Locating device of high precise locating chain conveying line for liquid shampoo caps

A technology of positioning device and shampoo, which is applied in the direction of conveyor control device, transportation and packaging, conveyor objects, etc., can solve the problems of low chain link accuracy, low transmission line positioning accuracy, chain stop position error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

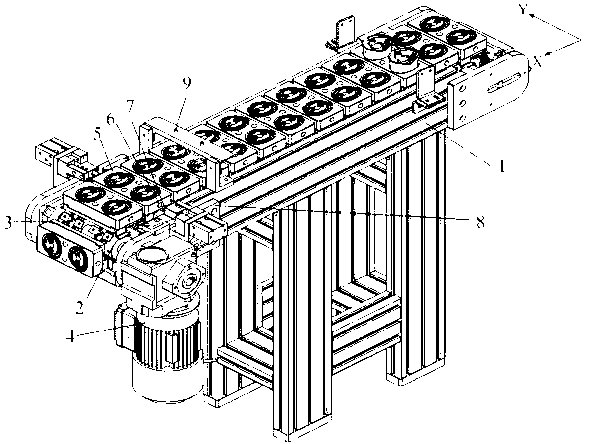

[0011] Such as figure 1 As shown, the high-precision positioning chain transmission line positioning device for the shampoo cover includes a chain transmission mechanism and a carrier. The chain transmission mechanism is installed on the frame 1. The chain transmission mechanism includes a sprocket 2, a chain 3 meshing with the sprocket and used for The motor 4 that drives the sprocket runs, and the outer edge of the chain 3 is distributed with a number of carriers 5 arranged in parallel along the circumferential direction. Each carrier is equipped with an in-position induction sheet. Each carrier is equipped with a positioning bush hole 6 in the axial direction, and a positioning guide pin driving mechanism is installed on the frame on both sides of the chain. Positioning guide pin 7, the positioning guide pins on both sides are opposite and on the same straight line, horizontal guide rollers 8 are respectively arranged along the axial direction of the chain on the frame on b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com