Method for producing high-quality gasoline and diesel oil by catalyzing diesel oil

A technology for catalyzing diesel oil and diesel oil, which is applied in the treatment of hydrocarbon oil, petroleum industry, hydrotreating process, etc. It can solve the problems of poor selectivity of single-ring aromatics, achieve high selectivity of single-ring aromatics, reduce hydrogen consumption, and reduce processing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

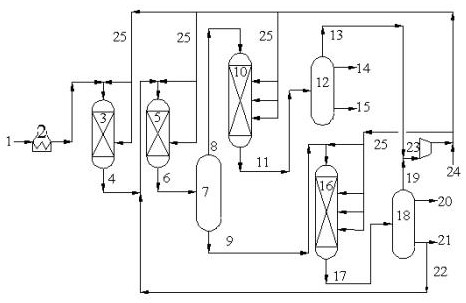

[0043] Embodiment 1~3 all adopts flow process of the present invention, figure 1The combined process flow shown. After the high-aromatic catalytic diesel is heated by the heating furnace, it is mixed with the circulating hydrogen and enters the I hydrofining reaction zone for hydrodesulfurization, polycyclic aromatic hydrocarbon saturation and other reactions; the obtained oil is mixed with the circulating hydrogen and enters the II hydrofining reaction zone for further Hydrodesulfurization reaction, selective reaction of aromatics; the obtained oil enters the separation equipment and is cut into light components and heavy components; the light components and circulating hydrogen are mixed into the hydrogenation upgrading reaction zone for hydrocarbon hydrogenation reaction to generate oil Obtain gas, gasoline fractions and diesel fractions with high cetane number through the separation system; heavy components are mixed with circulating hydrogen and enter the hydroconversion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com