Light cycle oil selective hydrorefining method

A light cycle oil, hydrorefining technology, applied in the petroleum industry, processing hydrocarbon oil, etc., can solve the problems of large loss of aromatics, low hydrogenation selectivity, etc., and achieve the effect of high denitrification activity and improvement of aromatics retention rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

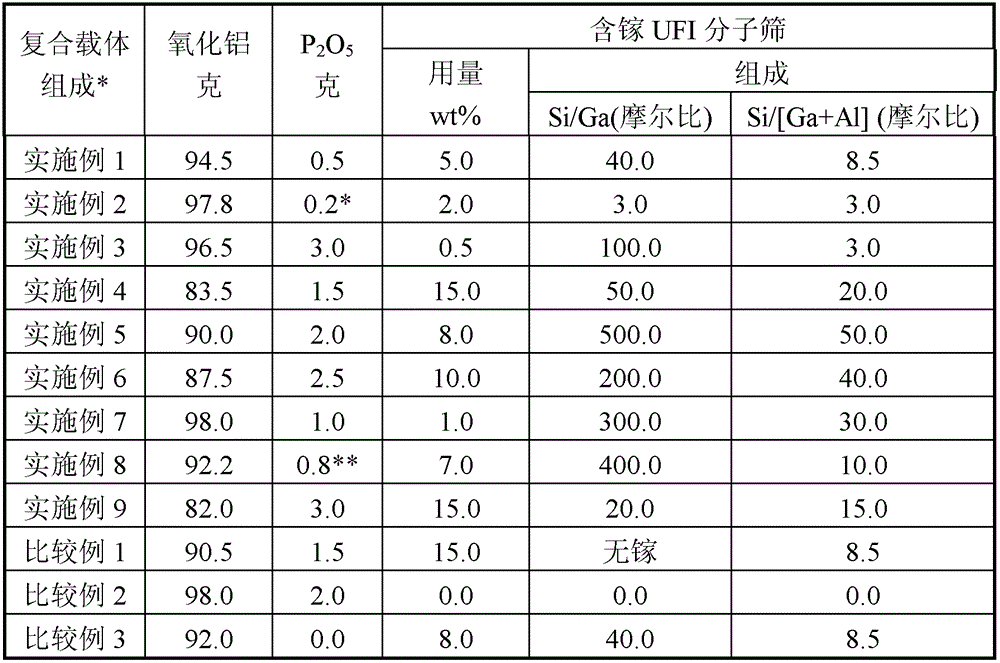

[0018] Preparation of composite carrier: A: Take 95 grams of boehmite and 5.0 grams of gallium-containing layered UFI molecular sieve (see Table 1 for the molar ratio of Si / Ga and Si / [Ga+Al]) and mix evenly. B: Take 20.0 grams of water, add 5.0 grams of aqueous solution containing 30% nitric acid in weight percentage, and 3.5 grams of 10 wt% phosphoric acid, mix and dissolve evenly. Slowly add B to A and stir evenly. After kneading for 40 minutes, dry at 130°C for 3 hours, and bake at 500°C for 2 hours to obtain γ-Al 2 o 3 Composite carrier 1, the composition of the composite carrier is shown in Table 1.

[0019] Catalyst preparation, the impregnation method is used to prepare the catalyst, and the impregnating solution is prepared by weighing 5.5 grams of basic cobalt carbonate, adding 5.6 grams of citric acid, 60.0 grams of water, heating and dissolving, adding 20.0 grams of ethylenediamine, and then adding 20 grams of ammonium molybdate Stir until completely dissolved, we...

Embodiment 2~9

[0022] The preparation method of the composite carrier is exactly the same as that in Example 1, except that the ratio of the raw materials of the carrier and the molar ratio of Si / Ga and Si / [Ga+Al] of the gallium-containing layered UFI molecular sieve are different. The composition of the prepared composite carrier is shown in Table 1. The preparation method of the catalyst is exactly the same as that of Example 1, except that when the active component is NiO or CoO+NiO, the basic cobalt carbonate in the impregnation solution is partially or completely replaced by nickel salt, and the active group loaded on the composite carrier is The specific active components in the catalyst are shown in Table 2. Catalyst activity evaluation conditions are the same as [Example 1], and the evaluation results are shown in Table 3.

[0023] Table 1

[0024]

[0025] *Phosphorus source is ammonium hydrogen phosphate, **ammonium dihydrogen phosphate, phosphoric acid is unmarked, wt% means ...

Embodiment 10~16

[0039] The catalyst of Example 4 is selected, and the results in Table 4 of different sulfur content LCO raw materials and different evaluation conditions are listed in Table 5.

[0040] Table 4

[0041] Sulfur content (ppm) Nitrogen content (ppm) PAH content (wt%) Total aromatics content (wt%) raw material 1 2000 350 45.5 72.6 raw material 2 4000 260 48.3 78.3 raw material 3 6000 530 52.6 80.6 raw material 4 8000 420 56.3 77.2 raw material 5 10000 760 48.7 85.3 raw material 6 15000 620 58.9 80.6

[0042] wt% means percentage by weight.

[0043] table 5

[0044]

[0045] wt% means percentage by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com