Environmental protection type friction material with less metal used for automobile brake block and preparation method thereof

A technology for friction materials and brake pads, which is applied in the field of metal-less environmentally friendly friction materials and its preparation, can solve the problems of damaging human organs and polluting the environment, and achieve the effects of less damage to the counterpart, simple preparation process, and low wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

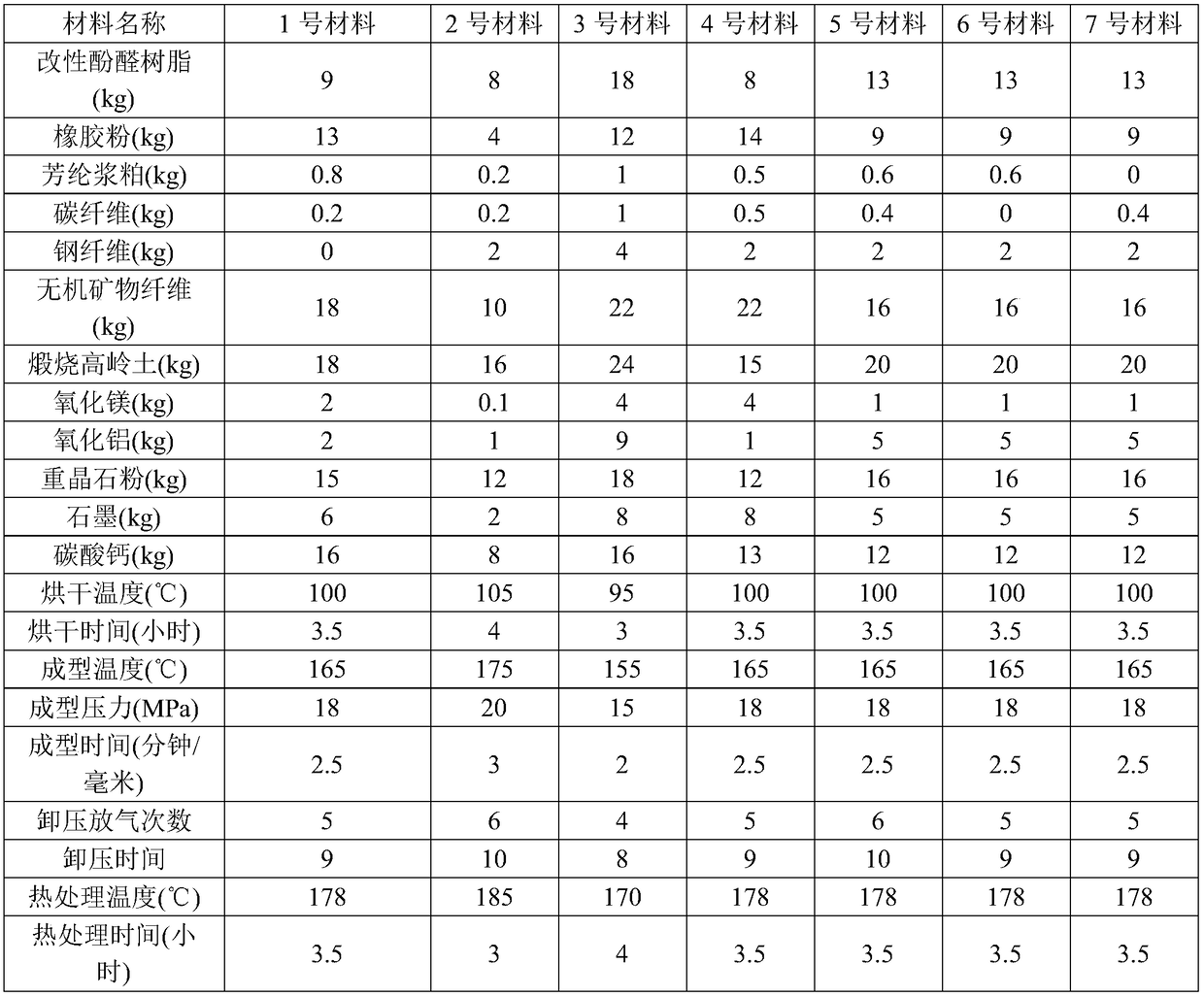

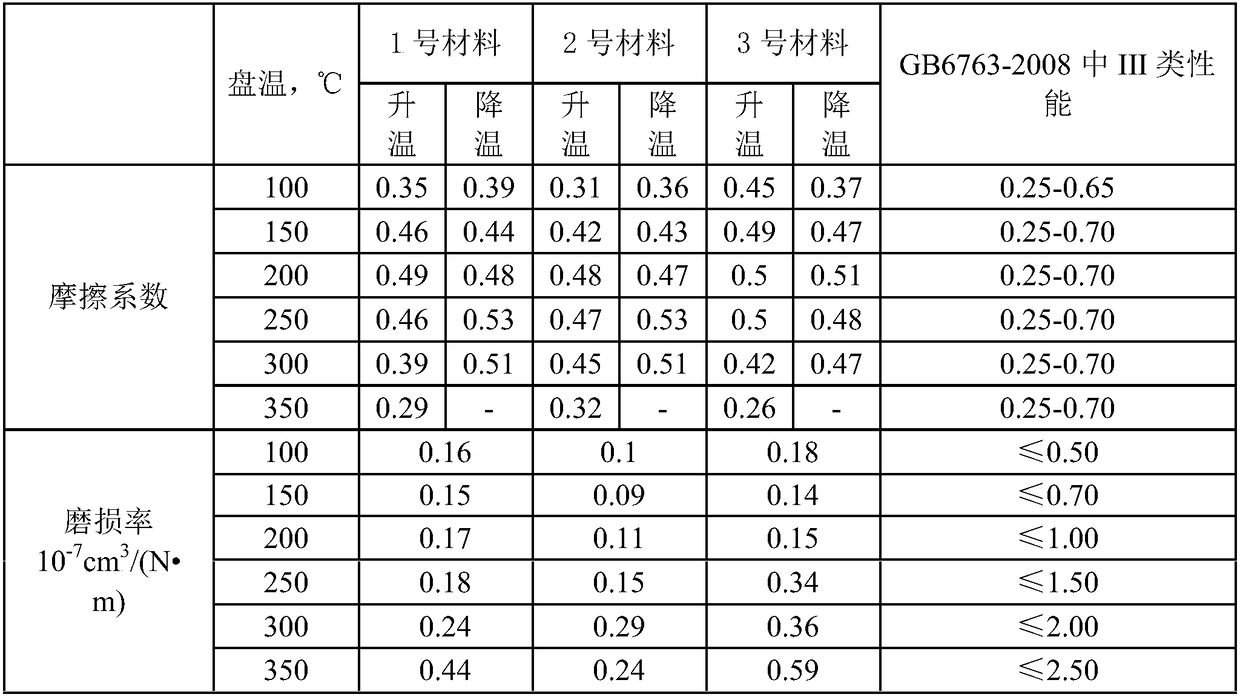

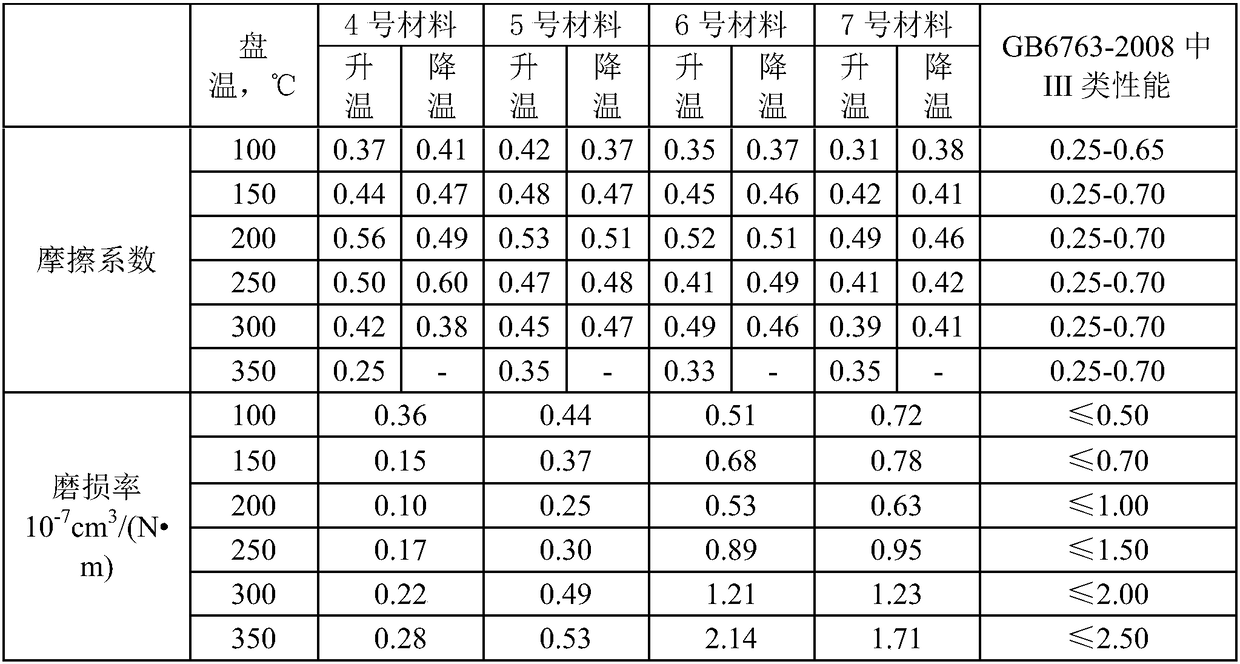

[0023] (1) Ingredients: prepare the raw materials shown in Table 1, first put the modified phenolic resin, rubber powder, aramid pulp, carbon fiber, and inorganic mineral fiber into a high-speed mixer and mix until uniform; then add calcined kaolin, magnesium oxide, Alumina, barite, graphite and calcium carbonate are put into a high-speed mixer and fully mixed to obtain a uniformly mixed molding material.

[0024] (2) Drying: The molded material is dried in an electrothermal constant temperature blast drying oven for the purpose of removing low molecular volatiles. See Table 1 for the drying temperature and drying time.

[0025] (3) Hot pressing: add the dried molding material into the mold that has reached the preset temperature and mold it. The molding temperature, molding pressure, molding time, the number of times of pressure relief and deflation at the initial stage of pressing, and the time of each pressure relief are shown in Table 1. , to get the friction plate to be t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com