Loader walking and braking energy recovery auxiliary driving device and control method

A braking energy recovery and auxiliary drive technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems affecting vehicle stability and compliance, poor stability and compliance performance, pump motor torque impact, etc. , to achieve the effect of high integration, good control performance, and elimination of sudden changes in torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

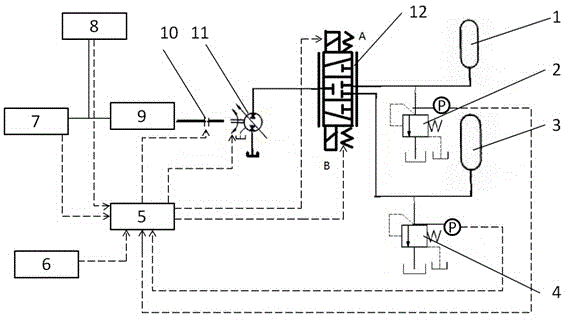

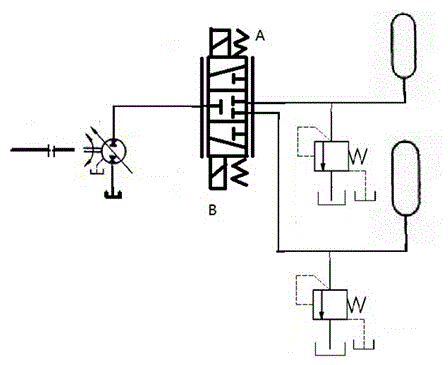

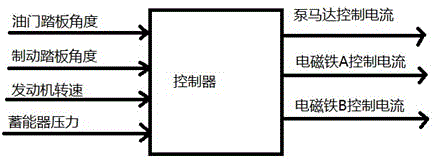

[0040] like figure 1 As shown, a loader walking braking energy recovery auxiliary driving device includes a controller 5, a signal monitoring module, a hydraulic auxiliary driving module, a braking module 6, and the controller 5 communicates with the signal monitoring module and the hydraulic auxiliary driving module through a communication cable. , the brake module 6 and other modules of the loader are connected to receive the state signal collected from the signal monitoring module, and combine the internal program of the controller 5 to process the collected state signal and generate a control command, through which the hydraulic auxiliary drive module , braking module 6, traveling mechanism 9 and other modules perform corresponding actions; the hydraulic drive module is the core component of the loader walking braking energy recovery auxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com