Tubular evaporation wall reactor used for supercritical water oxidation treatment

A technology of supercritical water oxidation and reactor, which is applied to the process under supercritical conditions, the pressure vessel used in the chemical process, and the method of chemically changing substances by using atmospheric pressure, which can solve the problem of single structure and safety accidents , low solubility of inorganic salts, etc., to achieve the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation.

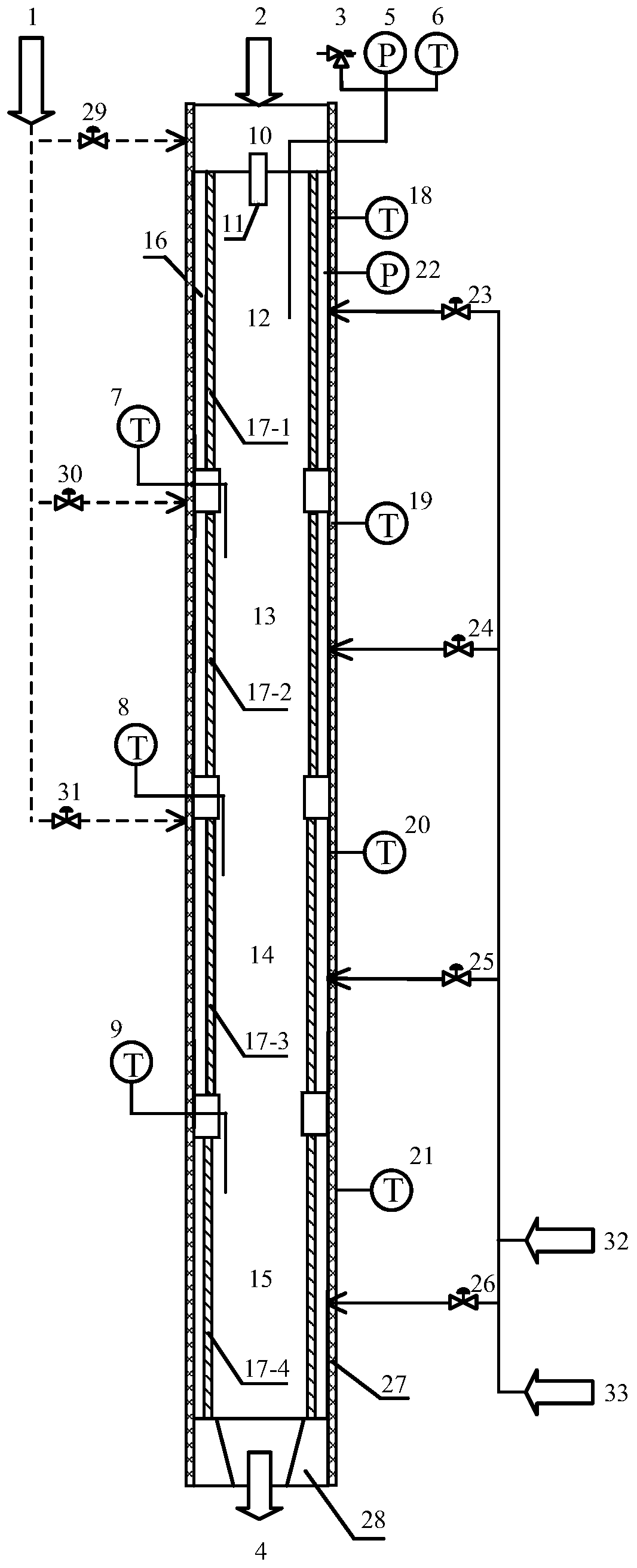

[0020] The structure of a tubular evaporation wall reactor for supercritical water oxidation treatment is as follows: figure 1 As shown, the system consists of oxygen inlet 1, material inlet 2, safety valve 3, reaction fluid outlet 4, pressure measuring point 5 in the reactor cavity, first temperature measuring point 6 in the reactor, and second temperature measuring point 7 in the reactor. , the third temperature measuring point 8 in the reactor, the fourth temperature measuring point 9 in the reactor, the top cover 10, the combustion nozzle 11, the first temperature zone 12 of the reactor, the second temperature zone 13 of the reactor, the third temperature of the reactor Zone 14, the fourth temperature zone 15 of the reactor, the partition wall water cavity 16, the first porous evaporation wall 17-1, the second porous evaporation wall 17-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com