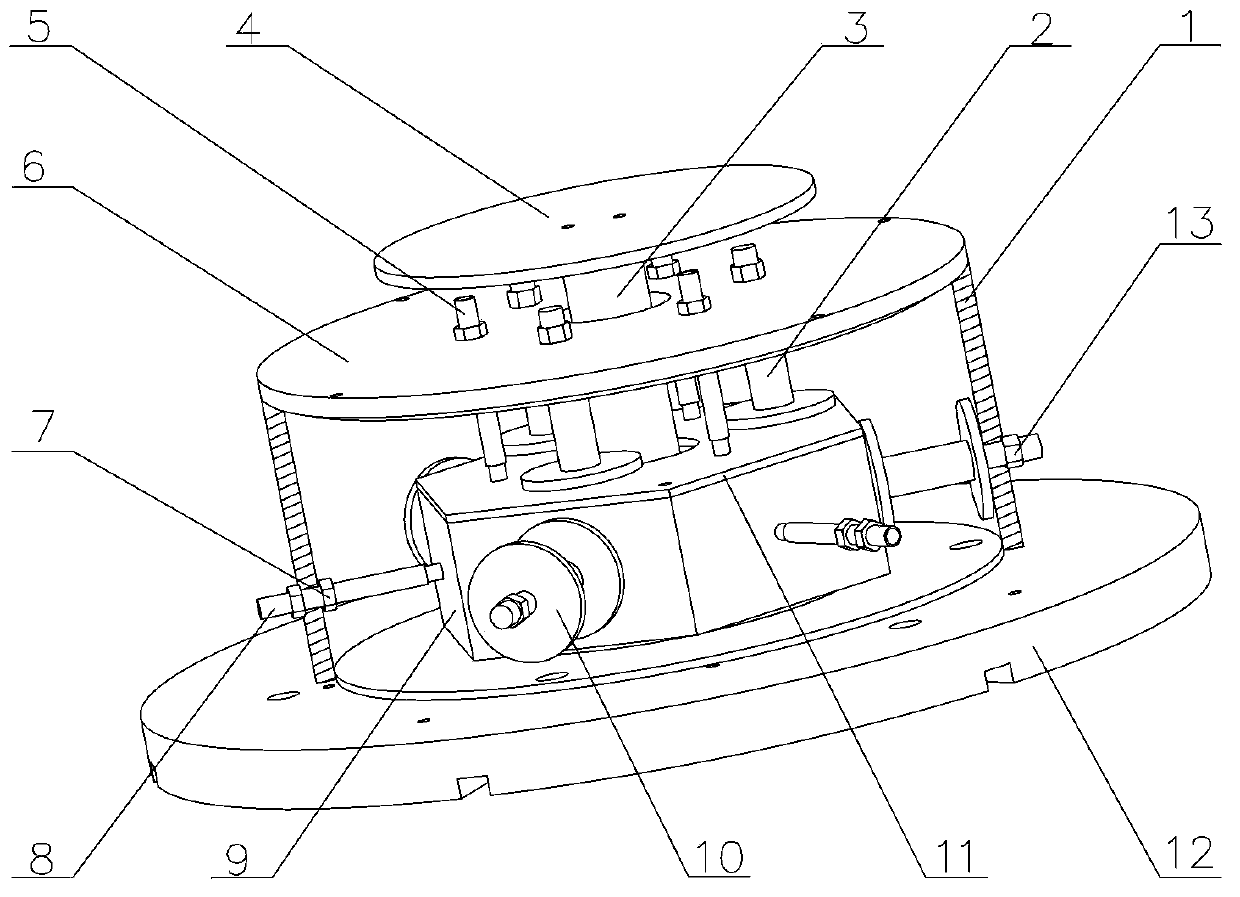

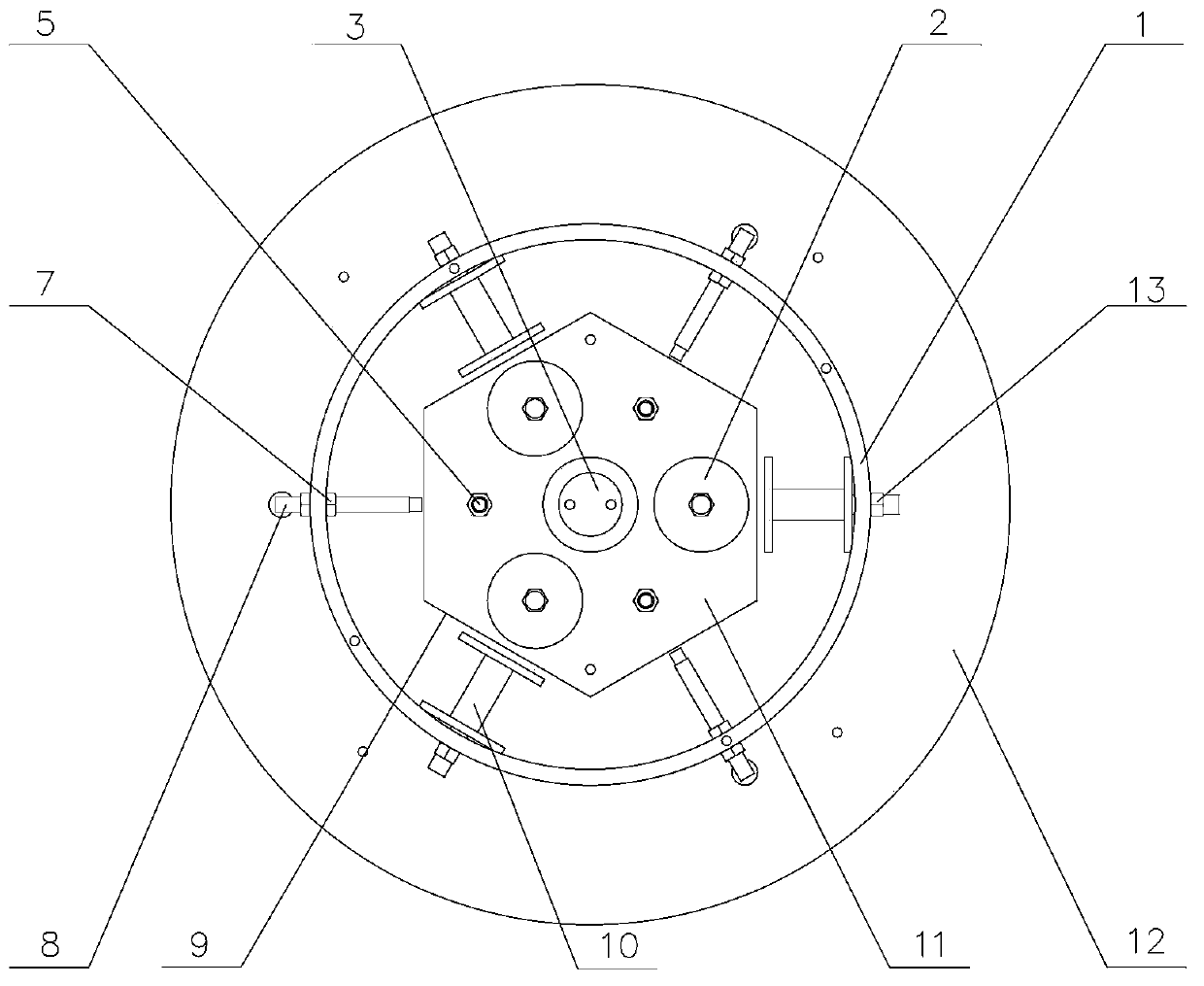

Experimental device of compact magnetic levitation worktable

A magnetic levitation workbench and experimental device technology, applied to teaching models, educational appliances, instruments, etc., can solve the problems of high manufacturing cost, low positioning accuracy, high-frequency vibration, etc., to overcome low positioning accuracy, improve motion accuracy, reduce The effect of disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] see figure 1 -2, the present invention includes a stator part and a mover part, the stator part includes a base 12 and a cylindrical stator cover 1 arranged on the base 12, the top end of the stator cover 1 is provided with a circular top cover 6; The mover part includes the mover 9, the mover 9 is arranged in the stator cover 1, the mover 9 adopts the upper hollow structure, and the mover 9 is a hollow hexagonal structure processed by steel (that is, the upper part of the mover 9 is hollowed out) , the stage 4 and the support column 3 are made of aluminum, so that on the one hand, the mass of the mover can be reduced; The disturbance caused by the horizontal drive to the vertical drive realizes the decoupling of the design of the maglev platform. Because the upper part of the mover 9 is hollowed out, a mover cover 11 is provided on the top of the mover 9, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com