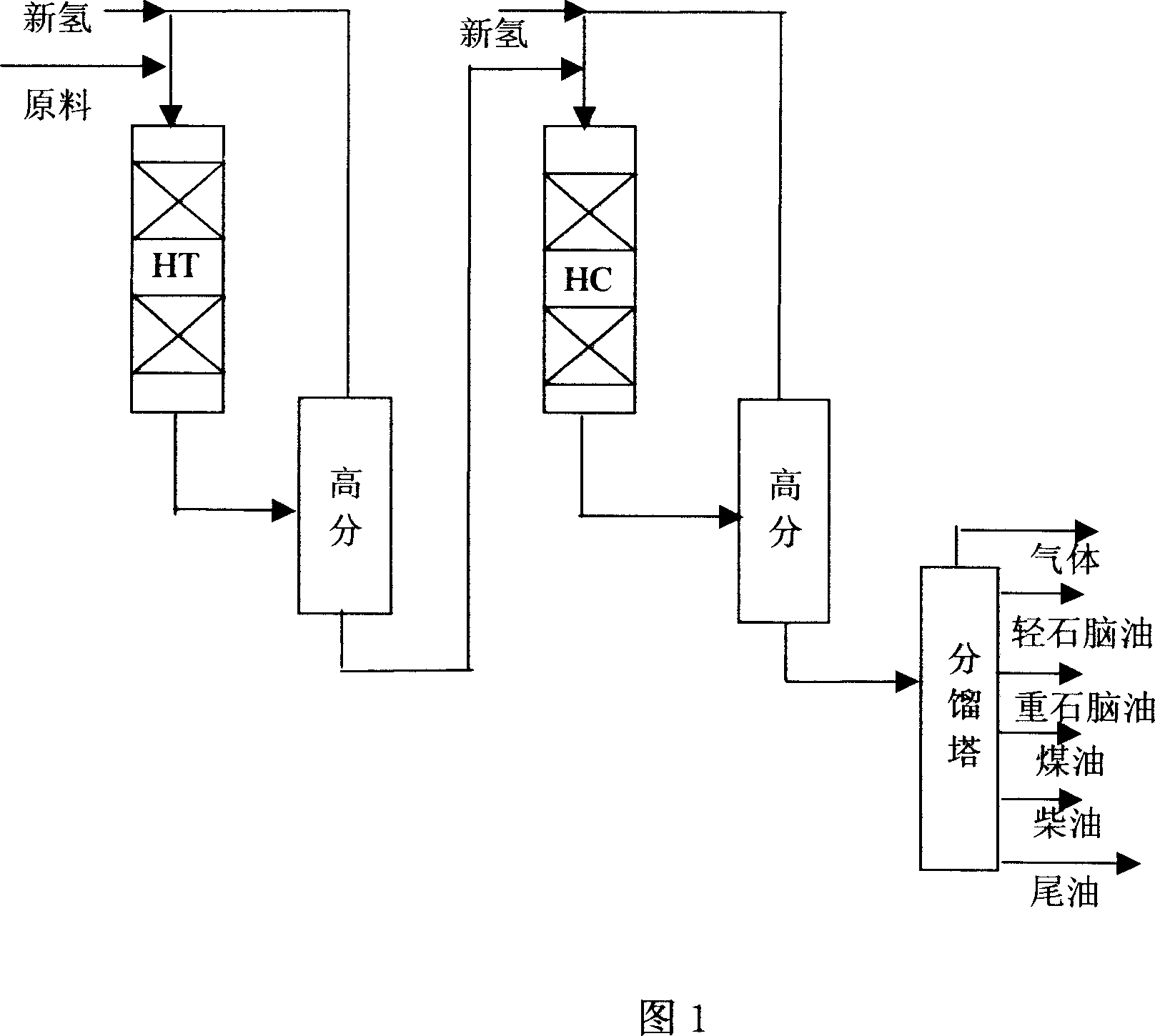

Two-stage hydrocracking method

A hydrocracking and hydrotreating technology, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, can solve the problems of high production cost, large hydrogen consumption, and no economic advantages, and achieve the effect of effective processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the modified Y zeolite described therein is: use NaY as raw material, carry out ion exchange with non-precious metal water-soluble salts, the specific conditions are: adjust the pH value to 2-8 with acid or ammonia water, use non-precious metal Water-soluble salts are exchanged for 1 to 5 times; after the last exchange, wash with distilled water for 1 to 3 times, and then dry at 100-150°C. The dried zeolite is subjected to hydrothermal treatment, ammonium ion exchange, acid washing, filtration and water washing, and Dry at 100-150°C for 1-48 hours to obtain the modified Y zeolite.

[0033] In the noble metal hydrocracking catalyst, since the ion-exchanged non-noble metal has a high dispersion degree and further isolates the noble metal, the dispersion degree of the noble metal is further improved. Simultaneously, because the contained non-noble metal itself is a kind of hydrogenation active metal, and the hydrogenation activity of non-noble met...

Embodiment 1

[0037] Take a certain amount of nickel nitrate and dissolve it in water to prepare a solution with a concentration of 10gNiO / 100ml, dilute 70ml of the above aqueous solution with distilled water to 1000ml, add 250g of NaY zeolite (80wt% on a dry basis), and heat to 70°C for 2 hours. Repeat the exchange 2 times. After the second exchange, filter and wash 3 times with water, then dry at 110°C for 8 hours, and put it into a hydrothermal treatment furnace at 550°C for 6 hours. The water vapor partial pressure is 0.05MPa. Put Y zeolite after hydrothermal treatment into 1000ml 1N ammonium nitrate / nitric acid aqueous solution (pH=2) for ammonium exchange, pickling for 2 hours, temperature 70°C, after pickling, filter and wash 3 times with water, then dry at 110°C for 8 hours to obtain Modified Y zeolite.

[0038] The above-mentioned modified Y zeolite 140g (dry basis 86wt%) and 150g binding agent (SB-Al 2 o 3 It is prepared by beating with an appropriate amount of dilute nitric aci...

Embodiment 2

[0041] Take a certain amount of cobalt nitrate and dissolve it in water to prepare a solution with a concentration of 10gCoO / 100ml. Dilute 150ml of the above solution with distilled water to 1000ml, add 250g of NaY zeolite (80wt% on a dry basis), and heat to 90°C for 2 hours. Repeat the exchange 2 times. After the second exchange, filter and wash 3 times, then dry at 110°C for 4 hours, and put it into a hydrothermal treatment furnace for 4 hours at 650°C. The partial pressure of water vapor is 0.15MPa. Put Y zeolite after hydrothermal treatment into 1000ml 1N ammonium nitrate / nitric acid aqueous solution (pH=2) to carry out ammonium exchange, pickling for 4 hours, temperature 90 ℃, after pickling, filter and wash 3 times with water, then dry at 110 ℃ for 8 hours, get Modified Y zeolite.

[0042] The above-mentioned modified Y zeolite 117g (dry basis 90wt%) and 225g binding agent (SB-Al 2 o 3 Prepared by beating with an appropriate amount of dilute nitric acid, kneading with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com