Soymilk machine and soymilk preparing method thereof

A soymilk maker and pulping technology, which is applied to dairy products, beverage preparation devices, milk substitutes, etc., can solve the problems of low crushing efficiency, additional parts, complex structure of soymilk machine, etc., and achieve the goal of improving the crushing efficiency and eliminating the crushing structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

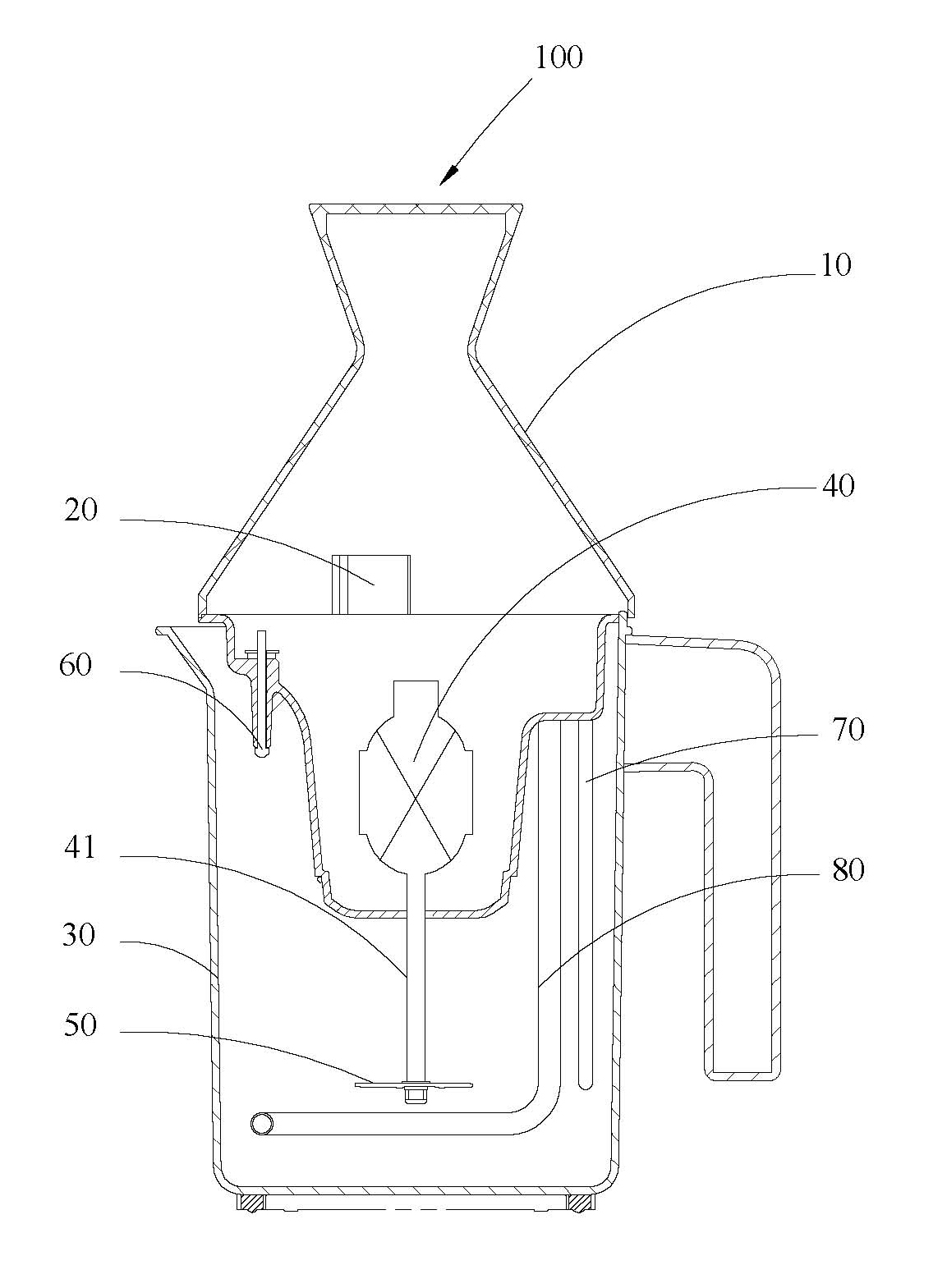

[0028] see figure 1 Shown is a preferred embodiment of the soymilk maker and its pulping method of the present invention, the soymilk maker 100 includes a machine head 10 , a circuit board 20 , a cup body 30 and a motor 40 . The machine head 10 is buckled on the cup body 30 , and the circuit board 20 is installed in the machine head 10 . One end of the motor 40 is installed on the machine head 10 .

[0029] The machine head 10 provides a carrier for mounting components such as a circuit board 20 , an overflow prevention device 60 , an anti-dry heating device 70 and a heating device 80 . The anti-overflow device 60 is used to control the height of the slurry in the cup body 30 to ensure that the slurry does not overflow the cup body 30 during the pulping process. The anti-dry burning device 70 is used to detect whether there is pulping material in the cup body 30 . In this embodiment, the heating device 80 is a heating tube installed on the machine head 10 for heating the p...

Embodiment approach 2

[0042] As the second embodiment of the soybean milk machine and its pulping method of the present invention, its pulping process and beneficial effects are consistent with the first embodiment, the difference is that the motor 40 is a variable frequency motor, and the circuit board includes micro A processor control unit and a motor drive module, the microprocessor control unit signal is connected to the motor drive module, the motor drive module includes a frequency converter unit, the frequency converter unit is connected to the motor signal, and the power supply provided to the stator winding of the motor is changed The size of the frequency to achieve the control of its speed change.

[0043] In this embodiment, other structures and beneficial effects are consistent with those in the embodiment, and will not be repeated here.

Embodiment approach 3

[0045] As the third embodiment of the soybean milk machine and its pulping method of the present invention, its pulping process and beneficial effects are consistent with Embodiment 1, the difference is that the motor 40 is a DC motor, and the motor drive module 23 includes at least a field effect triode or a bipolar triode. The microprocessor control unit controls the voltage provided by the motor drive module to the motor by adjusting the pulse width, thereby controlling the speed change of the motor speed.

[0046] In this embodiment, other structures and beneficial effects are consistent with those in the embodiment, and will not be repeated here.

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com