Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Act as a distraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

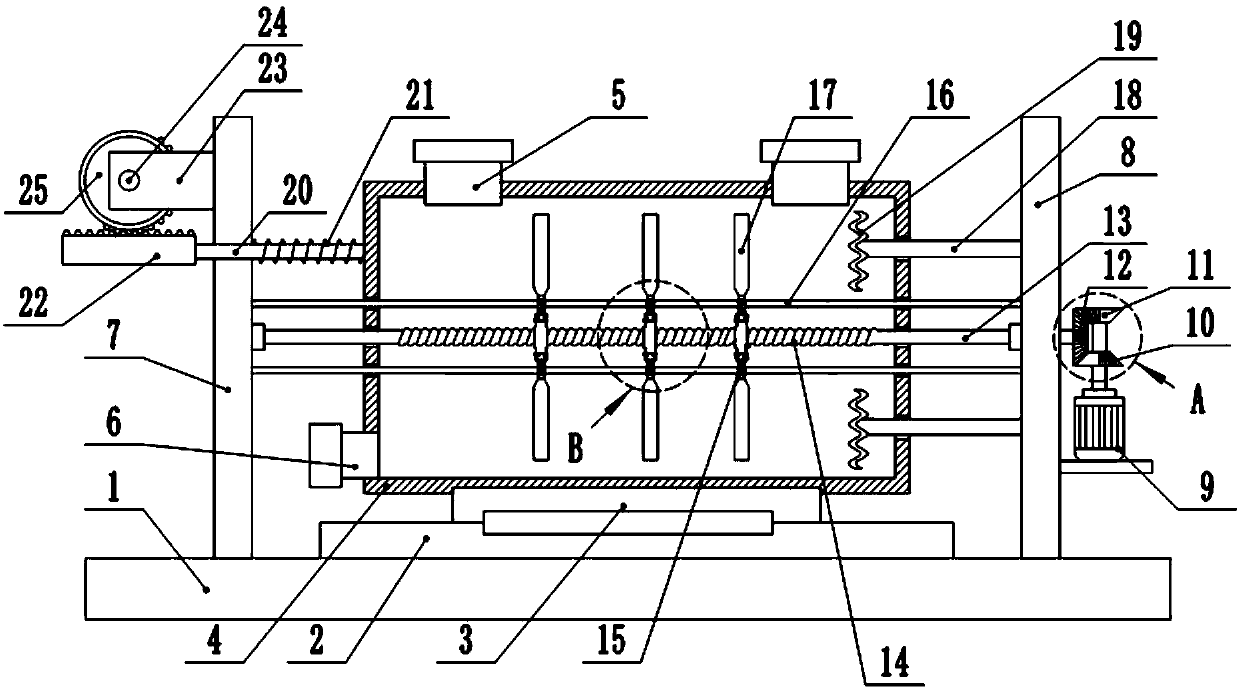

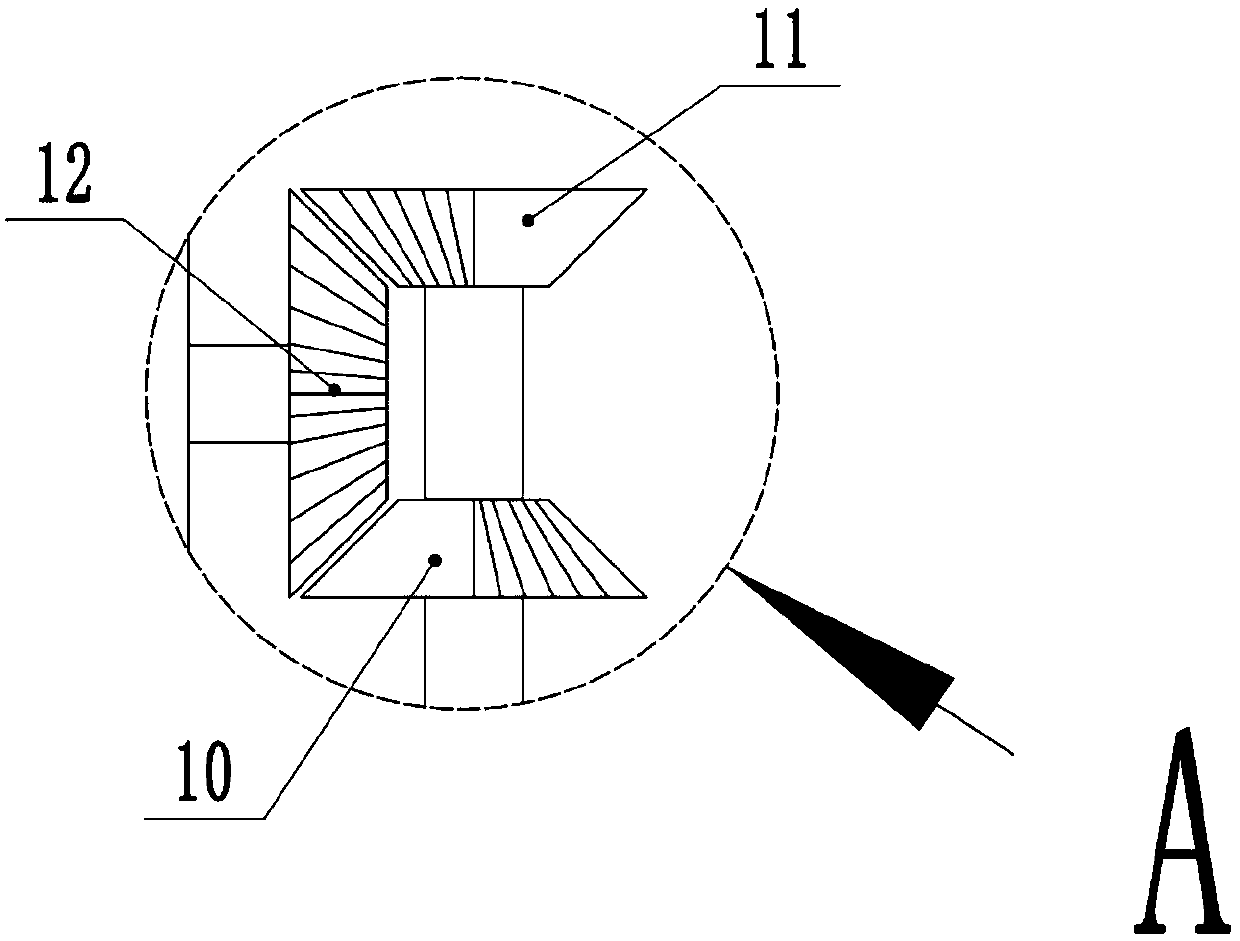

Stirring range-adjustable medical rapid mixing device for liquid medicaments

InactiveCN109012412AImprove the mixing effectImprove turnoverShaking/oscillating/vibrating mixersTransportation and packagingRelative displacementEngineering

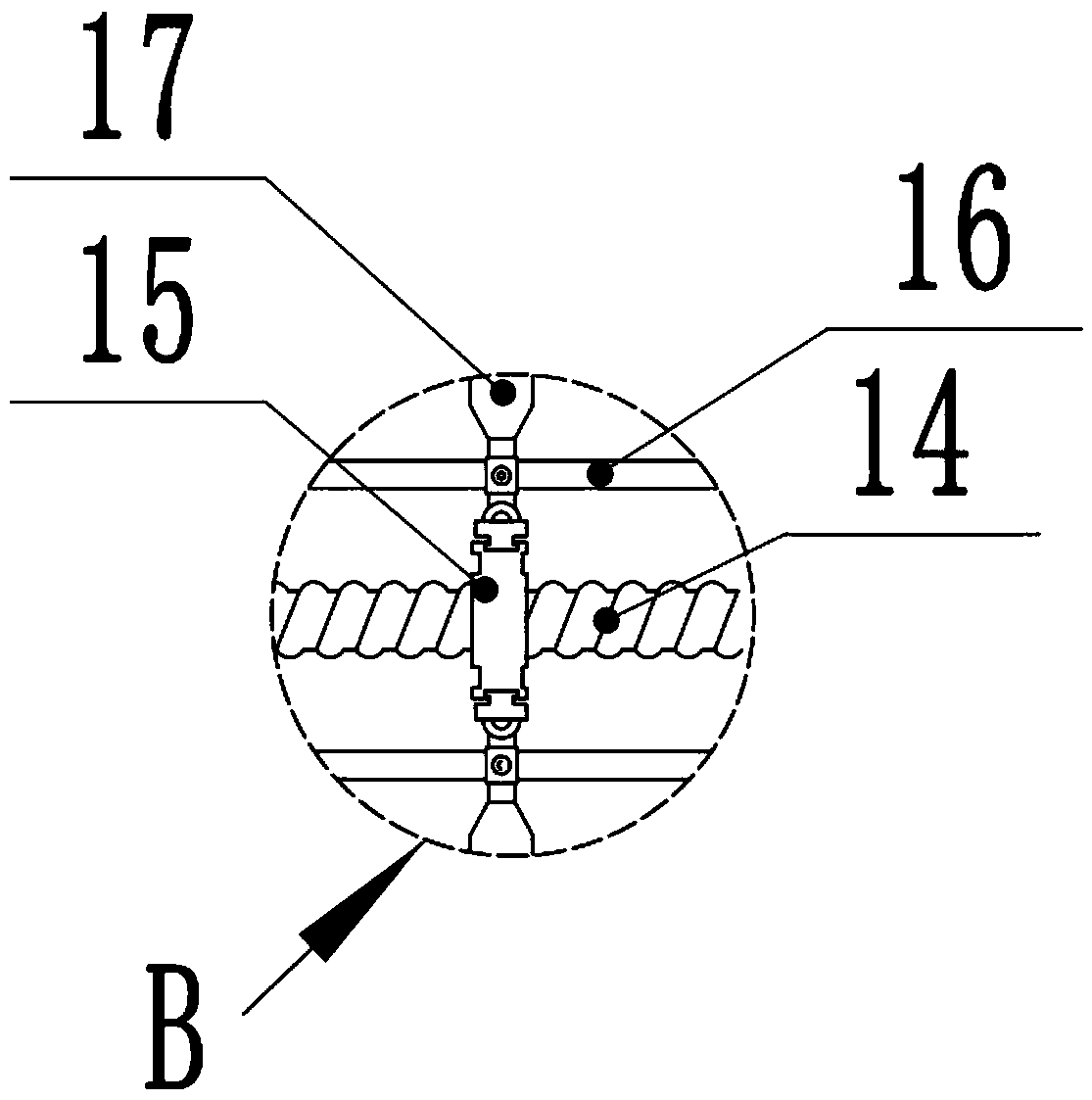

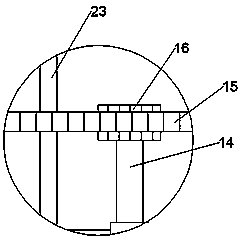

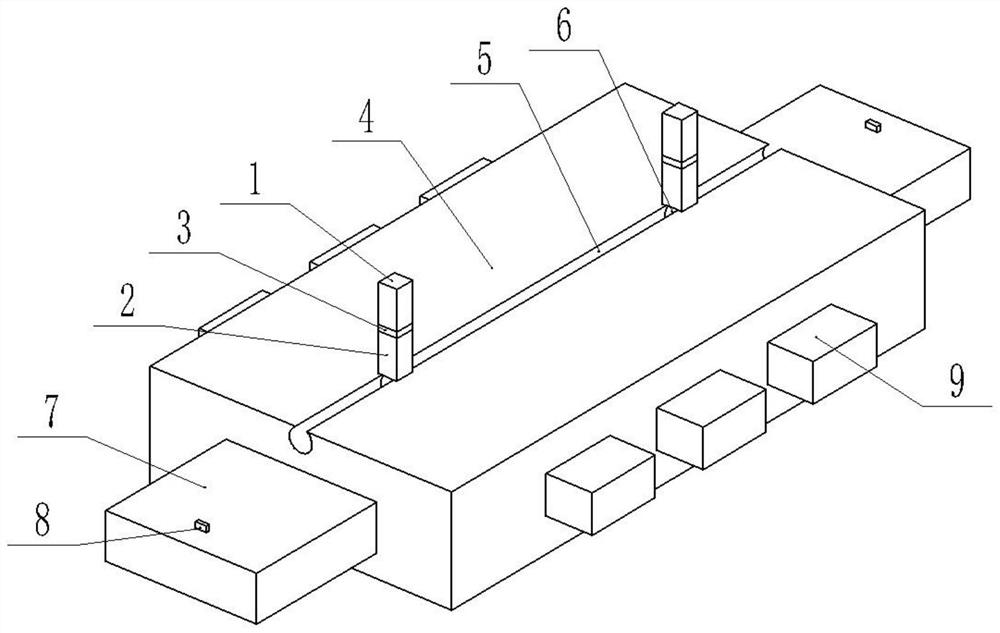

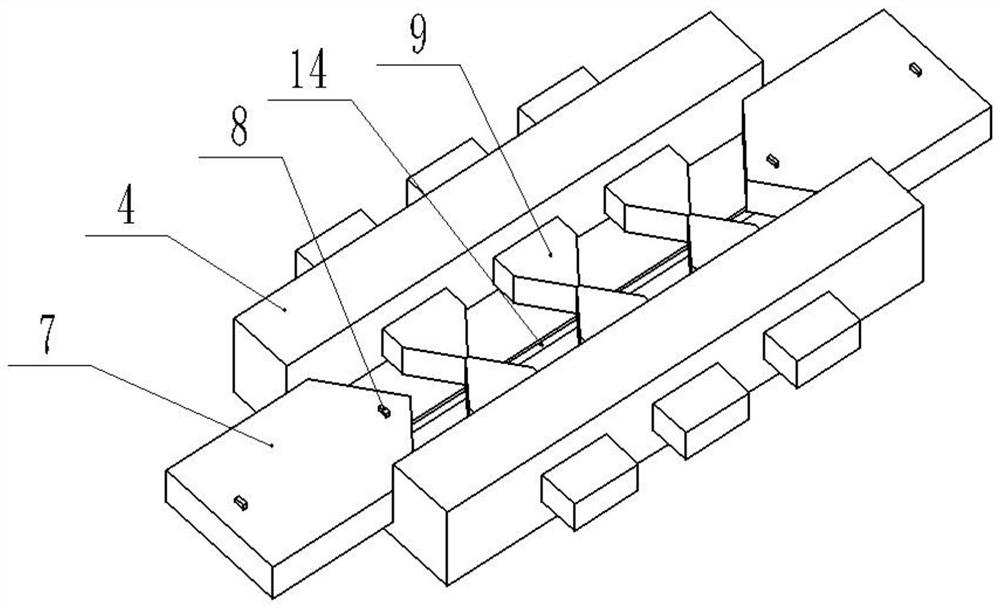

The invention discloses a stirring range-adjustable medical rapid mixing device for liquid medicaments. The device comprises a base, a mixing box, stirring blades, corrugated plates and a second driving motor, a sliding block is slidably mounted on a sliding rail, the mixing box is arranged at the upper side of the sliding block, a threaded rod is provided with a plurality of translational slidingblocks in a threaded manner, and the stirring blades are fixedly mounted at the upper sides and the lower sides of the translational sliding blocks. Different speeds of a connecting shaft make the centrifugal forces born by the lower blades and the upper blades different in order to change the expansion and contraction range of the lower blades and the upper blades, and the stirring range is changed in order to further improve the mixing effect; and the lateral translational movement of the mixing box greatly improves the flow rate of a liquid in the mixing box in order to further improve themixing effect, and the relative displacement between the mixing box and the corrugated plates makes the corrugated plates have a spoiling effect, so the mixing effect in the mixing box is greatly improved.

Owner:伍超群

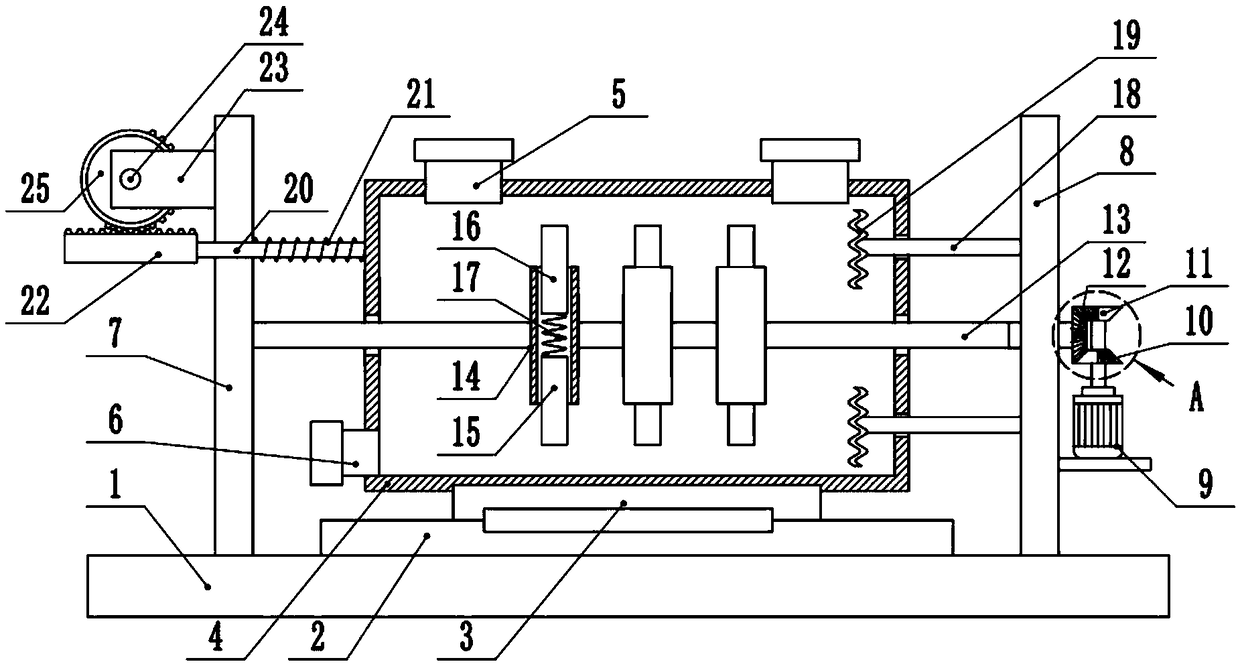

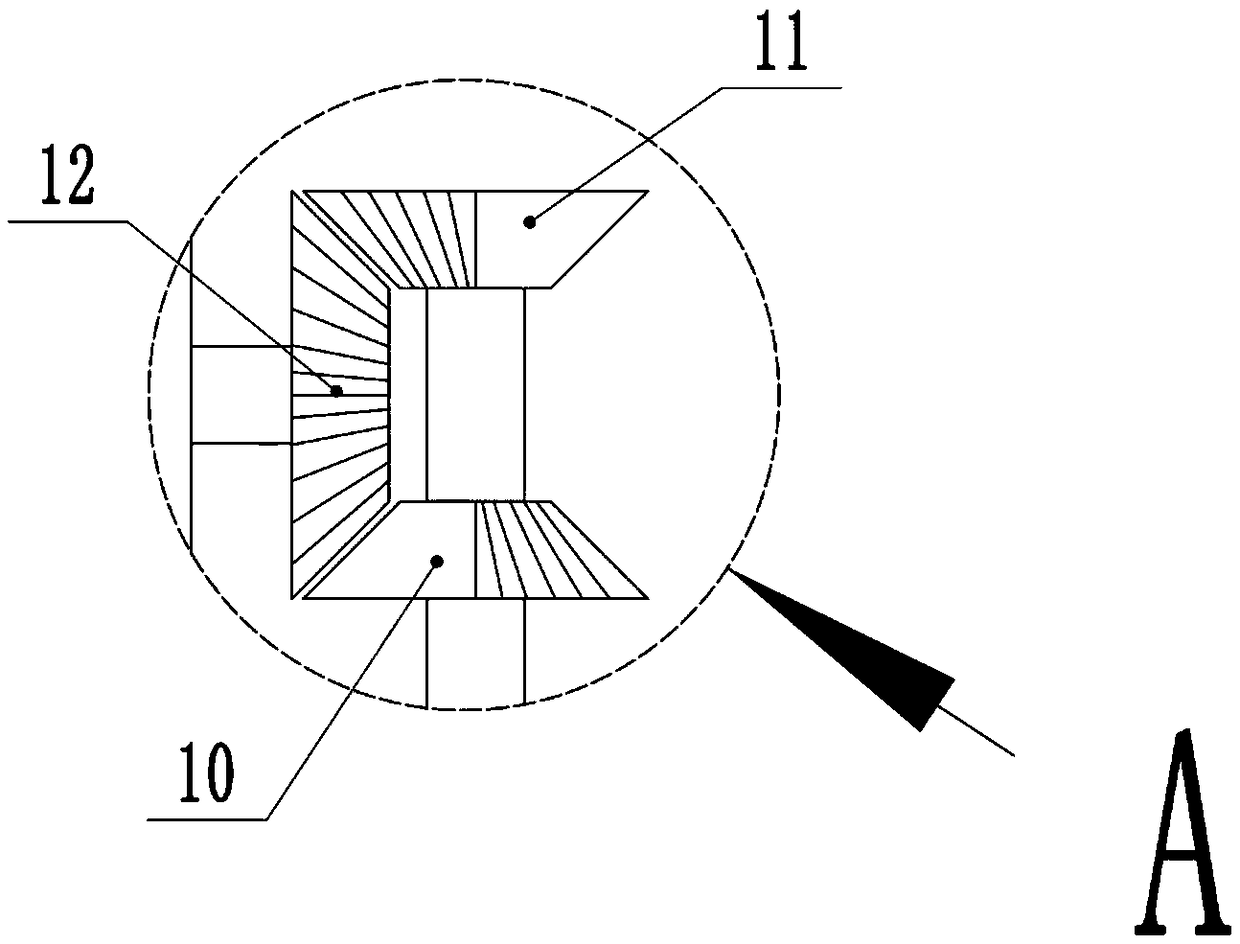

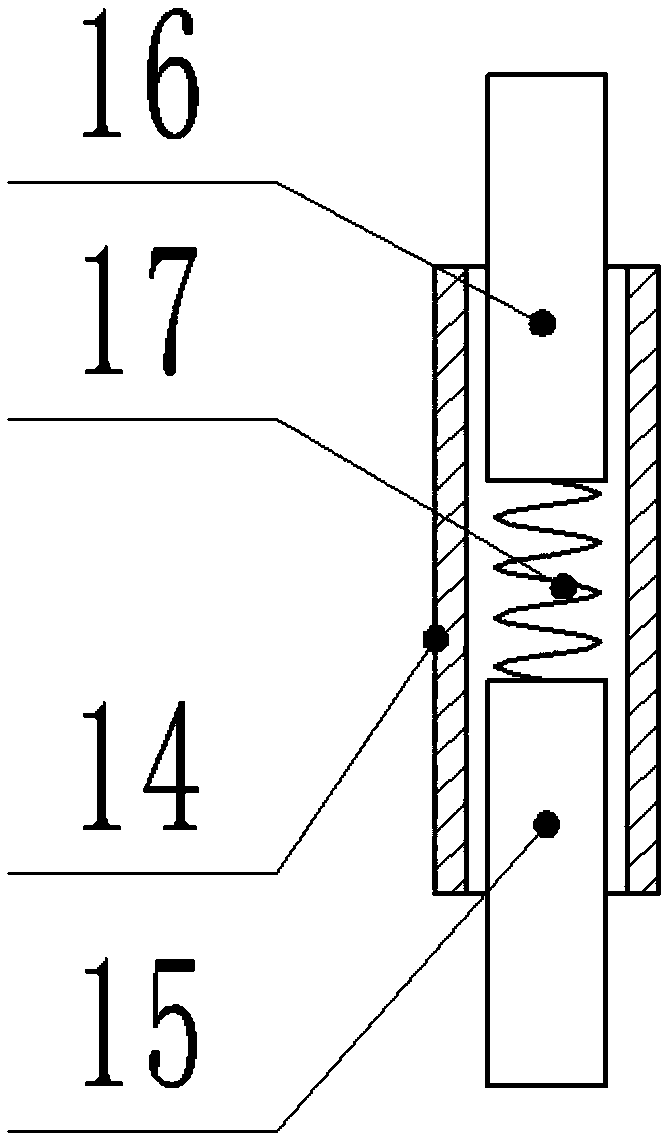

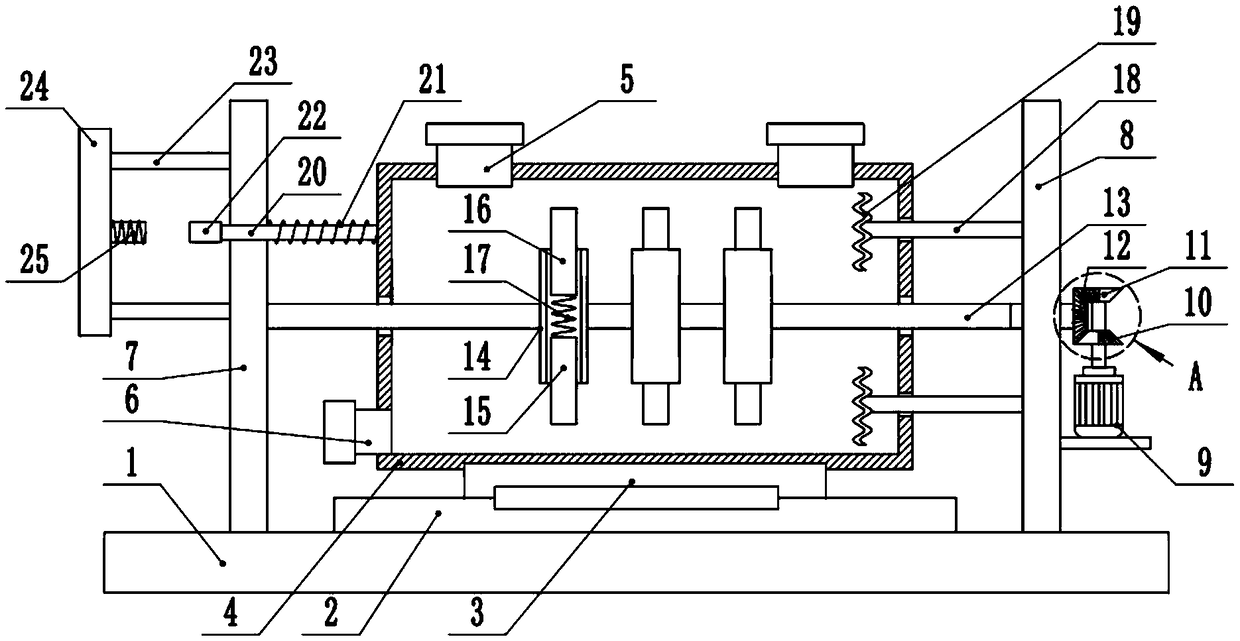

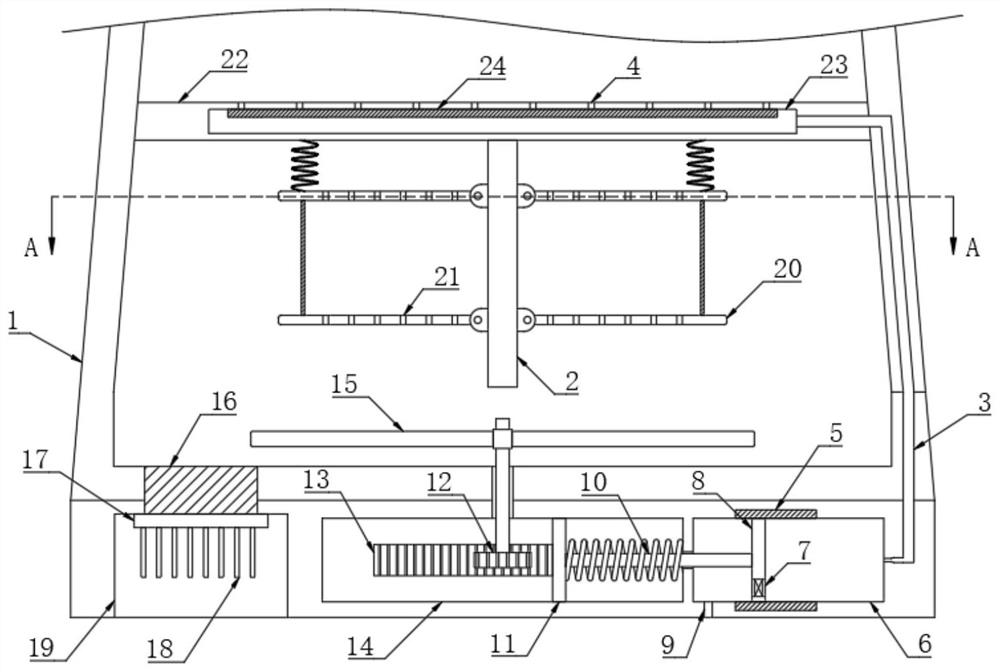

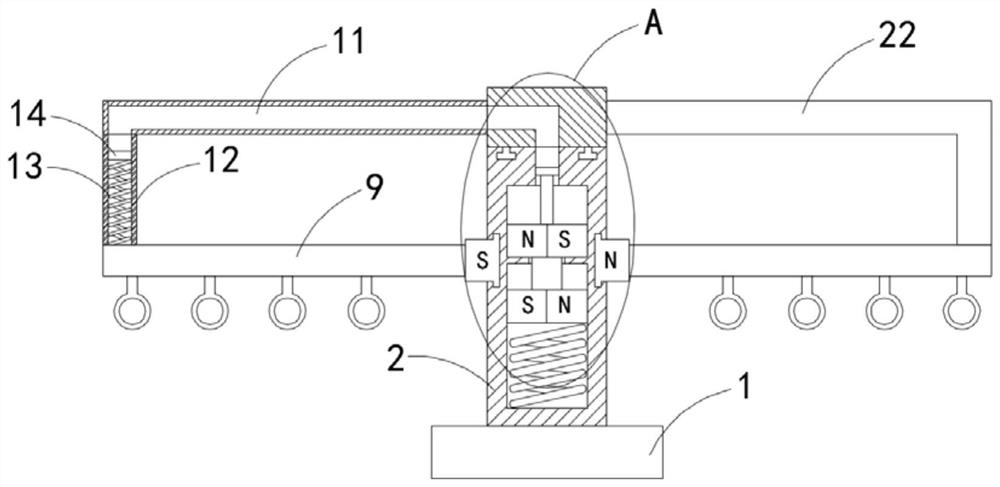

Electromagnetically-driven translational medical liquid medicament rapid mixing device

InactiveCN109012413AImprove the mixing effectImprove turnoverShaking/oscillating/vibrating mixersTransportation and packagingRelative displacementEngineering

The invention discloses an electromagnetically-driven translational medical liquid medicament rapid mixing device. The device comprises a base, a mixing box, stirring blades, corrugated plates and a second driving motor, a sliding block is slidably mounted on a sliding rail, the mixing box is arranged at the upper side of the sliding block, a screw rod is provided with a plurality of translationalsliding blocks in a threaded manner, and the stirring blades are fixedly mounted at the upper sides and the lower sides of the translational sliding blocks. Different speeds of a connecting shaft make the centrifugal forces of the lower blades and the upper blades different in order to change the expansion and contraction range of the lower blades and the upper blades, and the stirring range is changed in order to further improve the mixing effect; and the lateral translational movement of the mixing box greatly improves the flow rate of a liquid in the mixing box in order to further improvethe mixing effect, and the relative displacement between the mixing box and the corrugated plates makes the corrugated plates have a spoiling effect, so the mixing effect in the mixing box is greatlyimproved.

Owner:伍超群

Pesticide mixing device used for large-scale planting

InactiveCN107551912AAvoid stratificationSimple structureShaking/oscillating/vibrating mixersInterference fitBall screw

The invention discloses a pesticide mixing device for large-scale planting, which comprises a base, a wedge-shaped slider, a ball screw, a first drive motor, a rotating mixing barrel, a second drive motor, special-shaped gears and stirring blades, the first drive The output shaft of the motor is vertically upward and the output shaft of the first driving motor passes through the motor box and is connected with a rotating mixing bucket. The lower side of the frame is also welded with a special-shaped slider, and the lower end of the stirring rod extends into the rotating stirring barrel and is connected with stirring blades. The mixing method in this device can improve the fluidity of the pesticide in the rotating mixing tank and improve the mixing effect; at the same time, during the mixing process, the two sets of mixing blades can be moved "up and down" respectively, thereby playing the role of turbulence, further Improve the effect of mixing.

Owner:HUNAN WANGLONG ENTERPRISE MANAGEMENT CONSULTING CO LTD

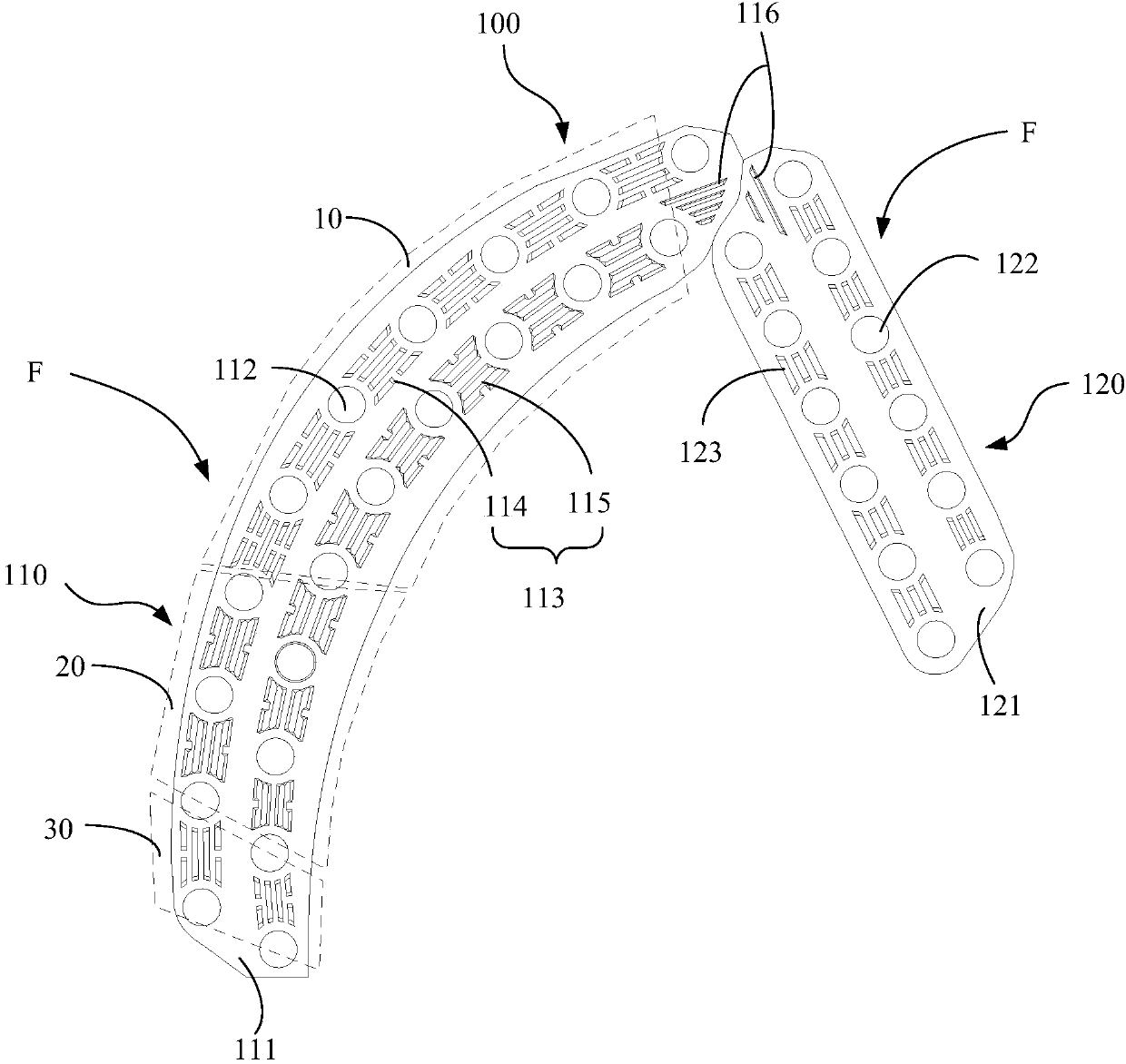

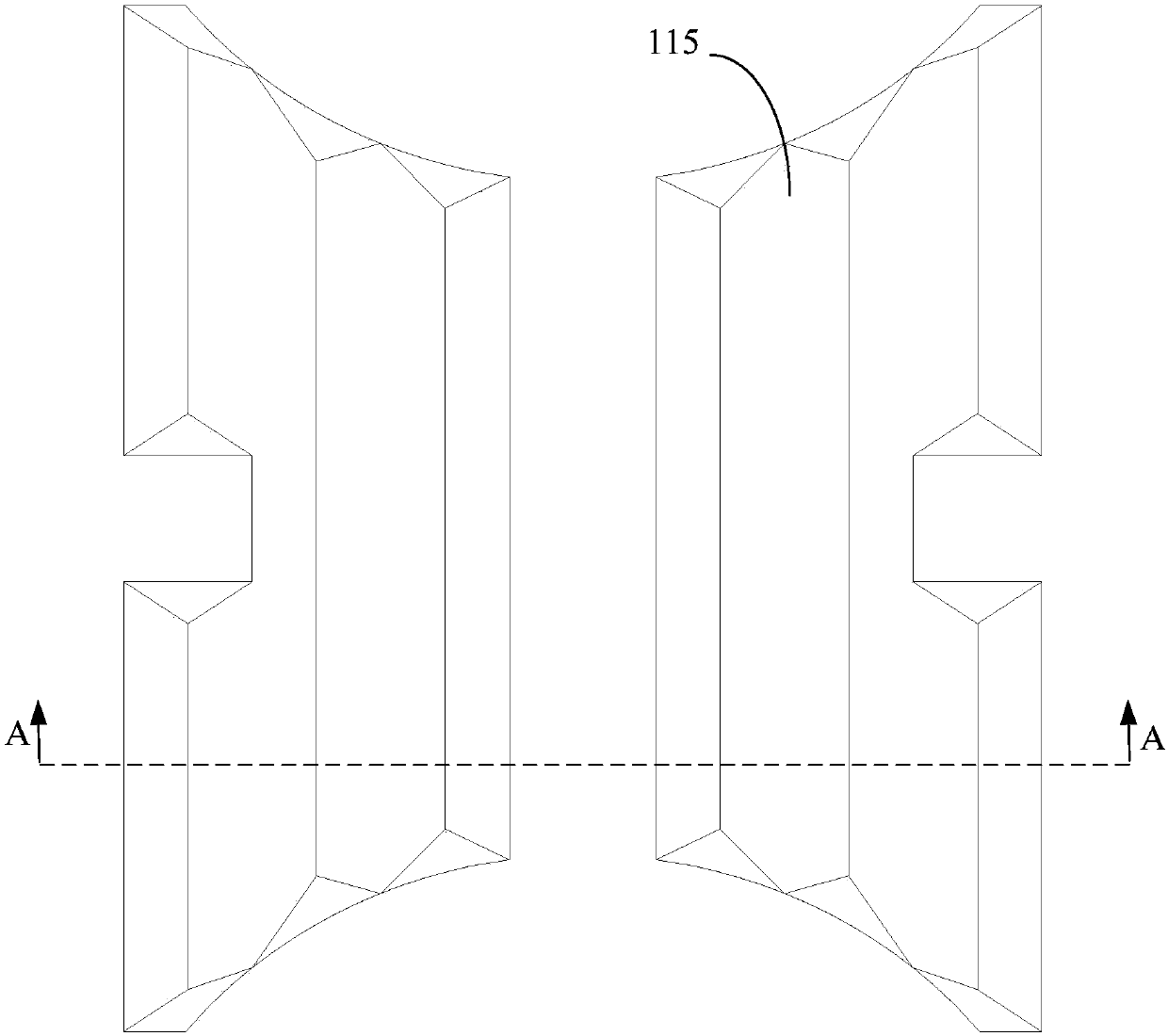

Indoor heat exchanger, indoor unit of air conditioner and air conditioner

PendingCN107843030AUniform and appropriate wind speedImprove heat transfer efficiencyEvaporators/condensersSpace heating and ventilation detailsEngineeringWind speed

The invention discloses an indoor heat exchanger, an indoor unit of an air conditioner and the air conditioner, wherein the indoor heat exchanger comprises a front heat exchange portion and a back heat exchange portion which extends from the upper end of t he front heat exchange portion to the back side; the front heat exchange portion comprises a plurality of front fins which are arranged in parallel, and a first wind shielding structure is arranged between two adjacent front pipe holes in each of the front fins; the front pins form a plurality of wind through regions in directions from top to bottom, and the wind shielding area of the first wind shielding structure in the upper wind through region is greater than that of the first wind shielding structure in the lower wind through region. According to the technical scheme, the front pins form the plurality of wind through regions in directions from top to bottom, and the wind shielding area of the first wind shielding structure in the upper wind through region is greater than that of the first wind shielding structure in the lower wind through region, so that the wind speed of wind flowing through the front heat exchange portionis uniform and proper, and therefore, the heat exchange efficiency of the indoor heat exchanger is improved integrally.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Mobile medical stirring blade rapid mixing device for liquid medicaments

InactiveCN109092162ARealize up and down movementImprove the mixing effectShaking/oscillating/vibrating mixersTransportation and packagingRelative displacementEngineering

The invention discloses a mobile medical stirring blade rapid mixing device for liquid medicaments. The mobile medical stirring blade rapid mixing device for the liquid medicaments comprises a base, amixing box, base stirring blades, corrugated plates and a second driving motor, wherein a sliding block is glidingly mounted on a sliding rail, the mixing box is arranged on the upper side of the sliding block, multiple sets of translational sliding blocks are further mounted on a screw rod in thread manners, and the stirring blades are further fixedly mounted on the upper sides and the lower sides of the translational sliding blocks. The screw rod is indirectly driven to intermittently rotate forwards and reversely, and in thread fit with the translational sliding blocks, so that the stirring blades move up and down to greatly improve the mixing effect of the liquid medicaments inside the mixing box and then uneven mixing is avoided; the flow rate of liquid inside the mixing box is greatly increased through the left and right translation movement of the mixing box, to further improve the mixing effect; furthermore, a relative displacement is further generated between the mixing box and the corrugated plates, so that the corrugated plates play roles of flow perturbation to greatly improve the mixing effect inside the mixing box.

Owner:伍超群

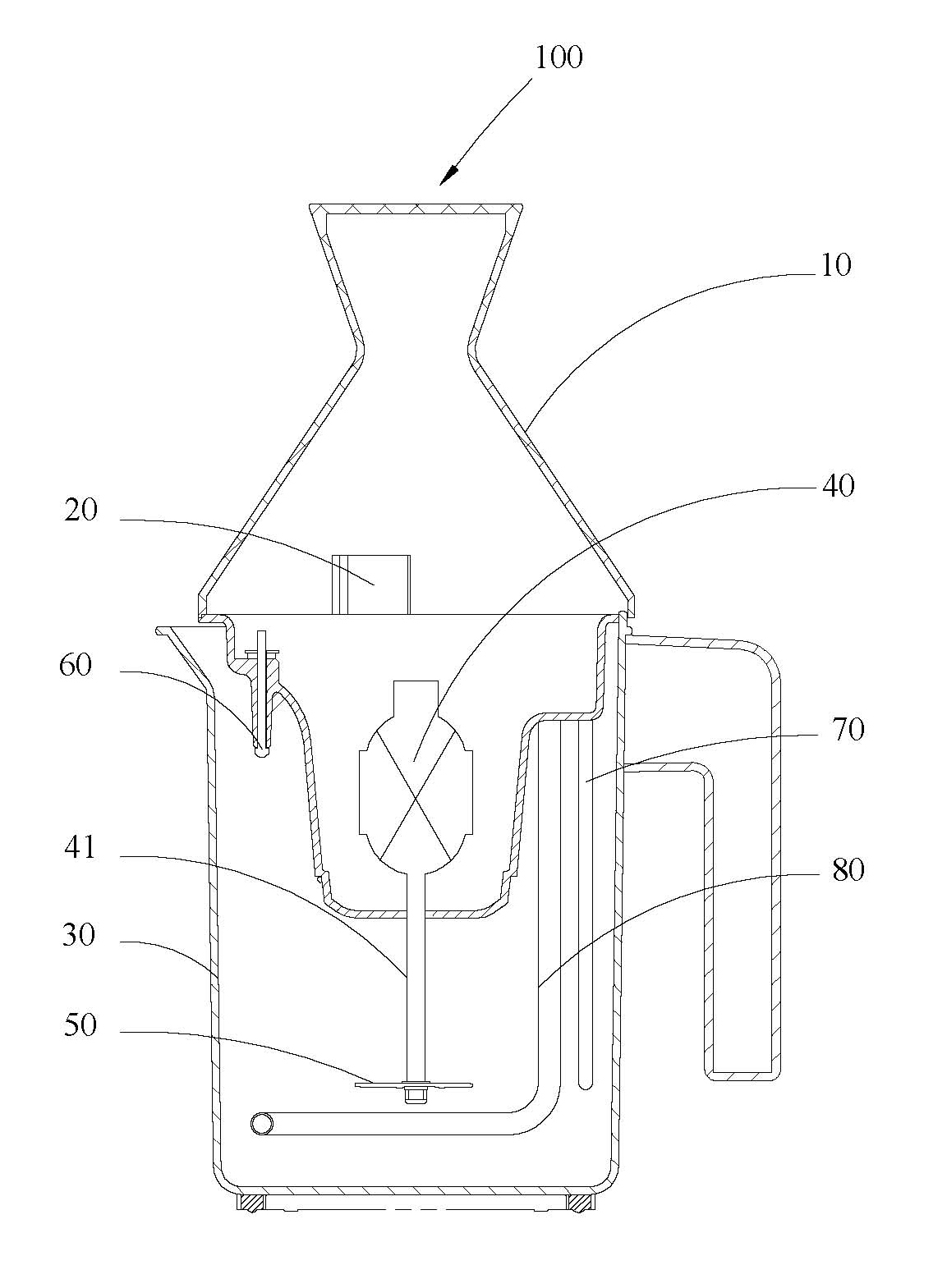

Soymilk machine and soymilk preparing method thereof

ActiveCN101810224AImprove crushing efficiencySimple structureBeverage vesselsMilk substitutesLow speedMotor drive

The invention relates to a soymilk machine and a soymilk preparing method thereof. The soymilk machine comprises a circuit board and a motor, wherein a motor shaft of the motor is fixedly provided with a cutter used for pulverizing soymilk preparing materials; the pulverization of the materials by the soymilk machine is realized thorugh the alternate transformation of the rotating speed of the motor driven by the circuit board; therefore, spoiler devices, such as traditional meshers, fluid dividers or spoiler bars, and the like are eliminated. The operation of the motor is switched between high speed and low speed in a circulating pulverizing process, thereby enabling a speed difference to generate between the materials and a pulverizing device and enhancing the pulverizing effect of the soymilk preparing materials.

Owner:JOYOUNG CO LTD

Computer mainboard reinforcing device with heat dissipation and dust prevention functions

ActiveCN110888501ATake away quicklyAct as a distractionDigital processing power distributionEnergy efficient computingClassical mechanicsEngineering

Owner:HUNAN COLLEGE OF INFORMATION

Electrical automatic spraying device

InactiveCN109045902AAct as a distractionAids in spray treatmentCombination devicesDispersed particle filtrationWater storage tankEngineering

The invention discloses an electrical automatic spraying device. The electrical automatic spraying device comprises a spraying chamber, a water storage tank, a filter screen, a draining pipe and spraying heads, wherein the water storage tank is fixedly welded on the upper surface of the spraying chamber; an air inlet pipe is arranged at the middle position of the left side wall of the spraying chamber; a fan is arranged between the air inlet pipe and the water storage tank; the air inlet pipe is communicated with the fan; the fan is communicated with the spraying chamber; the draining pipe ishorizontally arranged at the top of the spraying chamber; the plurality of spraying heads are horizontally and uniformly distributed below the draining pipe and are communicated with the draining pipe. The electrical automatic spraying device is characterized in that the filter screen is obliquely arranged at the middle position inside the water storage tank and is horizontally and uniformly provided with a plurality of vertical guide rails. The electrical automatic spraying device disclosed by the invention achieves reasonable design and high waste gas treatment capacity, and can be used forsufficient spraying treatment on waste gases, so that harmful substances in the waste gases can be adsorbed, and the pollution of exhausted waste gases to the environment is avoided.

Owner:INNER MONGOLIA UNIV FOR THE NATITIES

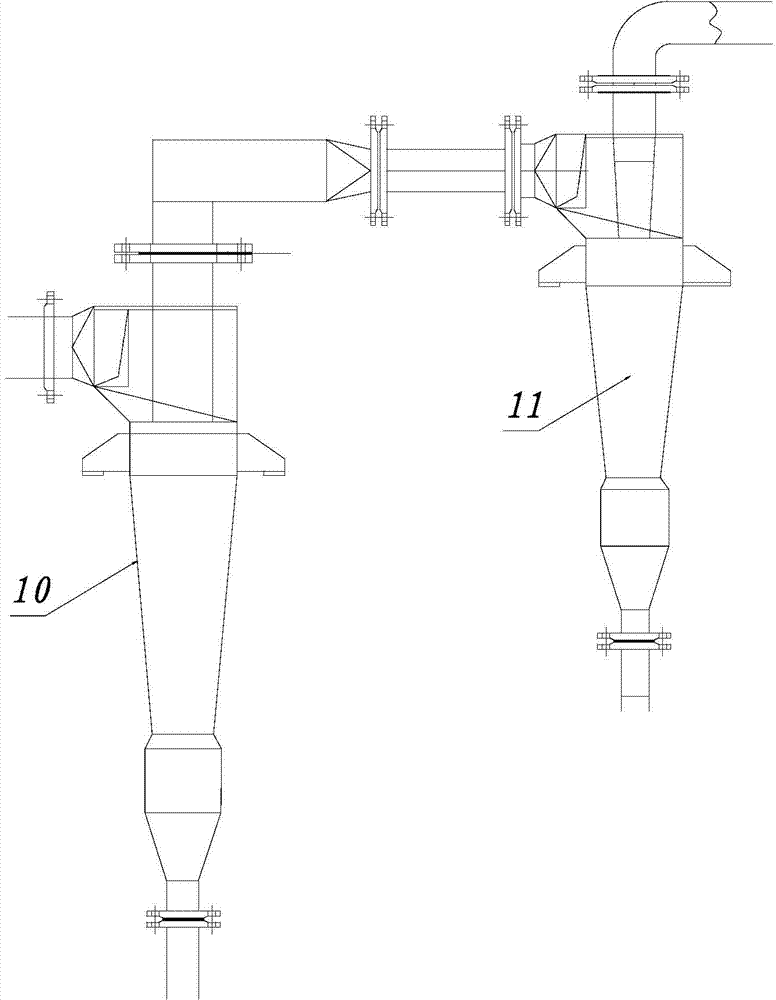

Bag type dust collector for producing silicon tetrachloride by direct method

InactiveCN103566669AAvoid direct impactAvoid breakingDispersed particle filtrationHalogenated silanesBaghouseProduct gas

The invention relates to a bag type dust collector for producing silicon tetrachloride by a direct method. The bag type dust collector comprises an outer shell body and a plurality of bag devices, wherein a baffle plate is arranged in the outer shell body to divide the outer shell body into a dust collecting chamber and a gas outlet chamber, the bag devices are fixedly arranged on the baffle plate, a gas inlet of the dust collector is arranged above the dust collecting chamber, a dust outlet is arranged at the bottom of the dust collecting chamber, a fine powder recycling tank is arranged below the dust outlet, a gas outlet of the dust collector is arranged on the side wall of the gas outlet chamber, a heating jacket is arranged on the outer side wall of the dust collecting chamber, and a plurality of bag devices are all made of high-temperature resistant materials. According to the bag type dust collector, a small quantity of fine silicon powder in the gas crude product is recycled through the bag type dust collector, therefore, most of silicon powder in the silicon tetrachloride crude product gas is removed, and the dust collection operation in the following process is avoided.

Owner:ZHEJIANG FUSHITE GROUP

Environment-friendly energy-saving washing device

ActiveCN110404647AEasy to cleanAchieve cycleDrying gas arrangementsCleaning using liquidsWater pipeEnvironmentally friendly

The invention discloses an environment-friendly energy-saving washing device and relates to washing equipment. The environment-friendly energy-saving washing device mainly aims to solve the problems that existing washing equipment is single in function and poor in washing effect. The environment-friendly energy-saving washing device comprises a box. A box opening is formed in the top end of the box. The box opening is provided with a feeding opening. The feeding opening communicates with a smashing device. The smashing device comprises first fixing plates connected into the box in a sliding manner. The tops of the first fixing plates are connected with sliding rods in a sliding manner. The smashing device communicates with a washing chamber through a first discharging opening. A first stirring box and a second stirring box are sequentially arranged in the washing chamber from top to bottom. The portion below a first partition plate is divided into a drying chamber and a filtering chamber through a second partition plate. The washing chamber communicates with the filtering chamber through a first water pipe. Water stop plates are arranged in the filtering chamber. Filtering films are arranged on the water stop plates. A water pump is arranged inside the water stop plates. The water pump is connected with nozzles on a baffle through a second water pipe. The washing device saves more energy, is environmentally friendly, and is high in functionality.

Owner:陕西众合泰达实业有限公司

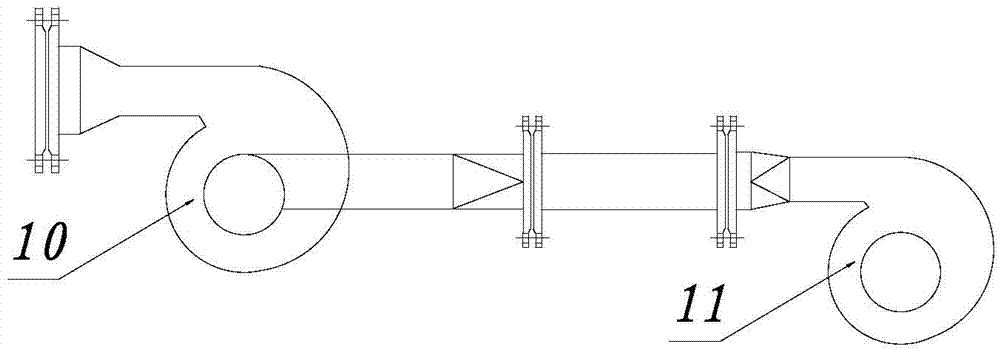

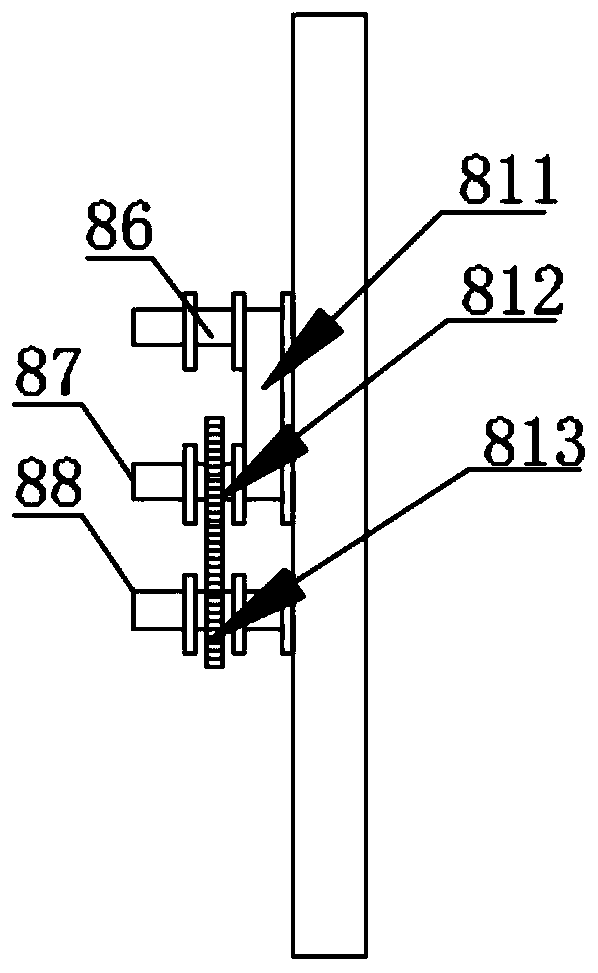

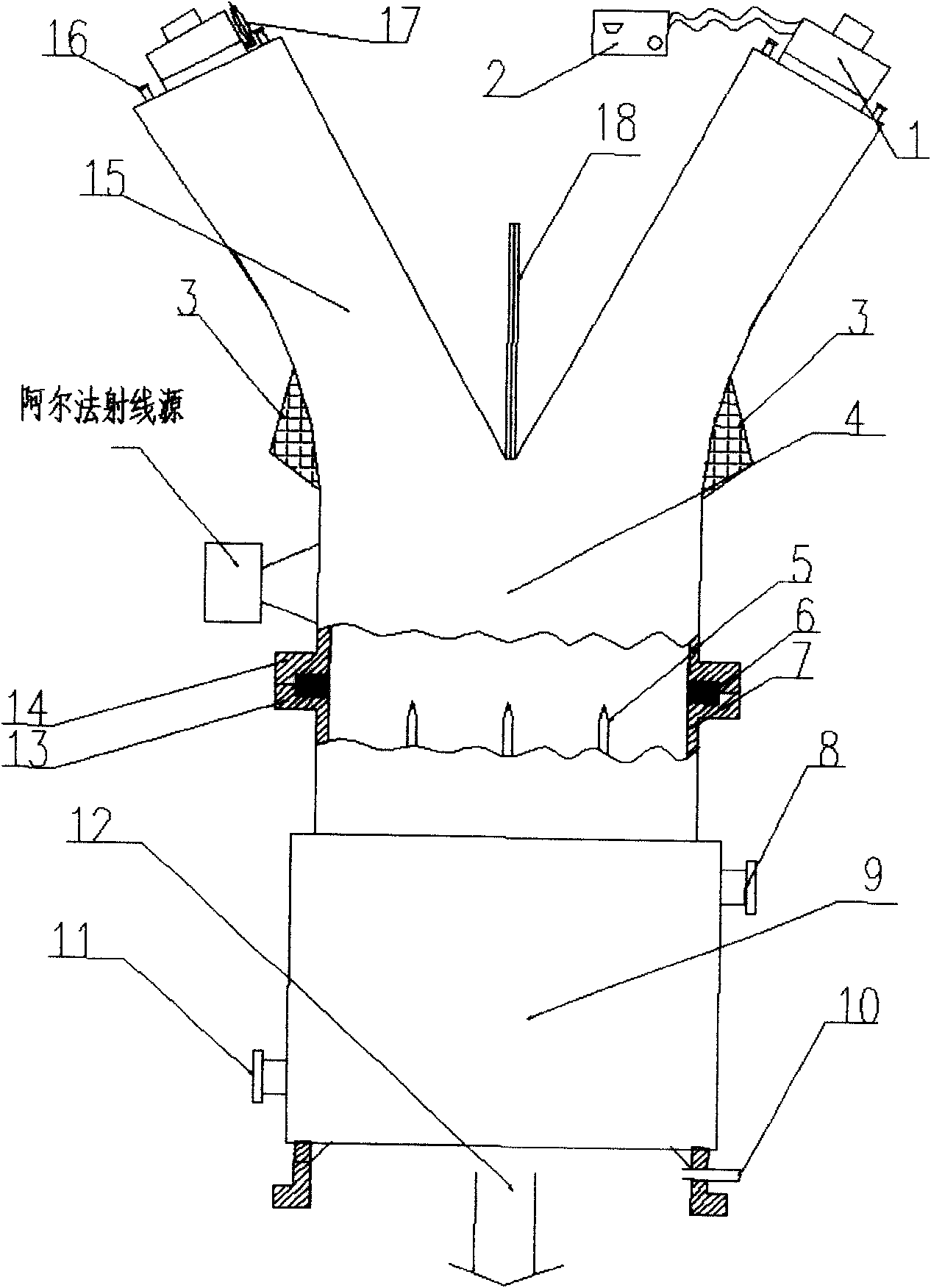

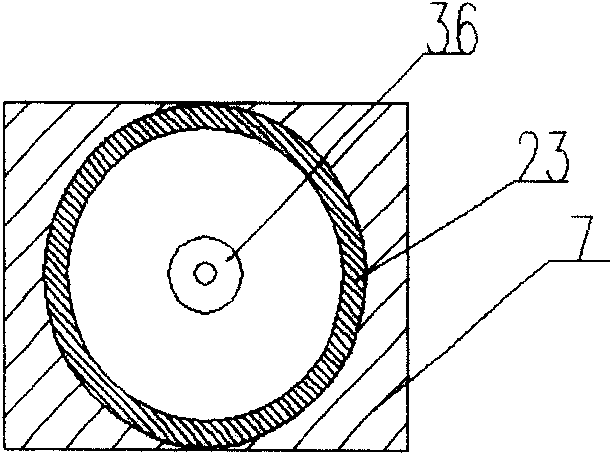

Process and device for preparing nano-powder by utilizing ultrasonic static electricity

InactiveCN101623616AGood monodispersityReduce reunionGranulation by liquid drop formationChemical/physical/physico-chemical nozzle-type rreactorsEngineeringPollution

The invention provides a process and a device for preparing nano-powder by utilizing ultrasonic static electricity. The process and the device combine the advantages of ultrasonic atomization and static atomization and skillfully overcome the disadvantages of the two. The process mainly comprises the following steps that: raw material is heated to be in a liquid state through a heating furnace, degassed through a degassing device and then conveyed to an atomizer through a pipeline; the raw material in the atomizer is first precharged via a precharging device and then is guided into a nozzle of a piezoelectric-type ultrasonic atomization system through a flow-guiding pipe in order to be atomized; the obtained material is accelerated through a primary acceleration-ring group, enters an inductive charging ring, and is charged and atomized again; the atomized raw material is accelerated through a secondary acceleration-ring group, joined and mixed through a Y-shaped pipe; mixed compounded fog drops are irradiated with an alpha ray source to remove surface charge; the charge-removed fog drops pass through a flow-guiding device (a resistance-wire heating pipe is arranged in the flow-guiding device to perform corresponding thermal decomposition on the fog drops needing thermal decomposition), enter a condenser, are condensed into solid powder; and the solid power leaves the atomizer and then enters a collection device in order to be collected. Therefore, the nano-powder with product stability, high performance, narrow particle distribution, uniform particle distribution, good monodispersity, little agglomeration, high purity and good sphericity can be prepared by utilizing equipment which is simple, low in cost, free from pollution, easy to control and suitable for large-scale continuous industrial production.

Owner:李洋

Energy-saving environment-friendly commercial stove

ActiveCN109827197AImprove combustion efficiencyImprove energy saving and environmental protection performanceDomestic stoves or rangesCooking fumes removalCombustorEngineering

The invention relates to an energy-saving environment-friendly commercial stove. The problem that in the prior art, the gas utilization rate is low is mainly solved. The stove comprises a hearth whichis provided with a supporting frame, and the lower portion of the supporting frame is provided with a supporting groove; the outer side surface of the supporting frame is annularly and uniformly provided with first air inlets, and the supporting frame is provided with an annular air outlet; the supporting frame is internally provided with a circulating channel communicating with the first air inlets and the air outlet; the bottom of the hearth is provided with a through hole, ad a combustor is arranged at the through hole and provided with a kindling gas feeding pipe, a main fire gas feedingpipe and an air feeding pipe; a fire collecting ring surrounding the combustor is arranged in the hearth; the bottom of the hearth is provided with an outlet, a fire collecting plate is arranged in the hearth, and the hearth, the supporting frame, the fire collecting plate and the fire collecting ring form a cavity; the air outlet and the outlet both communicate with the cavity; the outlet communicates with the input end of an exhaust fan, the output end of the exhaust fan communicates with the air feeding pipe, and a fireproof explosion-proof device is arranged between the exhaust fan and theair feeding pipe.

Owner:福建万聚通节能科技股份公司

Strawberry cleaning machine

InactiveCN108378386ASo as not to damageImprove cleaning efficiencyFood treatmentEngineeringMechanical engineering

The invention discloses a strawberry cleaning machine. The strawberry cleaning machine comprises a cleaning tank, wherein a feed hopper is arranged on one side of the cleaning tank; a discharge plateis arranged on the other side of the cleaning tank; a conveying belt is arranged in the cleaning tank, below the liquid level in the cleaning tank; scraping plates which are obliquely arranged are uniformly distributed on the conveying belt; the conveying belt comprises a horizontal part and a lifting part; one end of the horizontal part is located right under the feed hopper; the lifting part which inclines upwards is arranged at the other end of the horizontal part; the other end of the lifting part is located right above the discharge plate; a blower is arranged outside the cleaning tank, and communicates with a plurality of air distribution pipes arranged at bottom in the cleaning tank through an air supply pipe; and a plurality of air outlets facing upwards are uniformly formed in each air distribution pipe. The strawberry cleaning machine disclosed by the invention is reasonable in structural design and convenient to use; the damage rate during cleaning can be greatly reduced; and the cleaning efficiency is improved.

Owner:安徽省宇洲食品有限公司

Light-blocking glass window

ActiveCN111663886APlay the role of blocking lightAccelerated dissipationLight protection screensGlass sheetWind power

The invention discloses a light-blocking glass window. The light-blocking glass window comprises a shell, two glass plates are installed in the shell, a sealed space is formed between the two glass plates and the shell, the two sides of the shell are each provided with a strip-shaped first movable cavity, a movable plate is slidably connected in each first movable cavity, a handle is installed onone side of each movable plate, the bottom ends of the movable plates are fixedly connected with springs, the outer side of each spring is further wrapped with an insulating rubber layer, and first magnets are clamped in the first movable cavities. According to the light-blocking glass window, through the interaction of a magnetofluid, the first movable cavities, the movable plates, the springs, the first magnets, a valve, a corrugated hose and other structures, the magnetofluid in the corrugated hose flows into the sealed space between the glass plates and fills the sealed space, and therefore the effect of shielding light is achieved; and when the window is opened, the internal magnetofluid is not influenced by wind power and is kept stable.

Owner:江西省鼎盛天工玻璃有限公司

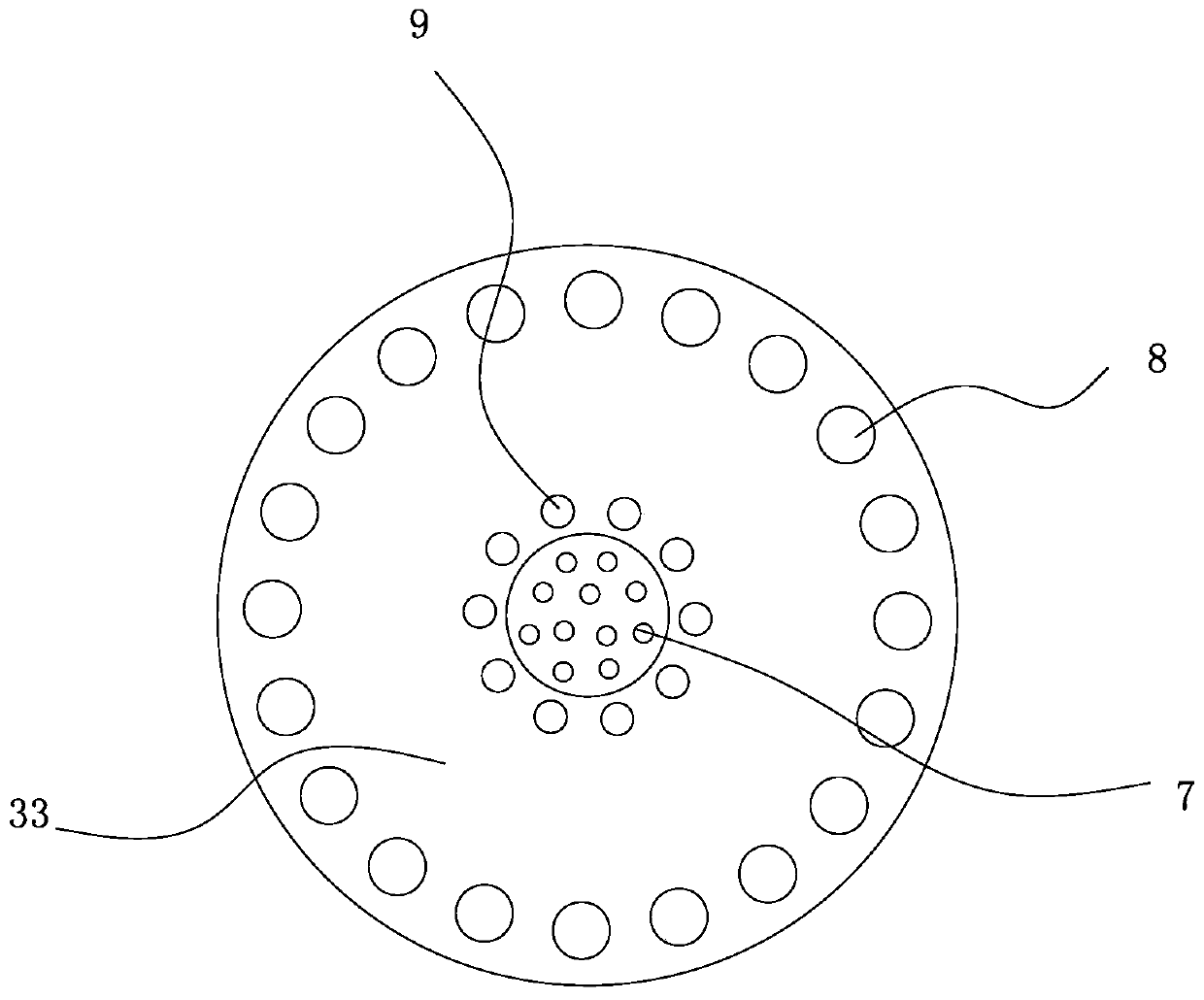

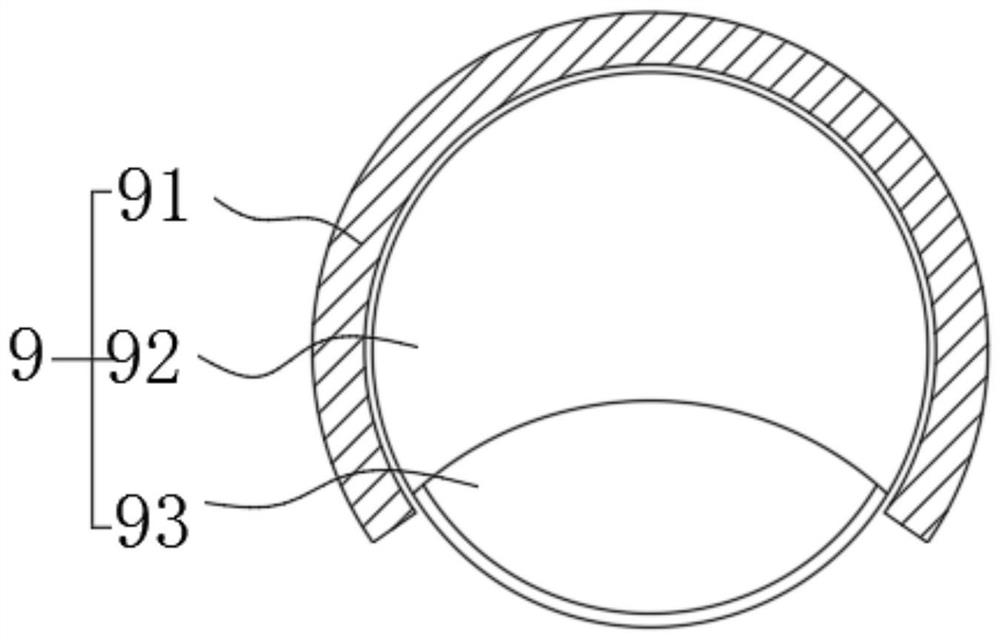

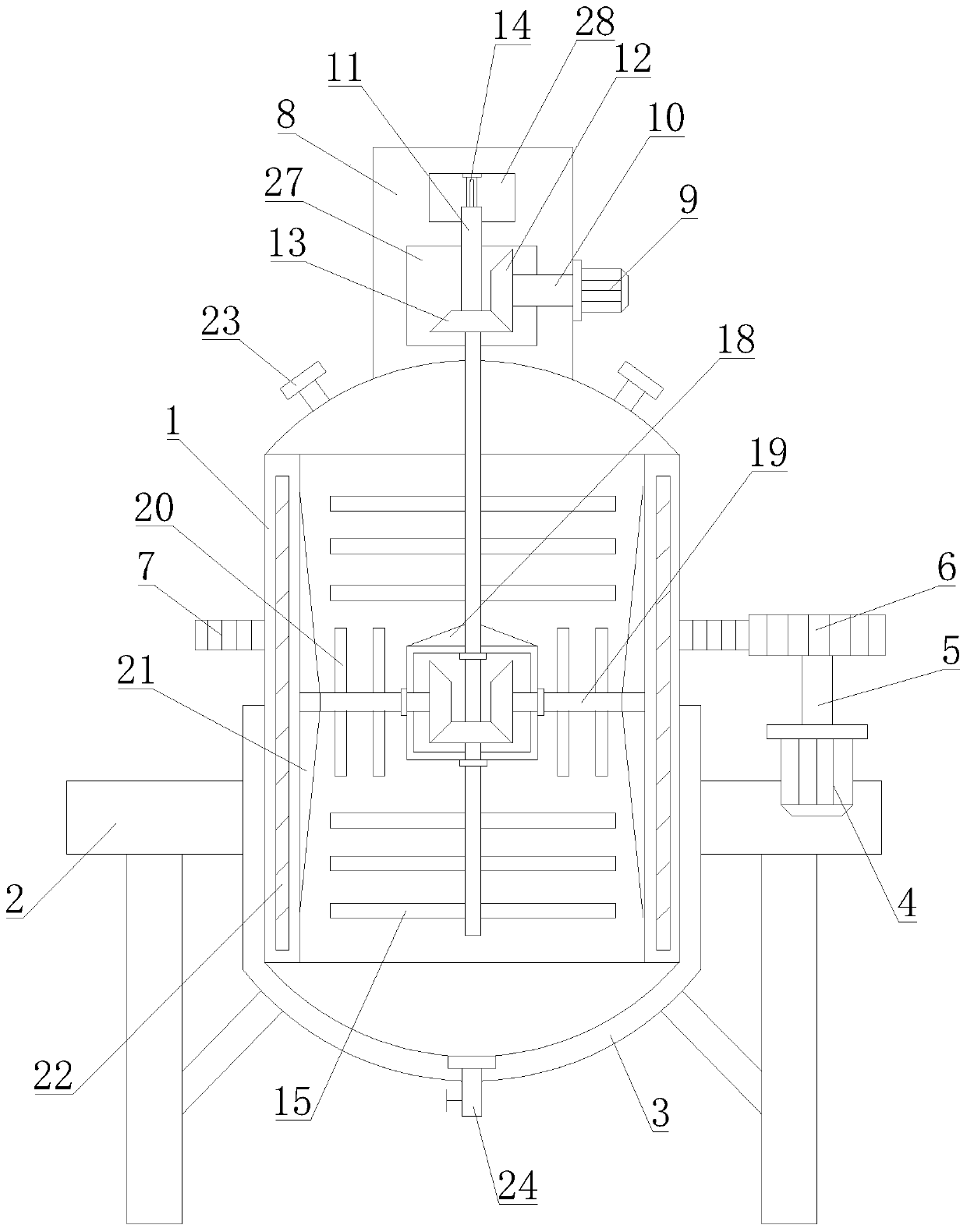

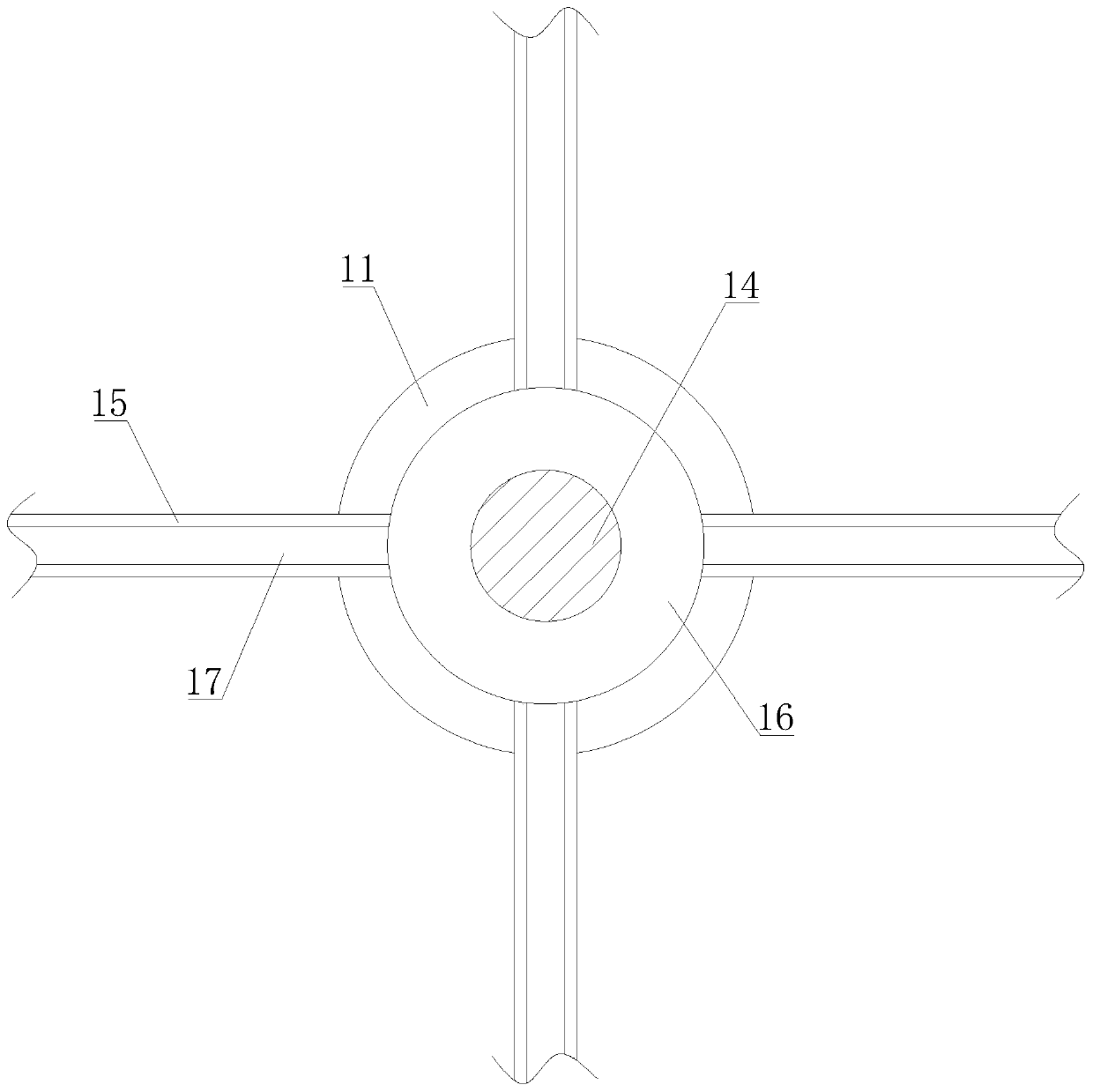

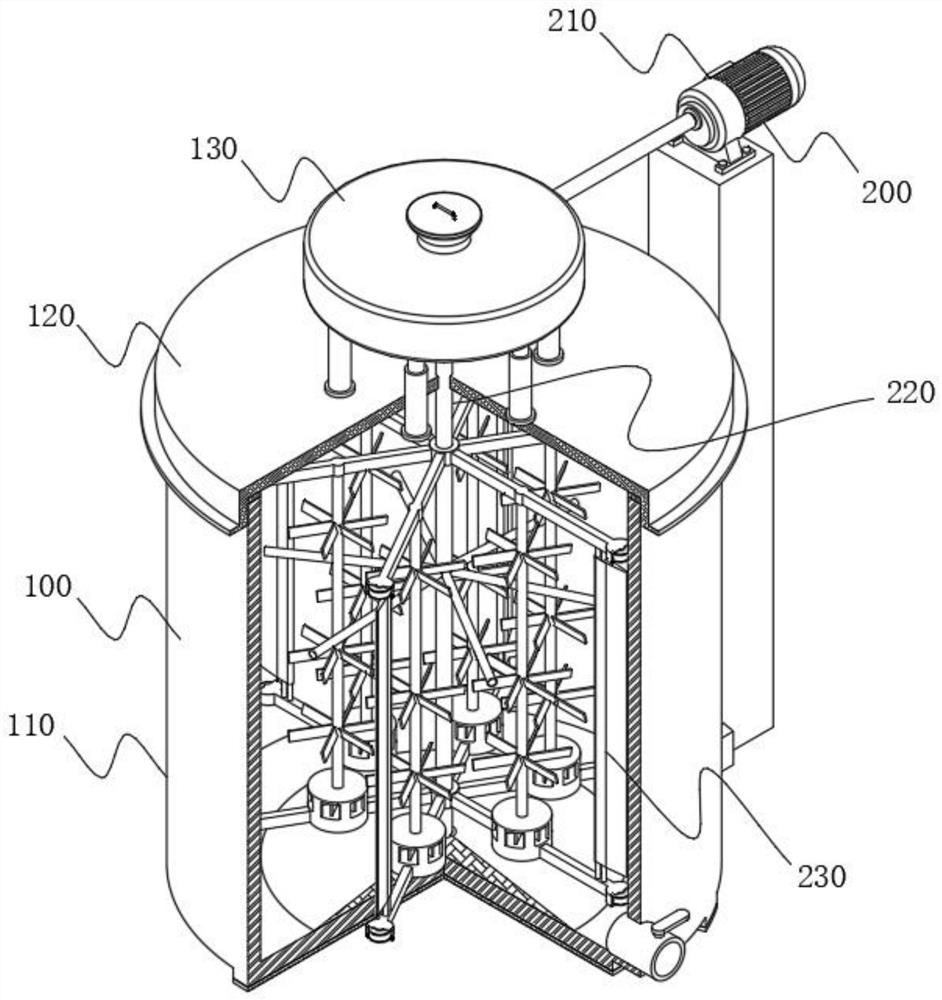

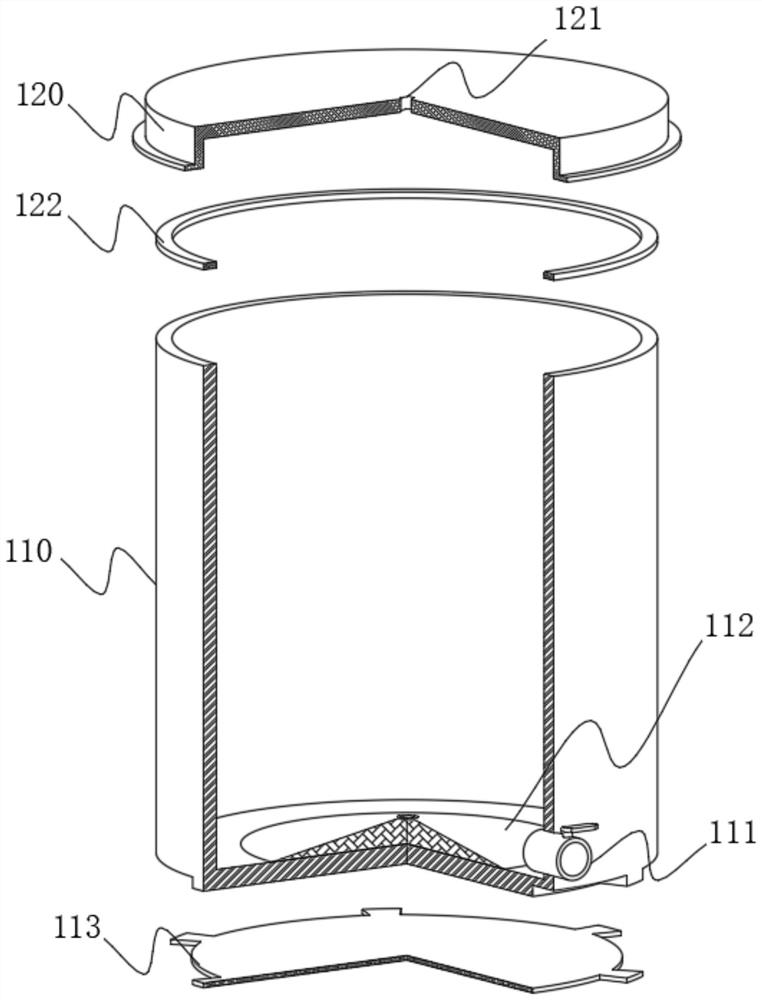

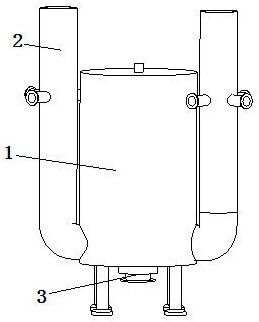

Vertical efficient reaction kettle for producing organic silicon sealant

InactiveCN110918033APlay a role in mixingImprove stirring and mixing effectChemical/physical/physico-chemical stationary reactorsLiquid storage tankEngineering

The invention discloses a vertical efficient reaction kettle for producing an organic silicon sealant. The vertical efficient reaction kettle comprises a reaction kettle body, the reaction kettle bodyis rotationally connected with a heat preservation cover, and an electric heating ring is arranged on the reaction kettle body; a first gear is arranged on a first transmission shaft, a second gear is arranged on the reaction kettle body, and the first gear is in engaged transmission connection with the second gear; a first rotating part is rotationally connected with the reaction kettle body; afirst liquid storage tank is arranged on the first rotating piece; an electric heating pipe is inserted into the first liquid storage tank; a second transmission shaft is in transmission connection with a first rotating part; a first stirring piece is arranged on the first rotating piece, and a second liquid storage tank is arranged on the first stirring piece; the second liquid storage tank communicates with the first liquid storage tank; a second rotating piece is rotationally connected with a second fixed piece, and the first rotating piece is in transmission connection with the second rotating piece; and a second stirring piece and a spoiler are arranged on the second rotating piece. Raw materials can be uniformly heated and fully mixed, the stirring efficiency is high, the stirring effect is good, and the product quality is remarkably improved.

Owner:江西纳森科技有限公司

Bridge vortex vibration control device

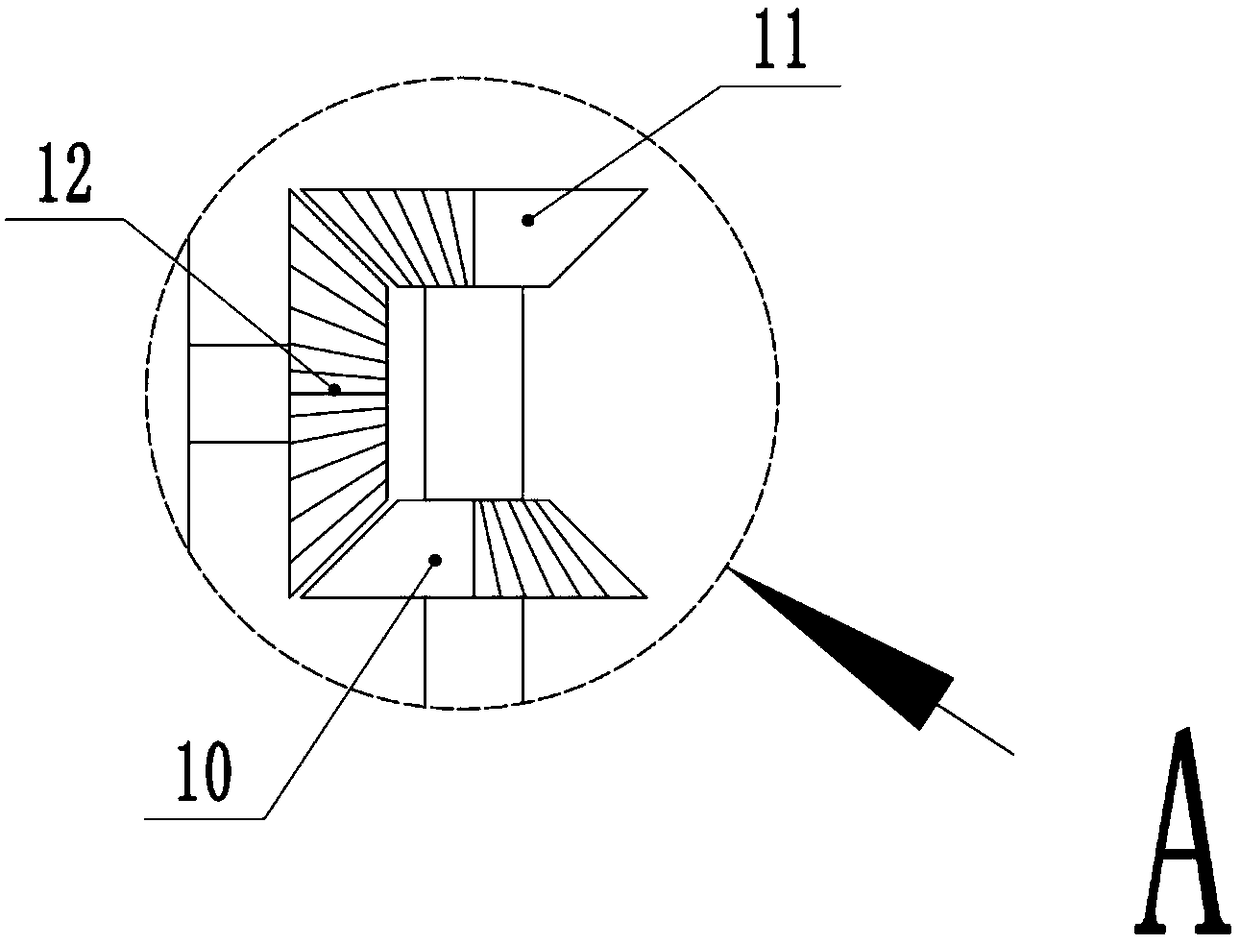

InactiveCN111809507AAct as a distractionEddy vibration reductionNon-rotating vibration suppressionBridge structural detailsBridge engineeringVibration control

The invention relates to the field of bridge engineering. The invention particularly discloses a bridge vortex vibration control device. The device comprises a control unit arranged at the bottom of abridge; the control unit comprises a plurality of controllers; the controller comprises a base and a plurality of sliding sheets; a sliding groove is formed in the base in the length direction; a wedge block is arranged in the sliding groove in a sliding mode; a plurality of sliding holes are formed in the two sides of the base; the sliding sheet is arranged in the sliding hole; a wedge surface matched with the wedge block is arranged at the end part of the sliding sheet; a wind shielding structure is arranged at the bottom of the sliding sheet; the wind shielding structure comprises a firstconnecting rod, a second connecting rod, a third connecting rod and a wind shielding curtain; the first connecting rod and the second connecting rod are hinged to the bottom of the sliding piece, thetwo ends of the third connecting rod are hinged to the first connecting rod and the second connecting rod respectively, the wind shielding curtain is quadrilateral, and three sides of the wind shielding curtain are arranged on the first connecting rod, the second connecting rod and the third connecting rod respectively. The technical problem that vortex vibration possibly occurs to a bridge underthe condition of low wind speed can be solved.

Owner:CHONGQING UNIV OF ARTS & SCI

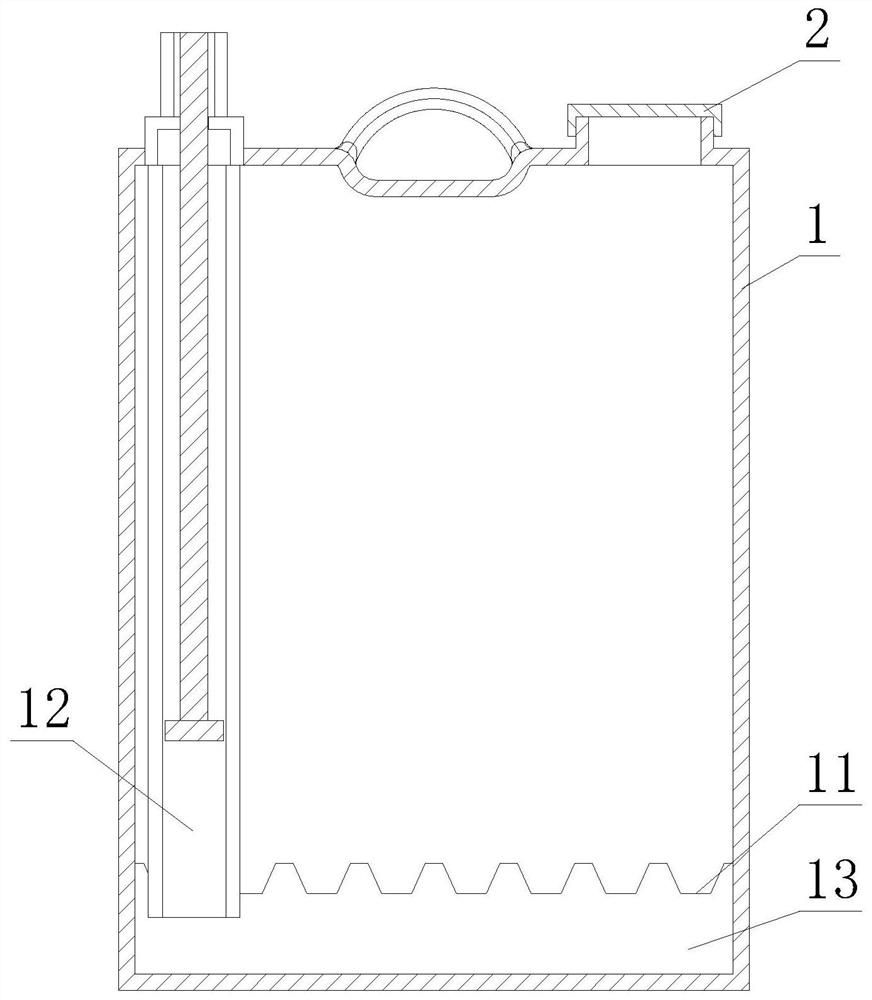

Filling slurry mixing device for prefabricated building installation

InactiveCN111644112AWell mixedAct as a distractionTransportation and packagingMixer accessoriesStructural engineeringMechanical engineering

The invention belongs to the technical field of buildings, particularly relates to a filling slurry mixing device for prefabricated building installation, and aims to solve the problem of poor mixingquality of the filling slurry mixing device. The device comprises a box body, a feeding pipe is arranged on one side of the top of the box body, a second discharging pipe is arranged on one side of the bottom of the box body, two first fixing plates distributed up and down are arranged on the inner walls of the two sides of the box body, and mixing plates are fixed to the inner sides of the two first fixing plates correspondingly and arranged obliquely downwards; a plurality of first flow guide grooves which are transversely and uniformly distributed are formed in the top of the mixing plates,the cross sections of the first flow guide grooves are S-shaped, two second fixing plates are symmetrically fixed to the inner walls of the two sides of the box body, an arc-shaped plate is fixed between the two second fixing plates, and a first discharging pipe is arranged at the bottom of the arc-shaped plate. According to the mixing device, the mixing plates are obliquely arranged in a staggered mode, and the multiple S-shaped first flow guide grooves are formed in the tops of the mixing plates, so that the turbulent flow effect on slurry is achieved, and the slurry is fully mixed.

Owner:胡勇强

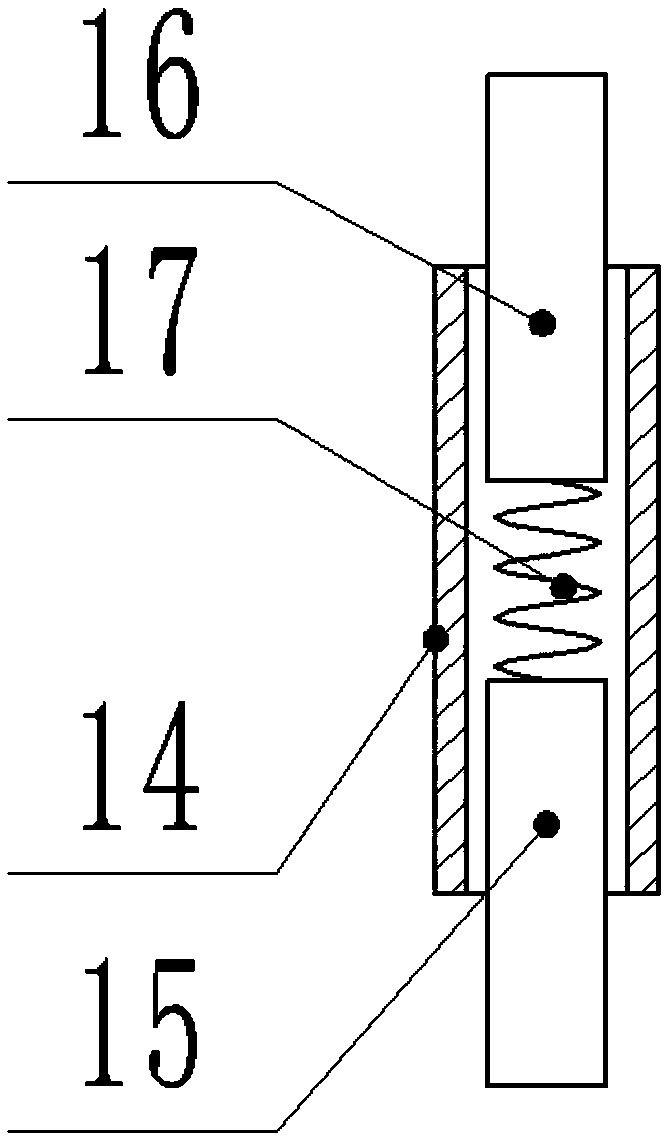

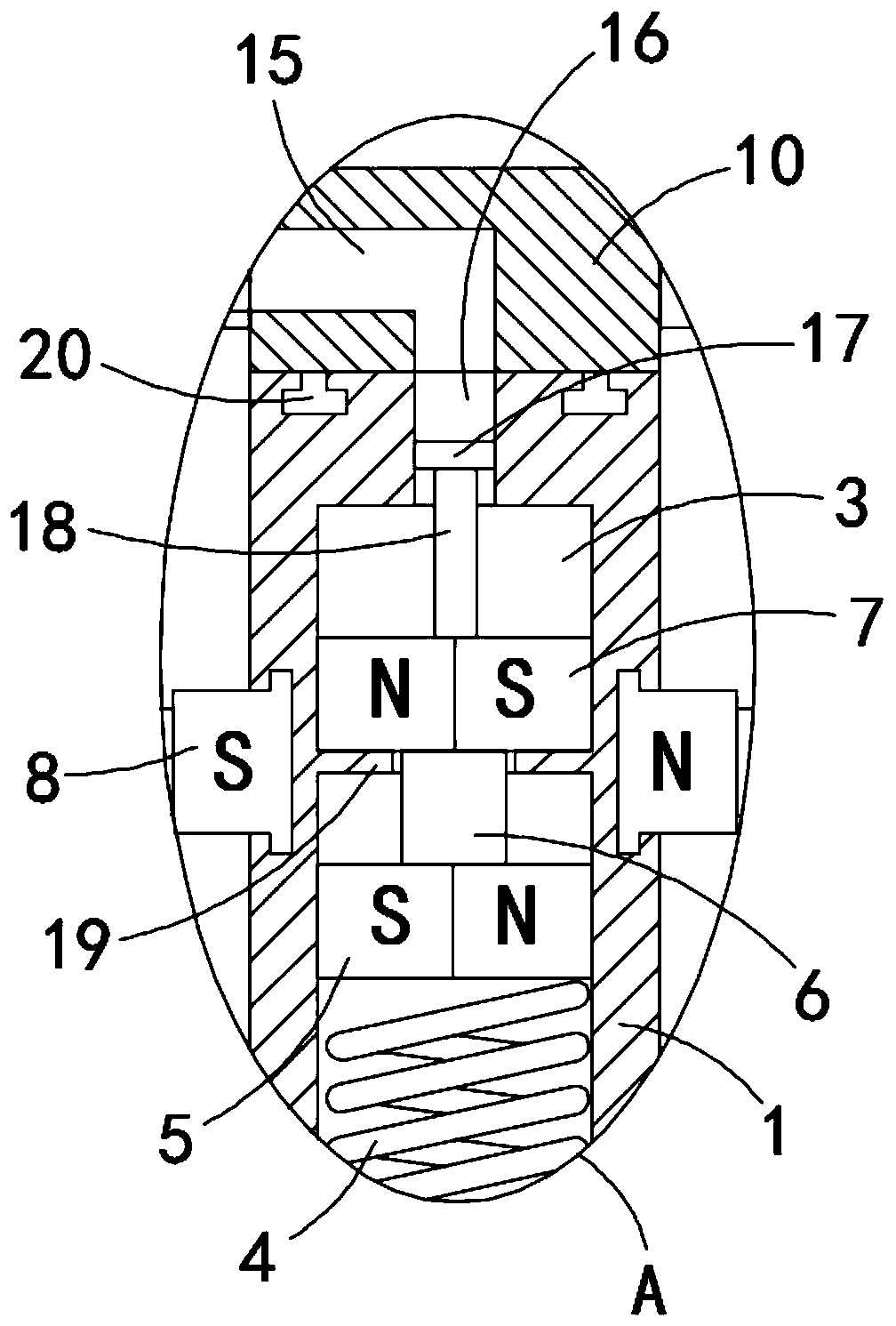

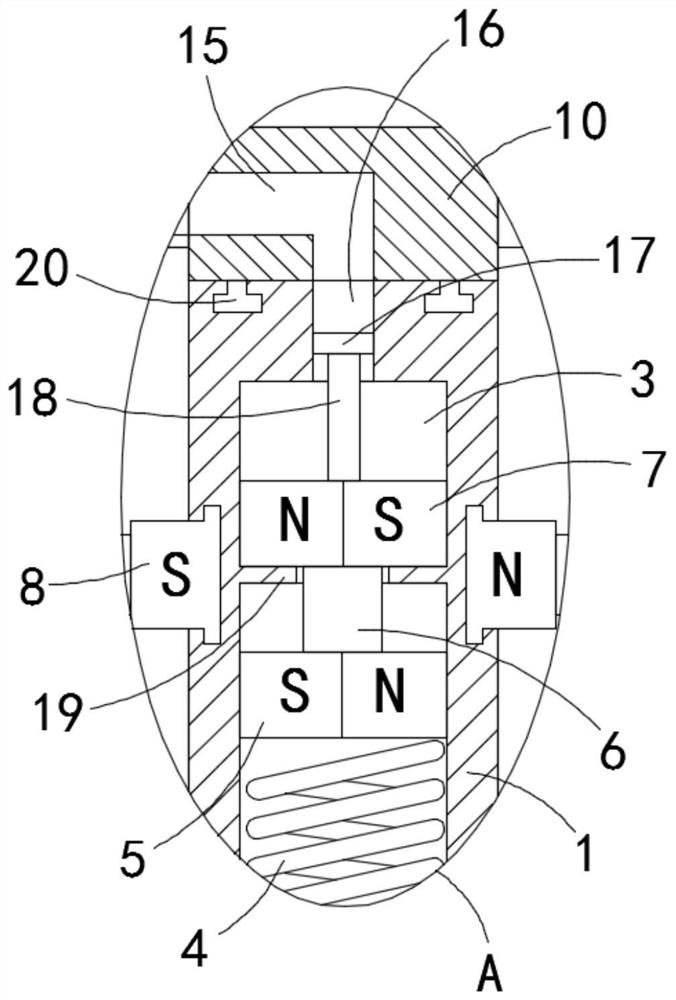

Magnetic self-rotating baking frame

ActiveCN109737713AEvenly bakedReducing Interaction DegaussingDrying gas arrangementsDrying chambers/containersCooking & bakingHeat conducting

The invention belongs to the field of preparation of traditional Chinese medicinal materials, and particularly relates to a magnetic self-rotating baking frame. The magnetic self-rotating baking framecomprises a base, a fixed column is fixedly connected to the upper end of the base, a cavity is formed in the fixed column, a reset spring is fixedly connected to the inner bottom of the cavity, theupper end of the reset spring is fixedly connected with a first magnetic sliding block, the upper end of the first magnetic sliding block is fixedly connected with a second magnetic sliding block through a connecting rod, a permanent magnet ring is rotationally connected to the outer side wall of the fixed column, an annular rotating disc is fixedly connected to the outer side wall of the permanent magnet ring in a sleeving mode, a rotating head is rotationally connected to the upper end of the fixing column, one side of the rotating head is fixedly connected with the upper end of the annularrotating disc through an L-shaped connecting rod, the other side of the rotating head is fixedly connected with a connecting pipe, the lower end of the connecting pipe is fixedly connected with the upper end of the annular rotating disc through a heat conducting pipe, the inner bottom surface of the heat conducting pipe is fixedly connected with a memory spring, and the upper end of the memory spring is fixedly connected with a first piston block. According to the baking frame, in the drying process, positions of traditional Chinese medicinal materials can be automatically adjusted, so that the drying effect of the traditional Chinese medicinal materials is better.

Owner:泰州市扬帆车件有限公司

Purification exhaust pipe

InactiveCN110657016AReduce kinetic energyReduce noise energyExhaust apparatusSilencing apparatusEngineeringExhaust pipe

The invention discloses a purification exhaust pipe. The purification exhaust pipe comprises a shell, wherein the shell comprises an inlet cavity and an outlet cavity and is characterized in that twoshunting cavities communicate between the outlet cavity and the inlet cavity; transversely arranged communication pipes are arranged on the two side walls of the outlet cavity; evaporation air bags are symmetrically arranged on the inner side wall of each communication pipe and filled with evaporation liquid; a first magnet is slidably connected to the inner wall of each communication pipe; and apressure plate is slidably connected in the outlet cavity. According to the purification exhaust pipe, tail gas impacts on the pressure plate, and the kinetic energy of the tail gas is converted intothe kinetic energy of the pressure plate, so that the kinetic energy of the tail gas is reduced, the noise energy generated by the tail gas is synchronously weakened, and thus the noise is lowered; and the high-temperature tail gas is rapidly cooled under the action of cooling liquid, and the high-temperature damage of the tail gas to an exhaust system is greatly reduced due to the lowering of thetemperature, so that the service life of the exhaust pipe is effectively prolonged.

Owner:李凤岭

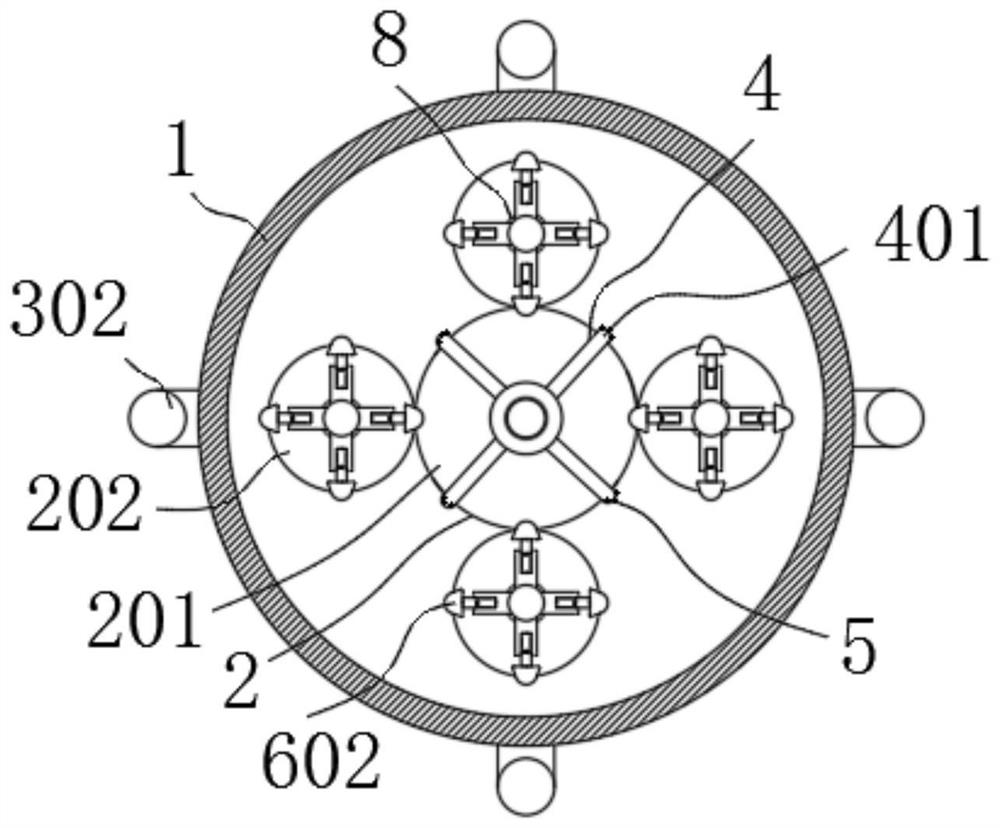

Homogenizing equipment for thermoplastic elastomer hand feeling pre-dispersed master batches

ActiveCN112873595AReduce workloadAct as a distractionHollow article cleaningVibration suppression adjustmentsElastomerThermoplastic elastomer

The invention relates to the technical field of plastic pre-dispersed master batches, in particular to homogenizing equipment for thermoplastic elastomer hand feeling pre-dispersed master batches. The homogenizing equipment for the thermoplastic elastomer hand feeling pre-dispersed master batches comprises an outer box and a homogenizing device, the outer box comprises a box body, a box cover is arranged at the top of the box body, a through hole is formed in the circle center of the box cover, a cavity is formed in the box body, a connecting base is arranged at the bottom end in the box body, a discharging pipe is arranged at the bottom of the front side of the box body, and the homogenizing device comprises a driving mechanism. According to the homogenizing equipment for the thermoplastic elastomer hand feeling pre-dispersed master batches, as raw materials are stirred through arranged stirring plates, and the multiple groups of stirring plates are arranged in the linear direction of a stirring shaft, multi-layer stirring of the raw materials in the cavity of the box body is achieved so that mixing and homogenizing are more sufficient; and meanwhile, the rotating force generated by the stirring plates of each stirring shaft has a flow disturbing effect on the stirring shafts around the stirring shaft, so that the possibility of vortex generation is reduced, and the mixing and homogenizing quality is improved.

Owner:NINGBO ACTMIX POLYMER

Circulating fluctuation type uniform heating electric kettle

The invention relates to a circulating fluctuation type uniform heating electric kettle comprising a kettle body; a fixed cavity, a control cavity and a containing groove are formed in the bottom of the kettle body; a heat conduction plate is fixedly embedded in the top in the containing groove, and a temperature difference power generation plate is fixedly connected to the lower side wall of theheat conduction plate; the lower side wall of the temperature difference power generation plate is fixedly connected with a plurality of heat dissipation fins; two conductive plates are fixedly embedded in the inner wall of the fixing cavity, a power connection plate is connected to the inner wall of the fixing cavity in a sealed and sliding mode, a penetrating opening is formed in the side wall of the power connection plate in a penetrating mode, a one-way valve is arranged in the penetrating opening, a connecting rod is fixedly connected to the side wall of the power connection plate, and anair guide pipe communicates with the inner wall of the fixing cavity. And the inner wall of the fixing cavity communicates with an air inlet pipe. According to the electric kettle, water in the kettle body can continuously fluctuate, heating is more uniform, the time required for complete boiling of water is shortened, water scale is not likely to be generated in the boiling process of the waterin the fluctuating state all the time, and the health of people can be guaranteed.

Owner:德清县丰润电光源有限公司

Double-roller based reverse rotation type feed stirring equipment and stirring method thereof

InactiveCN111773976AStir wellAvoid damageRotating receptacle mixersFeeding-stuffElectric machineryStructural engineering

The invention relates to the technical field of stirring devices, in particular to double-roller based reverse rotation type feed stirring equipment and a stirring method thereof. The feed stirring equipment comprises a stirring device, a supporting and protecting device and a transmission device arranged in the supporting and protecting device; the stirring device comprises an outer roller, the transmission device at least comprises a main transmission rod, a motor is arranged at the top end of the main transmission rod, a top bevel gear is arranged at the bottom of the motor, a bottom bevelgear is arranged at the bottom end of the main transmission rod, an outer transmission mechanism comprises an outer transmission rod, outer bevel gears are arranged at two ends of the outer transmission rod, an inner transmission mechanism comprises an inner transmission rod, and inner bevel gears are arranged at two ends of the inner transmission rod. The stirring device and the transmission device are combined to enable an inner roller and the outer roller to rotate reversely, and the relative rotation speed of an inner stirring rod and an outer stirring rod is increased through reverse rotation, so that the inner stirring rod and the outer stirring rod fully stir a feed.

Owner:朱欢

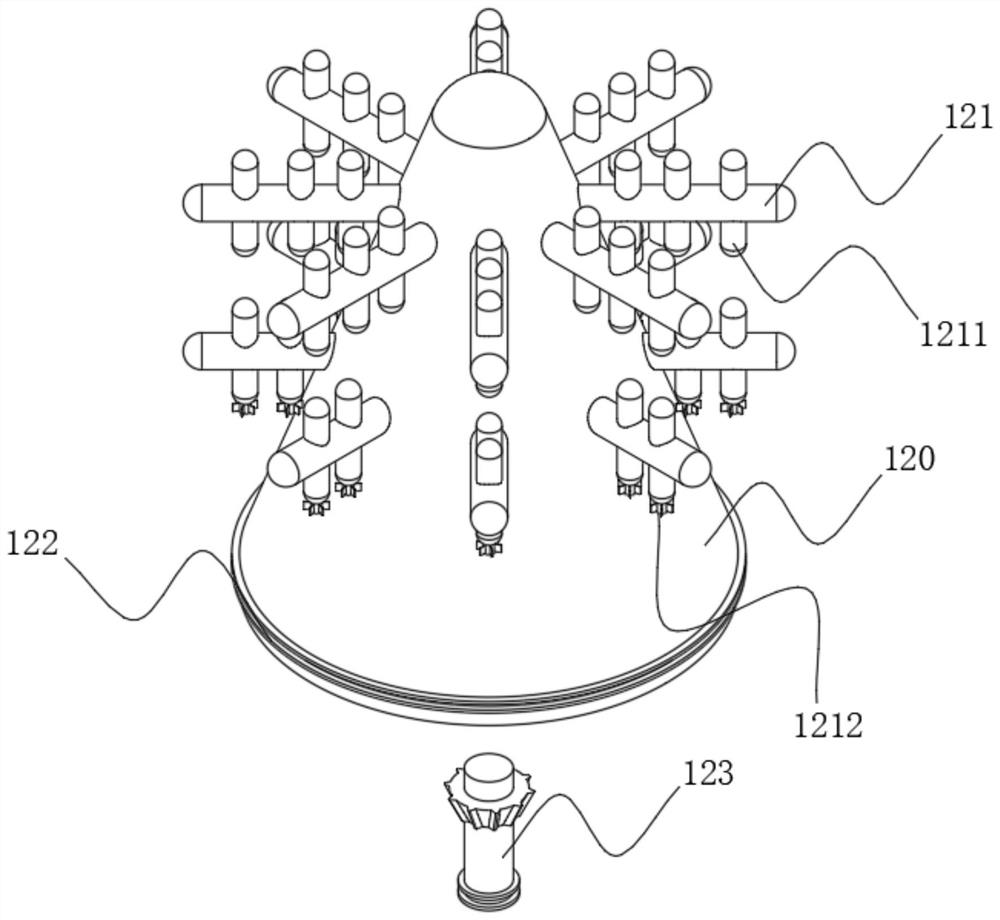

Multi-fluid mixing device

ActiveCN112007572AAchieve multi-step mixingAct as a distractionFlow mixersTransportation and packagingMixing effectMechanical engineering

The invention discloses a multi-fluid mixing device, and relates to the field of chemical equipment. The device comprises a shell, a feeding mechanism and a mixing mechanism, a mixing cavity is formedin the shell, the feeding mechanism is arranged beside the mixing cavity and is communicated with the mixing cavity, and the feeding mechanism comprises a feeding main pipe and an auxiliary feeding assembly. The auxiliary feeding assembly is arranged in the middle of the feeding main pipe. The mixing mechanism comprises a first mixing assembly, a second mixing assembly and a transmission assembly; the first mixing assembly and the second mixing assembly are both arranged in the mixing cavity, and the second mixing assembly is arranged in the middle of the first mixing assembly. The first mixing assembly is matched with the feeding mechanism, the transmission assembly is arranged between the first mixing assembly and the second mixing assembly, and the first mixing assembly is matched withthe second mixing assembly through the transmission assembly. Through the arrangement of the first mixing assembly and the second mixing assembly, the overall length of the device is shortened, the applicability is improved, and the multi-fluid mixing effect is improved.

Owner:莱州耀胜自动化设备有限公司

A magnetic self-rotating grill

ActiveCN109737713BEvenly bakedReducing Interaction DegaussingDrying gas arrangementsDrying chambers/containersHeat conductingRotating disc

The invention belongs to the field of preparation of traditional Chinese medicinal materials, and particularly relates to a magnetic self-rotating baking frame. The magnetic self-rotating baking framecomprises a base, a fixed column is fixedly connected to the upper end of the base, a cavity is formed in the fixed column, a reset spring is fixedly connected to the inner bottom of the cavity, theupper end of the reset spring is fixedly connected with a first magnetic sliding block, the upper end of the first magnetic sliding block is fixedly connected with a second magnetic sliding block through a connecting rod, a permanent magnet ring is rotationally connected to the outer side wall of the fixed column, an annular rotating disc is fixedly connected to the outer side wall of the permanent magnet ring in a sleeving mode, a rotating head is rotationally connected to the upper end of the fixing column, one side of the rotating head is fixedly connected with the upper end of the annularrotating disc through an L-shaped connecting rod, the other side of the rotating head is fixedly connected with a connecting pipe, the lower end of the connecting pipe is fixedly connected with the upper end of the annular rotating disc through a heat conducting pipe, the inner bottom surface of the heat conducting pipe is fixedly connected with a memory spring, and the upper end of the memory spring is fixedly connected with a first piston block. According to the baking frame, in the drying process, positions of traditional Chinese medicinal materials can be automatically adjusted, so that the drying effect of the traditional Chinese medicinal materials is better.

Owner:泰州市扬帆车件有限公司

Solid-liquid rocket engine annular slot plug nozzle

The invention discloses a solid-fluid rocket engine annular-seam-type plug nozzle. The solid-fluid rocket engine annular-seam-type plug nozzle comprises a ring laryngeal mask, a nozzle pressing plate, a nozzle shell body, a plug cone and a thermal-insulating plate. The ring laryngeal mask is installed at the outlet end of the nozzle shell body through the nozzle pressing plate, a boss is installed in the nozzle shell body through a ribbed plate, and the plug cone is arranged in the laryngeal part of the ring laryngeal mask in a suspended mode and connected with the boss; and the peripheral surface of the plug cone is matched with the laryngeal part of the ring laryngeal mask to form a convergent section and an expansion section, the thermal-insulating plate is installed at the inlet end of the nozzle shell body, and straight slots communicating with each other are formed in the thermal-insulating plate and the ribbed plate. High-temperature and high-pressure fuel gas in a combustion chamber of a solid-fluid rocket engine enters through the inlet end of the nozzle shell body, the fuel gas gradually accelerates at the convergent section, and after the sound speed is reached at the laryngeal part of the ring laryngeal mask, the fuel gas flows into the expansion section and continuously accelerates to the supersonic speed. The solid-fluid rocket engine annular-seam-type plug nozzle is suitable for the solid-fluid rocket engines with different working heights.

Owner:BEIHANG UNIV

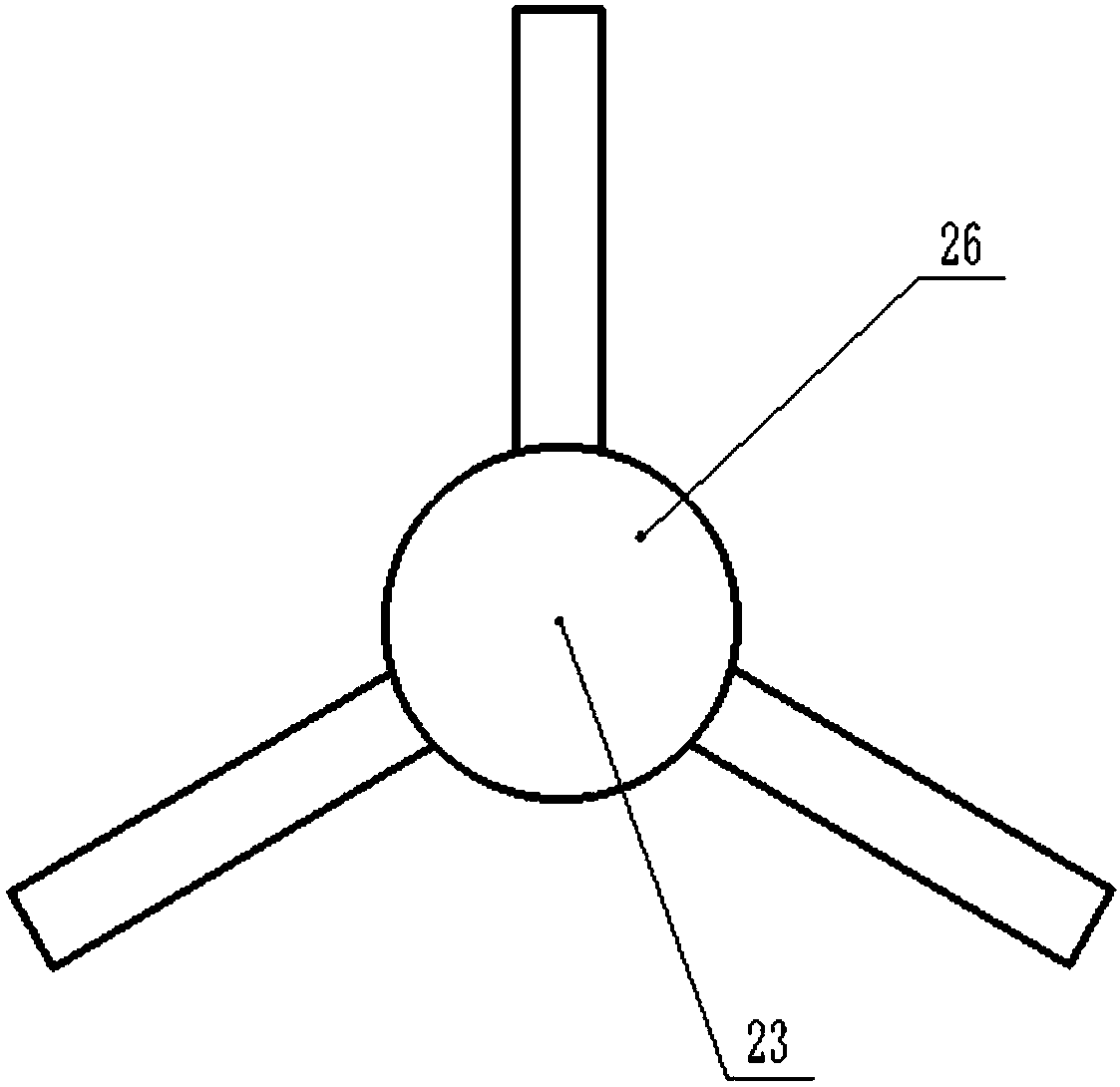

Agricultural mechanical pesticide spraying machine pesticide liquid mixing device based on fluid mechanics

PendingCN112841158AAct as a distractionAvoid less effectiveSpraying apparatusPlant protectionEnvironmental engineeringBiology

The invention discloses an agricultural mechanical pesticide spraying machine pesticide liquid mixing device based on fluid mechanics, and relates to the technical field of agricultural machinery. The agricultural mechanical pesticide spraying machine pesticide liquid mixing device comprises a case, a liquid inlet and a pressure cavity are correspondingly formed in two sides of the upper end of the case, a pressing rod is movably connected to the lower part of one side, close to the pressure cavity, of the case, and a material mixing plate is arranged below the middle part in the case. Through combination of a liquid flow channel, a turbulent flow grid and a material mixing wheel, the material mixing wheel is conveniently rotated through flowing of fluid when the pesticide spraying machine pressurizes and sprays; a turbulent flow effect is achieved when a solution passes through the cambered surface of the material mixing wheel; and by arranging an eccentric ball, when the material mixing wheel rotates, the material mixing wheel impacts a meniscus to generate vibration, so that undissolved and coagulated blocky pesticide in the solution is vibrated and scattered, the pesticide is mixed with water, when the solution passes through the turbulent flow grid, turbulent flow is generated, the pesticide is further mixed with water, and the situation that the pesticide cannot be completely sprayed into a farmland due to pesticide precipitation when the pesticide is sprayed is avoided.

Owner:龙利和

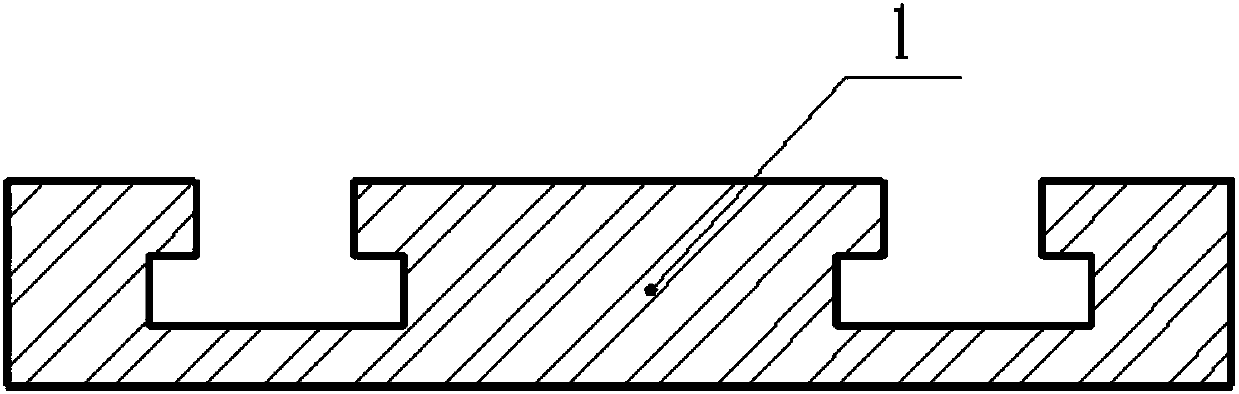

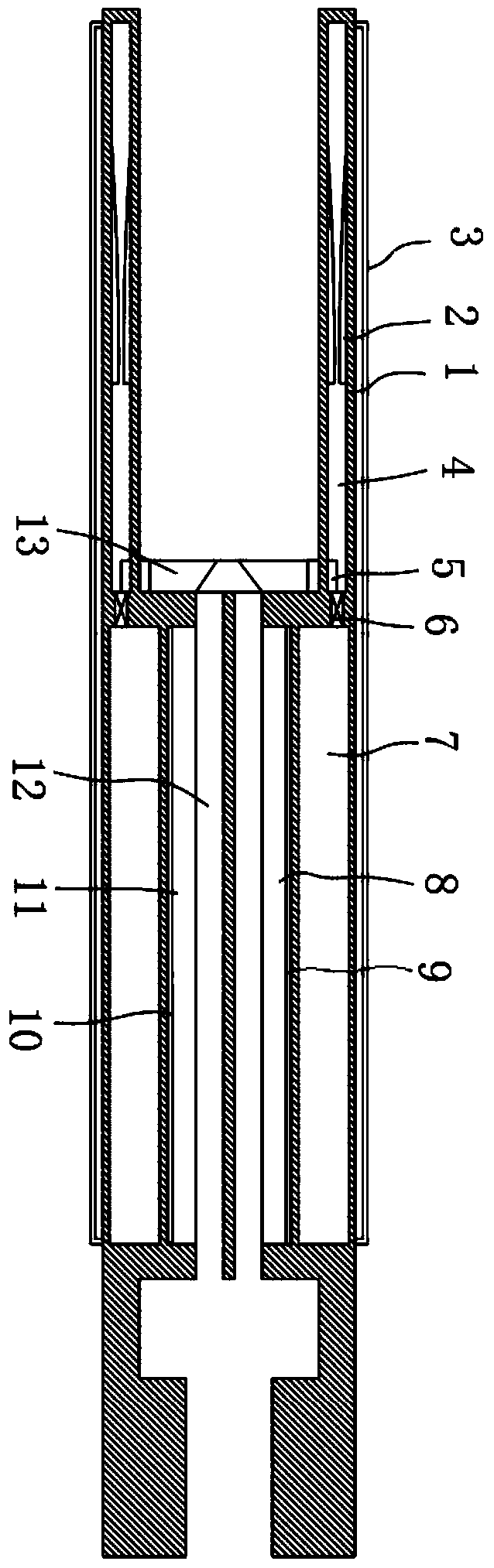

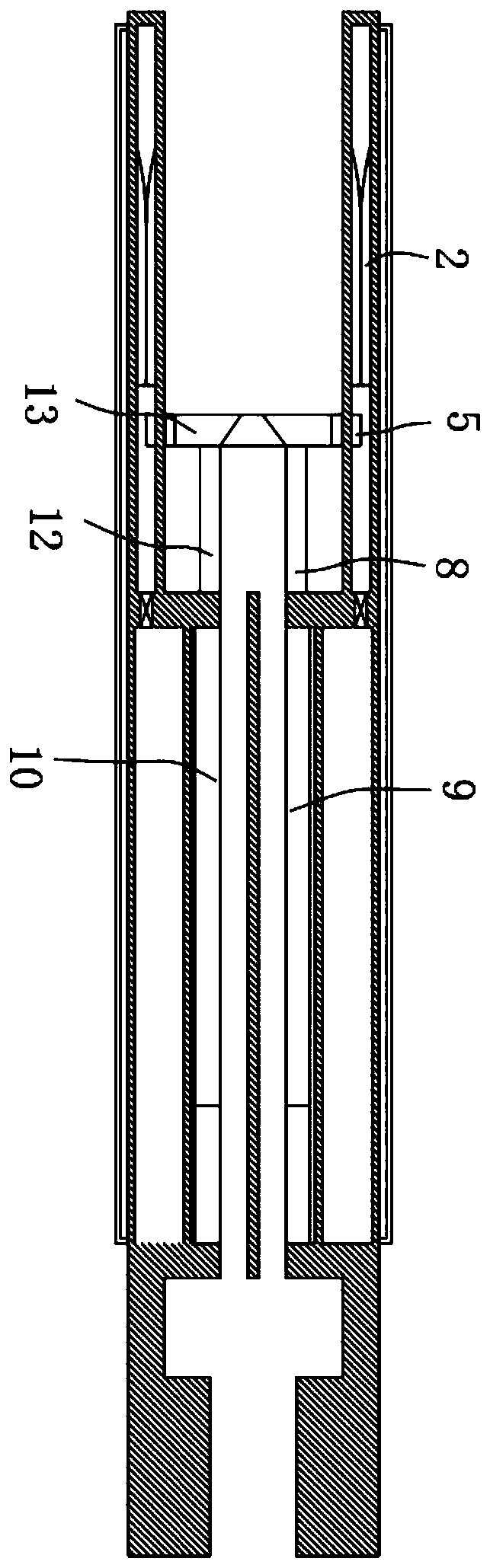

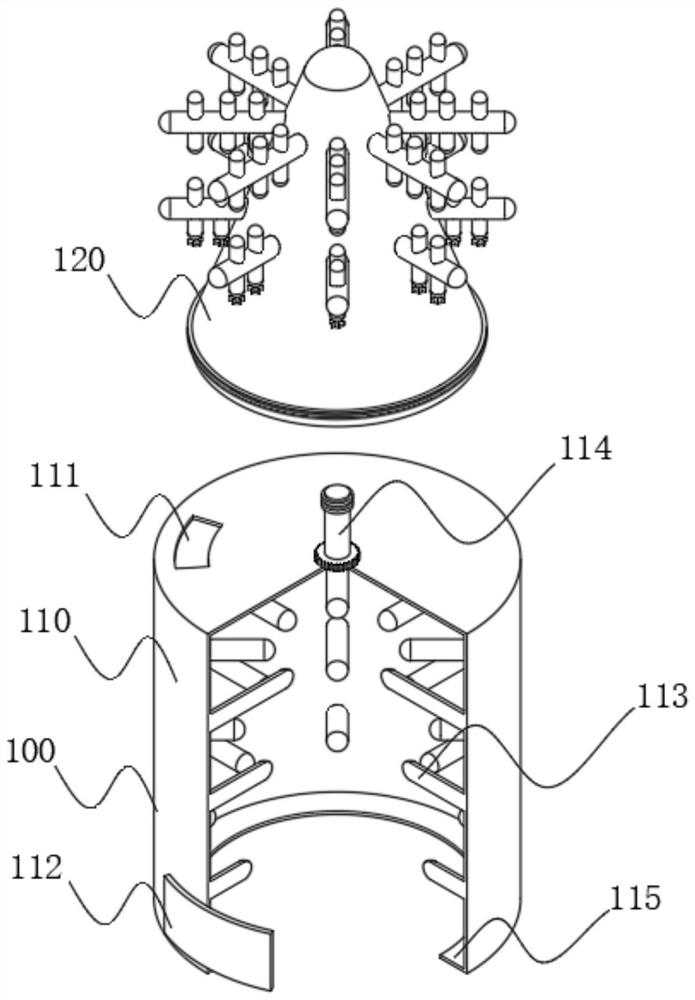

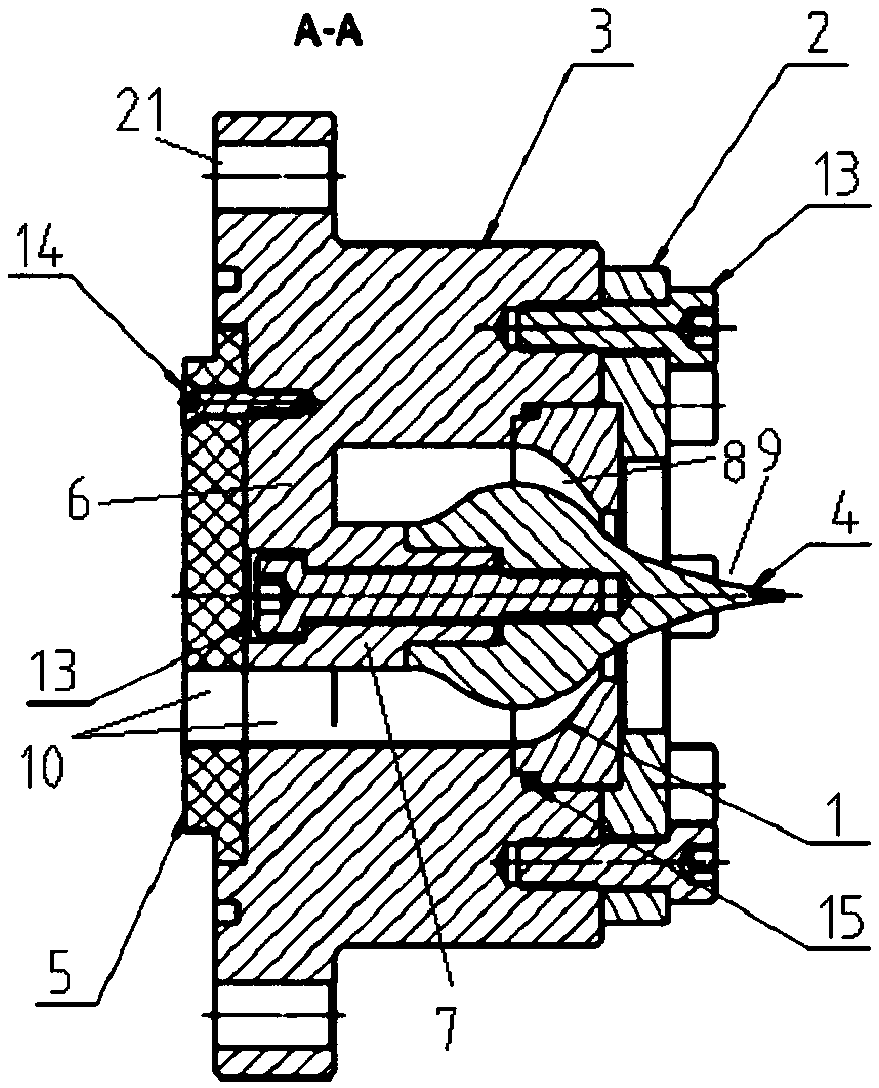

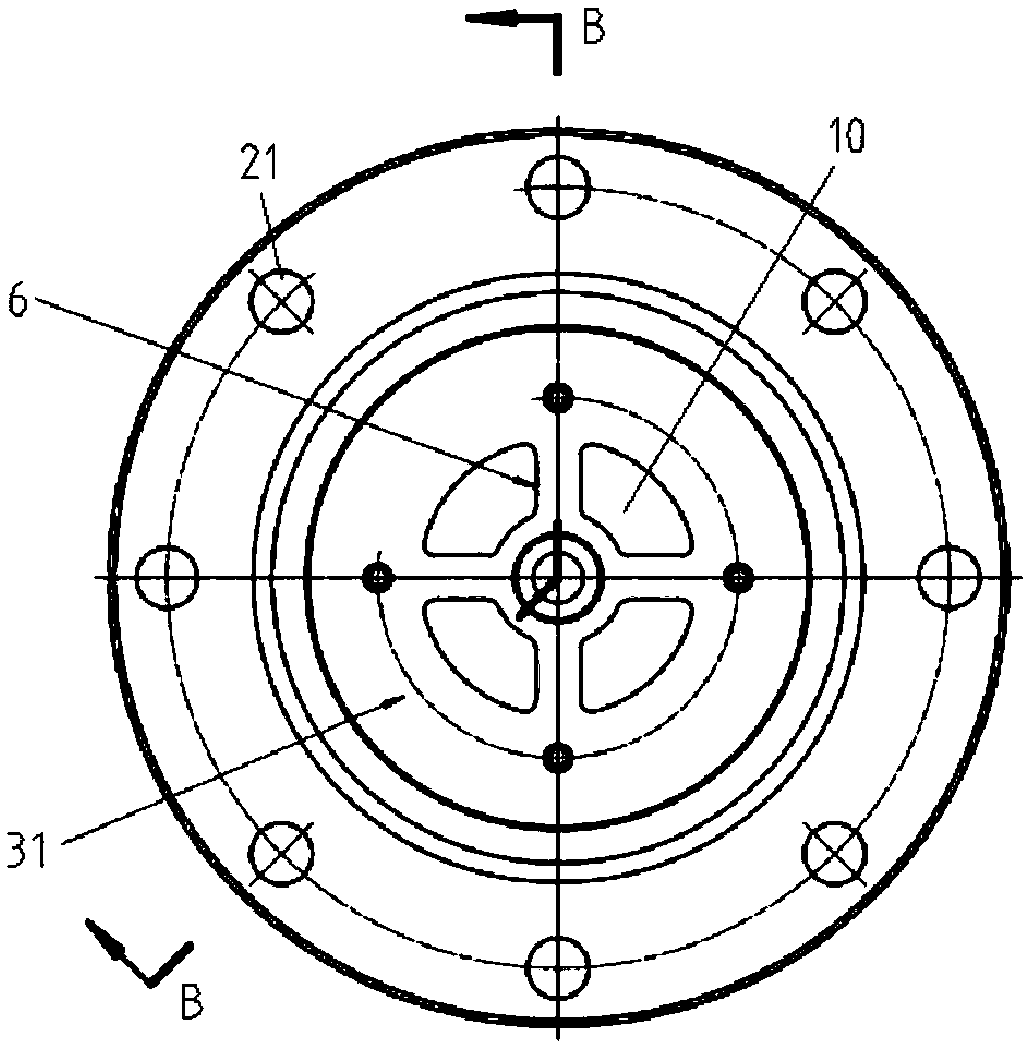

Pulping cutter head of soybean milk machine

InactiveCN105996831AImprove crushing efficiencyImprove crushing effectKitchen equipmentMilk substitutesEngineeringMechanical engineering

The invention discloses a pulping cutter head of a soybean milk machine. The pulping cutter head comprises a cutter (1), and a plurality of spiral first blades (2) are arranged on the outer surface of the cutter (1). The pulping cutter head has the advantages of being capable of carrying out stereoscopic multi-azimuth pulping, high in crushing capacity and short in pulping time, saving raw materials and reducing the soybean milk production cost.

Owner:HANGZHOU SINODOD ELECTRIC

Multi-fluid mixing device

ActiveCN112007572BAchieve multi-step mixingAct as a distractionFlow mixersRotary stirring mixersEngineeringMixing effect

The invention discloses a multi-fluid mixing device, which relates to the field of chemical equipment and includes a casing, a feeding mechanism and a mixing mechanism. A mixing chamber is arranged inside the casing, and the feeding mechanism is arranged on the side of the mixing chamber and the two are connected. The feeding mechanism includes a feeding main pipe and an auxiliary feeding assembly, the auxiliary feeding assembly is arranged in the middle of the feeding main pipe, the mixing mechanism includes a first mixing assembly, a second mixing assembly and a transmission assembly, the first mixing assembly and the second mixing assembly They are all arranged in the mixing chamber and the second mixing assembly is arranged in the middle of the first mixing assembly, the first mixing assembly cooperates with the feeding mechanism, the transmission assembly is arranged between the first mixing assembly and the second mixing assembly, and the first mixing assembly The component and the second mixing component cooperate through a transmission component. The present invention shortens the overall length of the device through the arrangement of the first mixing component and the second mixing component, improves applicability, and increases the mixing effect of multiple fluids.

Owner:莱州耀胜自动化设备有限公司

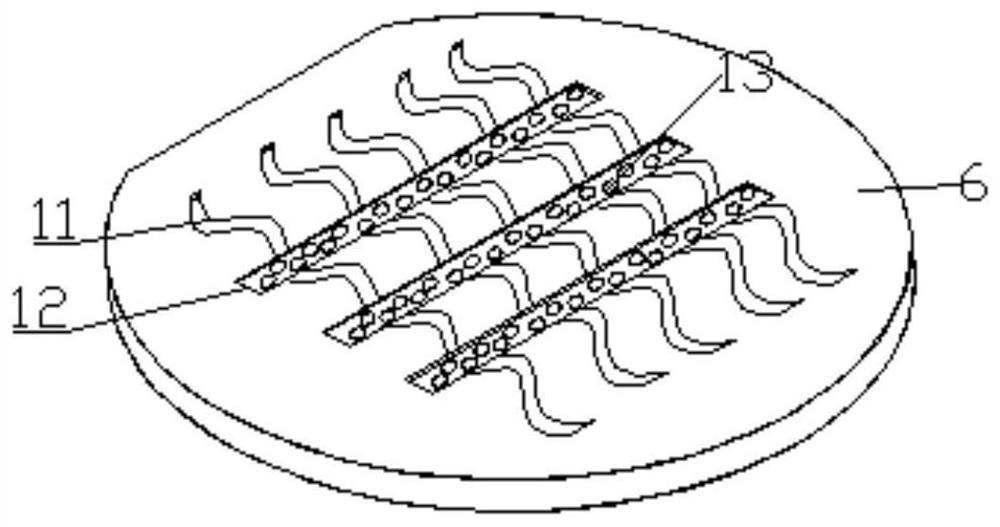

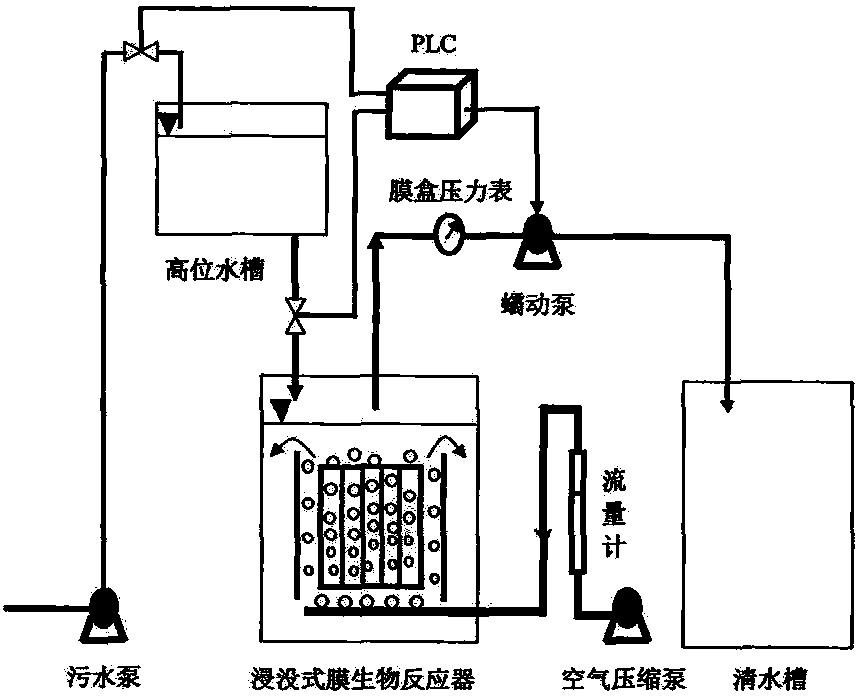

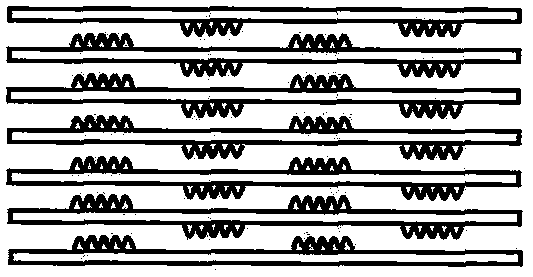

A submerged flat-plate membrane bioreactor with additional microchannel turbulent flow promoter

InactiveCN105036296BIncreased turbulence intensityImprove flushing effectTreatment with anaerobic digestion processesPorosityConcentration polarization

The invention discloses an immersed flat sheet membrane bioreactor with micro-channel turbulence-flow promoters. The micro-channel turbulence-flow promoters are arranged in the immersed flat sheet membrane bioreactor at certain intervals in a certain arrangement manner, so that the micro-channel turbulence-flow promoters can generate a sluggish flow since gas generated in an aerator and liquid carried in the micro-channel turbulence-flow promoters are combined to form a mixed fluid which is lifted in a channel between a membrane and the micro-channel turbulence-flow promoters. The micro-channel turbulence-flow promoters can increase the turbulent degree on the surface of the membrane and further generate a shear force on the surface of the membrane, thereby reducing the thickness of a boundary layer and slowly-reducing concentration polarization. When sewage passes through the micro-channel turbulence-flow promoters, sludge particles are blocked in the micro-channels due to adsorption and bridging and such effects so that pores in the membrane is not liable to be blocked. A plurality of micro-pores are distributed on the micro-channel turbulence-flow promoters so that when suspension particles are deposited on the surface of the membrane, a filter cake layer which is better in compression resistance and is higher in porosity is formed, so that the filter cake layer deposited on the surface of the membrane is promoted to fall, thereby reducing the accumulation speed of the filter cake layer, improving membrane flux and correspondingly slowly-reducing membrane pollution.

Owner:INNER MONGOLIA UNIV OF TECH

A new type of forming cooling device for condiment packaging machine

The invention discloses a novel forming and cooling device for a condiment packaging machine. The novel forming and cooling device for the condiment packaging machine comprises: a casing and a communication component, wherein the communication component includes a water tank, and the water tank passes through the diversion component. A plurality of communication pipes are connected, and the communication pipes pass through the bottom side wall of the casing and communicate with the water tank. In the present invention, when a large amount of fluid is poured into the housing, the first stirring component and the second stirring component are driven by the transmission component to achieve rapid stirring, which can accelerate the flow of the fluid, thereby speeding up the heat dissipation speed, and at the same time, the movable plate further lifts the To the effect of turbulence, the heat dissipation can be further accelerated. The use of circulating components can make the aqueous solution flow continuously, take away the heat of the intermediate fluid and quickly cool the aqueous solution with heat, which is convenient for continuous circulation and cooling, thereby improving the heat dissipation effect. Thus, the cooling effect is improved.

Owner:焦作特味龙生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com