Bag type dust collector for producing silicon tetrachloride by direct method

A bag-type dust collector and silicon tetrachloride technology, applied in the direction of silicon halide compounds, separation methods, halosilanes, etc., can solve the problems of cumbersome separation and purification process steps, and achieve the effect of avoiding dust removal and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

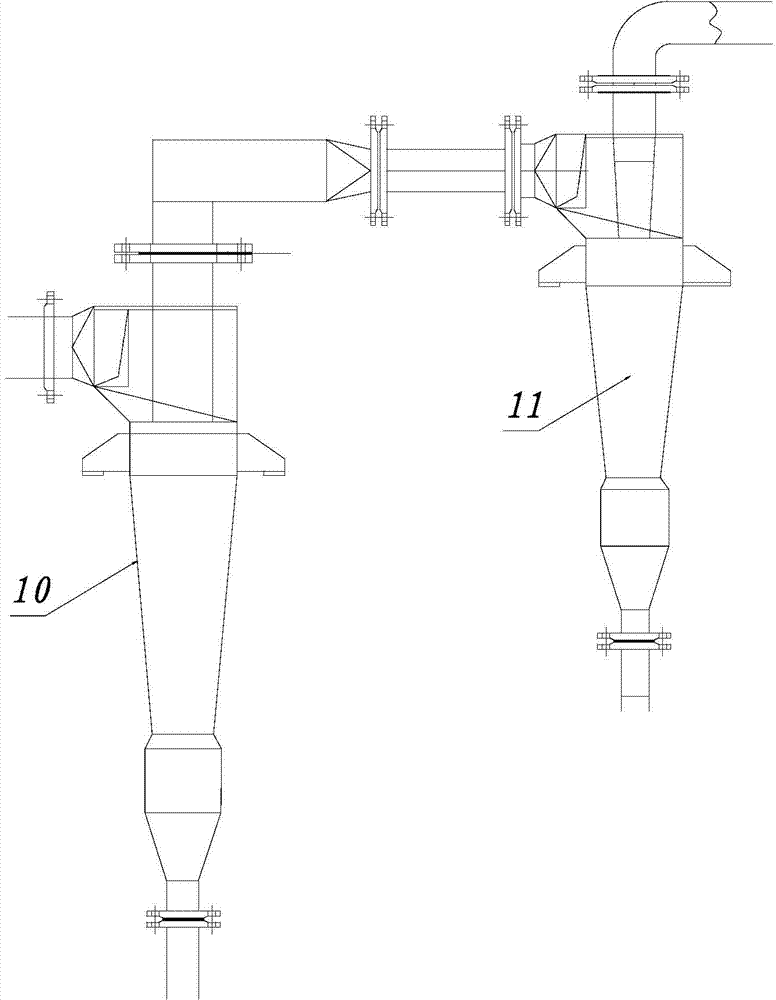

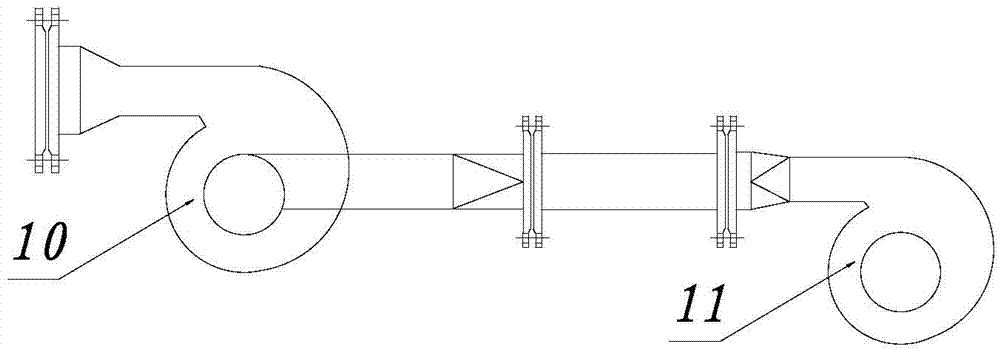

[0024] Such as figure 1 A kind of production device utilizing direct method to produce silicon tetrachloride shown, this device comprises liquid chlorine storage tank 1, liquid chlorine vaporizer 3, silicon powder feeding device 5, fluidized bed reactor 6, primary cyclone separator 10 , Secondary cyclone separator 11, bag filter 12, spray tower 14, alkali washing tower 18, etc. Wherein the outlet of the liquid chlorine storage tank 1 is connected with the inlet of the liquid chlorine vaporizer 3 with a canned pump 2 to facilitate continuous reaction. A vacuum buffer tank 4 is connected between the liquid chlorine vaporizer 3 and the fluidized bed reactor 6, so that the vaporized chlorine gas can flow into the fluidized bed reactor 6 stably at a stable air velocity. The silicon powder feeding device 5 is connected with a nitroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com