Weightlessness-principle-based powdery material continuous metering control method and device thereof

A technology for powdery materials and control methods, applied in measuring devices, weighing equipment for continuous material flow, weighing, etc., can solve the problems of reducing the measurement accuracy of the sensor, increasing the range of the sensor, and the pneumatic gate valve is not tightly closed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

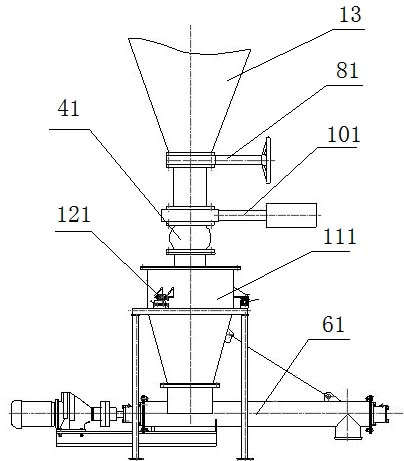

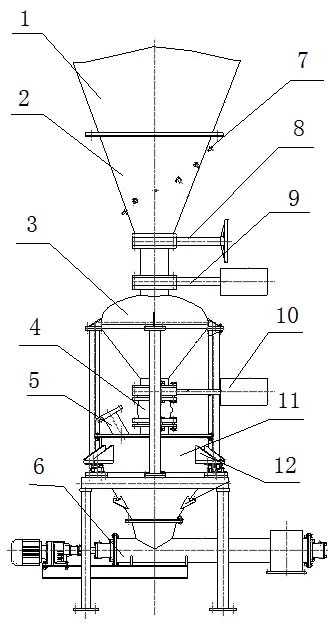

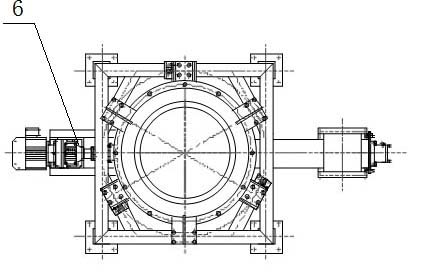

[0023] The embodiment of the powder material continuous metering control method based on the principle of weight loss of the present invention, the method relates to a weight loss scale device, the weight loss scale device includes a feed bin and a weighing bin connected from top to bottom through a feeding channel, the feed bin and the weighing bin A buffer bin is installed in series on the conveying channel between the heavy bins, and an upper pneumatic gate valve, a buffer bin and a weighing bin are installed on the feeding channel between the material bin and the buffer bin to control the on-off of the conveying channel. A lower pneumatic gate valve for controlling the on-off of the section of the conveying passage is provided on the conveying passage between them. The method includes the following steps:

[0024] 1) The upper pneumatic gate valve is opened, and the powdery material flows from the silo into the buffer silo;

[0025] 2) When the material in the buffer bin r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com