Sliding mechanism controlling ladle molten steel casting flow rate

A technology of flow control and sliding mechanism, applied in casting equipment, manufacturing tools, casting melt containers, etc., can solve the problems of high labor intensity, short service life and low production efficiency of workers, so as to reduce labor intensity of workers and improve safety. Use factor, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

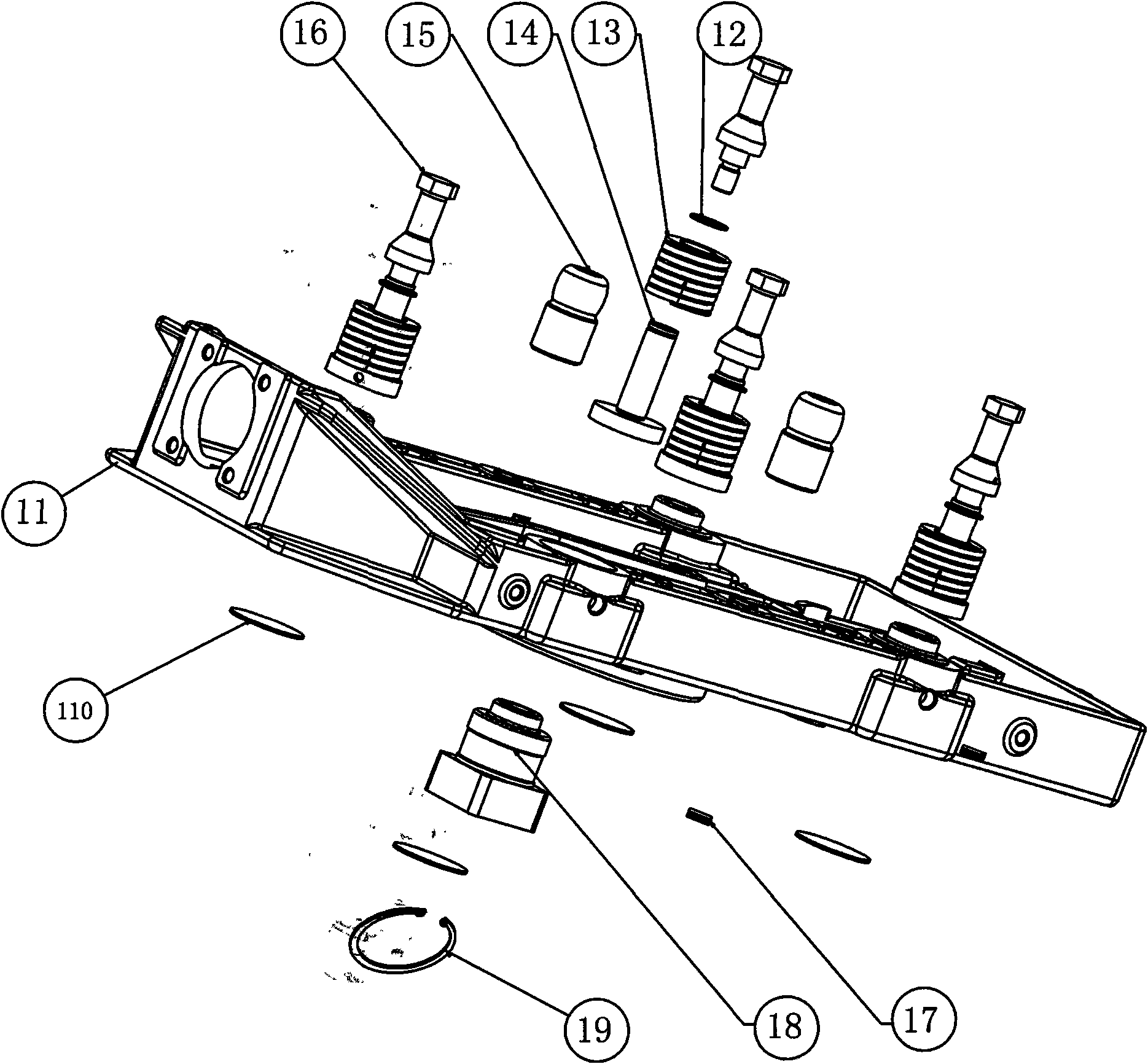

[0020] Embodiment one: see figure 1 , figure 2 , Figure 2-1 , image 3 , Figure 3-1 and Figure 4 . The ladle molten steel casting flow control sliding mechanism of the present invention includes a main frame 1 for installing a fixed slide plate, a slider 2 and a bracket 3 for installing a sliding slide plate, and the slider 2 is matched and slidably installed on the bracket at the lower end of the main frame 1 3, in the carriage frame 31 of the main frame 1 and the bracket 3, corresponding positioning mechanisms are provided on both sides of the docking surface of the main frame 1 and the bracket 3. The main frame 1, the slider 2, and the bracket 3 are connected by elastic tensioning elements. In one piece, four pulleys are respectively installed on both sides of the slider 2 through the wheel shaft 22, and the front end is connected to the external hydraulic cylinder push rod through the cylinder connection pin 25, and two guide rails are arranged symmetrically on bo...

Embodiment 2

[0023]Embodiment 2: The ladle molten steel casting flow control sliding mechanism of this embodiment is different from Embodiment 1 in that: the main frame 1 includes a support 11, and the positioning mechanisms provided on the docking surfaces of the main frame 1 and the bracket 3 respectively adopt positioning The pin 15 and the pin hole matched with the positioning pin 15, the elastic tensioning element adopts a nickel-based alloy double coil spring 13, and the positions on both sides of the positioning pin 15 are respectively set on the frame body on both sides of the main frame 1 and the bracket 3 joint surface One group, each group of double helical springs 13 will main frame 1, sliding The block 2 and the bracket 3 are connected together, and the elastic tensioning element adopts nickel base alloy double coil spring, so that the gap between the fixed slide plate and the sliding slide plate can be controlled between 0.01-0.04mm.

[0024] The ladle molten steel casting fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com