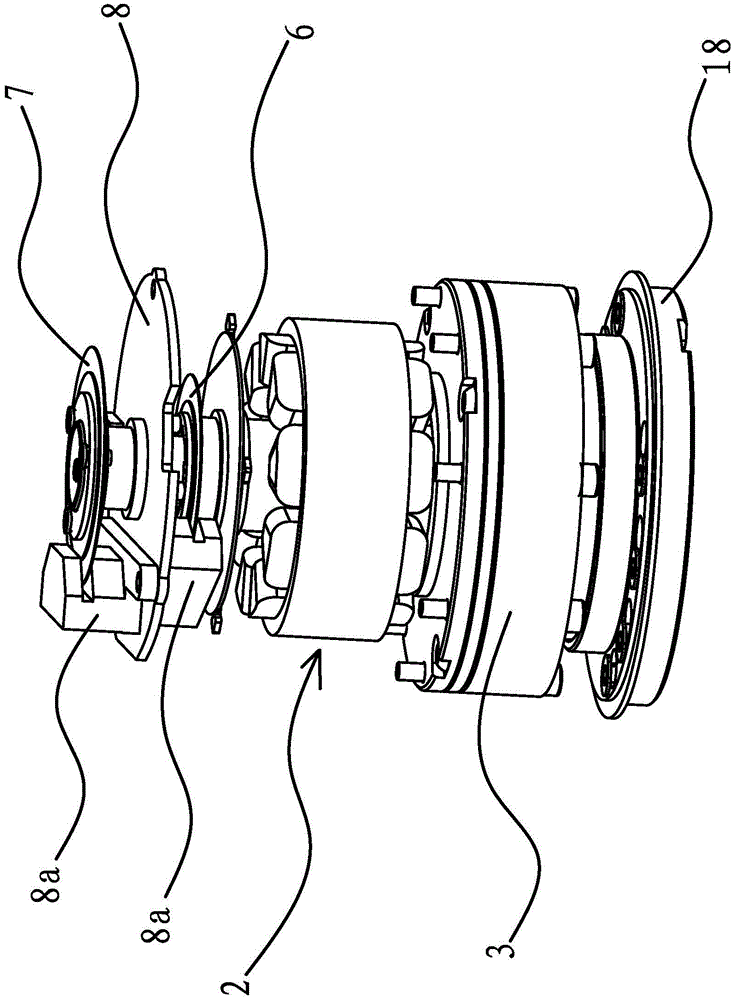

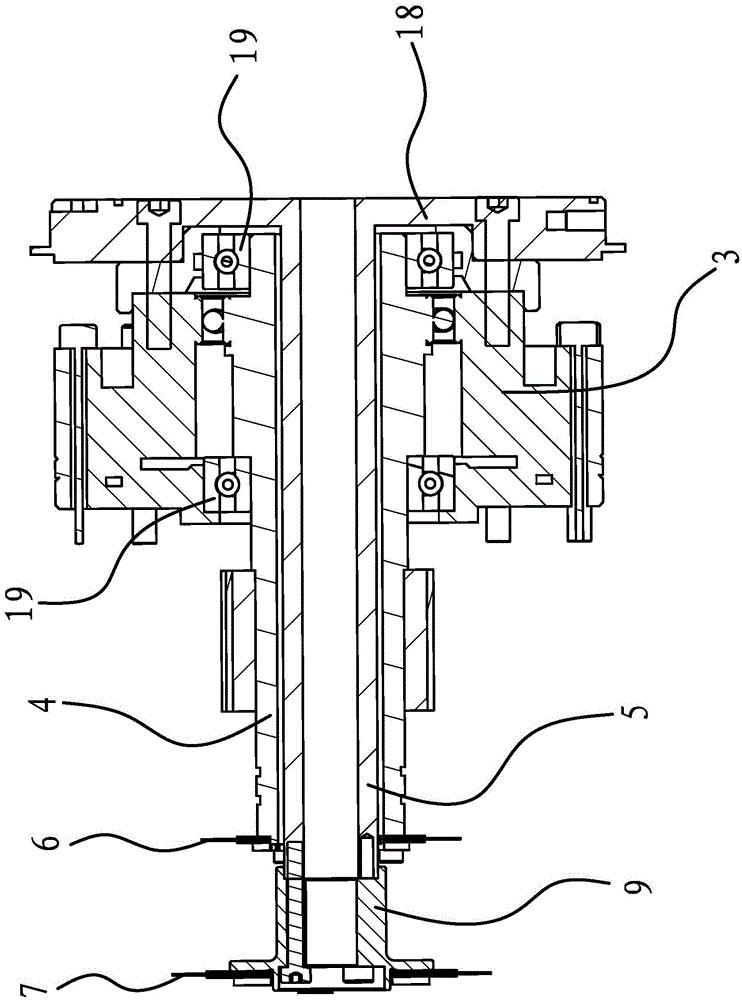

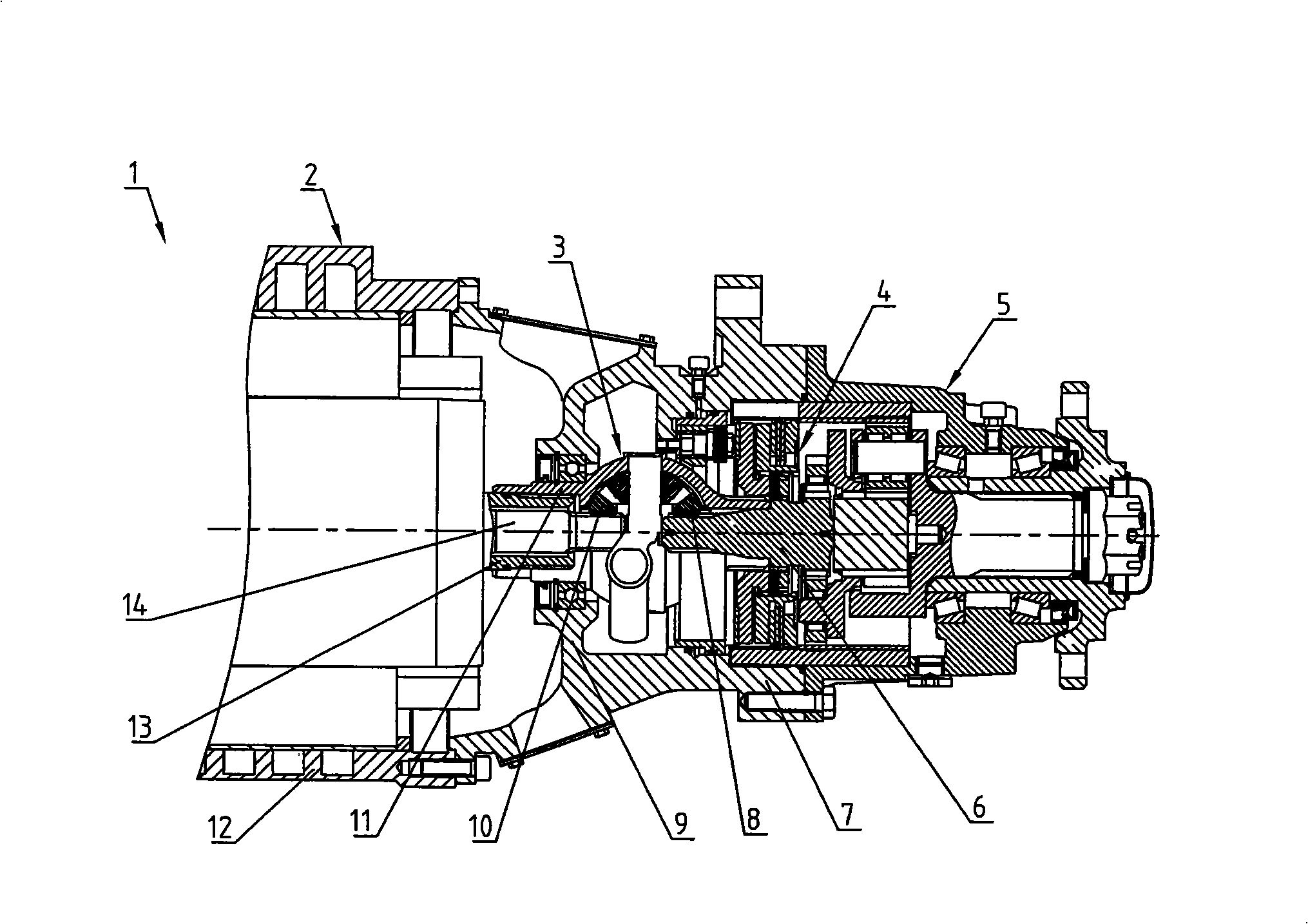

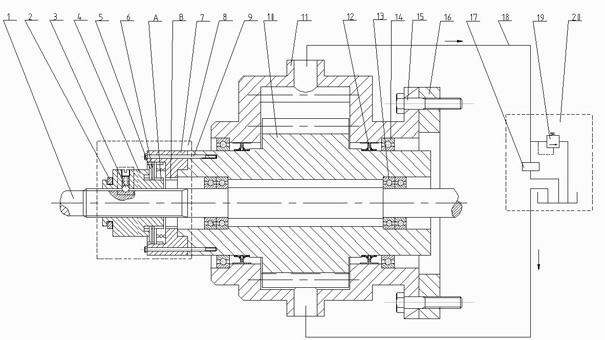

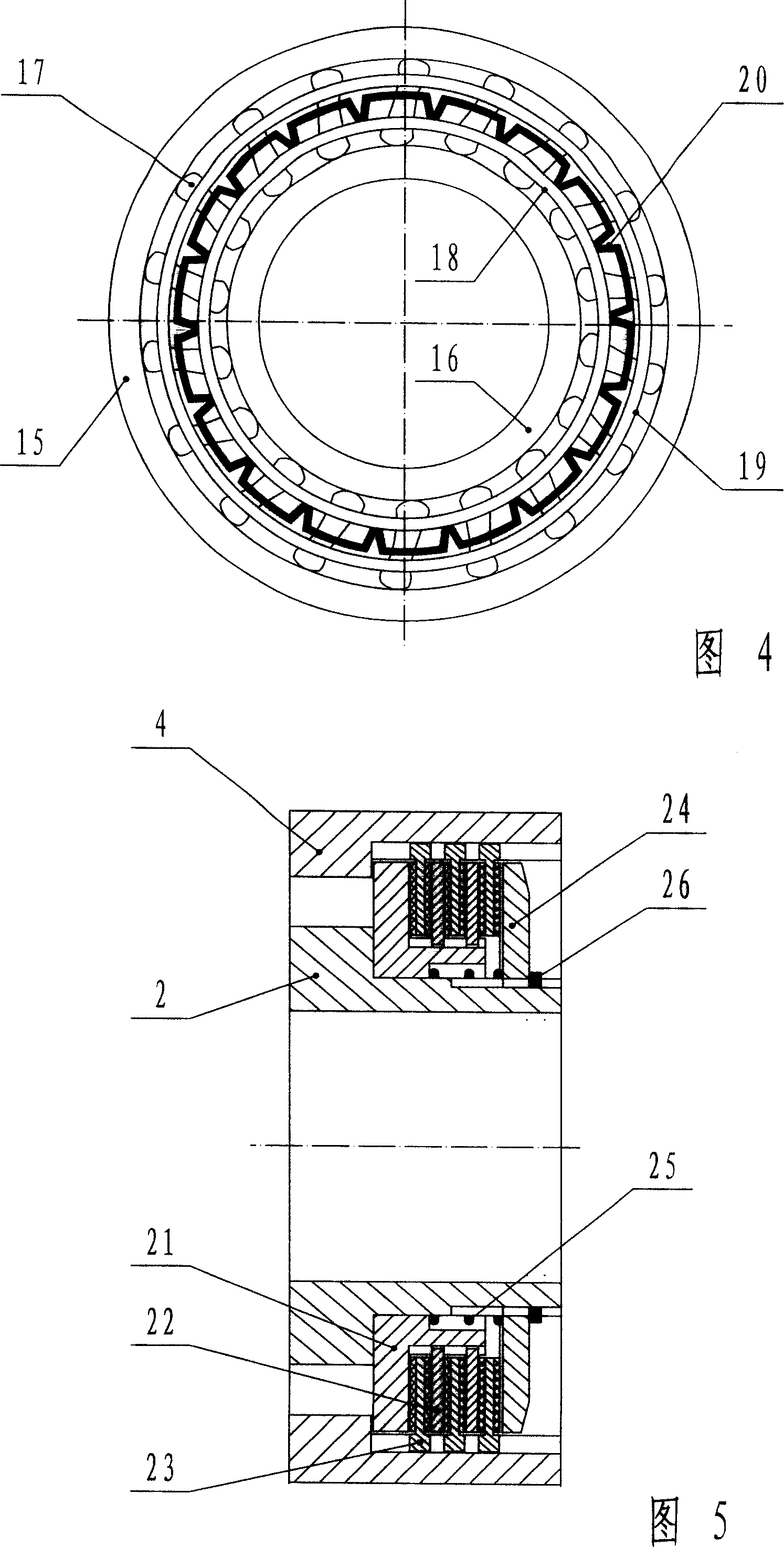

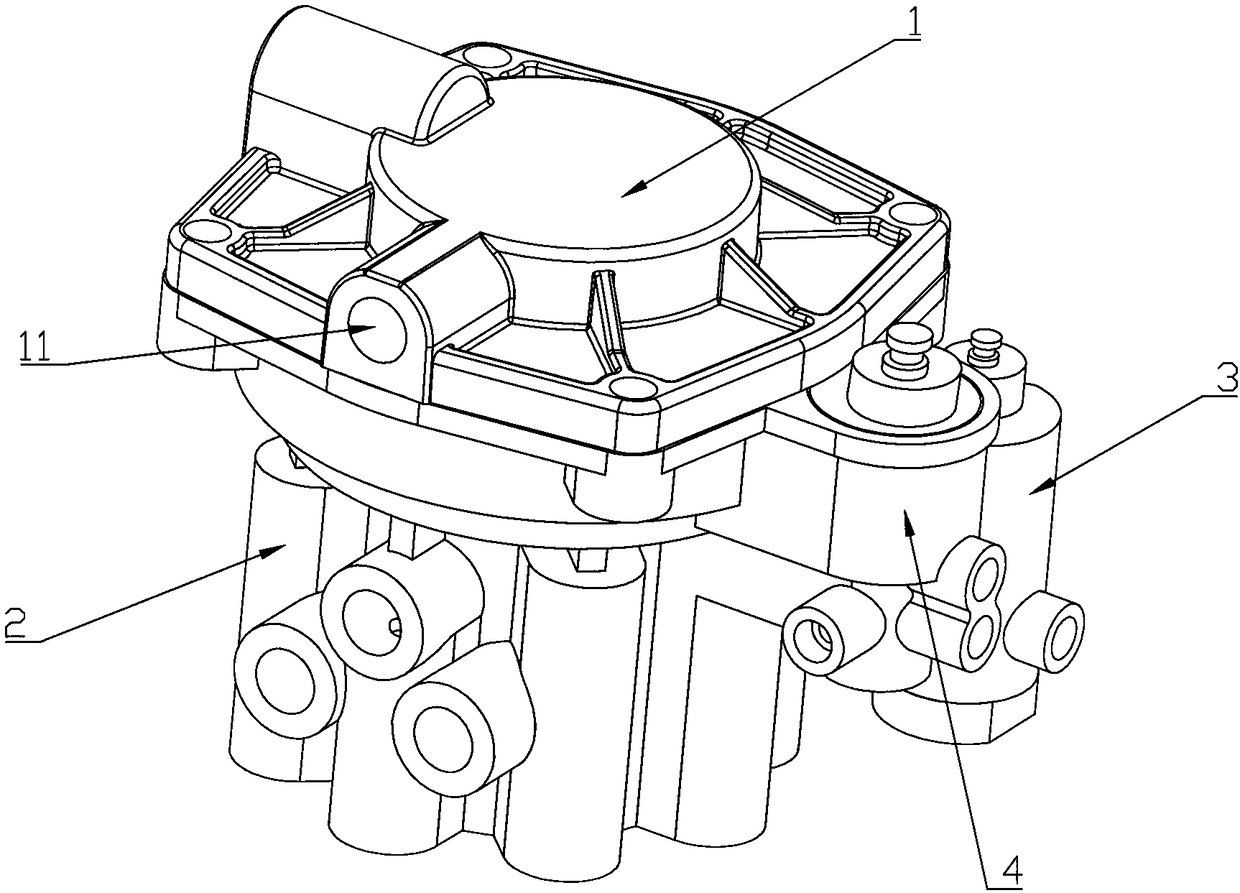

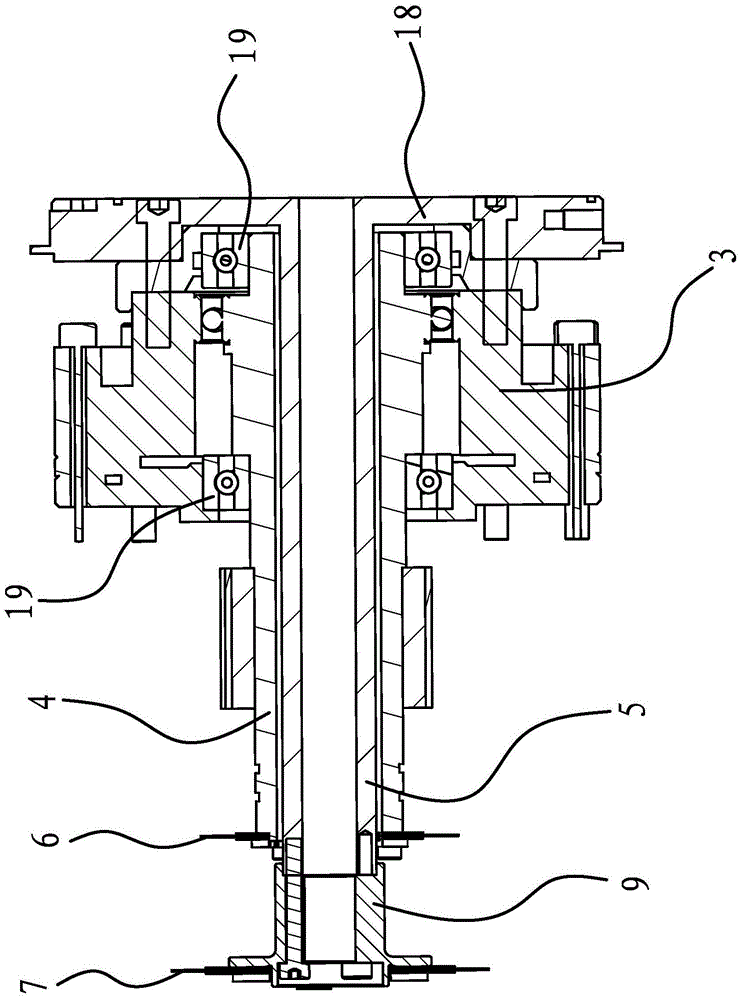

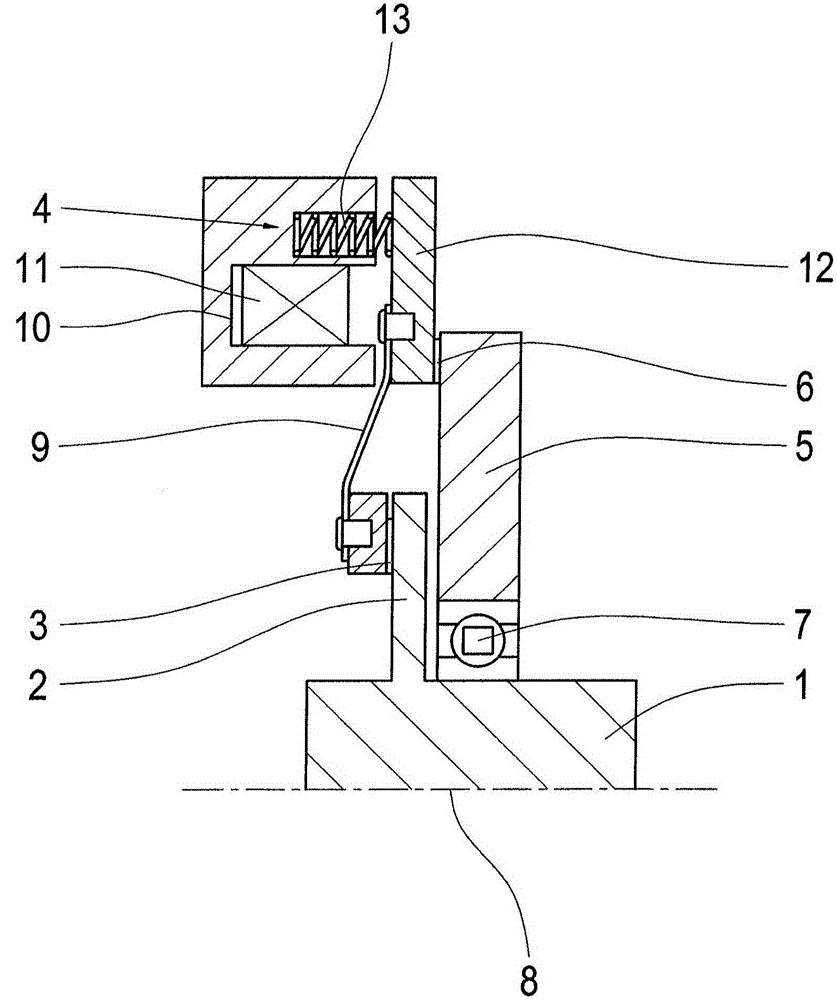

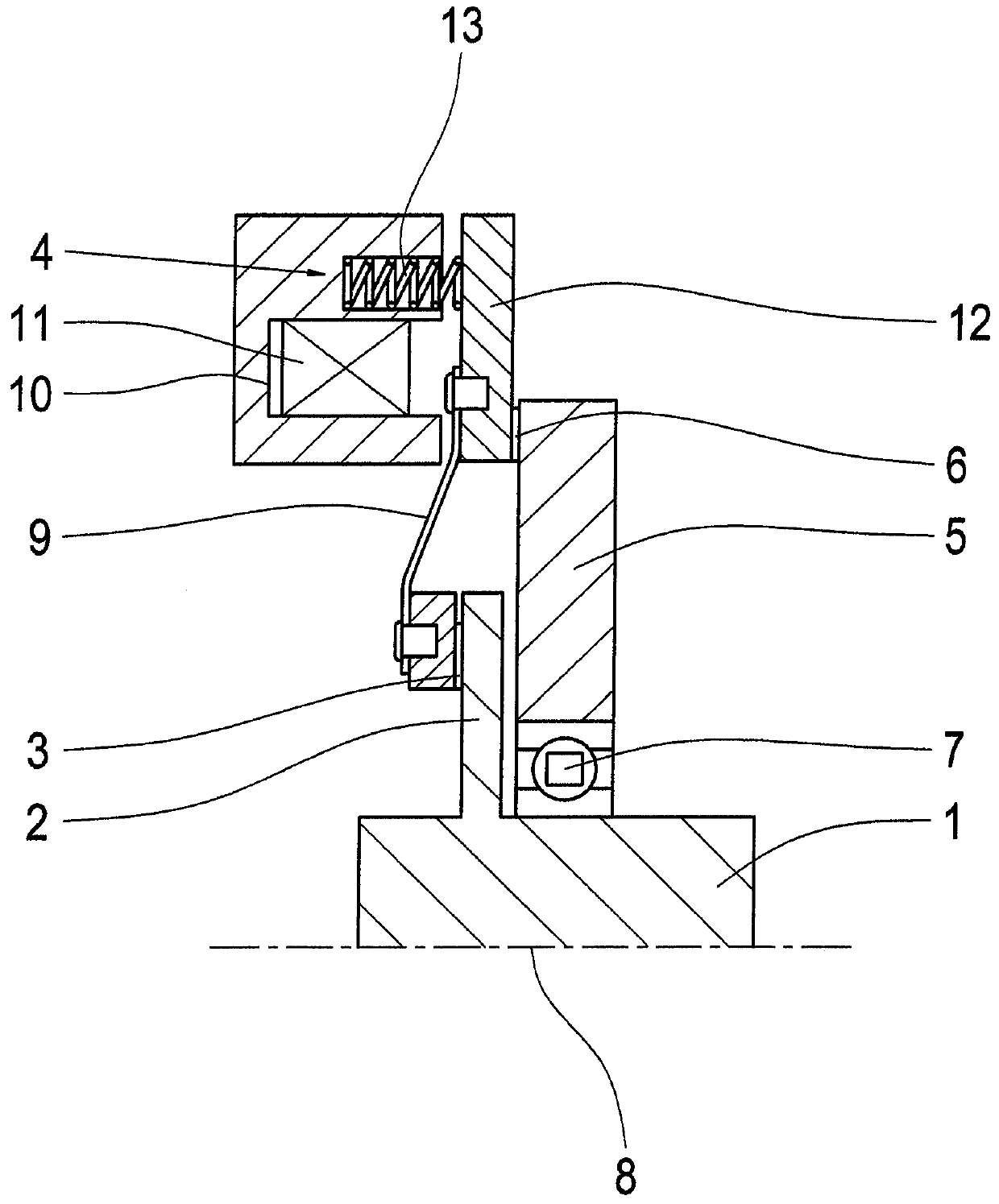

Joint of mechanical arm

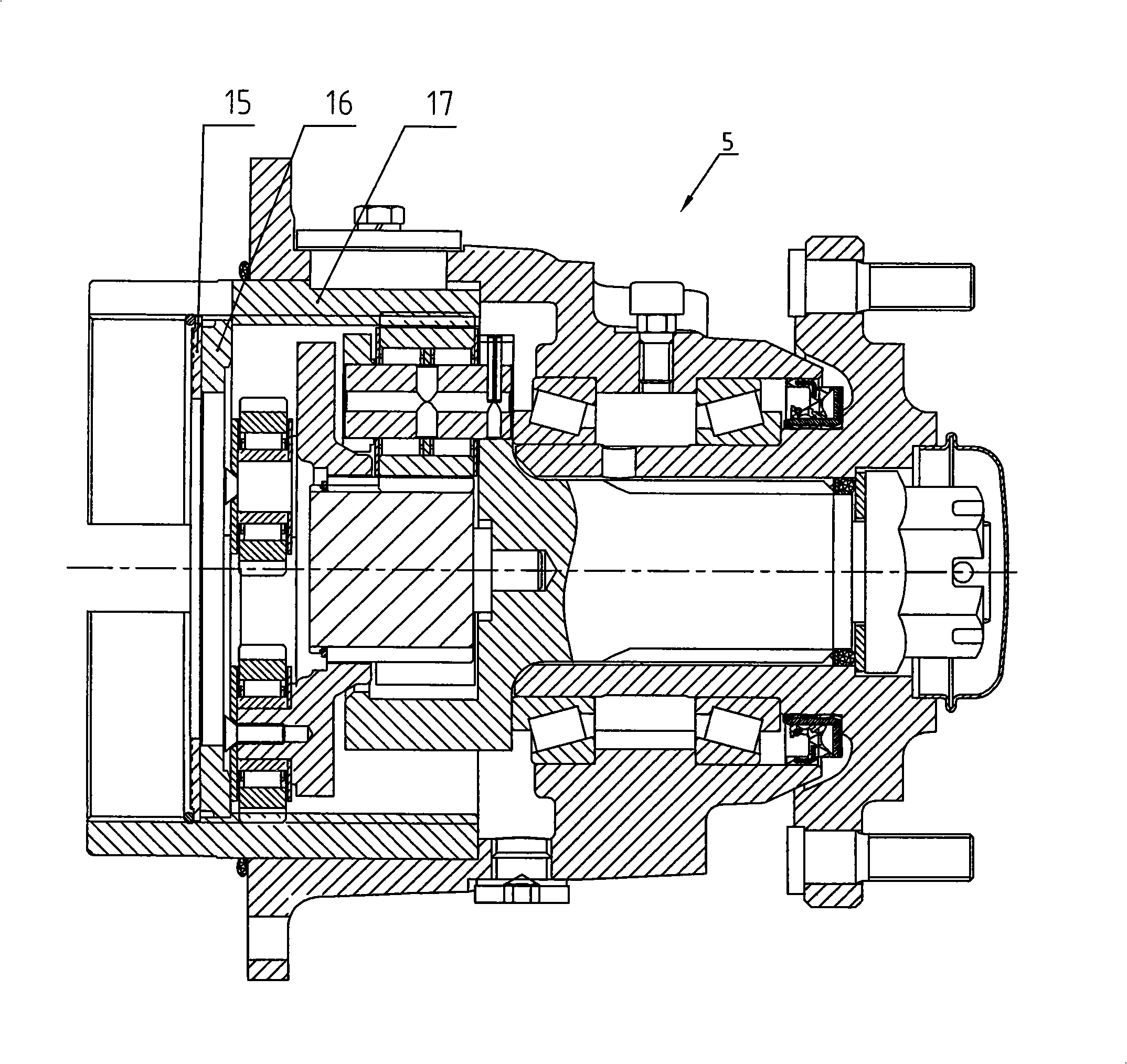

The invention provides a joint of a mechanical arm, and belongs to the technical field of machinery. The joint solves the problem that the joint of an existing mechanical arm is large in size. The joint of the mechanical arm comprises a shell, a motor and a harmonic reducer, wherein the motor and the harmonic reducer are integrated in the shell; the inner end of a rotating shaft of the motor is connected with the input end of the harmonic reducer; the output end of the harmonic reducer is connected with an output shaft; the rotating shaft of the motor is hollow; the inner end of the output shaft is fixed with the output end of the harmonic reducer, and the outer end of the output shaft penetrates through the outer end of the rotating shaft of the motor; a motor raster is fixed at the outer end of the rotating shaft of the motor; an output shaft raster is fixed at the outer end of the output shaft; an encoder is fixed in the shell; the output shaft raster and the motor raster are respectively positioned on the upper side and the lower side of the encoder; optoelectronic switches matched with output shaft raster and the motor raster are respectively arranged on the upper side and the lower side of the encoder. The joint has the advantages of small size, high space utilization rate, long service life and the like.

Owner:QIXING INTELLIGENT TECH CO LTD

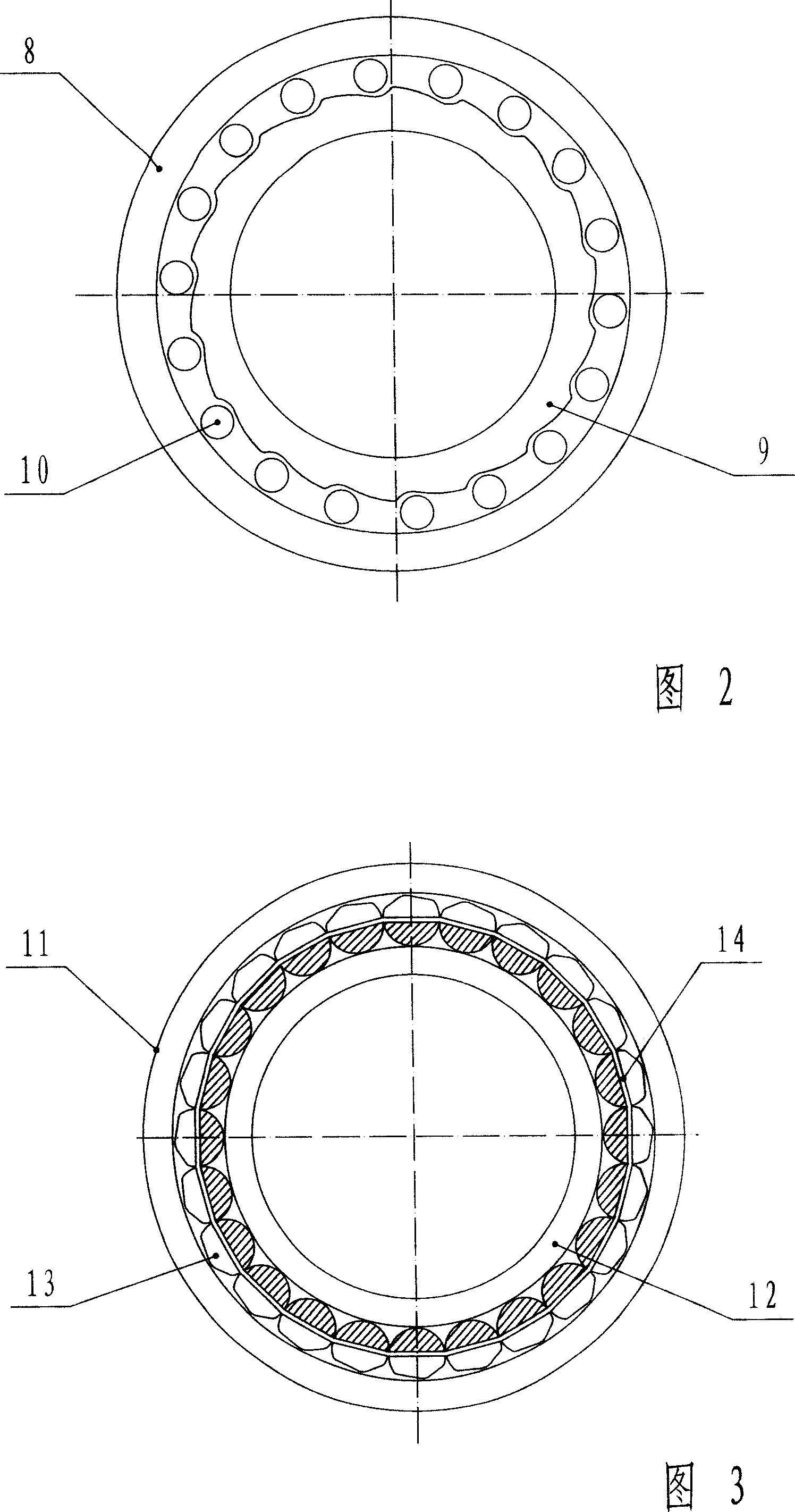

Vehicular hub drive device

InactiveCN1836969ASoft brakingSimple and fast operationMotorcyclesRider propulsionDrive shaftAgricultural engineering

The motor vehicle hub driver belongs to the field of hub driver technology, and solves the technological problem of providing flexibly connected hub driver. The motor vehicle hub driver includes a driving shaft, a chain wheel on the driving shaft, an auto-controlled clutch between the left section of the chain wheel and the middle section of the driving shaft, and a controlling clutch between the right section of the driving shaft and the right section of the chain wheel. The auto-controlled clutch has rotor on the driving shaft and wedge between the rotor and the chain wheel. The controlling clutch has its input end connected to the driving shaft and the output end connected to the chain wheel. The present invention can realize sliding and backward braking.

Owner:广州天马集团天马摩托车有限公司

Ceramic-based friction material and method for preparing same

ActiveCN101831273AGood friction performanceModerate coefficient of frictionOther chemical processesFriction liningFrictional coefficientHot press

The invention discloses a ceramic-based friction material and a method for preparing the same. The ceramic-based friction material consists of the following raw materials in part by weight: 6 to 8 parts of thermal plasticity phenolic resin or modifier thereof, 7 to 8 parts of potassium titanate whisker, 5 to 6 parts of attapulgite clay, 3 to 4 parts of expanded vermiculite, 4 to 5 parts of butyronitrile rubber powder, 4 to 5 parts of chromite powder, 12 to 13 parts of ceramic fiber, 3 to 4 parts of powdered coke, 14 to 15 parts of barium sulfate, 5 to 6 parts of artificial graphite, 9 to 10 parts of scale graphite, 7 to 8 parts of organic rubbing powder, 3 to 4 parts of sericite, 0.5 to 1 part of aluminum oxide, 3 to 4 parts of copper fiber, 3 to 4 parts of coloring agent and 0.5 to 1 part of organic fiber. The preparation method comprises the following steps of: material blending, cold press moulding, hot press moulding, polishing and curing treatment. The ceramic-based friction material has the advantages of high and stable frictional property, suitable frictional coefficient, low wear rate, low hardness, no damage to friction coupling materials, low braking noise, and extremelylow environmental pollution; and in use, the ceramic-based friction material has the advantages of smooth braking, gentleness, comfortability, safety and reliability.

Owner:YUTIAN COUNTY JUNDA AUTOMOBILE PARTS MFG CO LTD

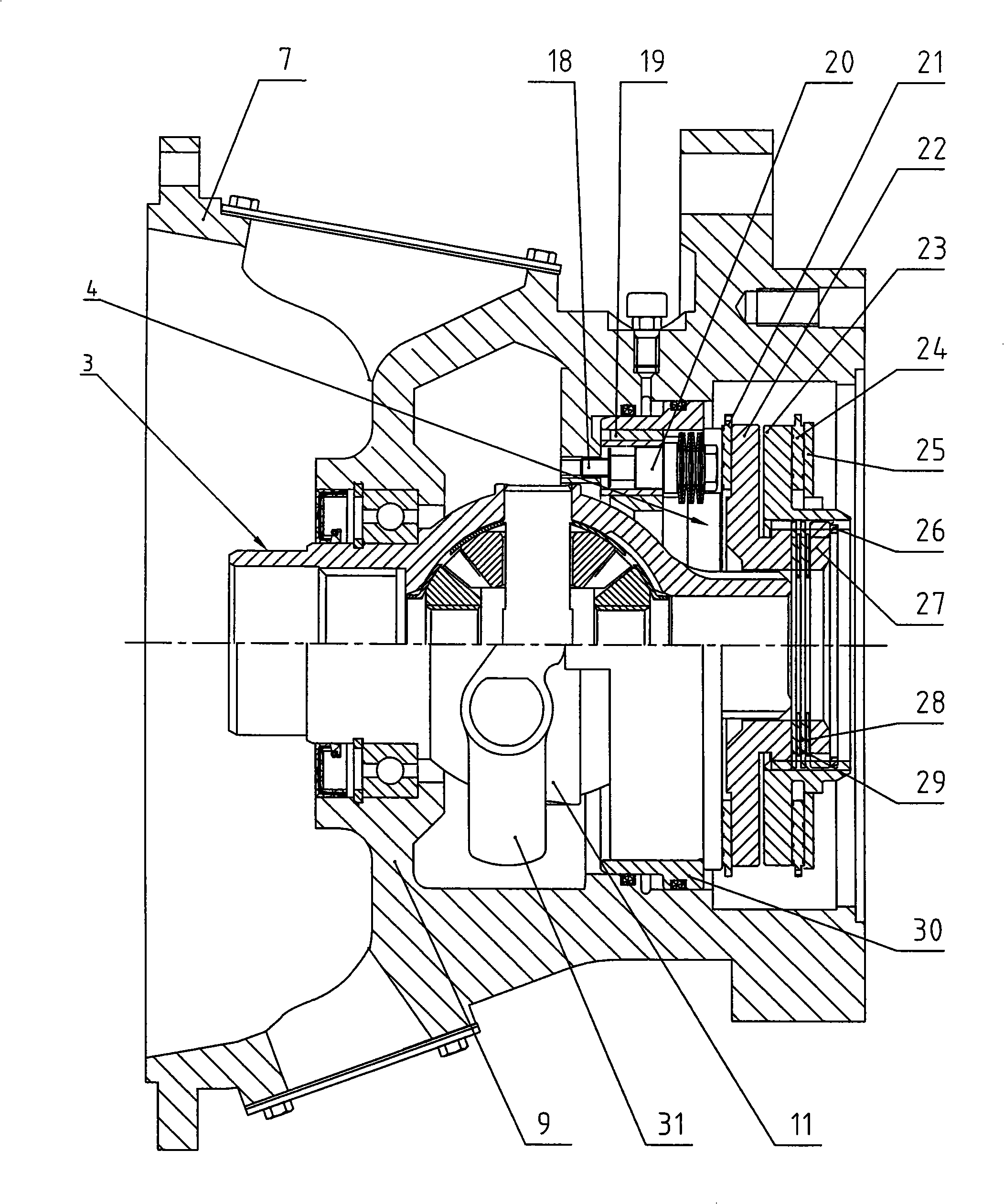

Multifunctional wet multi-disc brake

InactiveCN101603573ADriving safetySimple structureAxially engaging brakesBrake actuating mechanismsParking brakePiston

The invention provides a multifunctional wet multi-disc brake, which comprises an axle shaft shell, a pallet, a stator plate, a friction plate, a compression spring, a pressure plate, a brake shell, a disc spring, a disc spring seat, a parking brake piston, a driving brake piston, a central shell, an axle shaft and the like, wherein the axle shaft shell, the brake shell and the central shell are connected as a whole through screws to form a brake cavity; the pressure plate is positioned between the brake shell and the friction plate; the compression spring is arranged on the pressure plate; the driving brake piston is arranged between the pressure plate and the brake shell; a parking brake piston is arranged between the brake shell and the disc spring seat; the disc spring is arranged between the disc spring seat and the parking brake piston; the stator plate and the friction plate are alternately arranged in turn between the pressure plate and the pallet; and the pallet and an adjustment washer are arranged in turn between the friction plate and the axle shaft shell. The brake has the advantages of simplifying the transmission system structure of a whole machine and having gentle brake, good safety, convenient operation and easy maintenance.

Owner:一拖(洛阳)开创装备科技有限公司

Automotive disc ceramic brake without heavy metal, heavy metal sulfide or heavy metal fluoride

The invention relates to an automotive disc ceramic brake without heavy metal, heavy metal sulfide or heavy metal fluoride. The automotive disc ceramic brake is prepared from the following components in parts by weight: 9-16 parts of barium sulfate, 1-5 parts of high-lead alumina powder, 5-15 parts of garnet powder, 3-8 parts of palygorskite powder, 1-5 parts of magnesium oxide powder, 1-6 parts of diatomite powder, 3-9 parts of mica powder, 3-6 parts of talcum powder, 1-6 parts of white carbon black, 3-6 parts of aluminum hydroxide, 6-10 parts of calcium hydroxide, 1-3 parts of zinc borate, 3-7 parts of friction particles, 6-10 parts of vermiculite powder, 1-4 parts of tire powder, 5-12 parts of nitrile modified resin, 2-8 parts of nitrile gelatine powder, 2-4 parts of rigid cellulose fiber, 5-8 parts of natural organic fiber, 4-8 parts of mineral fiber, 10-15 parts of ceramic fiber and 8-15 parts of friction powder. The raw materials are mixed, baked and formed to obtain the brake. The automotive disc ceramic brake without heavy metal, heavy metal sulfide or heavy metal fluoride has good friction performance and is environment-friendly and harmless to human health.

Owner:重庆绿陶摩擦材料有限公司

Braking device of drive axle

InactiveCN101348109ASimple structureLarge braking forceBraking element arrangementsElectric propulsion mountingElectric machineryReducer

The invention relates to a brake device used for an engineering vehicle driving bridge, in particular to a wet-typed multi-sheet brake which is used on the engineering vehicle driving bridge; the brake device mainly comprises a motor end cover, a piston, a large friction plate, an auxiliary friction device, a main friction device and a planetary gear reducer; the motor end cover is axially provided with the piston; the main friction device and the auxiliary friction device are matched with each other; the motor end cover is fixedly connected with the planetary gear reducer; the piston is internally sleeved by a first pressing disc; a second pressing disc and the large friction plate are embedded inside the planetary gear reducer by the tooth tip which is arranged on the external circumference thereof; the fixed disc is axially fixed inside the internal tooth ring of the planetary gear reducer. The brake device of the invention integrates a running brake system and a stopping brake system and has simple, safe and reliable structure; the auxiliary friction device brakes firstly and drives the main friction device to brake subsequently; the braking is carried out from interior to the exterior, the braking force changes from small force to large force; the braking is stable and soft.

Owner:WUXI KIPOR POWER CO LTD

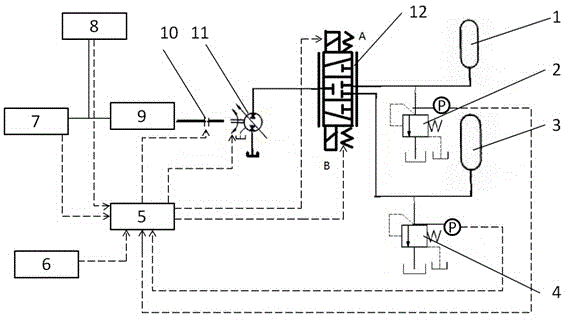

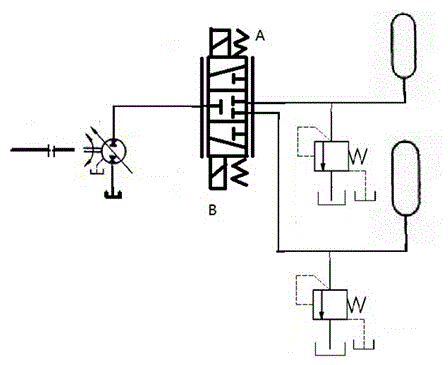

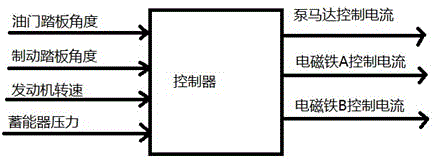

Loader walking and braking energy recovery auxiliary driving device and control method

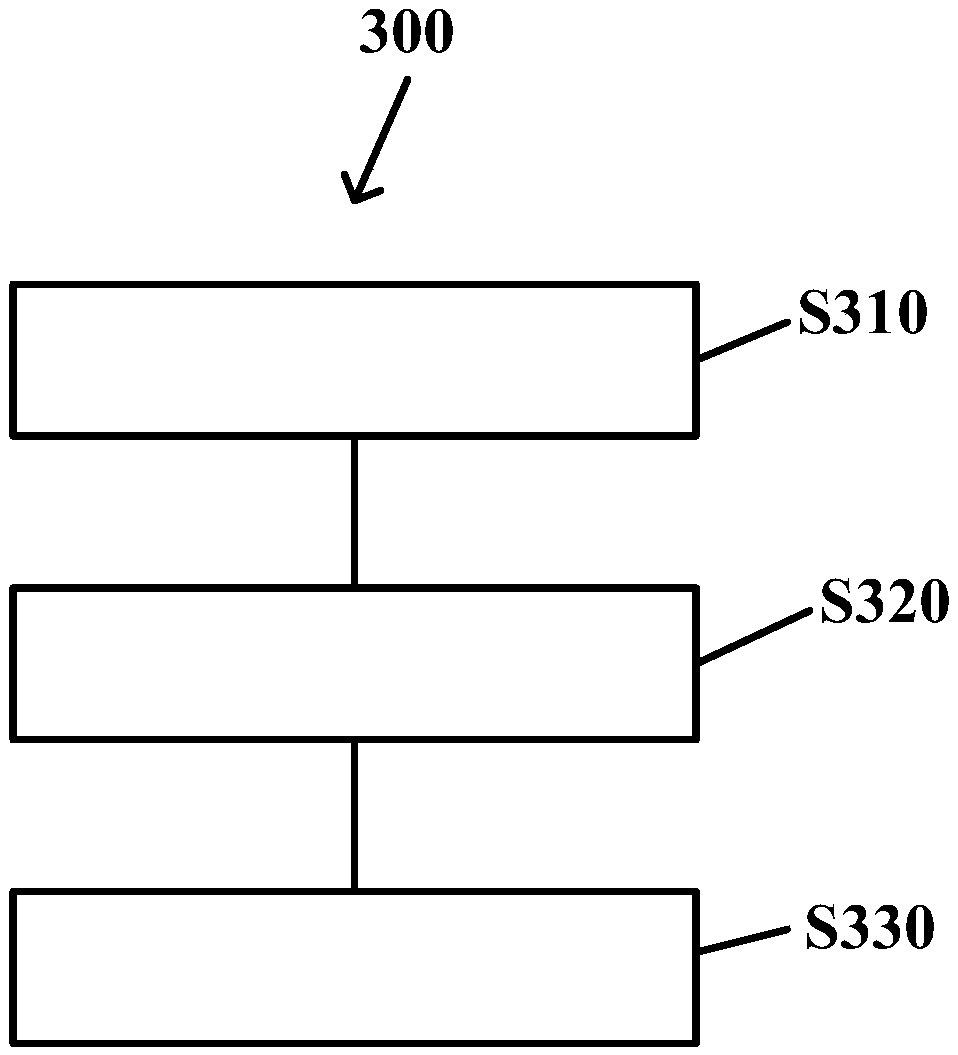

InactiveCN104831774ASmooth rideSmooth brakingSoil-shifting machines/dredgersProportional controlComputer module

The invention provides a loader walking and braking energy recovery auxiliary driving device and a control method. The walking and braking energy recovery auxiliary driving device comprises a controller, a signal monitoring module, a hydraulic auxiliary driving module and a brake module. The hydraulic auxiliary driving module comprises a pump / motor, a three-way flow valve, a small-size accumulator, a large-scale accumulator, an overflow valve 1 and an overflow valve 2. The control method comprises a pump / motor control step and a three-way flow valve control step. Through a three-way proportional control valve, torque impact on the pump / motor is effectively eliminated, so that a loader is allowed to be more smooth and stable in the driving and brake process, the vehicle control performance can be improved; meanwhile, the three-way flow valve is higher in integration level; and compared with two or more switch valves, fault points are reduced, and the device cost is reduced.

Owner:HUNAN WANGDA TECH

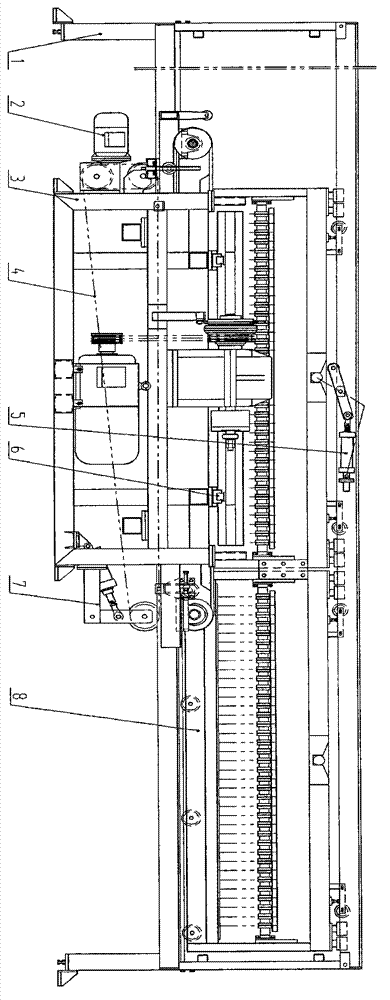

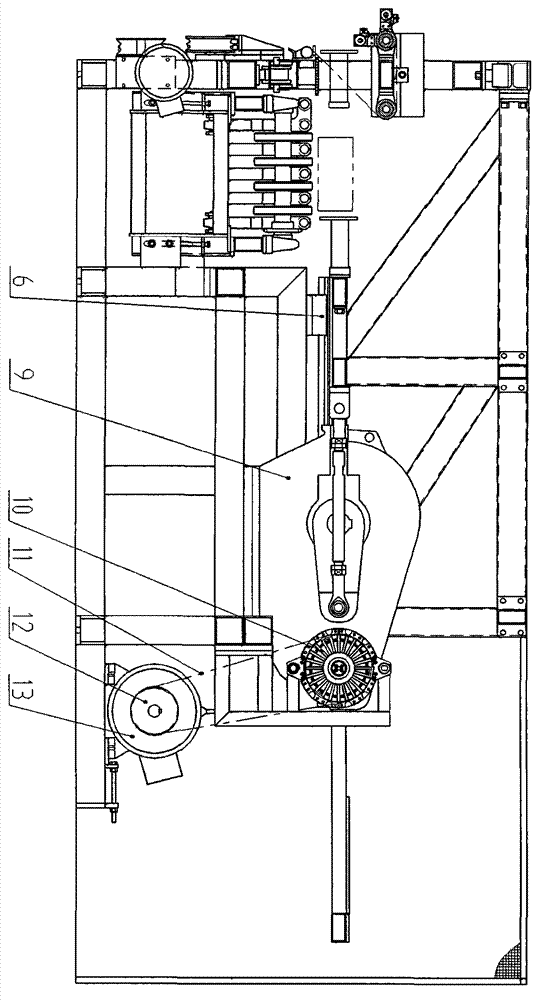

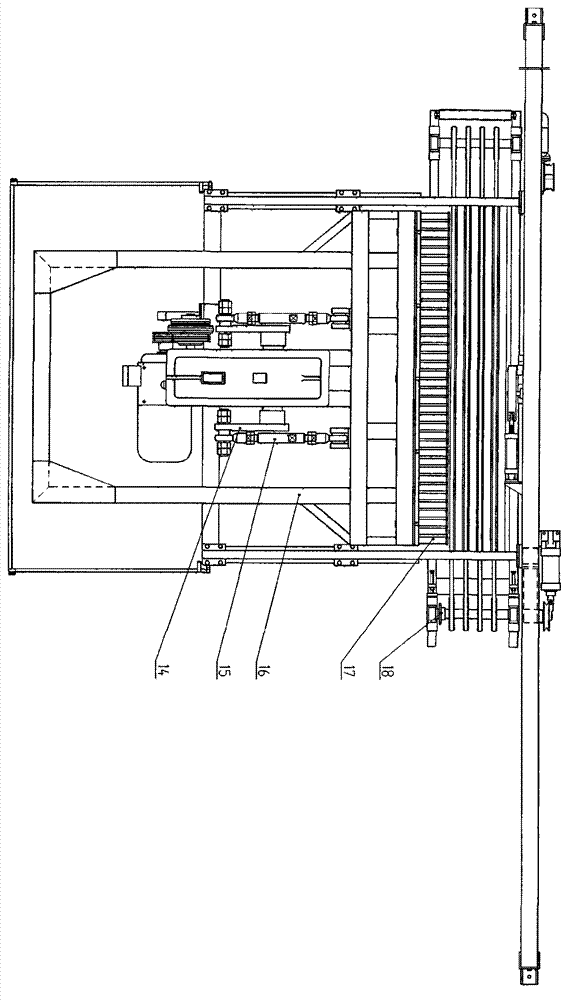

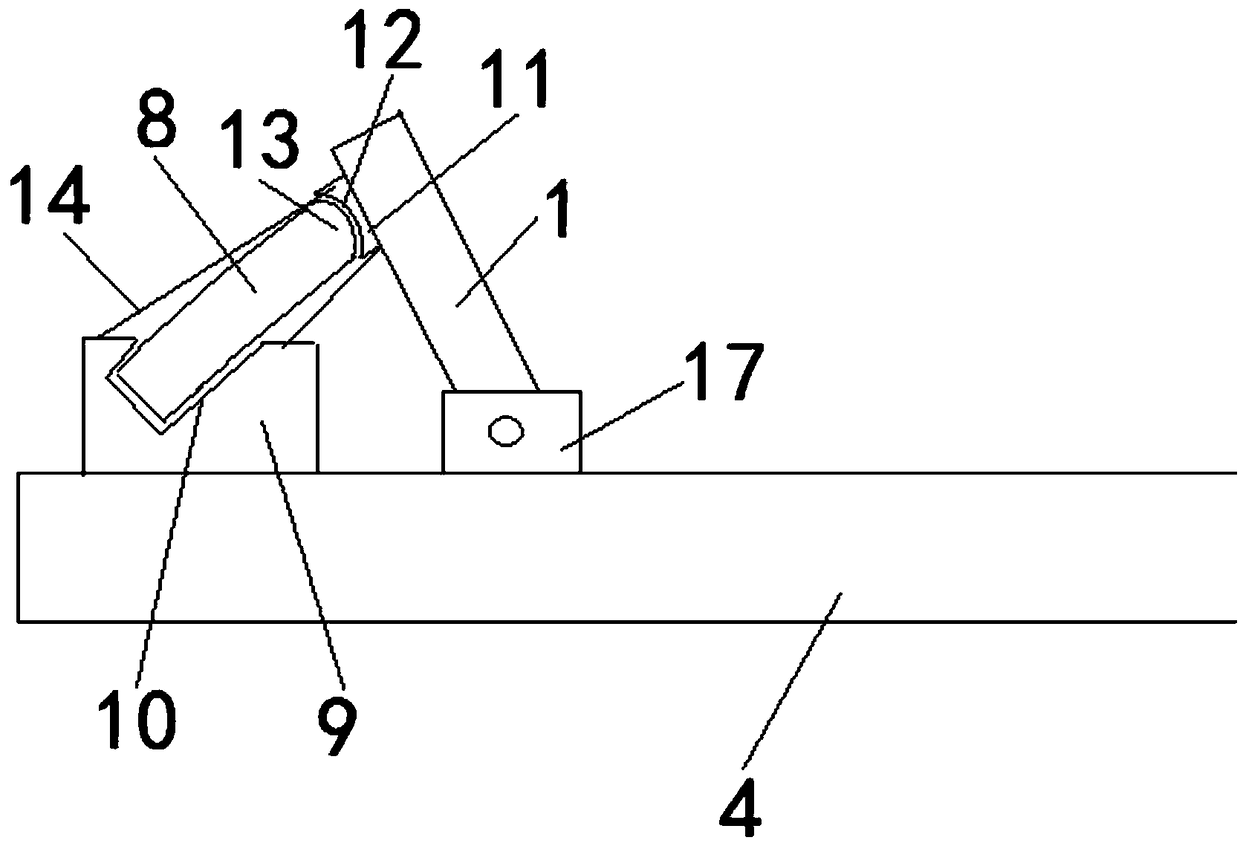

Automatic blank cutter for rigid plastic

ActiveCN102814857ASolve the high frequency of billet cuttingSoft brakingCeramic shaping apparatusClutchAutomaticity

The invention provides an automatic blank cutter for rigid plastic, which mainly consists of a plurality of parts of a rack, a blank cutting steel wire rack track frame, a main transmission device, a blank transporting platform, a blank cutting steel wire rack and a blank cutting steel wire rack traction device. A pneumatic clutch which can be frequently started and braked is adopted as a speed reducer of the main transmission device; after the blank cutting steel wire rack with a double-steel wire blank cutting station is adopted, the blank cutting steel wire rack blank cutting stations can be automatically changed when a blank cutting steel wire is broken; the blank transporting platform adopts a stroke-adjustable air cylinder, so that the lifting height of a roller support can be conveniently controlled; the rack of the blank cutter is wholly welded by hollow square steel, so that the blank cutter is very good in stability and rigidity, and the cutting requirement of a rigid plastic extrusion molding blank body can be met; and due to the use of a linear guide rail pair, the moving precision and the moving stability of the blank body can be improved. The automatic blank cutter for the for rigid plastic is simple in structure, stable to run, reliable in performance, high in automaticity, and suitable for cutting the large-batch rigid plastic extrusion molding mud stripes.

Owner:中节能东方双鸭山建材设备有限公司 +1

Coaxial type hydraulic retarding braking device

InactiveCN102424043ASmall sizeReduce weightAuxillary drivesFluid braking transmissionControl systemDrive shaft

The invention discloses a coaxial type hydraulic retarding braking device, which comprises a transmission shaft, a pulling fork, a positioning mechanism, a clutch assembly, an oil pump rotor, an oil pump casing and an oil pressure control system, wherein the oil pump rotor is born on the transmission shaft through a bearing, a clutch inner sleeve is born on the transmission shaft through a sliding spline in a matching way, a clutch outer sleeve is fixedly connected onto the oil pump rotor for realizing the clutching of the transmission shaft and the rotor, and the oil pump casing is connectedonto a machine frame through screw bolts. The coaxial type hydraulic retarding braking device has the advantages that the size is compact, the weight is light, the energy is saved, the reliability isrealized, and the service life is long. The braking device is convenient to install and refit, the braking force is not attenuated after long-time work, no power consumption is generated during no work, the safety factor is improved, the braking is mild and smooth, no collision is caused, and the coaxial type hydraulic retarding braking device is suitable for vehicle braking, is also suitable forhydraulic motor driving and can also be used for deep wells, deep seas, tool and substance hanging and conveying and the like.

Owner:谢陵波

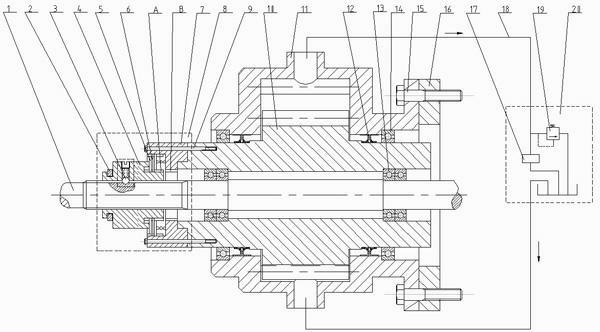

Cam type brake mechanism

The invention discloses a cam type brake mechanism, which comprises a rack, a brake wheel, a rotating shaft, a cam and a steel plate spring. The brake wheel is hinged with the rack. The rotating shaft is connected with a shaft sleeve. The cam is hinged between the rotating shaft and the inner wall of the brake wheel. One end of the cam is a sliding end, and the other end of the cam is a brake end. The outline radius of the brake end is more than or equal to a distance between the rotating center of the cam and the inner wall of the brake wheel, and the outline radius of the other end is less than or equal to the distance between the rotating center of the cam and the inner wall of the brake wheel. The steel plate spring is arranged at the brake end of the cam, and is connected with the shaft sleeve. According to the cam type brake mechanism, the shortcomings of poor brake effects, long brake time and the like are overcome.

Owner:CHONGQING JIANWEI MACHINERY

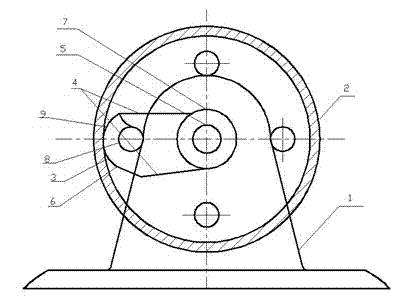

Driving assistance system and brake control unit and brake control method thereof

PendingCN111497843ASuitable for target braking forceImprove experienceControl engineeringControl theory

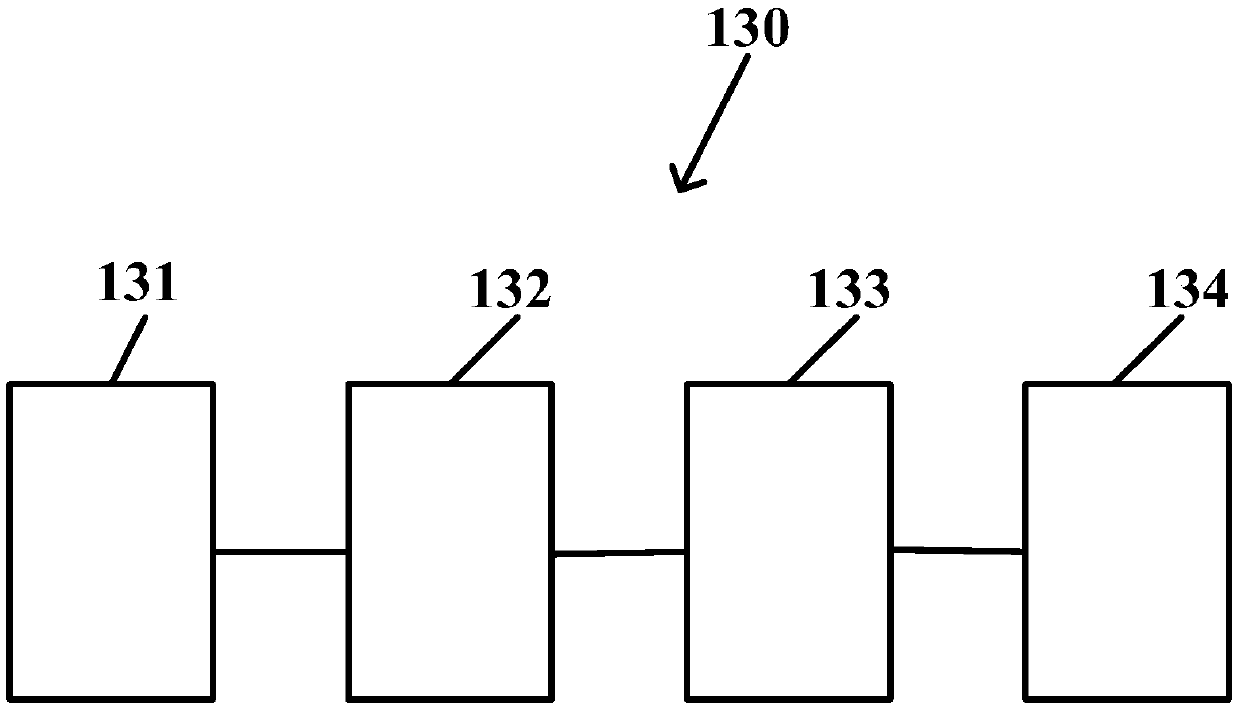

The invention provides a driving assistance system and a brake control unit and a brake control method thereof. A brake control unit (130) according to the present invention includes: an acquisition module (131) configured to acquire driving states of a preceding vehicle and a host vehicle during a climbing period, with the driving states including at least speeds of the preceding vehicle and thehost vehicle and a distance between the preceding vehicle and the host vehicle; a processing module (132) configured to determine whether or not a driving assistance system (100) of the vehicle needsto perform braking on the vehicle based on the acquired driving state, when the vehicle is judged to be braked, acquire the target deceleration of the vehicle, calculate a first braking force item according to the target deceleration, and calculate a second braking force item according to the slope value of the road where the vehicle is located; and a braking force determining module (133) configured to determine a target braking force required by the driving assistance system (100) to brake the vehicle according to the first braking force item and the second braking force item.

Owner:ROBERT BOSCH GMBH

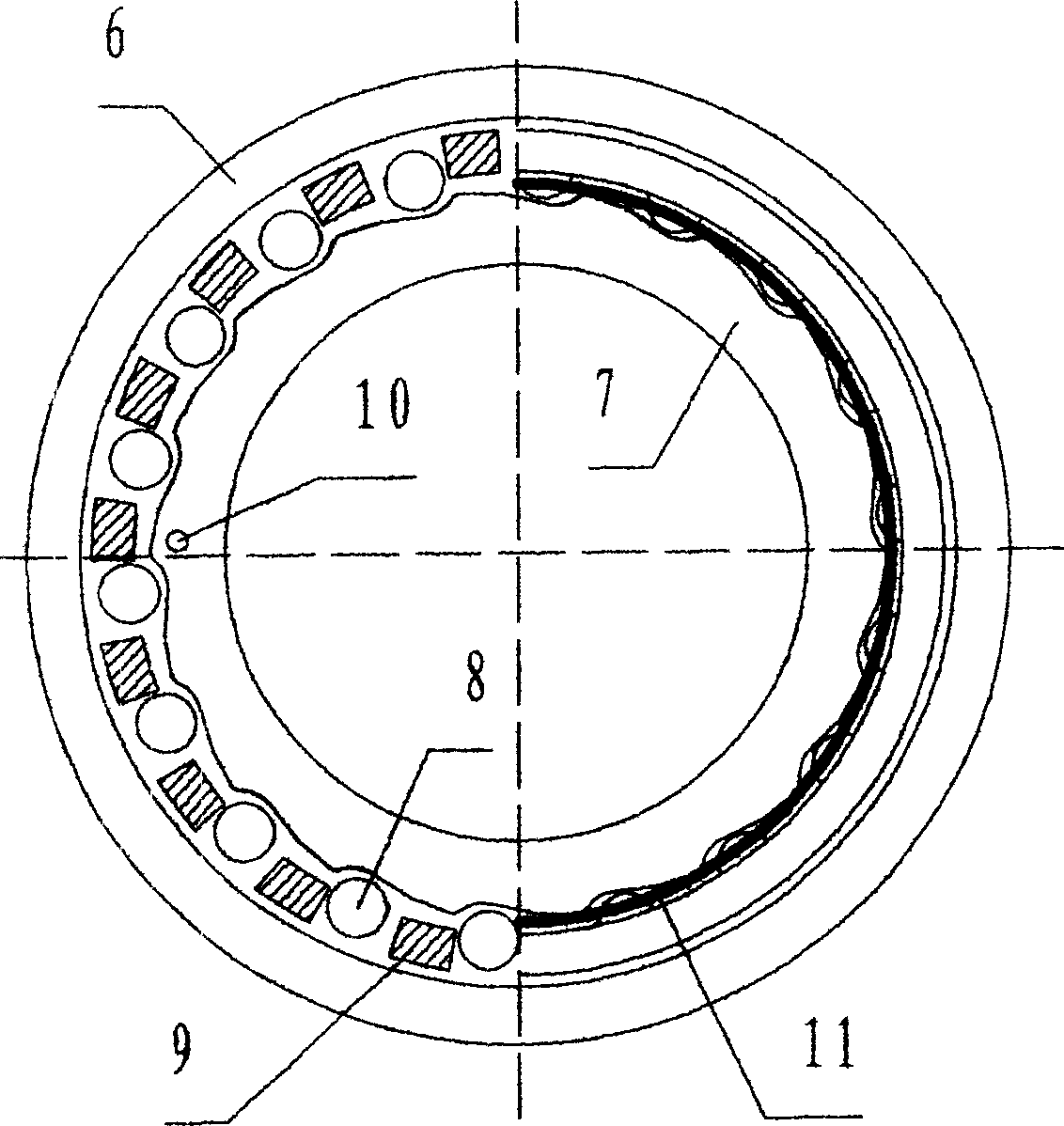

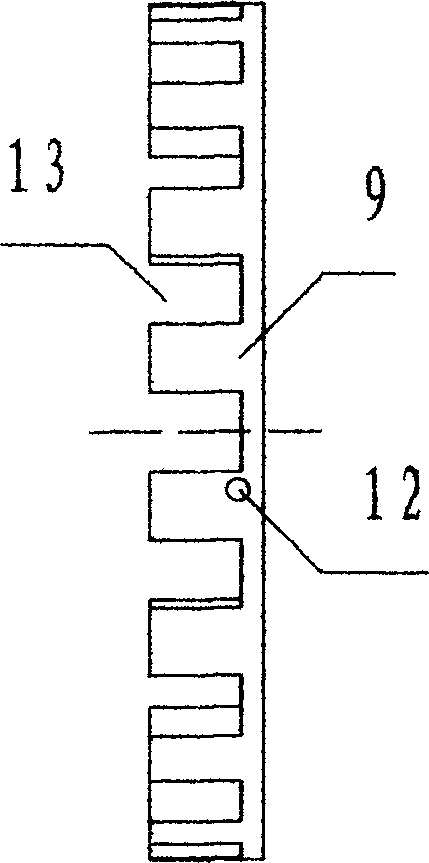

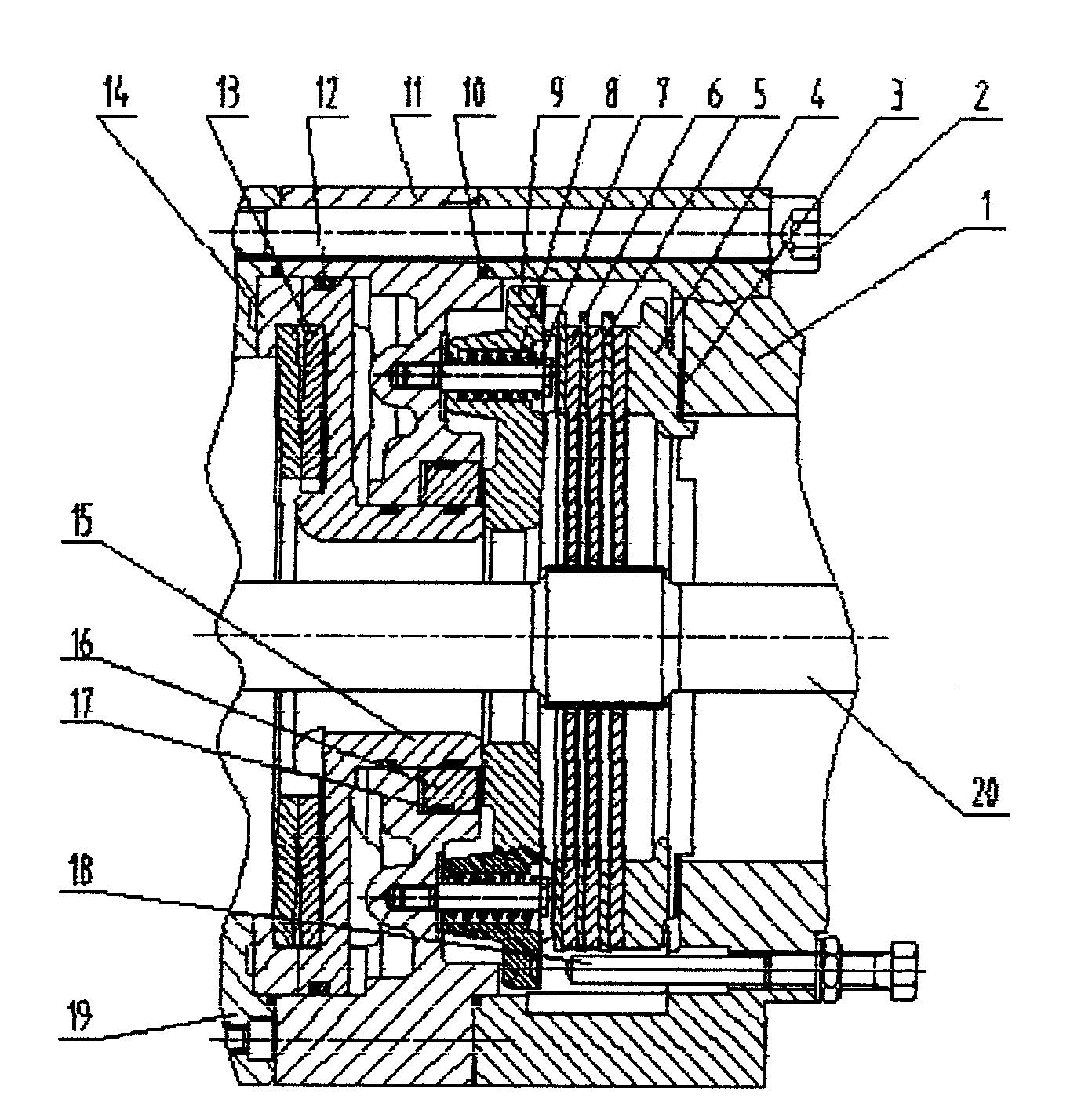

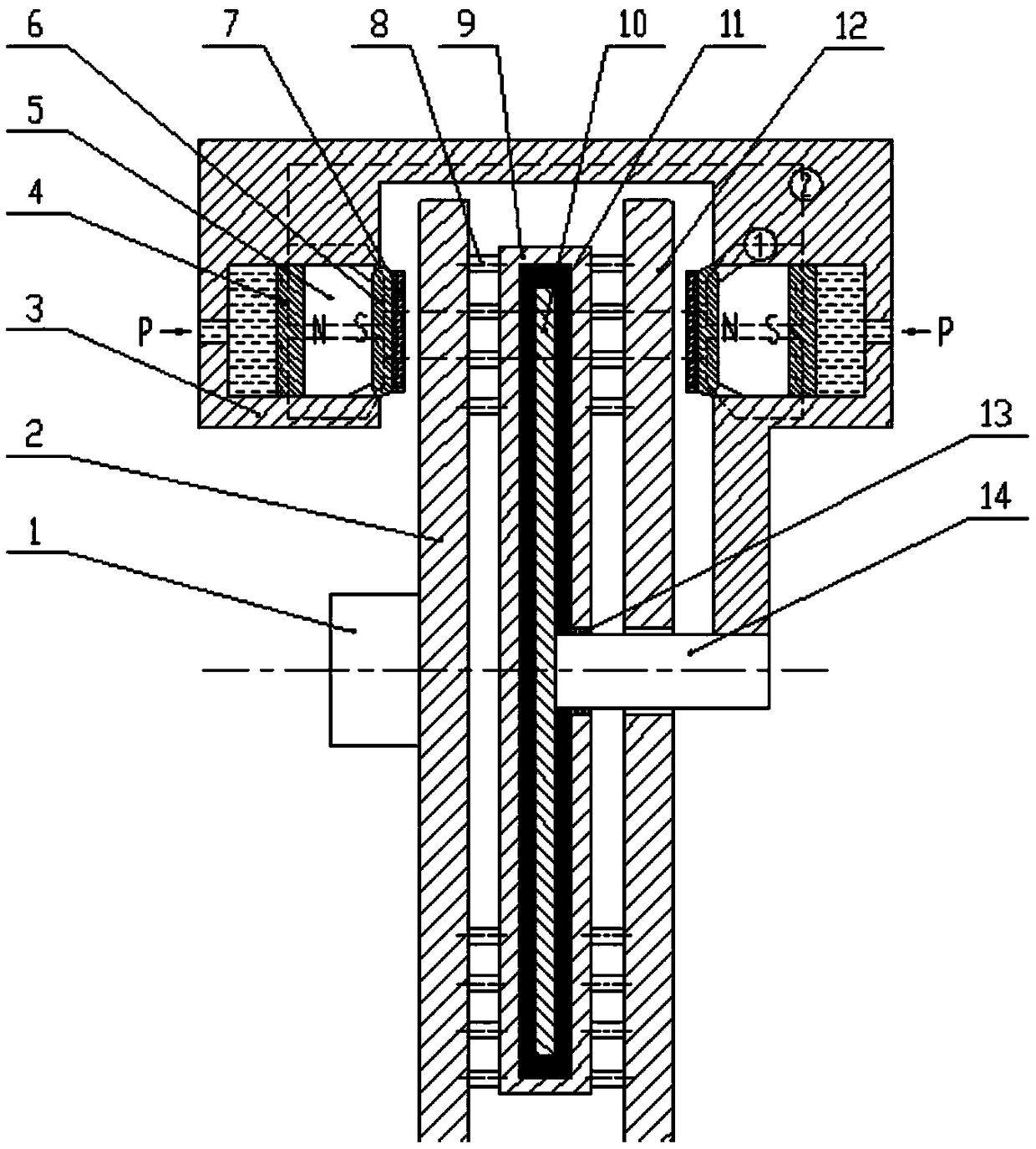

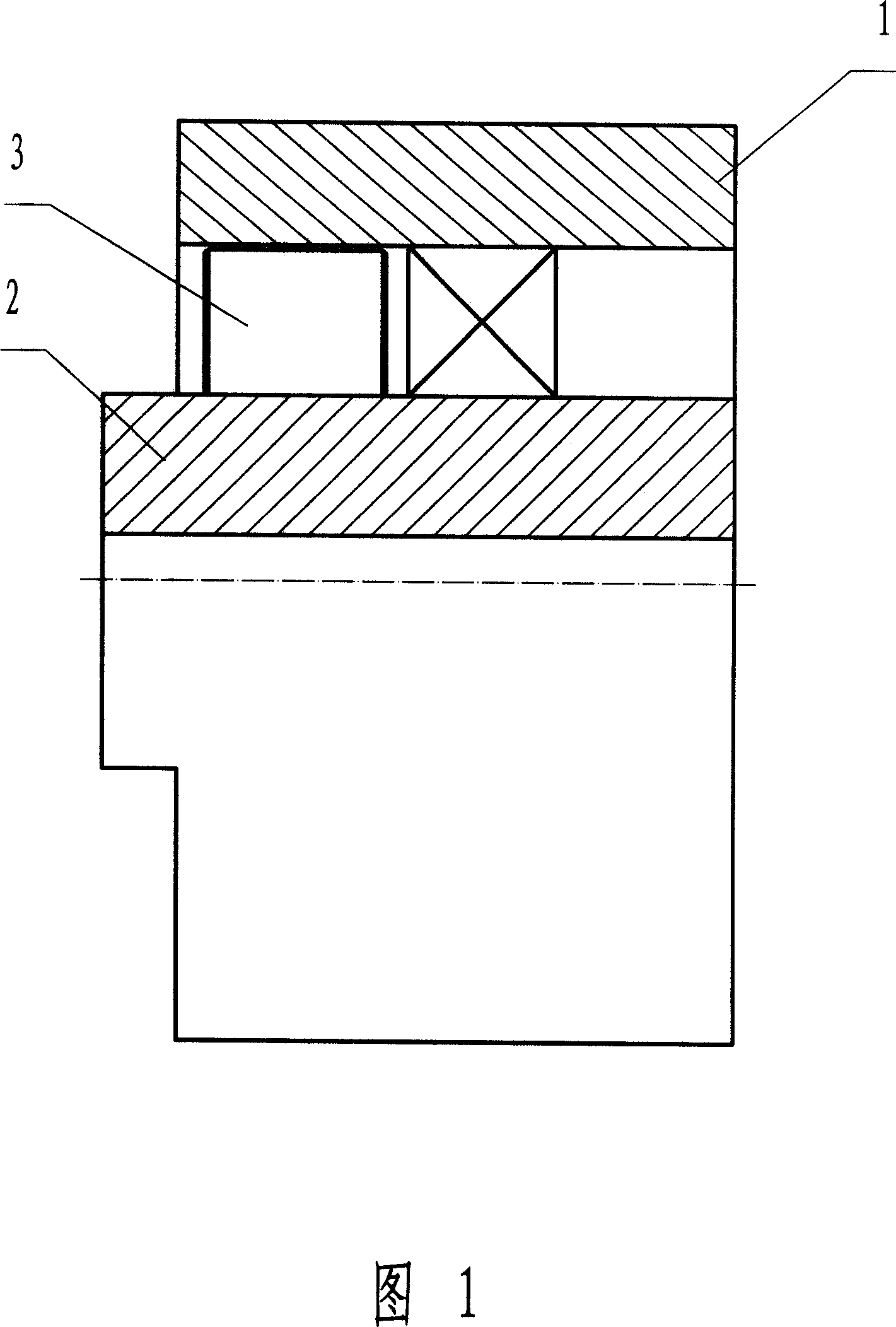

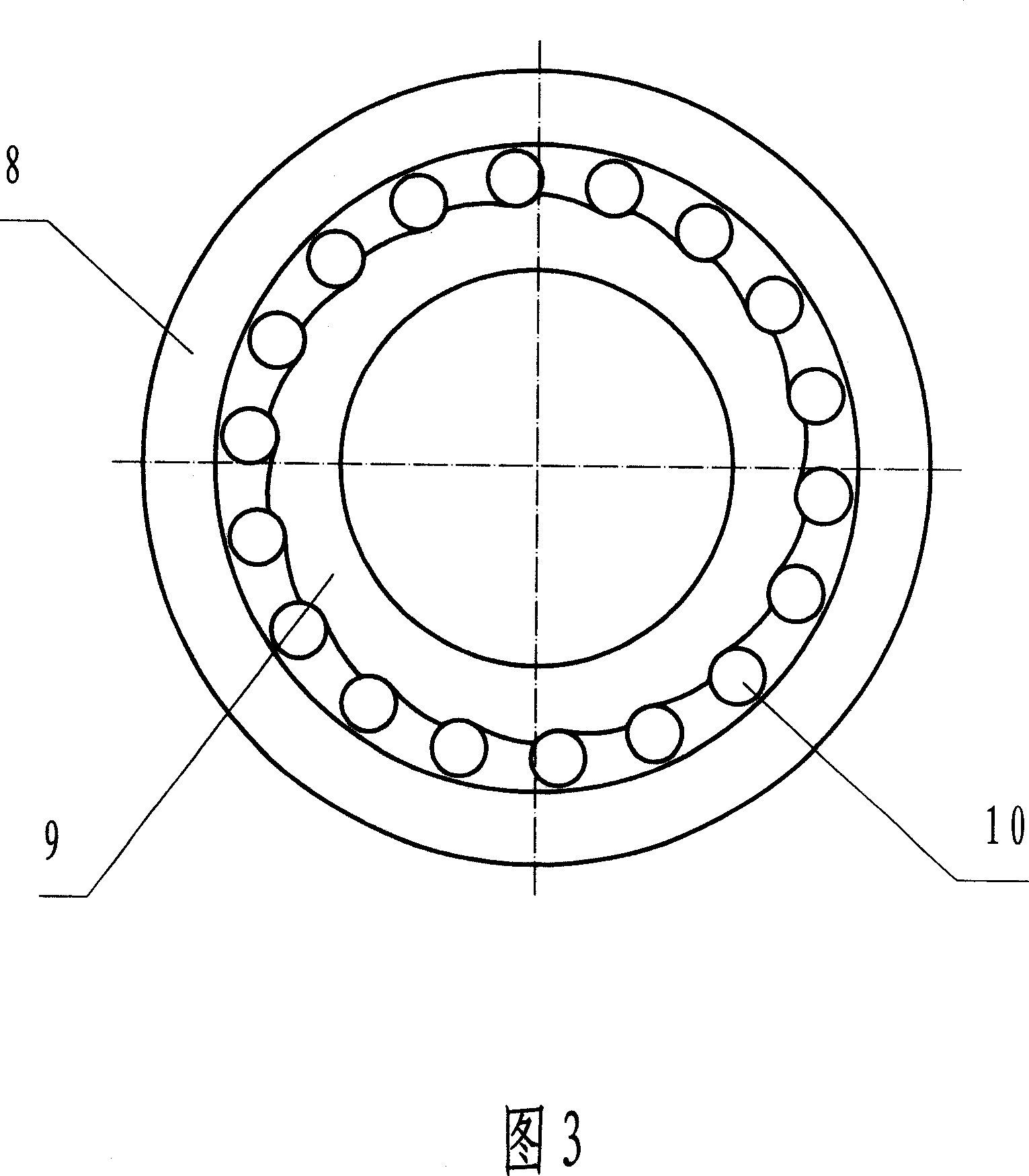

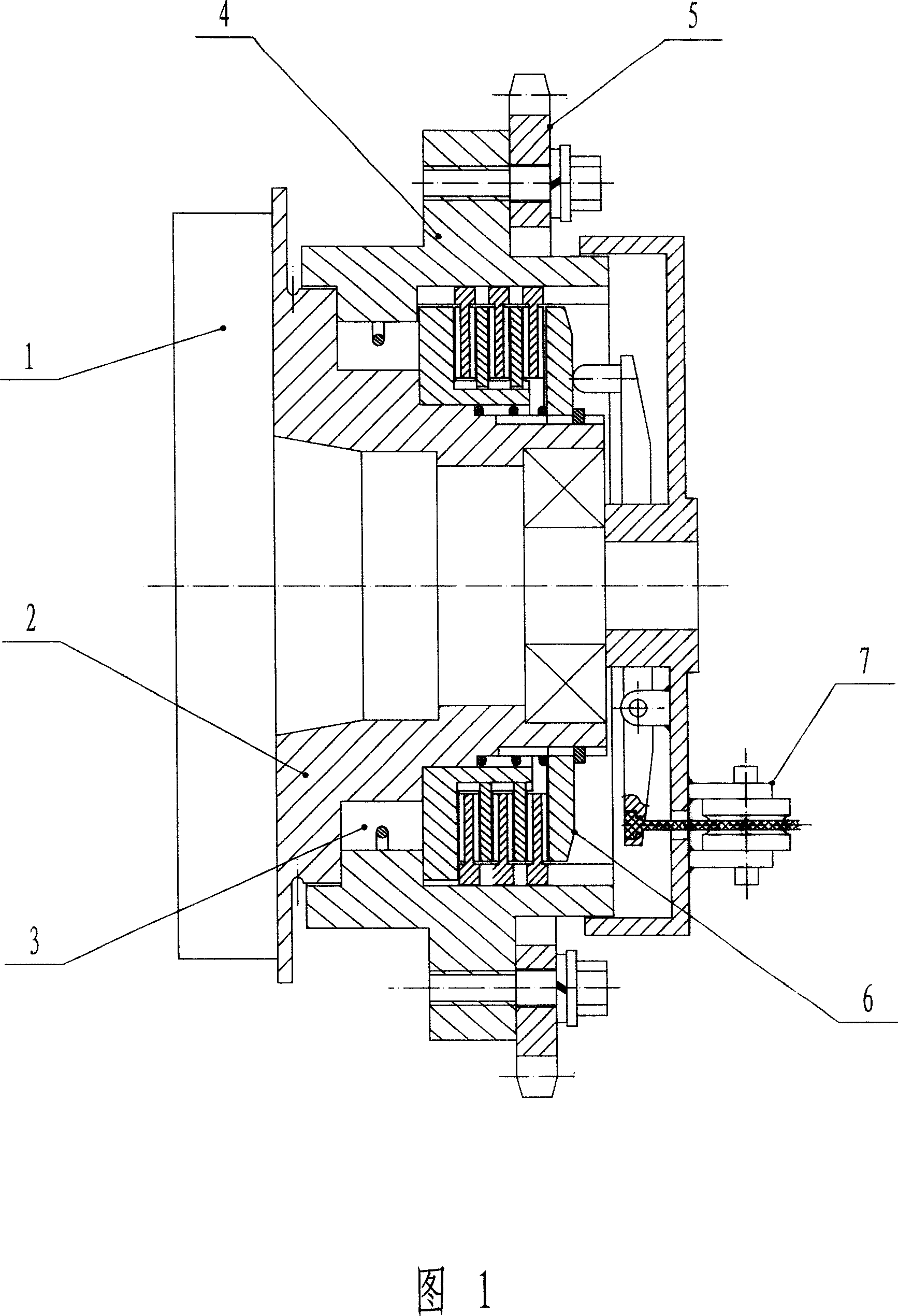

Magnetorheological brake for vehicle

PendingCN109027057AStrong brakingQuick responseLiquid resistance brakesSlack adjustersMagnetorheological fluidPiston

The invention discloses a magnetorheological brake for a vehicle. The magnetorheological brake comprises a brake disc and a brake gate, wherein the brake disc comprises a brake connecting shaft (1), abrake left disc (2), a magnetic-conducting ventilating connecting column group (8), and a magnetorheological fluid shell body (9), a brake right disc (12) and a magnetorheological fluid brake disc (10) which are fixedly connected in sequence; and the brake gate comprises an outer piston (4), a magnetic field generating device (5), an inner piston (6) and a friction liner (7) which are connected in sequence. The magnetorheological brake disclosed by the invention has the magnetorheological fluid brake and mechanical-friction composite brake functions, and the brake capability is strong; the magnetorheological fluid brake function can be achieved in an instant when the pistons of the brake gate move, the response speed is high, the idle brake stroke is avoided, and the safety is high; the magnetorheological fluid brake power flexibility is controllable, the impact is small, and the degree of comfort is high; and the vehicle brake safety, reliability and comfort can be effectively improved.

Owner:XUZHOU UNIV OF TECH

Ceramic-based friction material and method for preparing same

ActiveCN101831273BReduce generationReduce pollutionOther chemical processesFriction liningFrictional coefficientMaterials science

The invention discloses a ceramic-based friction material and a method for preparing the same. The ceramic-based friction material consists of the following raw materials in part by weight: 6 to 8 parts of thermal plasticity phenolic resin or modifier thereof, 7 to 8 parts of potassium titanate whisker, 5 to 6 parts of attapulgite clay, 3 to 4 parts of expanded vermiculite, 4 to 5 parts of butyronitrile rubber powder, 4 to 5 parts of chromite powder, 12 to 13 parts of ceramic fiber, 3 to 4 parts of powdered coke, 14 to 15 parts of barium sulfate, 5 to 6 parts of artificial graphite, 9 to 10 parts of scale graphite, 7 to 8 parts of organic rubbing powder, 3 to 4 parts of sericite, 0.5 to 1 part of aluminum oxide, 3 to 4 parts of copper fiber, 3 to 4 parts of coloring agent and 0.5 to 1 part of organic fiber. The preparation method comprises the following steps of: material blending, cold press moulding, hot press moulding, polishing and curing treatment. The ceramic-based friction material has the advantages of high and stable frictional property, suitable frictional coefficient, low wear rate, low hardness, no damage to friction coupling materials, low braking noise, and extremelylow environmental pollution; and in use, the ceramic-based friction material has the advantages of smooth braking, gentleness, comfortability, safety and reliability.

Owner:YUTIAN COUNTY JUNDA AUTOMOBILE PARTS MFG CO LTD

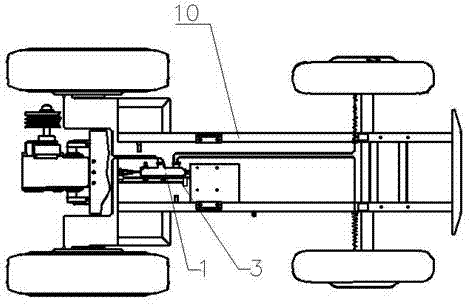

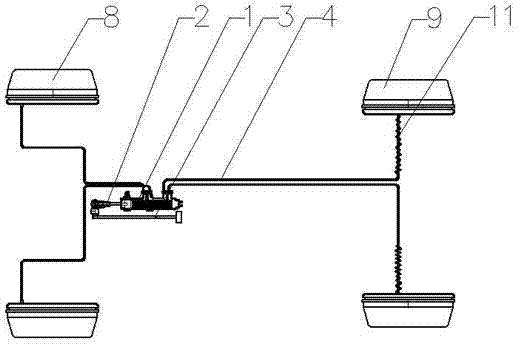

Agricultural vehicle four-wheel brake device

InactiveCN103832415ASafe and smooth brakingSimple structureBraking element arrangementsFluid braking transmissionDrum brakeVehicle frame

The invention discloses an agricultural vehicle four-wheel brake device which comprises a frame, front wheels, back wheels and a brake system. The brake system comprises a brake master pump, a brake foot bar, brake drums and a pipeline system, the brake master pump and the brake foot bar are installed on the frame, and the brake foot bar is connected with the brake master pump through a brake push rod. The brake drums are fixedly installed on the two front wheels and the two back wheels respectively, and the four brake drums are respectively connected with the brake master pump through the pipeline system. Brake pads and brake auxiliary pumps are installed in the brake drums, the brake pads are connected with the brake auxiliary pumps through sliding blocks, and the brake auxiliary pumps are connected with the brake master pump through the pipeline system. The agricultural vehicle four-wheel brake device is improved by an original gear brake mode of a 91 chassis, a four-wheel drum brake is achieved, braking is safe and stable, and the agricultural vehicle four-wheel brake device is better suitable for rural areas complex in road condition. The agricultural vehicle four-wheel brake device is simple in structure, soft in braking, safe and reliable.

Owner:GUANGXI HECHI DEJIAN AGRI EQUIP MFG

Motor vehicle hub driving device

The invention is an engine hub driver, belonging to the technical field of hub drivers, providing a flexible connected driver, compriisng hub, drive shaft, auto-controlled clutch and controlled clutch, where the drive shaft is arranged in the hub, the auto-controlled clutch is arranged between the left segments of the hub and drive shaft, and the controlled clutch is arranged between their right segments; a spider of the auto-controlled clutch is arranged on the drive shaft, the roller is arranged between the spider and the hub, when the speed of the spider is higher than that of the hub, the drive shaft drives the hub through the spider, and when the speed of the hub is higher than that of the spider, the hub exceeds the drive shaft to rotate; the input end of the controlled clutch is connected with the hub and the output end of the controlled clutch is connected with the drive shaft, and ordinarily, the controlled clutch is separated from the hub and the drive shaft but jointed with them by control so that the hub can be driven by the drive shaft to reversely drag the engine.

Owner:广州天马集团天马摩托车有限公司

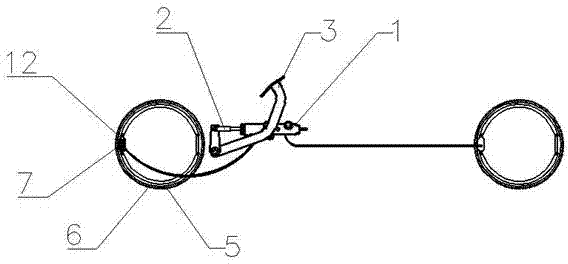

Motorcycle flexible controllable wheel-hub driving device

The flexible and controllable hub driving device of motorcycle belongs to the technical field of hub driving device. The resolved technical problem is to provide a flexible driving device. The project for resolving the problem contains hub, driving axis, self-control clutch, chain pulley seat, chain pulley, control clutch and its control device. The chain pulley locates on the right section of the chain pulley seat. The self-control clutch sets between the left section of driving axis and the left section of chain pulley seat. When the rotate speed of the chain pulley seat is larger than that of the driving axis, the chain pulley seat drives the driving axis rotating. When the rotate speed of the chain pulley seat is smaller than that of the driving axis, the driving axis exceeds the chain pulley seat for rotating. The control clutch equips between the right section of the driving axis and the right section of the chain pulley seat. Its input ends links the driving axis and output end links the chain pulley seat. It always separates but combines when controlling. Its control device locates on the right end of the control clutch. Its output end contacts the control clutch and input end links the manual or foot control operation device.

Owner:广州天马集团天马摩托车有限公司

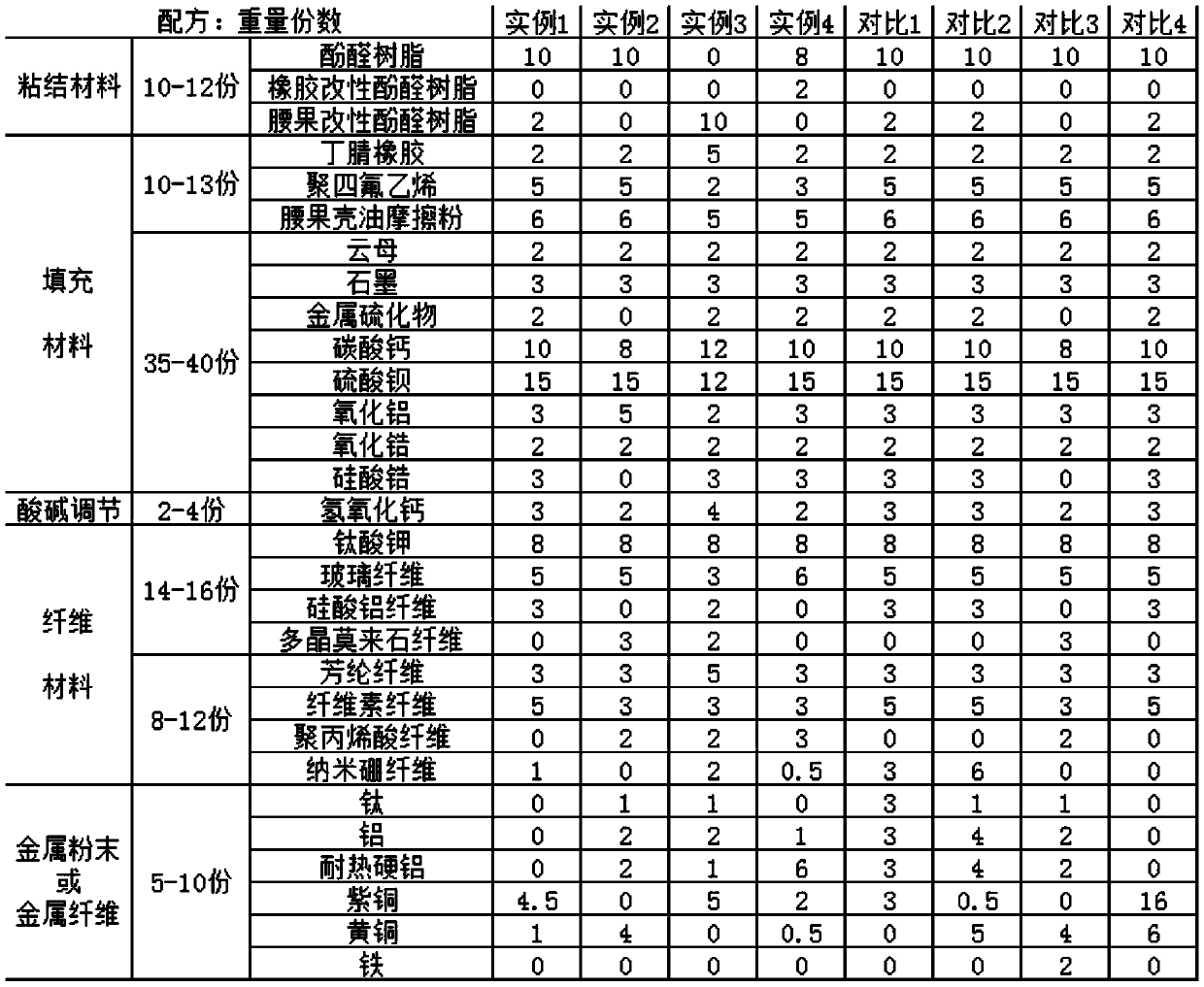

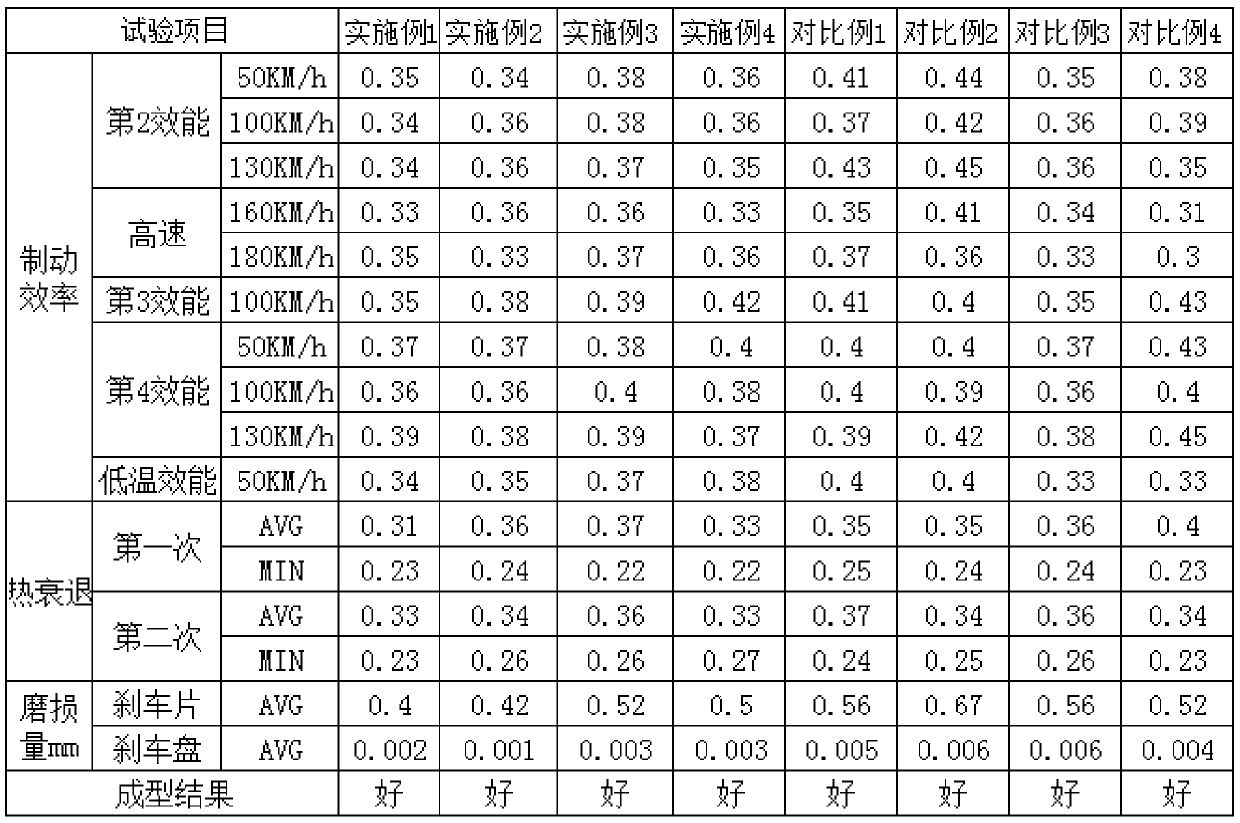

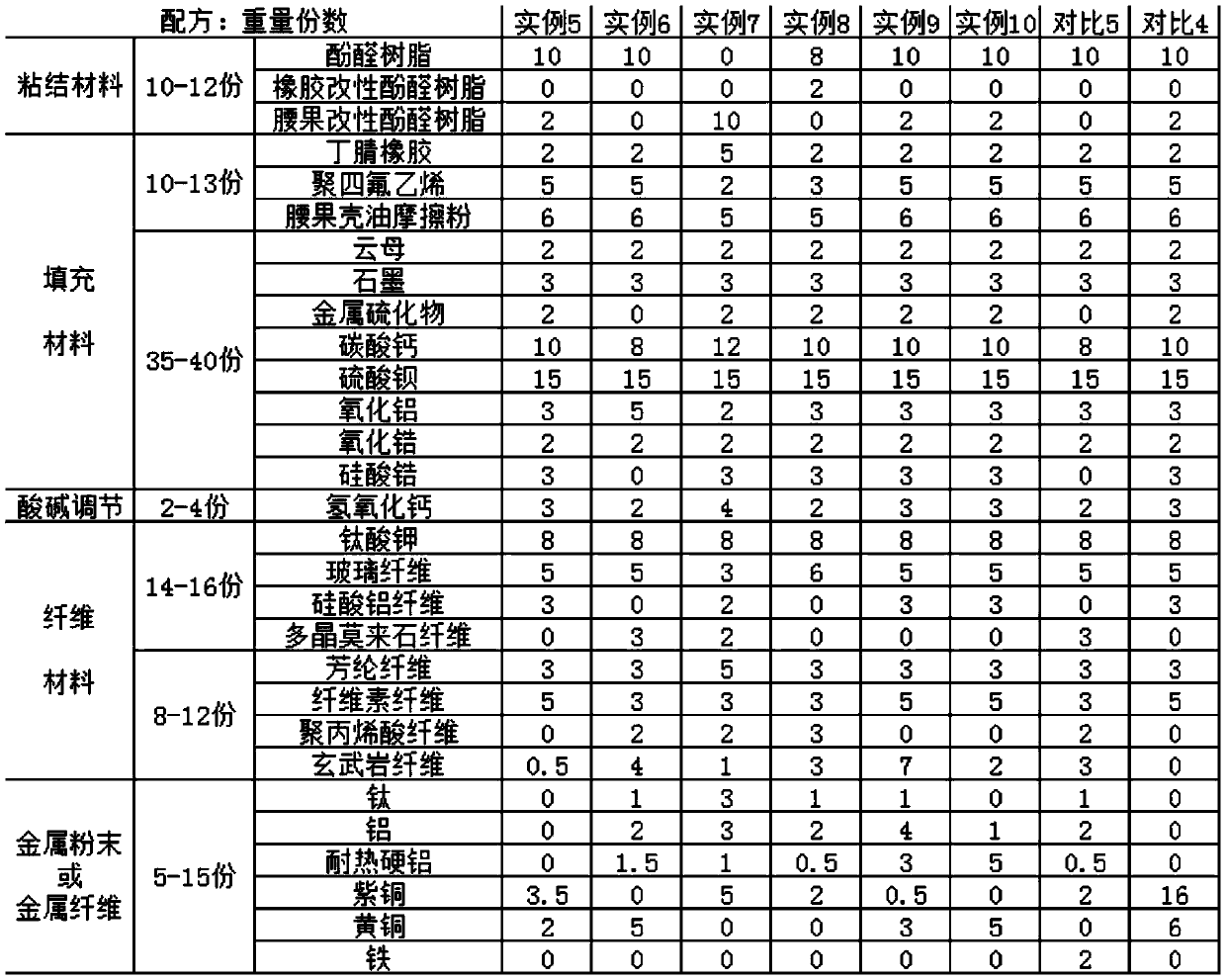

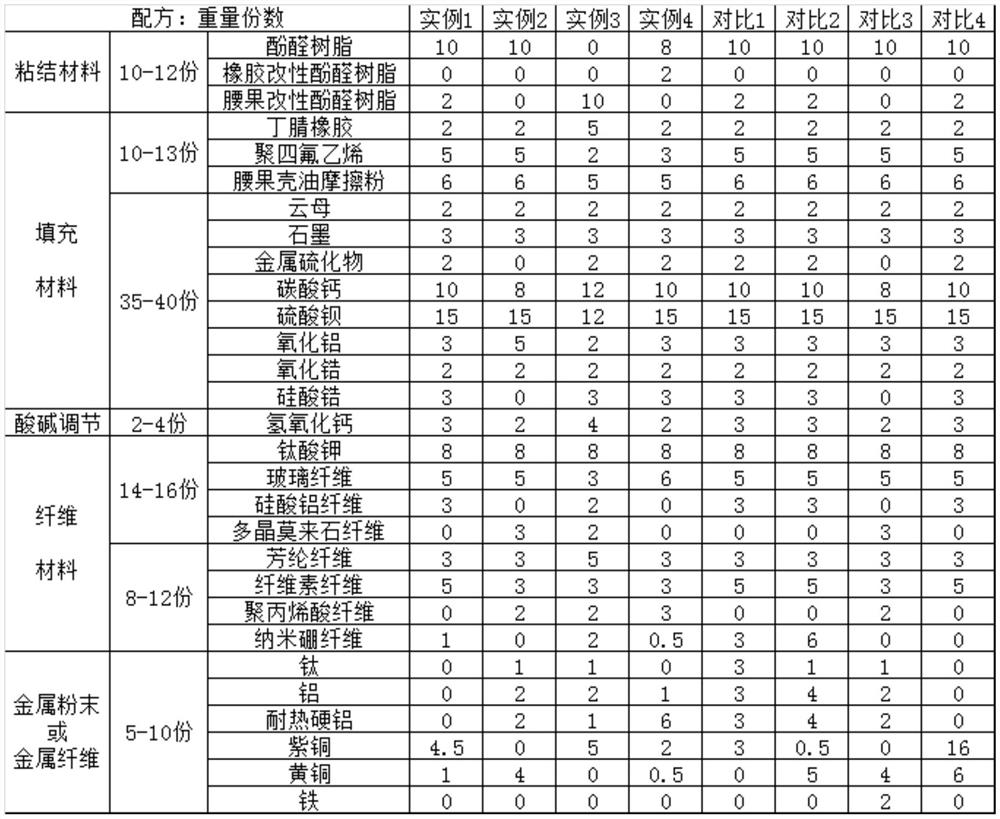

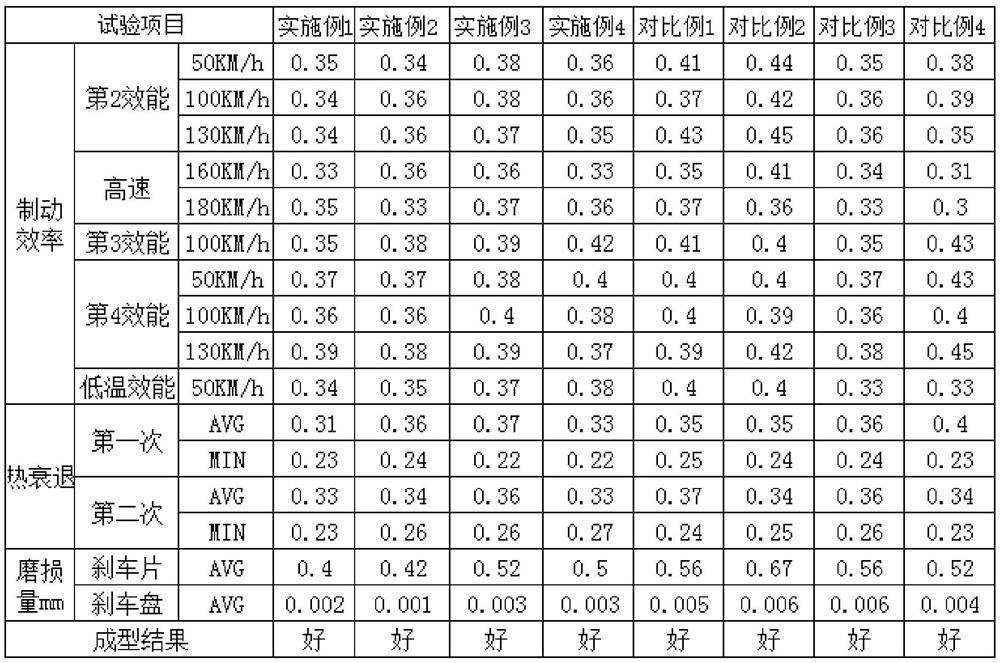

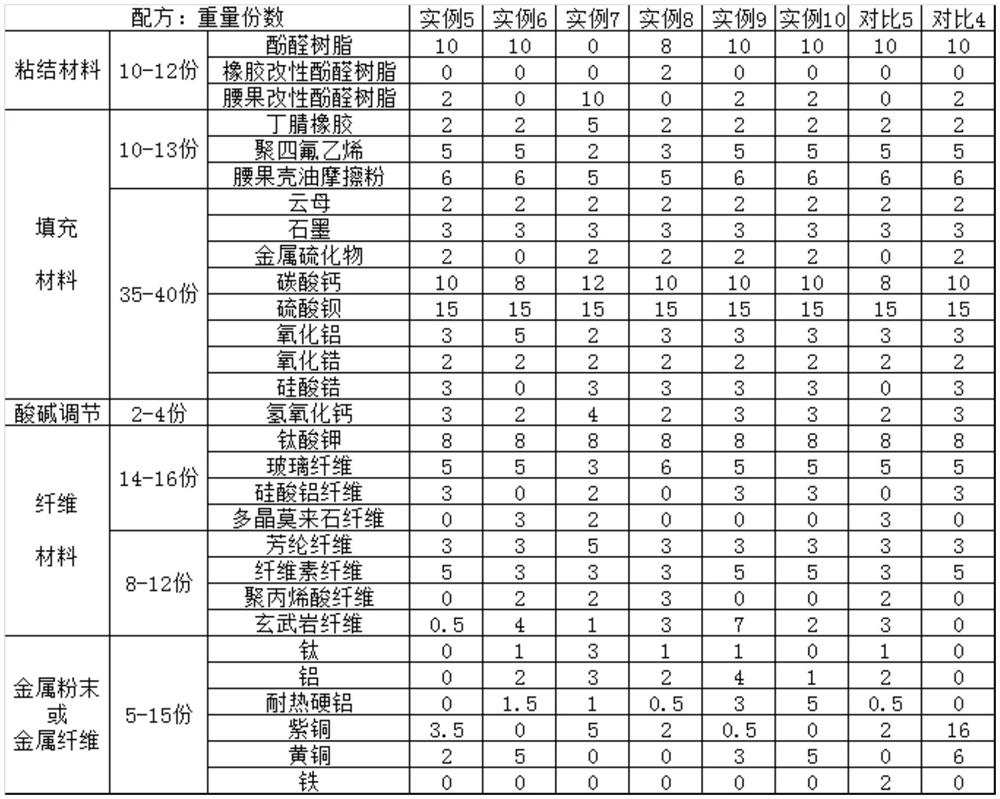

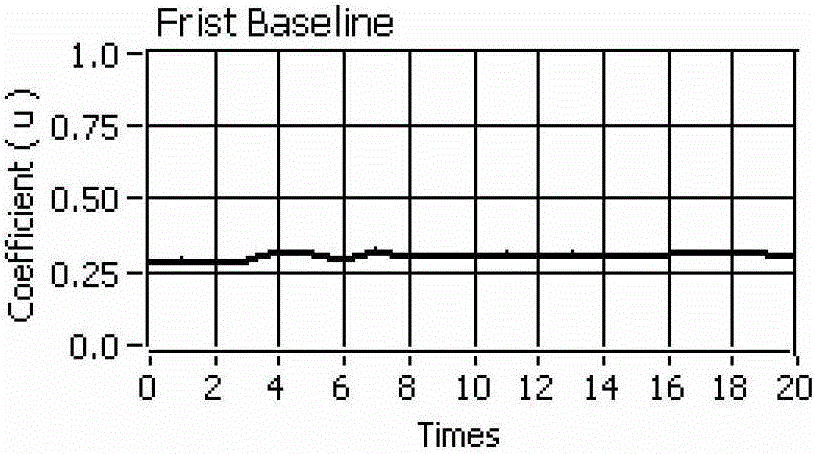

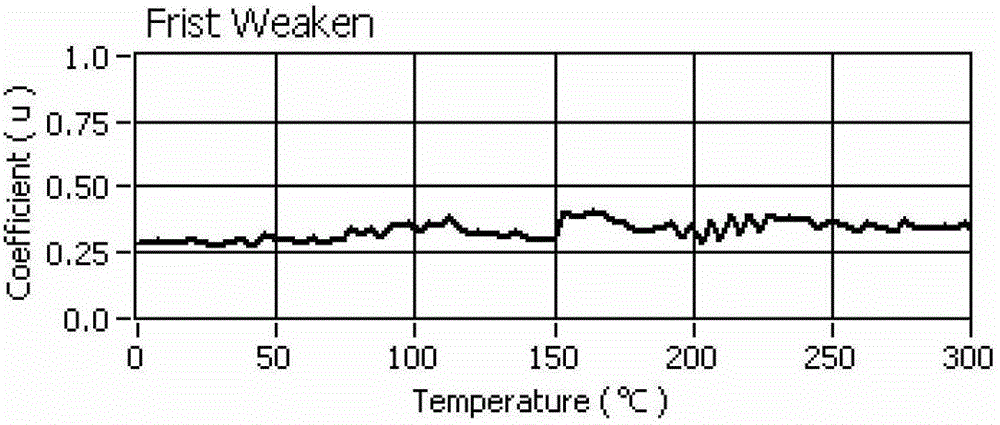

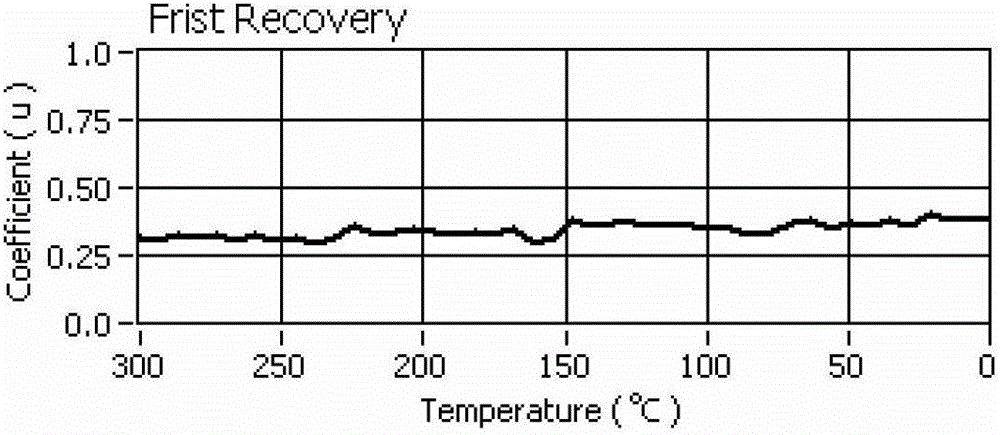

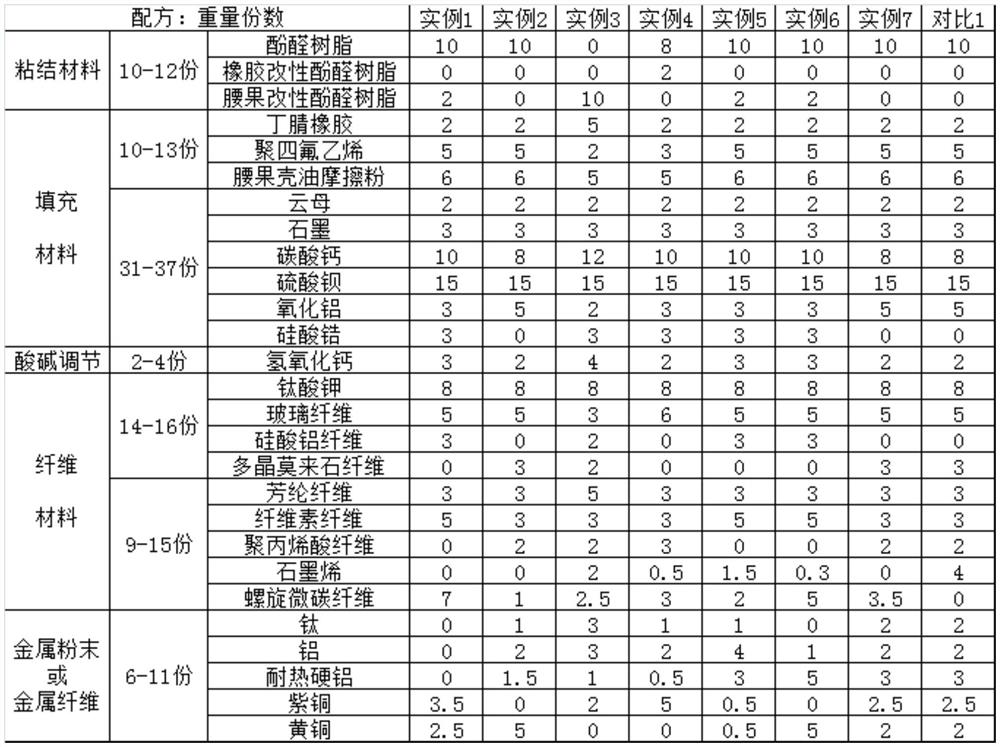

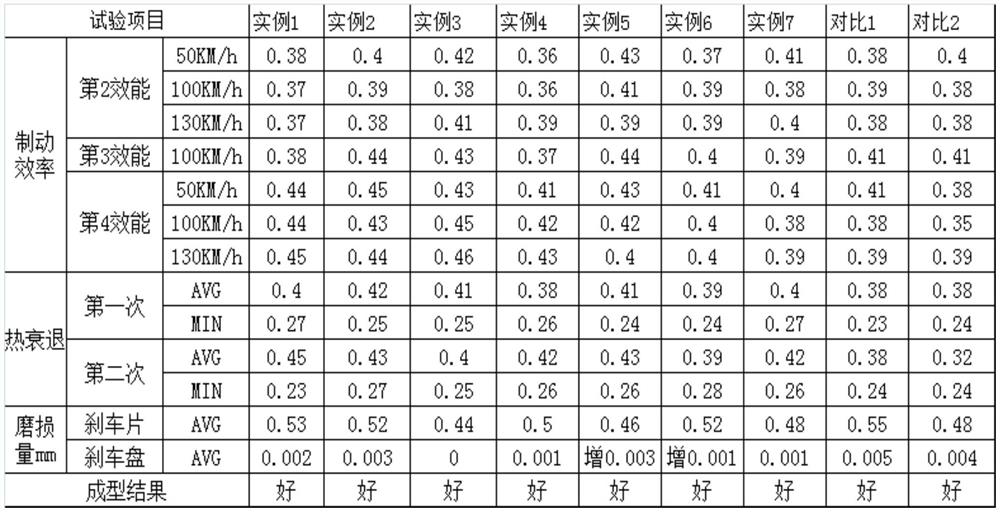

Low-copper asbestos-free organic friction material and product

ActiveCN110273952AStable coefficient of frictionReduce aggressionOther chemical processesFriction liningMetal fibersBoron fiber

The invention relates to a low-copper asbestos-free organic friction material. The low-copper asbestos-free organic friction material is prepared from the following components in parts by weight: 10-15 parts of a binding material, 45-55 parts of a filling material, 20-30 parts of a fiber material, 2-4 parts of an acidity-alkalinity adjusting material and 5-15 parts of metal fiber or metal powder, wherein the fiber material contains nano boron fiber or basalt fiber; the metal fiber or the metal powder is selected from one or combination of more of titanium, aluminum, heat-resistant hard aluminum, red copper and brass; and the content of copper is less than 5%. According to the formula of the friction material, consumption of red copper and brass is reduced; the strictly-selected and added metal components comprise titanium, aluminum and heat-resistant hard aluminum; the organic fiber contains nano boron fiber or basalt fiber, so that the impact toughness of the product is improved; the stable friction coefficient of the friction material is maintained; the braking process is gentle, stable and comfortable; the defect of unstable friction coefficient of the commercially available high-copper organic friction material under the high-speed and low-temperature condition can also be overcome; and the friction pair aggression can be effectively reduced.

Owner:晋江市凯燕新材料研究院股份有限公司

Three-bridge relay valve

The invention discloses a three-bridge relay valve. The three-bridge relay valve comprises a valve cover and a valve body in tight connection with the valve cover, wherein a control hole is formed inthe valve cover, an air supply hole, a braking air inlet, six braking air outlets and a braking air exhausting hole are formed in the valve body, and a braking piston is mounted in the valve piston; abraking air cavity is communicated with the braking air outlets; a heavy braking variable-pressure adjustment valve and a light braking variable-pressure adjustment valve are arranged on one side ofthe valve body, an air inlet of the heavy braking variable-pressure adjustment valve is communicated with the braking air outlets, an air outlet of the heavy braking variable-pressure adjustment valveis communicated with an air inlet of the light braking variable-pressure adjustment valve, and an air outlet of the light braking variable-pressure adjustment valve is communicated with a buffer aircavity through a third pipeline. According to the three-bridge relay valve, the flexible and smooth braking can be realized when a vehicle is light or the road condition is simple, and the braking sensitivity is high when the vehicle is heavy or the road condition is complex, so that the three-bridge relay valve can meet the braking requirements of different loads or road conditions.

Owner:李中辉

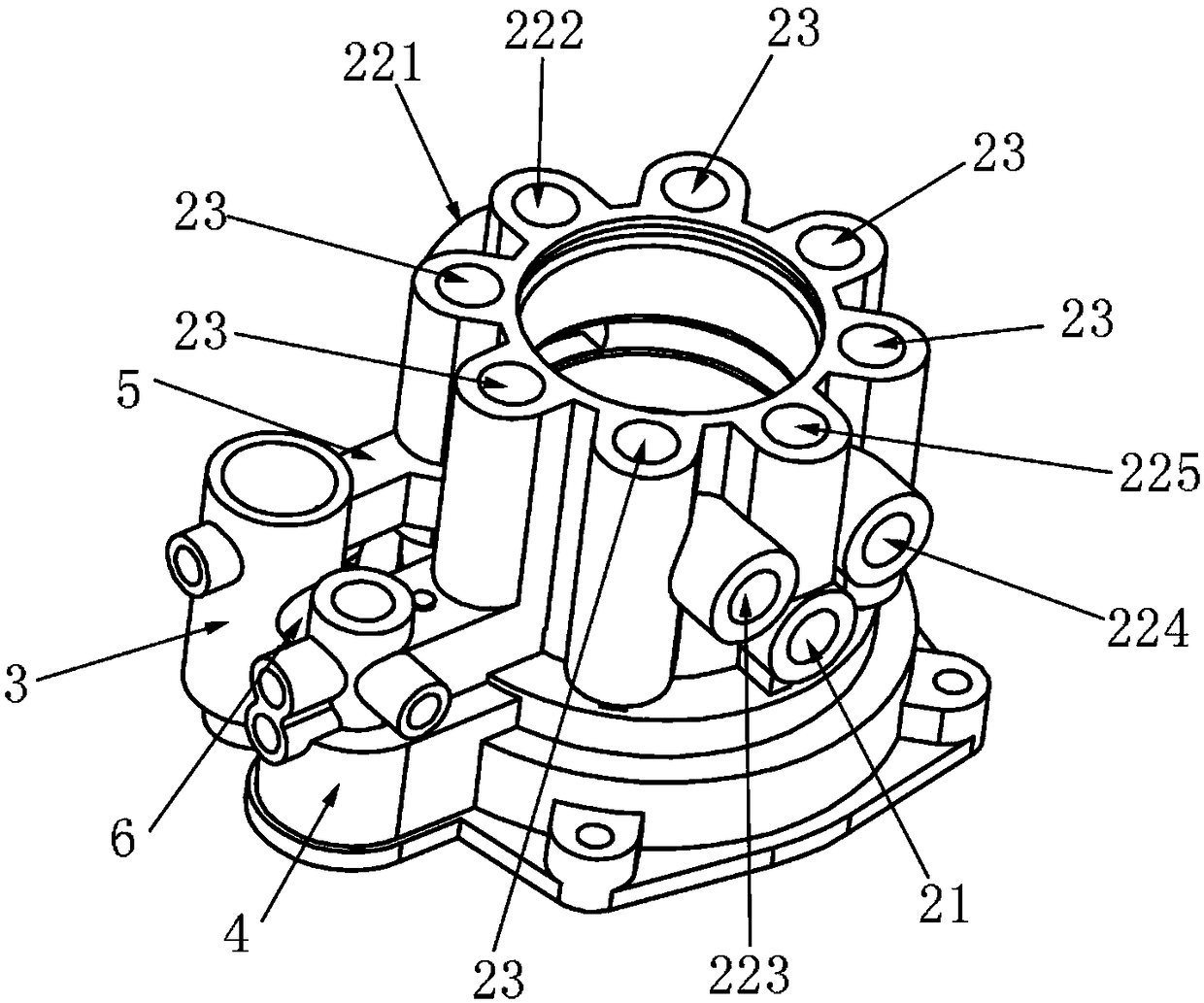

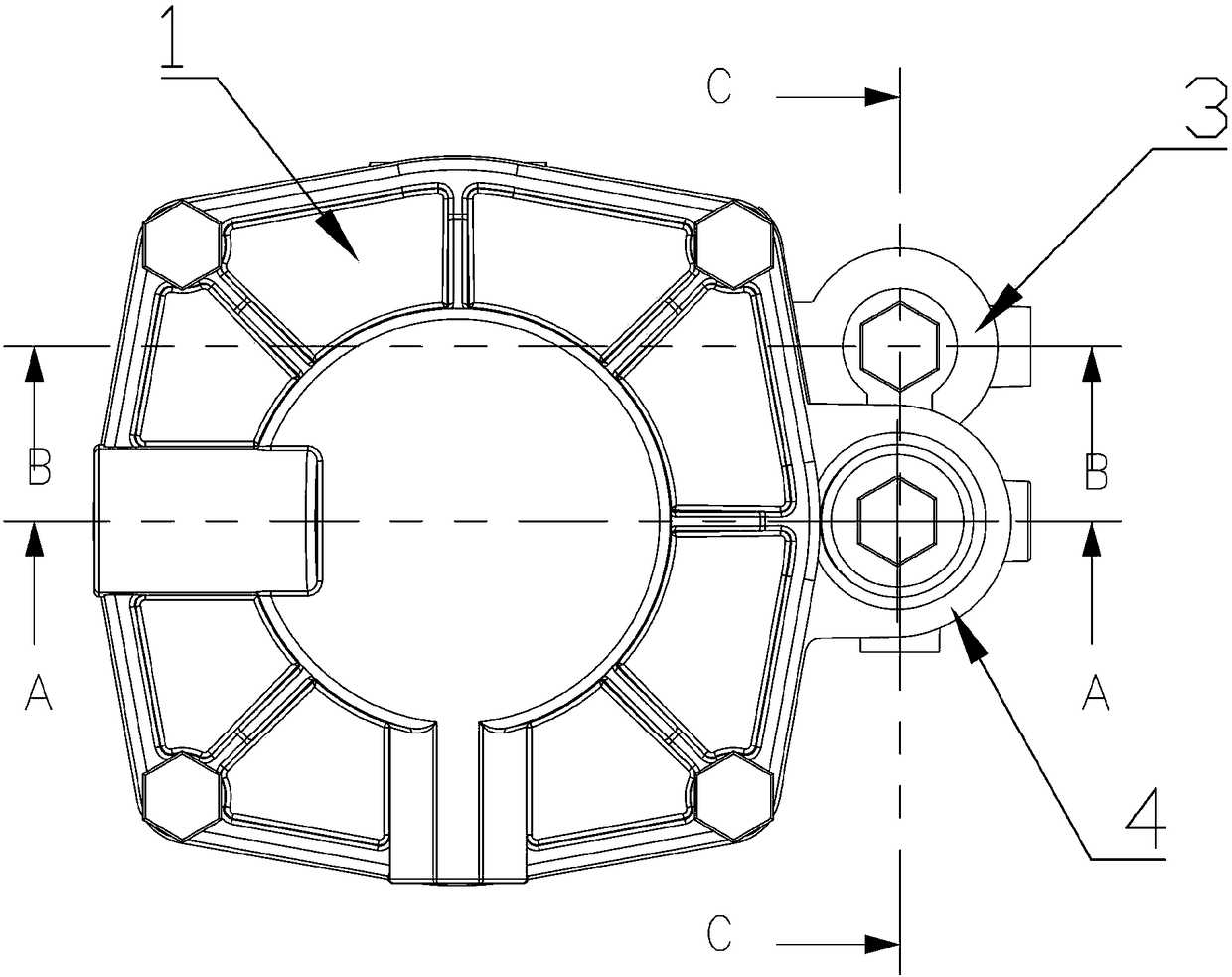

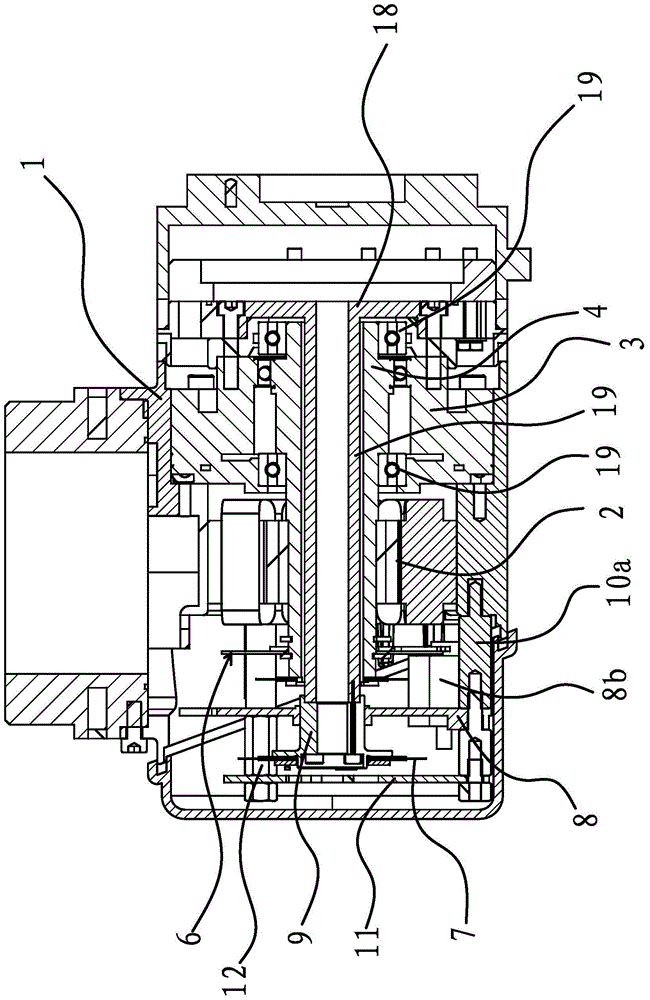

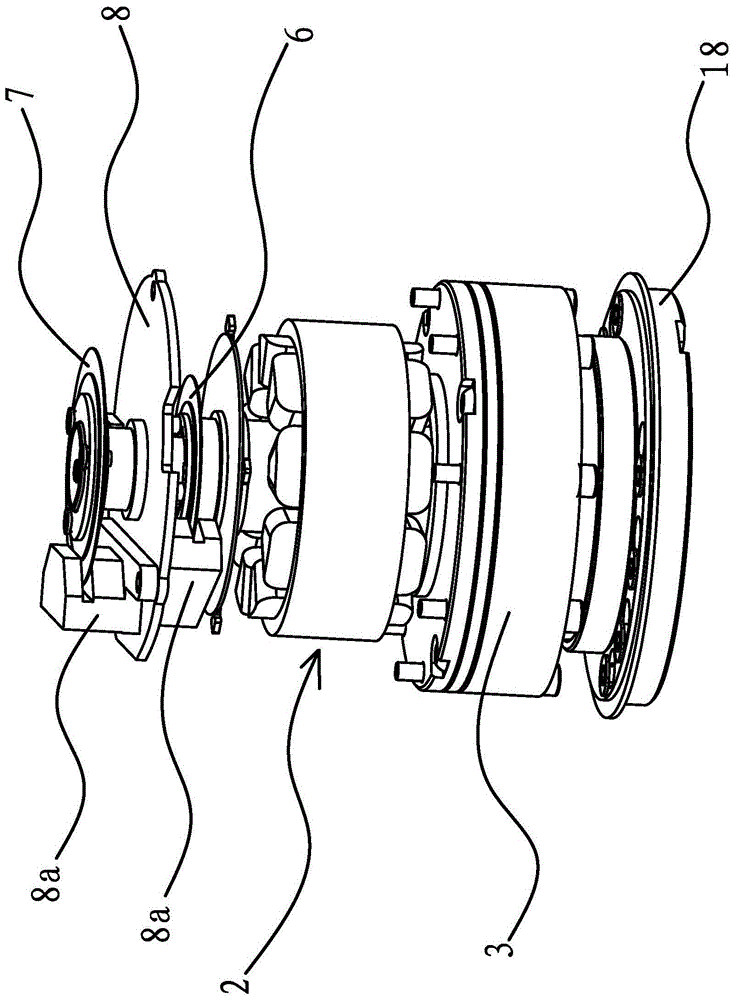

A joint of a mechanical arm

The invention provides a joint of a mechanical arm, and belongs to the technical field of machinery. The joint solves the problem that the joint of an existing mechanical arm is large in size. The joint of the mechanical arm comprises a shell, a motor and a harmonic reducer, wherein the motor and the harmonic reducer are integrated in the shell; the inner end of a rotating shaft of the motor is connected with the input end of the harmonic reducer; the output end of the harmonic reducer is connected with an output shaft; the rotating shaft of the motor is hollow; the inner end of the output shaft is fixed with the output end of the harmonic reducer, and the outer end of the output shaft penetrates through the outer end of the rotating shaft of the motor; a motor raster is fixed at the outer end of the rotating shaft of the motor; an output shaft raster is fixed at the outer end of the output shaft; an encoder is fixed in the shell; the output shaft raster and the motor raster are respectively positioned on the upper side and the lower side of the encoder; optoelectronic switches matched with output shaft raster and the motor raster are respectively arranged on the upper side and the lower side of the encoder. The joint has the advantages of small size, high space utilization rate, long service life and the like.

Owner:QIXING INTELLIGENT TECH CO LTD

Coaxial type hydraulic retarding braking device

InactiveCN102424043BSmall sizeReduce weightAuxillary drivesFluid braking transmissionDrive shaftControl system

Owner:谢陵波

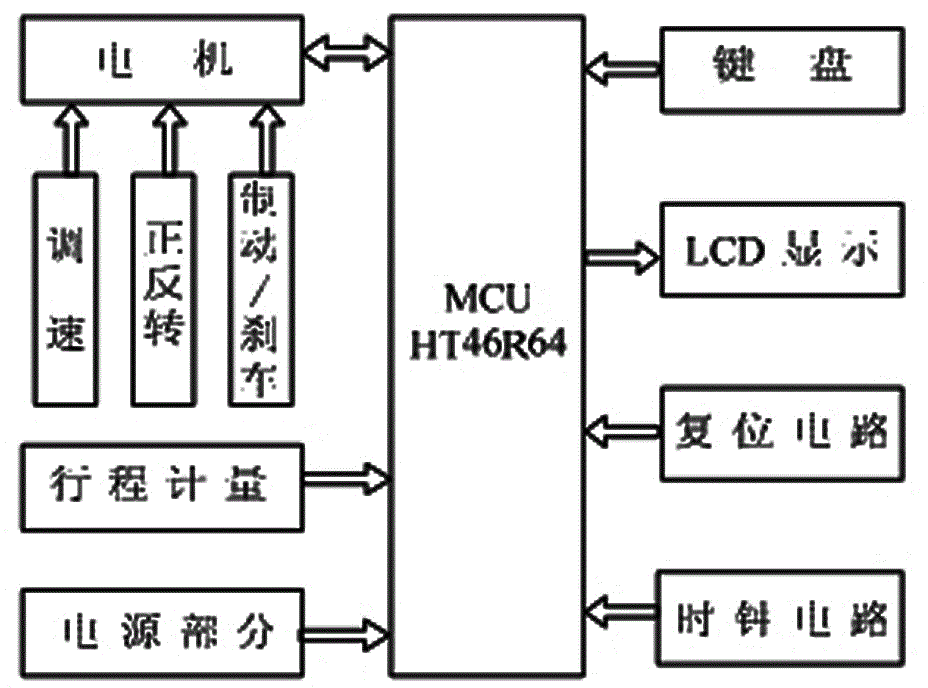

Vehicle controller

InactiveCN104656484ALow costEasy to operateProgramme controlComputer controlControl engineeringElectric machinery

A vehicle controller relates to the technical field of vehicle control, and especially relates to a vehicle controller. The invention provides a vehicle controller which is simple to operate and high in reliability. The vehicle controller comprises an MCU, a distance metering part, a power part, a speed control part, a forward and reverse rotation control part, a braking / brake control part, an input keyboard, an LCD display part, a reset circuit, and a clock circuit, and is structurally characterized in that the MCU is connected with the distance metering part, the power part, the input keyboard, the LCD display part, the reset circuit, the clock circuit and a motor, and the speed control part, the forward and reverse rotation control part and the braking / brake control part are connected with the motor.

Owner:张立洁

Clockwork self-deceleration valve protection device

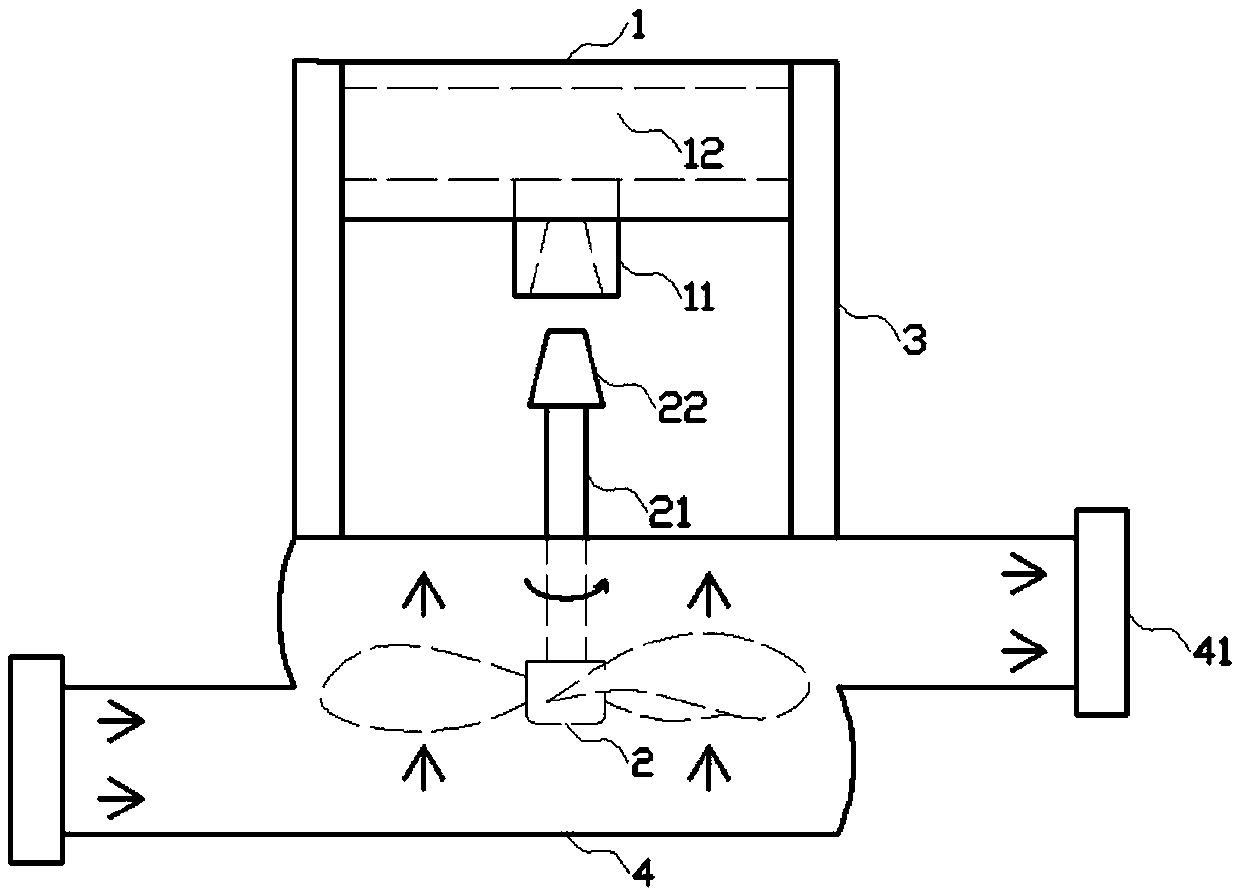

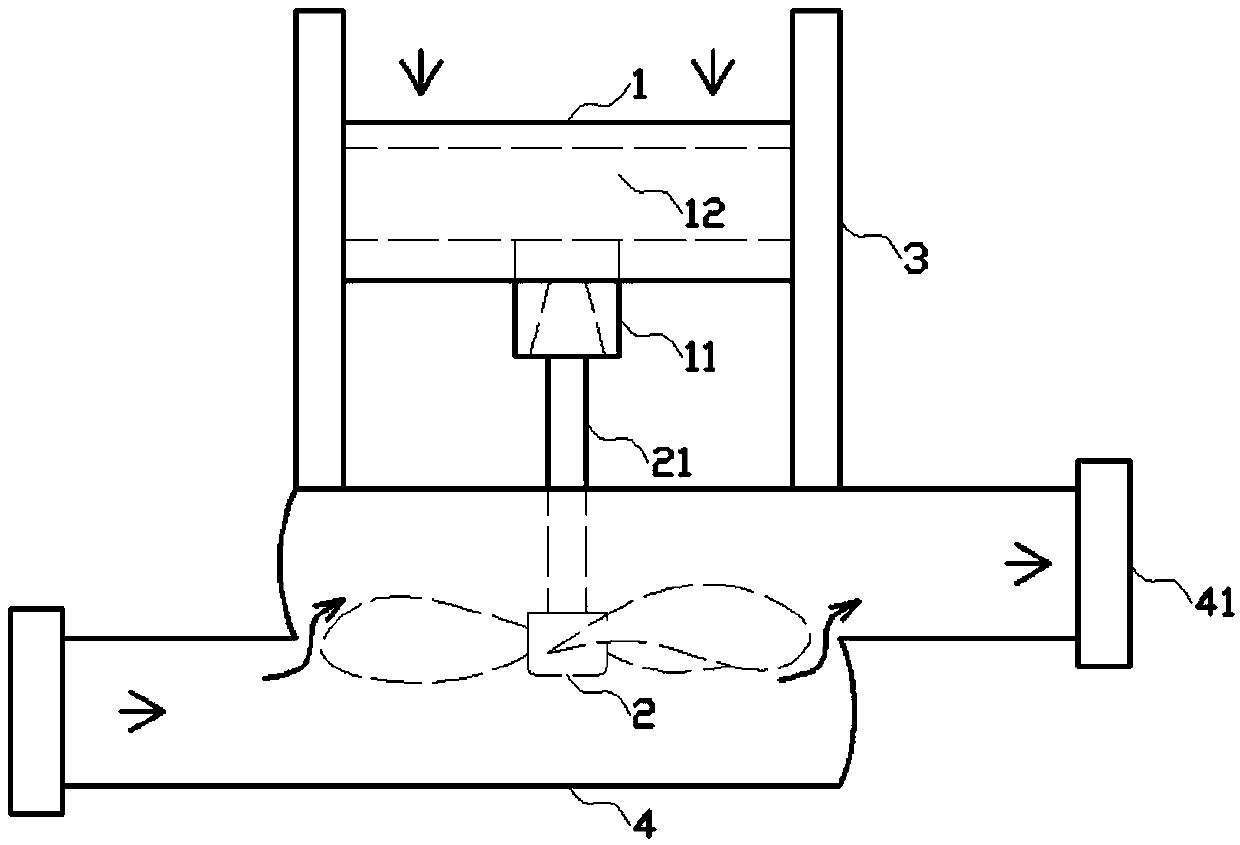

ActiveCN107939985BExtended service lifeSoft brakingLift valvePreventing unauthorised/accidental actuationImpellerEngineering

The invention provides a spring type self-decelerating valve protecting device. The device comprises a spring module, a blade module, a sliding rail plate and a pipeline module; the spring module comprises a casing, a spring and a rotating shaft; the blade module comprises a connecting rod and an impeller; strip-shaped grooves are formed in the sliding rail plate; a round cake-shaped pipeline is designed on the pipeline module and includes an upper layer and a lower layer; and pipeline openings are designed in the upper layer and the lower layer of the round cake-shaped pipeline respectively.By the aid of the device, the flow speed of a fluid inside the pipeline can be reduced, so that the stress required during opening and closing of a valve is reduced; and meanwhile, the acting force isabsorbed by the aid of the elastic structure of the spring device, so that the buffer protection effect is realized for the device.

Owner:浙江祥和阀门有限公司

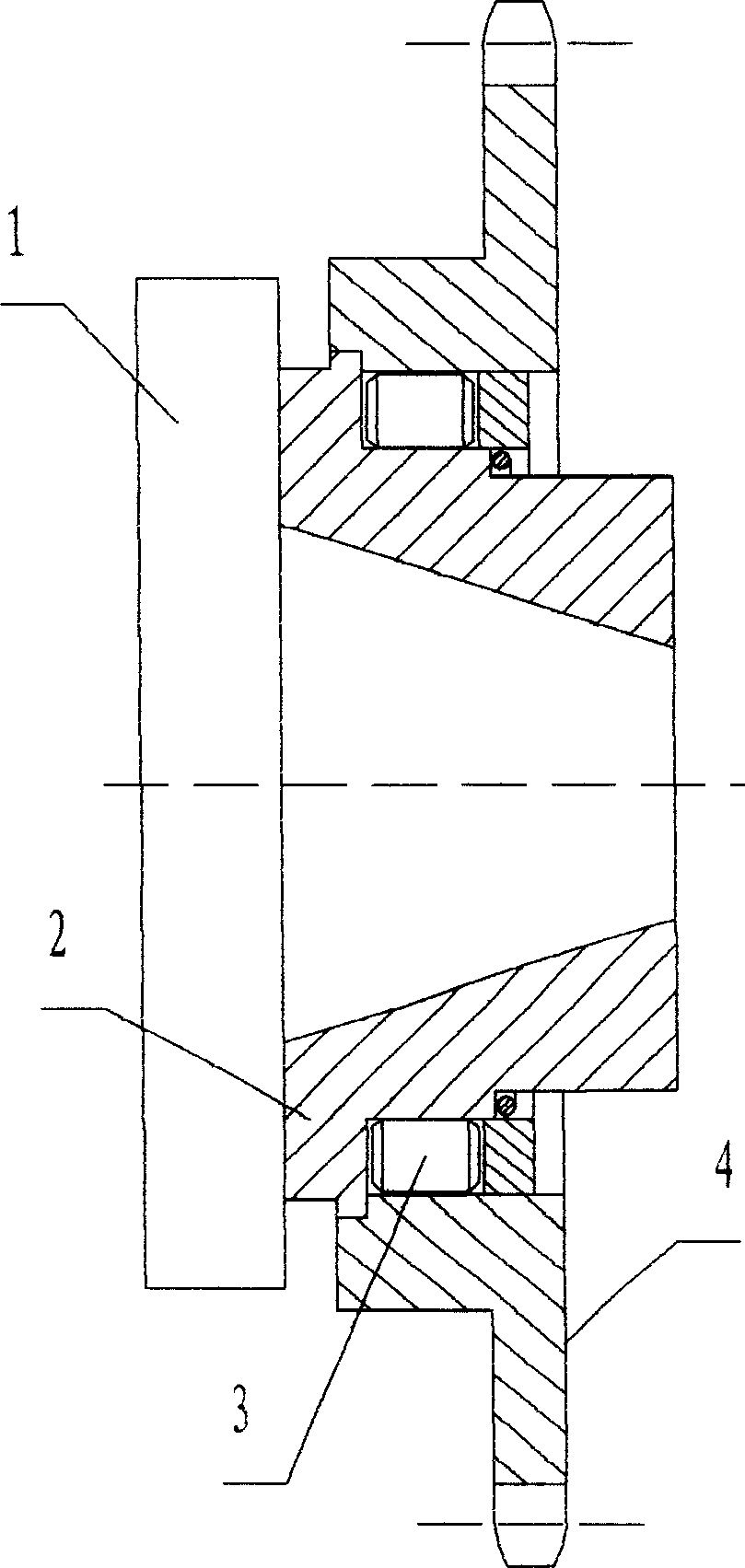

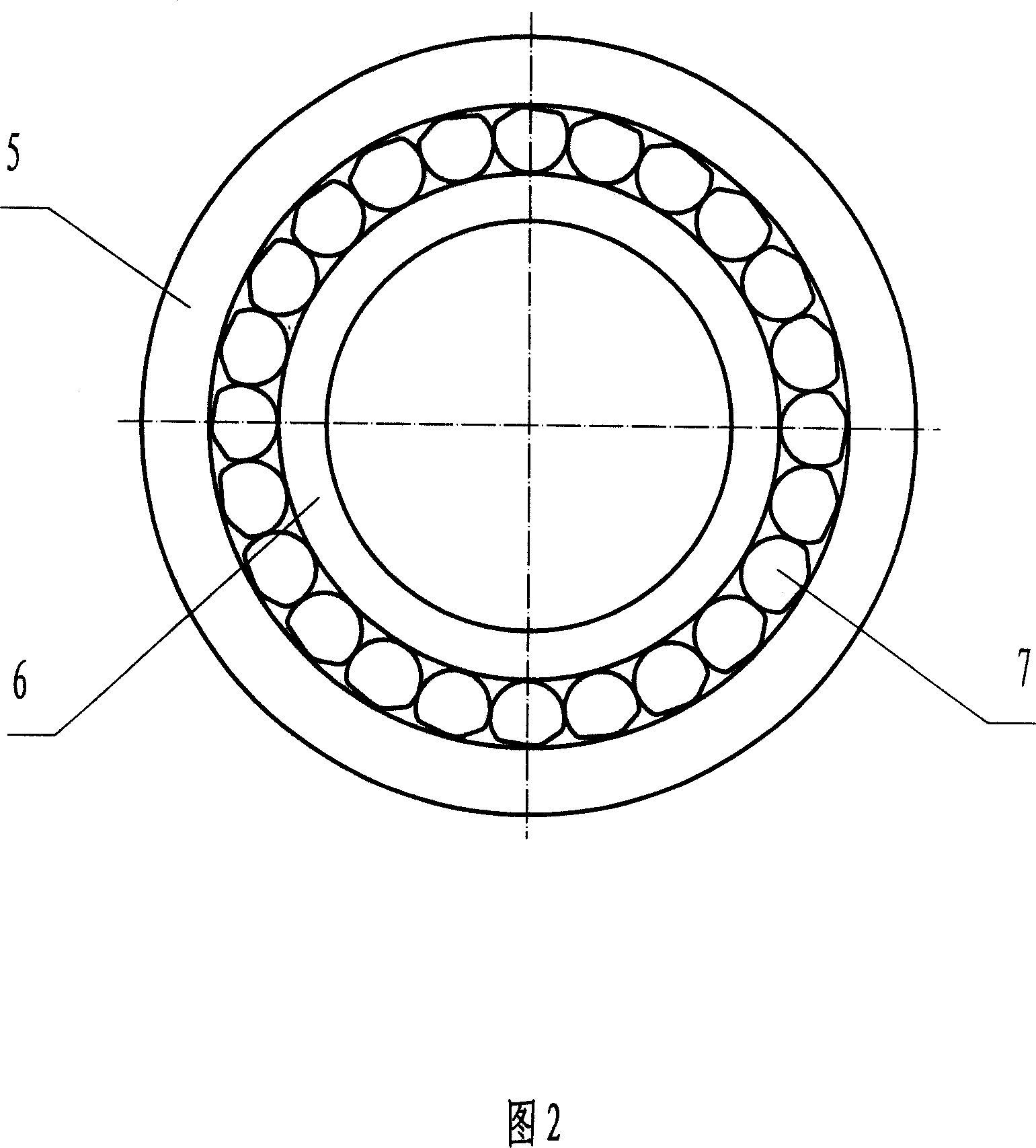

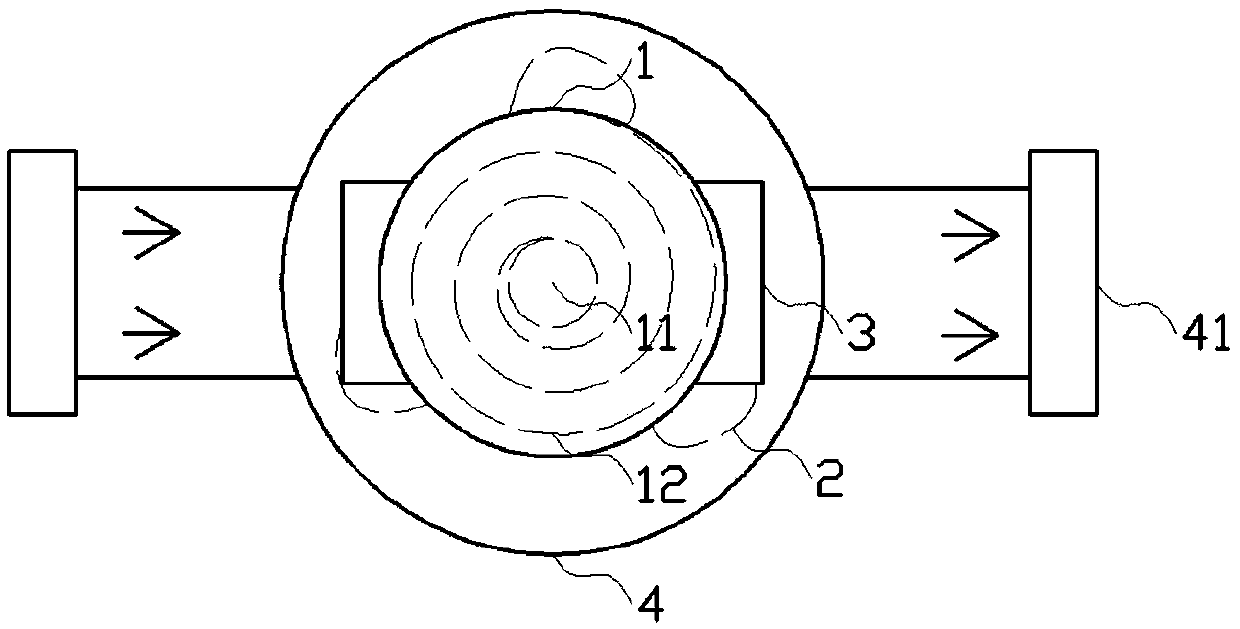

Disc brake assembly

InactiveCN105370766AActive connectionSoft brakingAxially engaging brakesBraking elementsBrake torqueActuator

Disclosed is a disc brake assembly for rotational direction-dependent applying a predetermined braking torque for braking a shaft (1) having a first brake disc (2) and with at least one associated first friction surface (3) in a brake actuator (4) for applying a desired braking torque operative connection can be brought, at least a second brake disc (5) and at least a second friction surface (6) are provided, wherein the on the second brake disc (5) transferable braking torque is dependent on the direction of rotation transmitted to the shaft (1).

Owner:ZF FRIEDRICHSHAFEN AG

disc brake mechanism

InactiveCN105370766BActive connectionSoft brakingAxially engaging brakesBraking elementsEngineeringMechanical engineering

The utility model relates to a disc brake mechanism and automatic escalator disc brake mechanism or automatic walkway disc brake mechanism, disc brake mechanism are used for applying predetermined braking moment according to the rotation direction for make axle (1) slow down, this disc brake mechanism has first brake disc (2) and at least one is attached first friction surface (3), this first brake disc and first friction surface can effectively be connected via braking operating means (4) that are used for applying the braking moment of expectation each other, wherein, is provided with at least one second brake disc (5) and at least one second friction surface (6), wherein, and on the braking moment of transferable to the second brake disc (5) can transmit axle (1) according to the rotation direction.

Owner:ZF FRIEDRICHSHAFEN AG

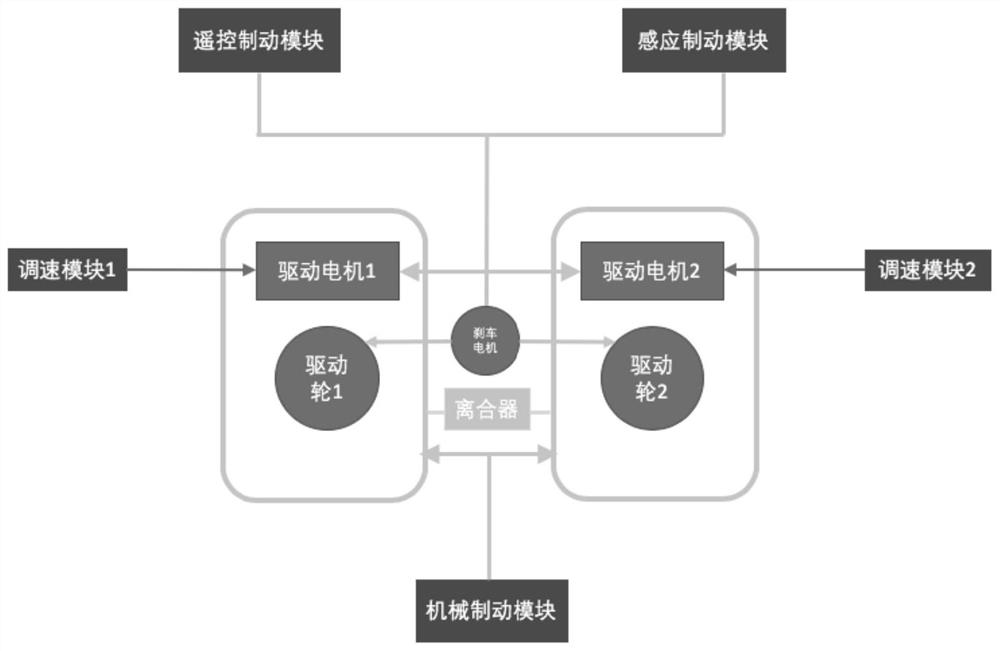

Novel hybrid brake control system and control method thereof

ActiveCN111923879AHigh degree of mechanical automationImprove driving safetyBraking action transmissionAutomatic initiationsDrive wheelControl system

The invention discloses a novel hybrid brake control system which comprises a remote control brake module, an induction brake module, a mechanical brake module, a brake motor module, a drive motor module, a drive wheel module and a clutch module. The remote control brake module is electrically connected with the brake motor module and the drive motor module. The induction brake module is electrically connected with the brake motor module and the drive motor module. A brake device is arranged on the driving wheel module, and the mechanical brake module is connected with the driving wheel modulethrough the brake device; the driving motor module is connected with the driving wheel module through the clutch module; the brake motor module is connected with the driving wheel module through thebrake device. According to the technical scheme, through a hybrid braking structure with three different braking modes of induction braking, remote control braking and mechanical braking, the mechanical automation degree of pavement operation is improved, and the driving safety is improved.

Owner:天伦实业(广州)有限公司

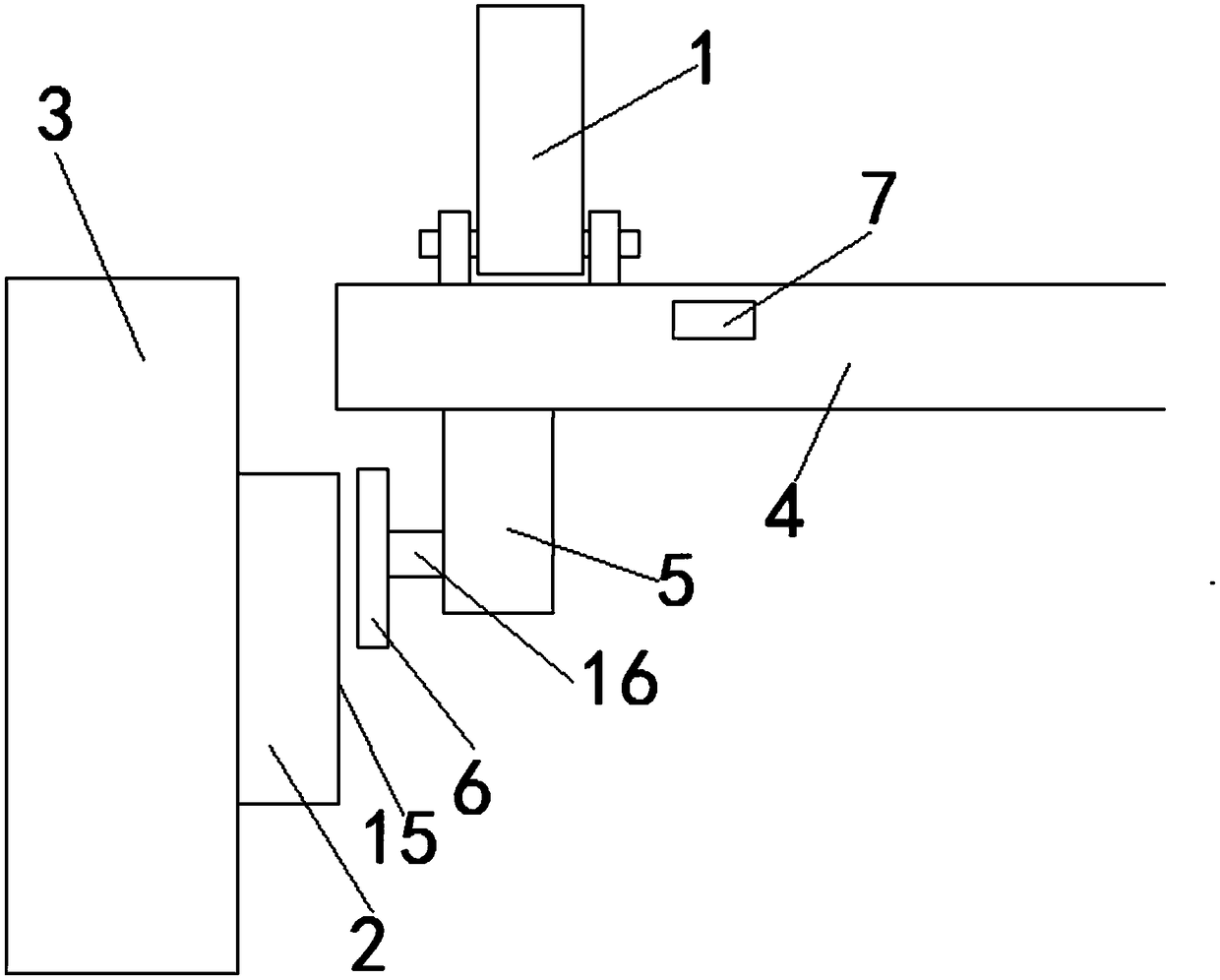

Electric vehicle breaking system

InactiveCN108791238AEasy to brakeBraking is convenient and reliableBraking element arrangementsBraking action transmissionEngineeringElectric cars

The invention provides an electric vehicle breaking system applied in the technical field of electric vehicle parts. The electric car braking system includes a brake pedal (1), a brake disc (2), the brake disc (2) is installed on a brake wheel (3), a telescopic cylinder (5) is installed on a vehicle chassis (4), a moving friction plate (6) is installed on the end portion of a telescopic rod of thetelescopic cylinder(5), the telescopic cylinder(5) is connected with a control unit (7) which controls the telescopic rod to stretch out and draw back, a pressure sensor (8) is arranged below the brake pedal (1), and the pressure sensor (8) is connected with the control unit (7). The electric vehicle breaking system is simple in structure and low in cost, can realize the braking of an electric vehicle quickly and conveniently, improves the braking sensitivity and buffering performance, ensures that the braking force is relatively soft when braking, plays a buffering effect, and improves the overall performance of the electric vehicle.

Owner:WUHU ZHANGHONG ENG TECH CO LTD

Copper-less and asbestos-free organic friction materials and products

ActiveCN110273952BStable coefficient of frictionReduce aggressionOther chemical processesFriction liningPhysical chemistryDuralumin

The invention relates to a copper-less and asbestos-free organic friction material, which is composed of the following components in parts by weight: 10-15 parts of bonding material, 45-55 parts of filling material, 20-30 parts of fiber material, and 2-30 parts of acid-base adjustment material. 4 parts, 5-15 parts of metal fiber or metal powder, wherein the fiber material contains nano-boron fiber or basalt fiber, and the metal fiber or metal powder is one or more of titanium, aluminum, heat-resistant duralumin, copper and brass A combination, and the copper content is less than 5%. The present invention reduces the amount of red copper and brass in the friction material formula and strictly selects the added metal components as titanium, aluminum and heat-resistant duralumin. The stable friction coefficient of the material makes the braking process soft, smooth and comfortable. It can also overcome the instability of the friction coefficient of commercially available high-copper organic friction materials under high-speed and low-temperature conditions, and effectively reduce the aggressiveness of the friction couple.

Owner:晋江市凯燕新材料研究院股份有限公司

Preparation method of new high temperature resistant ceramic car disc brake pad modified by zirconia

ActiveCN103335044BReduce conductionImprove cooling effectOther chemical processesFriction liningAntimony trisulfideAramid

The invention provides a zirconium oxide modified novel high temperature resistant ceramic car disc brake pad and a preparation method of the brake pad. The brake pad is prepared by the following steps: mixing barium sulfate, red copper fiber, ceramic fiber, zirconium oxide, synthetic graphite, antimony trisulfide, aramid fiber, mica powder, frictional powder, phenolic resin, light calcium carbonate and rubber powder, and putting the mixture into an oven with 70 DEG C to form mixed surface material; preparing steel fiber, synthetic graphite, flake graphite, petroleum coke powder, blanc fixe, porous iron powder, phenolic resin, light magnesium oxide, rubber powder and wollastonite into mixed backing material in the same way; pre-pressing and molding the mixed backing material, the mixed surface material and steel backing on a cold-pressing molding machine, then putting the product into a hot-pressing molding mould, and carrying out hot-pressing molding; after that, putting the product into a heat treatment oven, and carrying out heat treatment; and grinding the surface of the product, processing by other existing steps, and packaging. The zirconium oxide modified novel high temperature resistant ceramic car disc brake pad is free from heat fade, stable in friction coefficient, good in friction performance, stable in brake, sensitive and reliable, low in hardness and low in wear rate.

Owner:武汉市祥龙摩擦材料有限责任公司

Asbestos-free organic friction materials and products for transmission and braking with less copper

ActiveCN110285166BReduce wearWeak elasticityOther chemical processesFriction liningMetal fiberCarbon fibers

The invention relates to a little-copper and asbestos-free organic friction material for transmission braking. The little-copper and asbestos-free organic friction material consists of the following components: a bonding material, a filling material, a fiber material, an acid-base adjusting material, metal fiber or metal powder, wherein the metal fiber or metal powder is a combination of titanium, aluminum, heat-resistant hard aluminum, red copper and brass, the copper content is less than 5% and comprises spiral microfiber. The used amounts of red copper and brass are reduced, and the metal components are strictly selected and added as titanium, aluminum and heat-resistant hard aluminum, so that the wear of a product is reduced, and a stable friction coefficient and heat resistance are ensured. Also, the spiral micro-carbon fiber is contained, on one hand, a filling and reinforcing role can be played, the inherent vibration rate of the product is improved, and the noise is reduced; on the other hand, the spiral micro-carbon fiber is of a spiral spring type structure, so that the elastic modulus and hardness of the product are reduced, the adhesion among the various components is improved, the strength and toughness of the product are improved, the stability of the friction coefficient of the product is improved, the deterioration of heat resistance is avoided and the aggressiveness to friction duality can be effectively reduced.

Owner:晋江市凯燕新材料研究院股份有限公司

High-performance ceramic friction sheet and production process thereof

ActiveCN102632233BIncrease frictionModerate coefficient of frictionFriction liningGraphiteCompressive strength

The invention belongs to the technical field of friction sheets, and relates to a high-performance ceramic friction sheet and a production process thereof. The high-performance ceramic friction sheet consists of the following substances in parts by weight of: 60 to 68 parts of copper, 10 to 15 parts of ferrum, 2 to 5 parts of tin, 5 to 10 parts of silica, 3 to 8 parts of molybdenum disulfide, 5 to 10 parts of calcium aluminate, 5 to 13 parts of graphite and 0.5 to 1.5 parts of kerosene. The production process of the friction sheet comprises the following steps of: mixing materials; pressing and forming; and sintering and detecting under a dry working environment. The high-performance ceramic friction sheet has the beneficial effects of high friction performance, high compression strength and low abrasion rate; and when the high-performance ceramic friction sheet is used, the number of produced gas and the number of produced powder are small, the environment pollution is low, and the high-performance ceramic friction sheet brakes steadily, softly, safely and reliably.

Owner:浙江台基摩擦材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com