Hydrocracking method for blending ethylene tar

A technology of ethylene tar refining and hydrocracking, which is applied in the field of light fuel oil produced by hydrocracking of vacuum gas oil blended with ethylene tar, can solve the problems of not being effectively treated and unable to process ethylene tar fractions, and achieve safety Smooth operation is beneficial, equipment investment is saved, and the effect of reducing aromatics content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

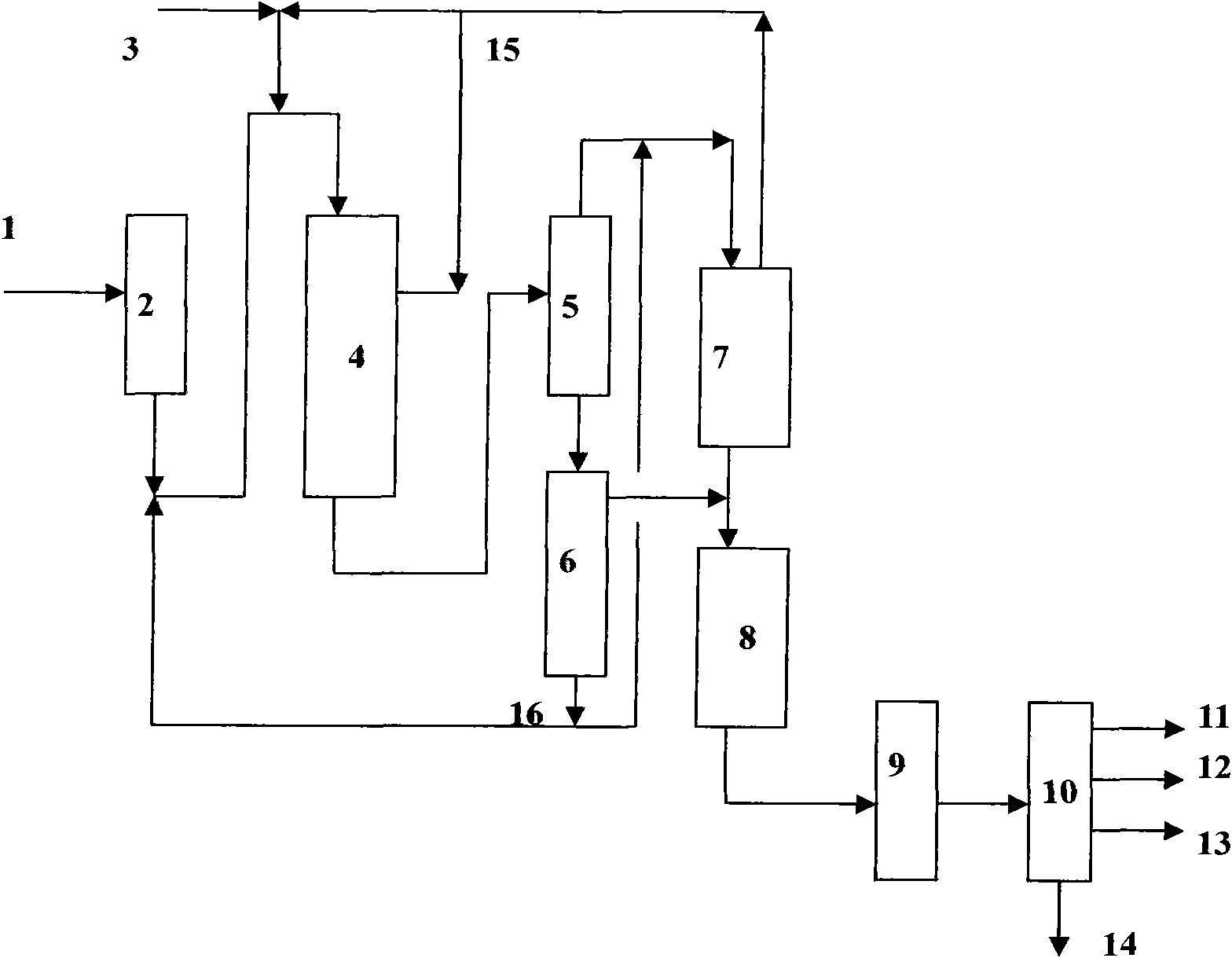

Method used

Image

Examples

Embodiment 1~4

[0043] The properties of the ethylene tar light fraction and VGO raw materials used are shown in Table 2.

[0044] The hydrogenation protection catalyst used in this example is FZC-103, and the hydrogenation refining catalyst used is 3936. This embodiment adopts a series hydrogenation process, two reactors, the first reactor is filled with a hydrogenation protection catalyst and a hydrofining catalyst, and the second reactor is filled with a hydrogenation carbon removal catalyst and a hydrocracking catalyst. Embodiments 1 and 3 adopt thermal low fraction oil circulation, and the weight ratio of the heat low fraction oil recycled back to the hydrogenation reaction zone to the sum of the ethylene tar light fraction and heavy fraction is 2.0. Example 2 adopts hot high-fraction oil circulation, and the weight ratio of the heat high-fraction oil recycled back to the hydrogenation reaction zone to the sum of the ethylene tar light fraction and heavy fraction is 2.0. Embodiment 4 ad...

Embodiment 5

[0055] The heavy fraction of ethylene tar is heat-treated at 380°C under normal pressure for 20 minutes to obtain mesophase pitch; the mesophase pitch is melt-spun with a pneumatic spinning machine, and the spun pitch fiber is oxidized by air at 300°C-400°C to form The fibers were not melted, and then carbonized into carbon fibers at 1000°C under nitrogen. The properties of the obtained pitch-based carbon fibers are shown in Table 5.

[0056] Table 4 Properties of ethylene tar heavy fraction

[0057] crude oil name

Ethylene tar heavy fraction (>430°C)

carbon to hydrogen ratio

1.07

Softening point / ℃

225

Quinoline insoluble matter / %

0.60

[0058] Table 5 Properties of pitch-based carbon fibers

[0059] project

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com