Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Zirconolite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zirconolite is a mineral, calcium zirconium titanate; formula CaZrTi₂O₇. Some examples of the mineral may also contain thorium, uranium, cerium, niobium and iron; the presence of thorium or uranium would make the mineral radioactive. It is black or brown in color.

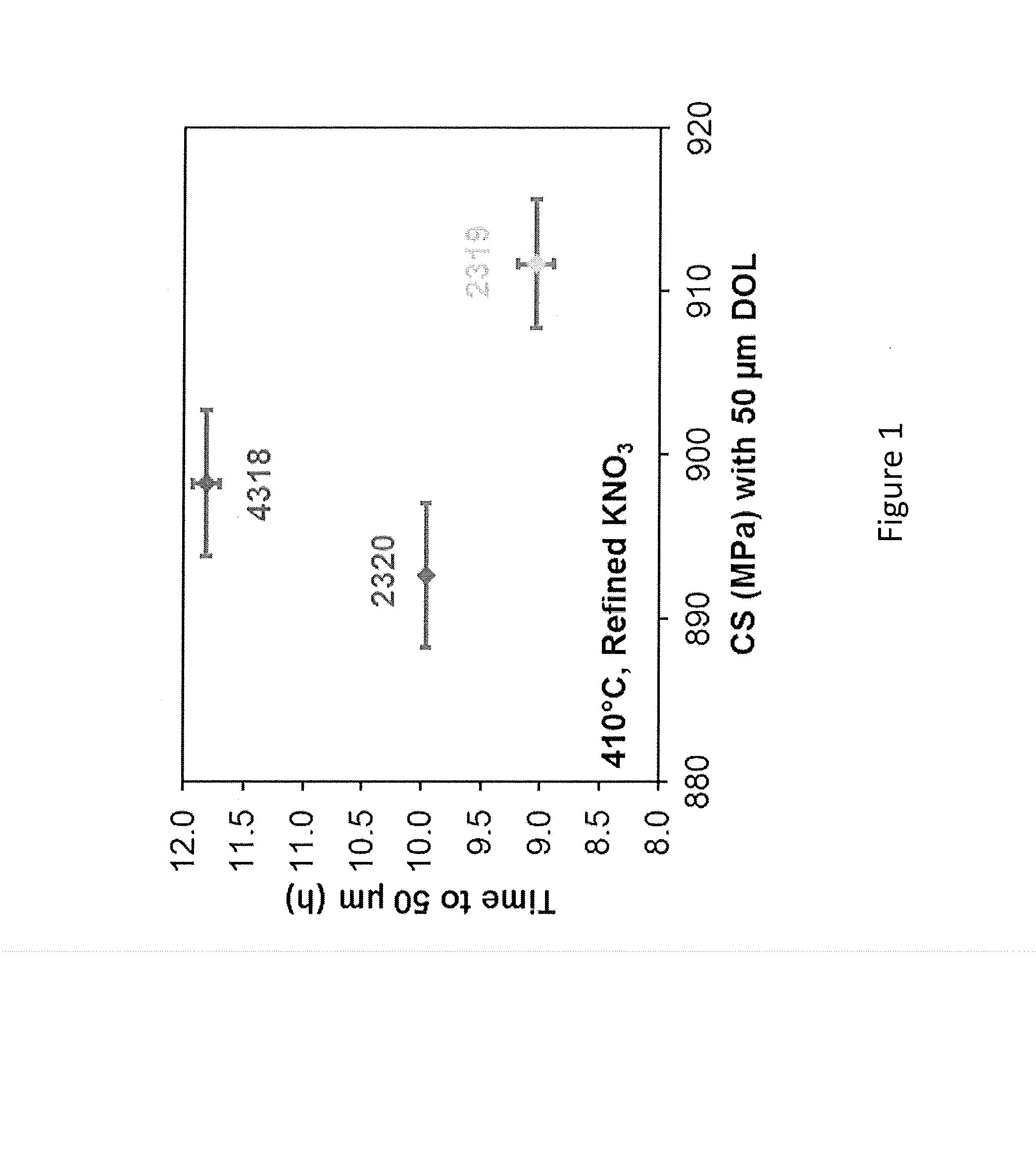

Zircon compatible, ion exchangeable glass with high damage resistance

An ion exchangeable glass having a high degree of resistance to damage caused by abrasion, scratching, indentation, and the like. The glass comprises alumina, B2O3, and alkali metal oxides, and contains boron cations having three-fold coordination. The glass, when ion exchanged, has a Vickers crack initiation threshold of at least 10 kilogram force (kgf).

Owner:CORNING INC

Corundum castable refractory

InactiveCN103539475AImprove medium temperature strengthImproved thermal shock stabilityZirconoliteHydrated alumina

The invention discloses a corundum castable refractory, comprising coarse aggregate, intermediate aggregate, fine aggregate, sodium silicate, nanometer magnesium oxide, nanometer zinc oxide, alumina micro powder and hydrated alumina, wherein the corundum castable refractory comprises the following raw materials in parts by weight: 15-20 parts of coarse aggregate, 35-40 parts of intermediate aggregate, 15-30 parts of fine aggregate, 5-10 parts of sodium silicate, 5-10 parts of nanometer magnesium oxide, 1-5 parts of nanometer zinc oxide, 10-15 parts of alumina micro powder and 1-6 parts of hydrated alumina; the coarse aggregate is corundum, the intermediate aggregate comprises silicon carbide and zircon corundum, and the fine aggregate is corundum.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

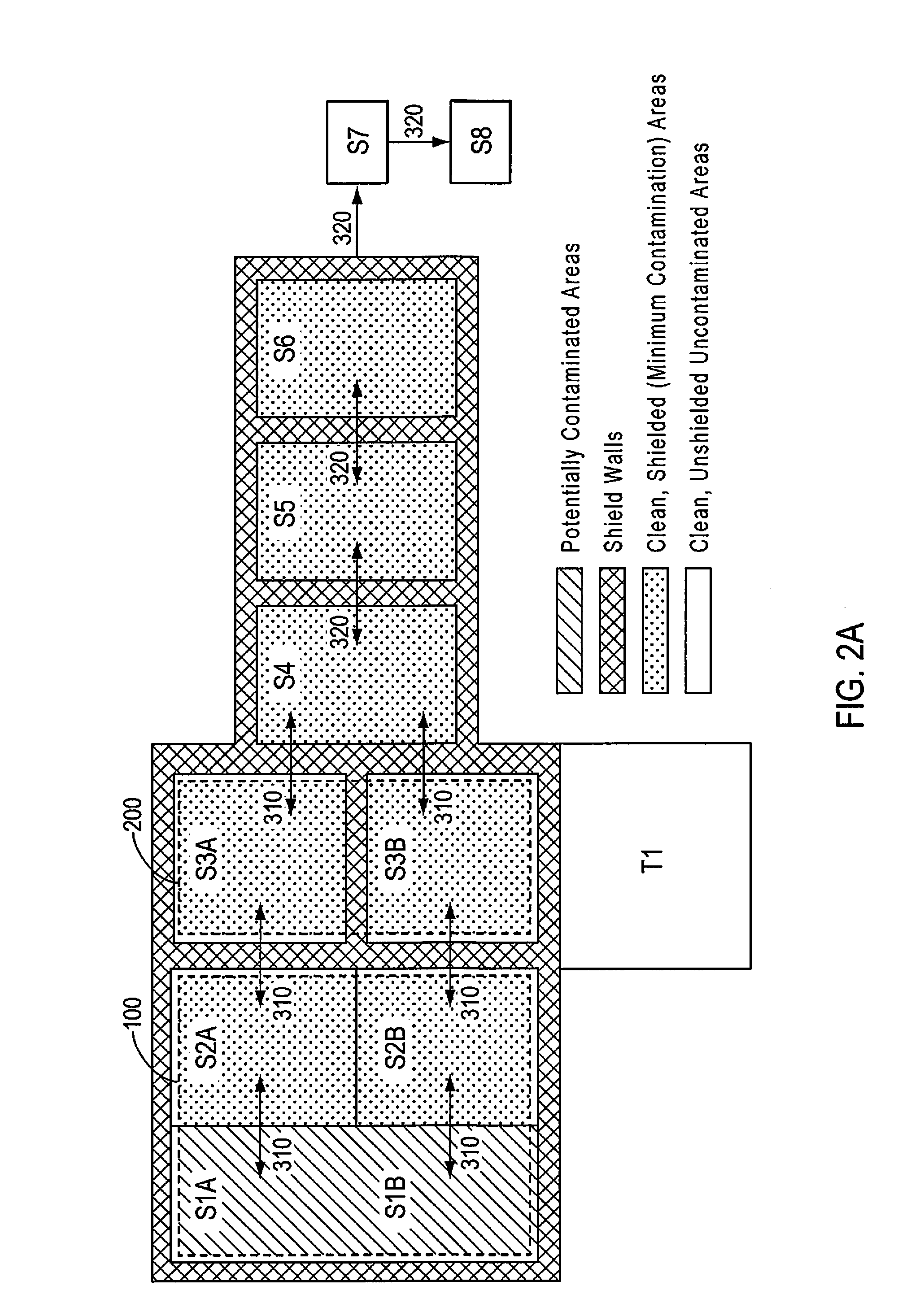

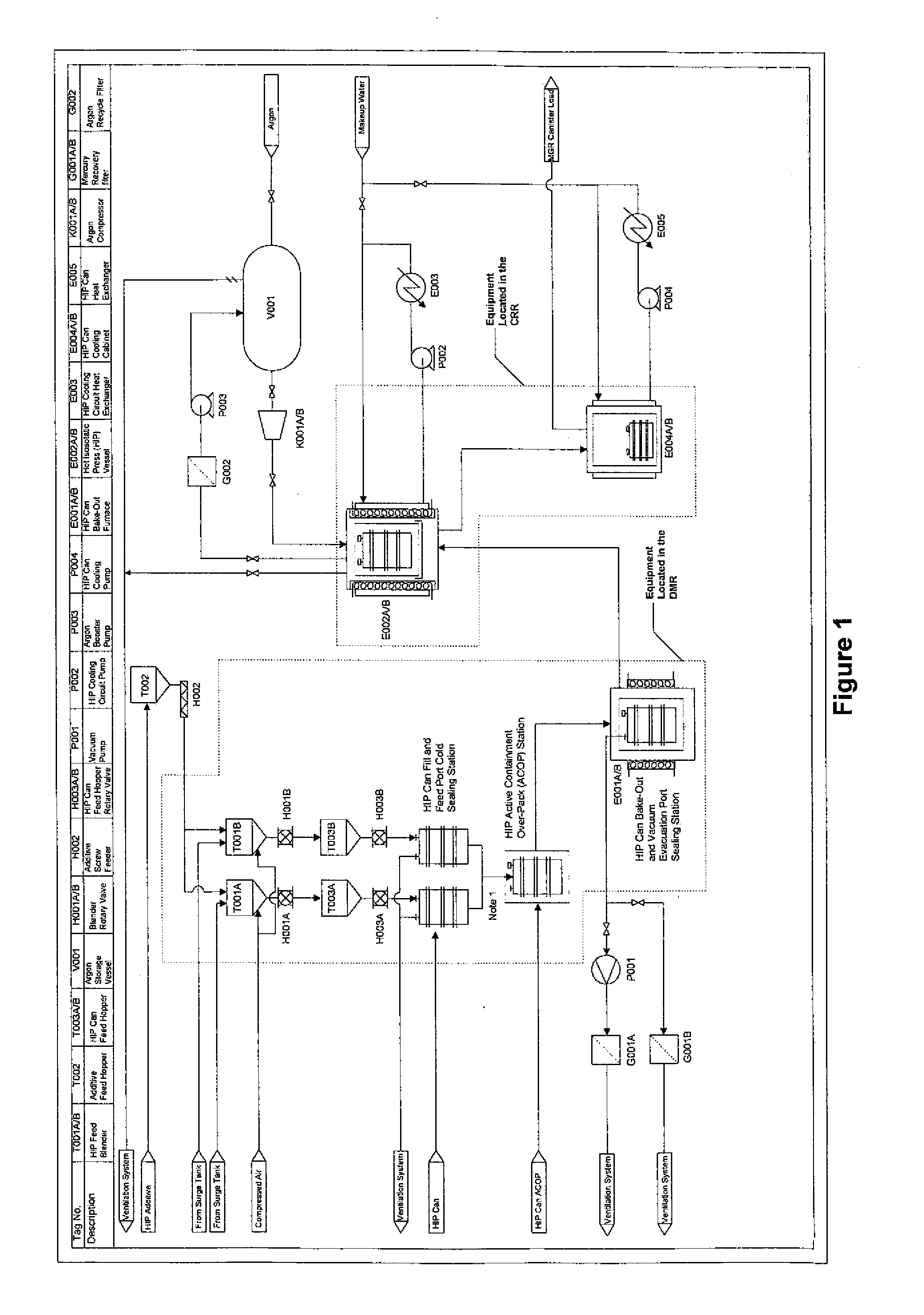

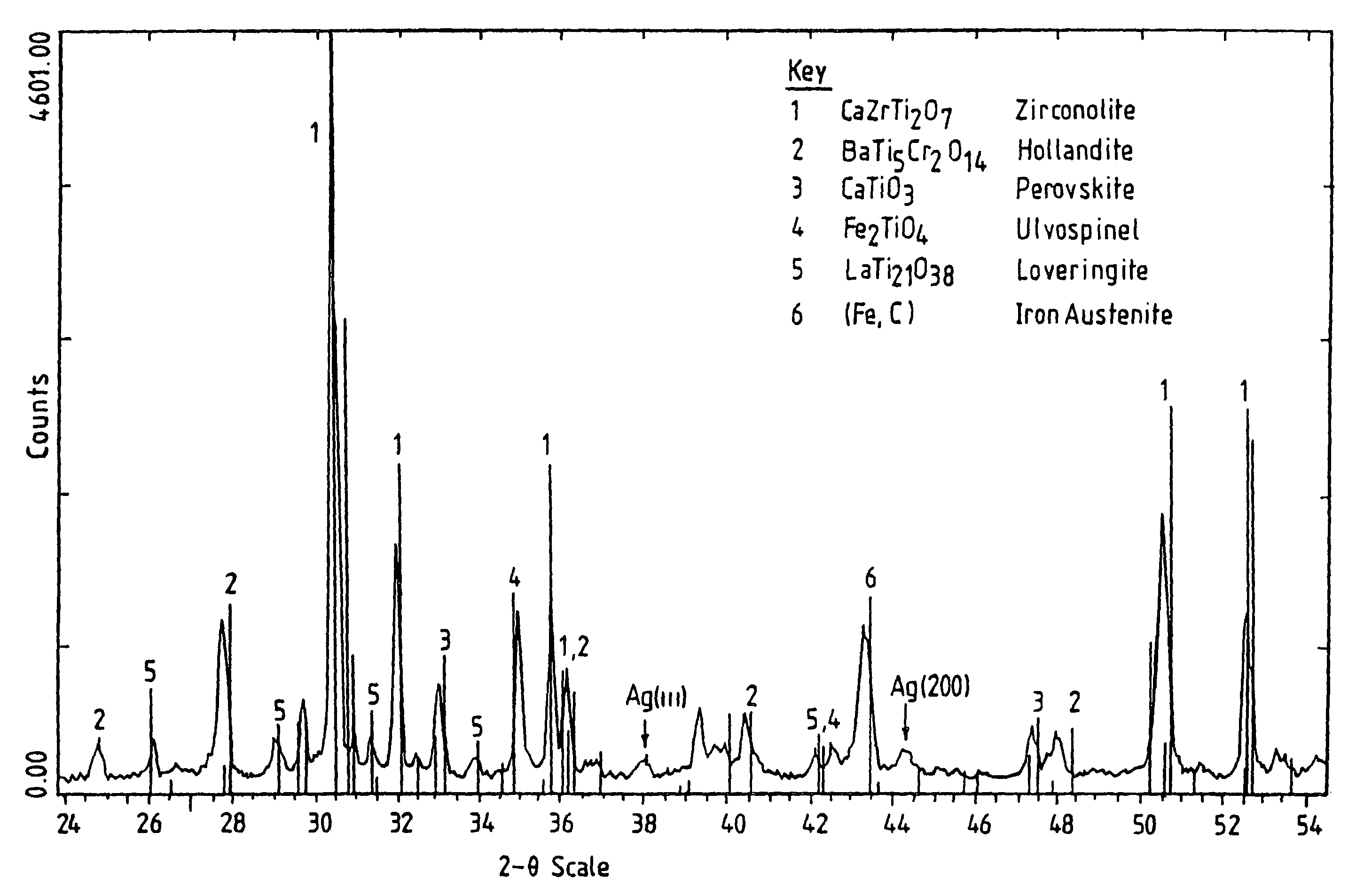

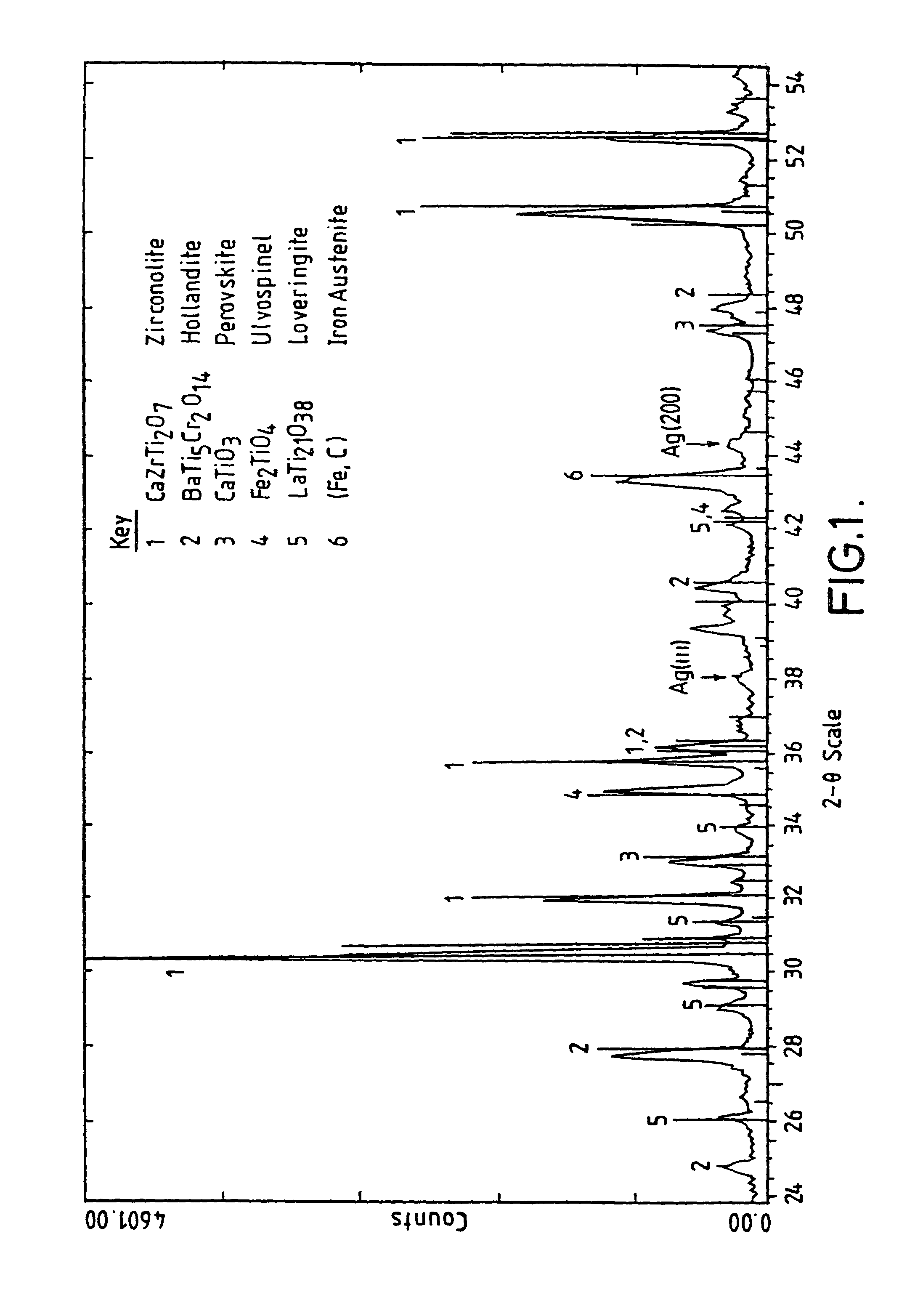

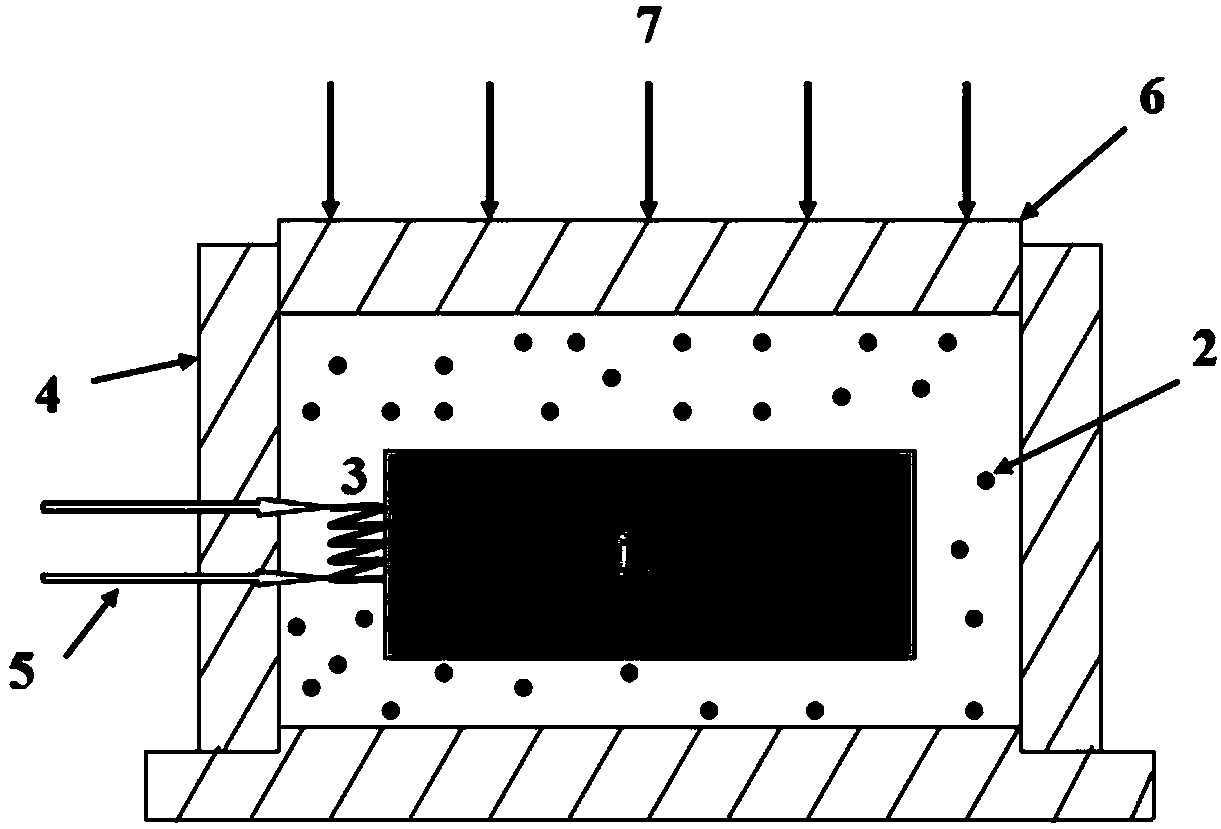

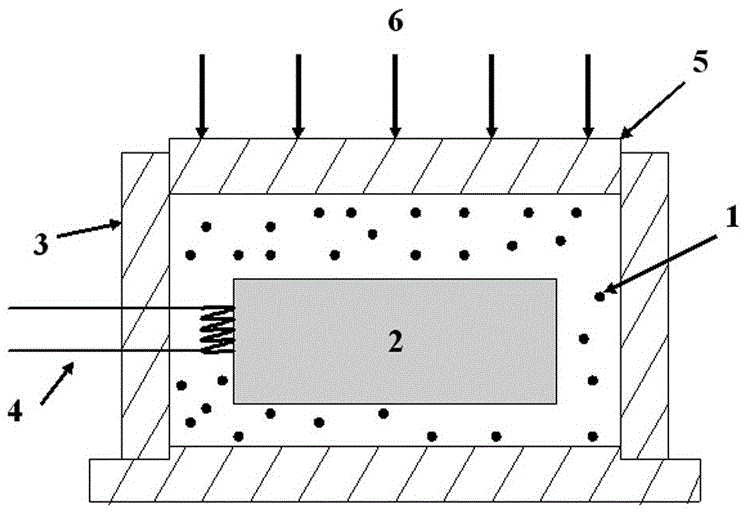

Methods of consolidating radioactive containing materials by hot isostatic pressing

ActiveUS8754282B2Reduce processing timeGlass furnace apparatusOhmic-resistance heatingZirconoliteHollandite

The present disclosure relates to a method of consolidating a calcine comprising radioactive material, the method comprising mixing 60-80% (by weight) of a radionuclide containing calcine with at least one non-radioactive additive, such as an oxide, and hot isostatic pressing the mixture to form a stable monolith of glass / ceramic. In one embodiment, the ratio of radionuclide containing calcine to additives is about 80:20 by weight, wherein the non-radioactive additive comprises oxides such as BaO, CaO, Al2O3, TiO2, SiO2 and others, that combine with the waste elements and compounds to form a ceramic mineral or glass / ceramic material, after hot isostatic pressing. Non-limiting examples of mineral phases that may be formed are: hollandite (BaAl2Ti6O16), zirconolite (CaZrThO7), and perovskite (CaTiO3).

Owner:AMERICAN ISOSTATIC PRESSES

Methods of consolidating radioactive containing materials by hot isostatic pressing

The present disclosure relates to a method of consolidating a calcine comprising radioactive material, the method comprising mixing 60-80% (by weight) of a radionuclide containing calcine with at least one non-radioactive additive, such as an oxide, and hot isostatic pressing the mixture to form a stable monolith of glass / ceramic. In one embodiment, the ratio of radionuclide containing calcine to additives is about 80:20 by weight, wherein the non-radioactive additive comprises oxides such as BaO, CaO, Al2O3, TiO2, SiO2 and others, that combine with the waste elements and compounds to form a ceramic mineral or glass / ceramic material, after hot isostatic pressing. Non-limiting examples of mineral phases that may be formed are: hollandite (BaAl2Ti6O16), zirconolite (CaZrThO7), and perovskite (CaTiO3).

Owner:AMERICAN ISOSTATIC PRESSES

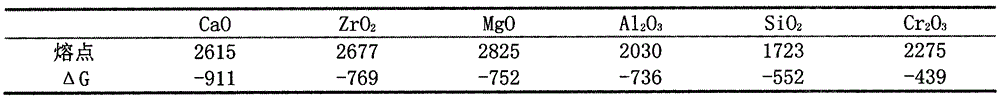

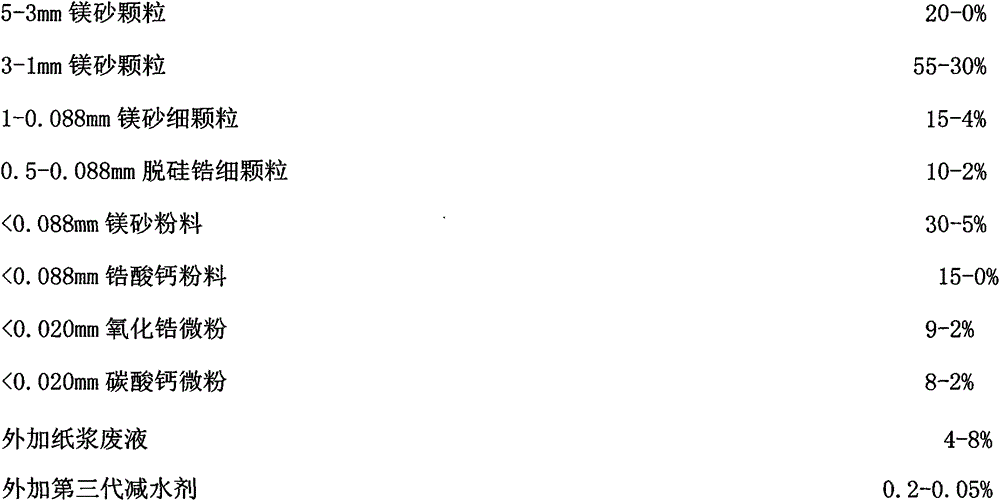

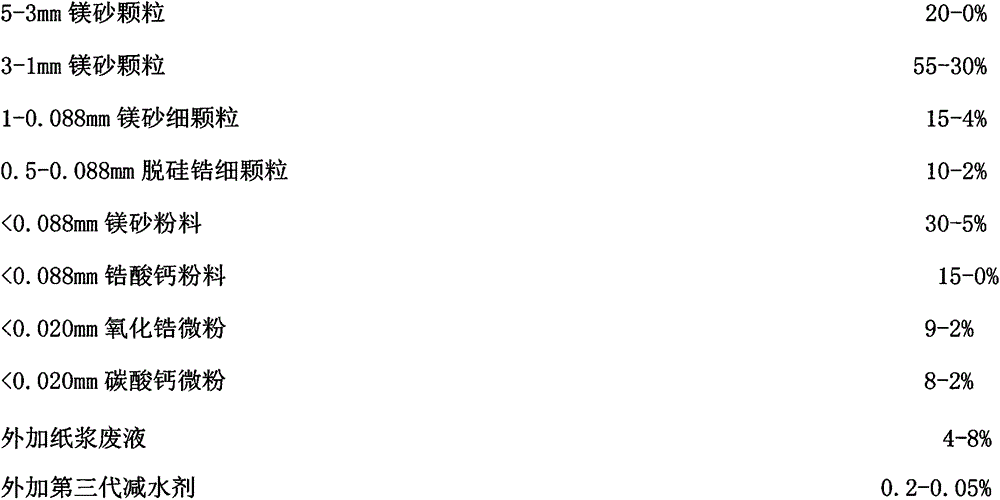

Magnesium-calcium-zirconium brick manufactured by means of in-situ reaction and used for secondary refining and production method

The invention relates to a magnesium-calcium-zirconium brick manufactured by means of in-situ reaction and used for secondary refining and a production method. During manufacturing, 0-20% of 3 mm-5 mm magnesia particles, 30-55% of 1 mm-3 mm magnesia particles, 4-15% of 0.088 mm-1 mm fine magnesia particles, 2-10% of 0.088 mm-0.5 mm fine desilicated zirconia particles, 5-30% of magnesia powder with the diameter being less than 0.088 mm, 0-15% of calcium zirconate powder with the diameter being less than 0.088 mm, 2-9% of zirconia micro powder with the diameter being less than 0.020 mm, 2-8% of calcium carbonate micro powder with the diameter being less than 0.020 mm, 4-8% of additional waste pulp liquid and 0.2-0.05% of additional third-generation water reducing agents are used; during production, the adopted process includes the steps that firstly, the zirconia micro powder and the calcium carbonate micro powder are premixed; secondly, the 3 mm-5 mm magnesia particles, the 1 mm-3 mm magnesia particles and the 0.088 mm-1 mm fine magnesia particles are added to a mixing mill, and he waste pulp liquid and the third-generation water reducing agents are added to the mixing mill to be mixed; thirdly, magnesia powder with the diameter being less than 0.088 mm, calcium zirconate with the diameter being less than 0.088 mm and premixed zirconia-calcium carbonate micro powder with the diameter being less than 0.020 mm are add and mixed until the mixture is even; finally, forming, drying, 1580-1700 DEG C sintering and checking are conducted on the mixture to obtain a refractory material with periclase-calcium zirconate-baddeleyite as a main crystal phase. The magnesium-calcium-zirconium brick has the advantages of being convenient to manufacture, low in cost, simple to use and excellent in performance, has excellent anti-erosion performance and thermal shock resistance, excellent high-temperature physical and chemical stability, and is competent for the work of secondary refining to make clean steel.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

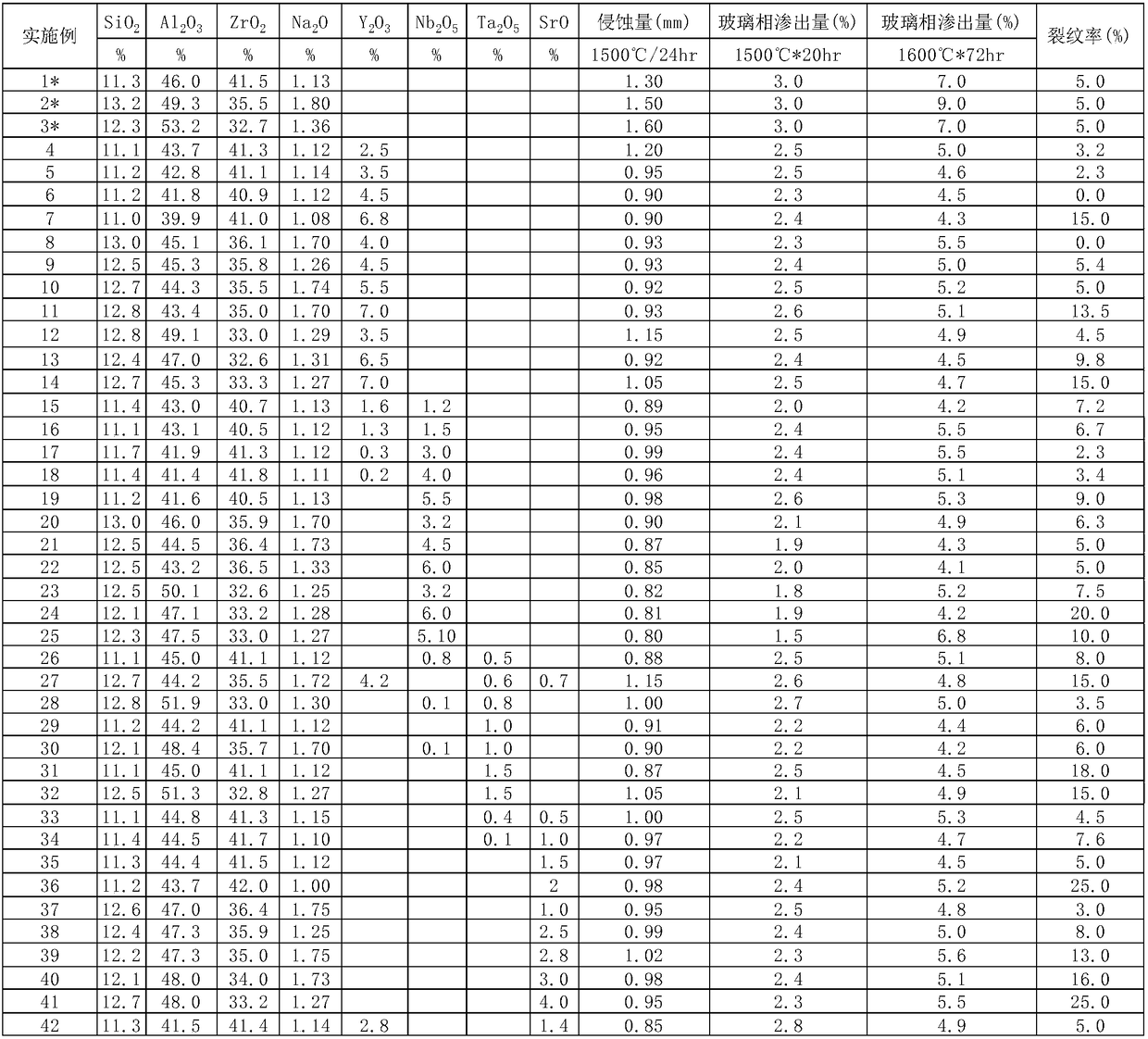

Sintered and doped product based on zircon + nb2o5 or ta2o5

Sintered product produced from a starting charge containing 75 to 99% zircon, and having the following average chemical composition by weight, the percentages by weight being based on the oxides: 60% < ZrO2 + HfO2 < 75%; 27%.< SiO2 < 34%; O < TiO2; O < Y2O3 < 3.5%; 0.1 % < Nb2O5 + Ta205 <= 5%; and other oxides: < 1,5 %; for a total of 100%. Use in a glass furnace.

Owner:SAINT GOBAIN CENT DE RES & DEVS & DETUD EUROEN

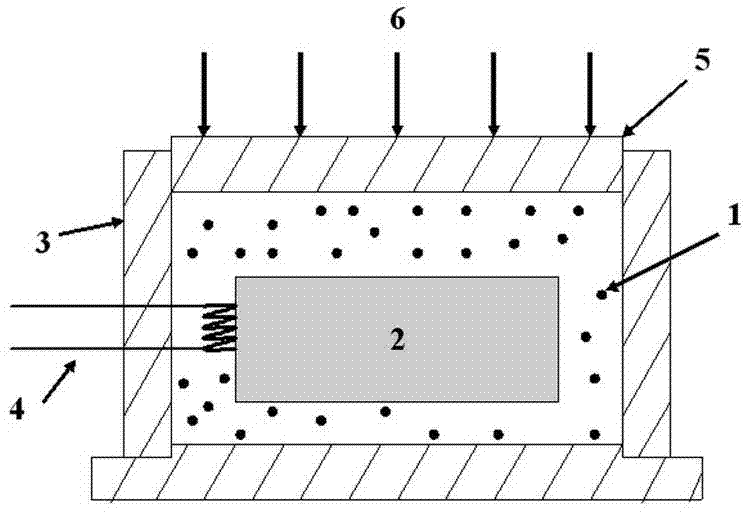

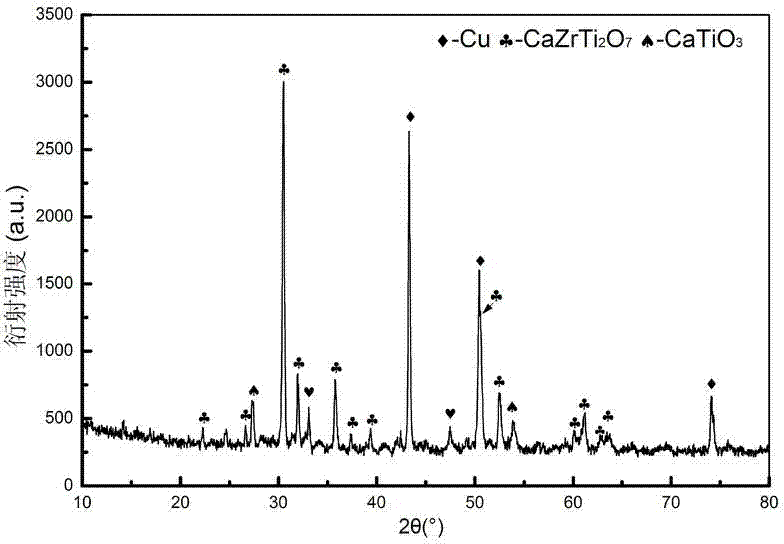

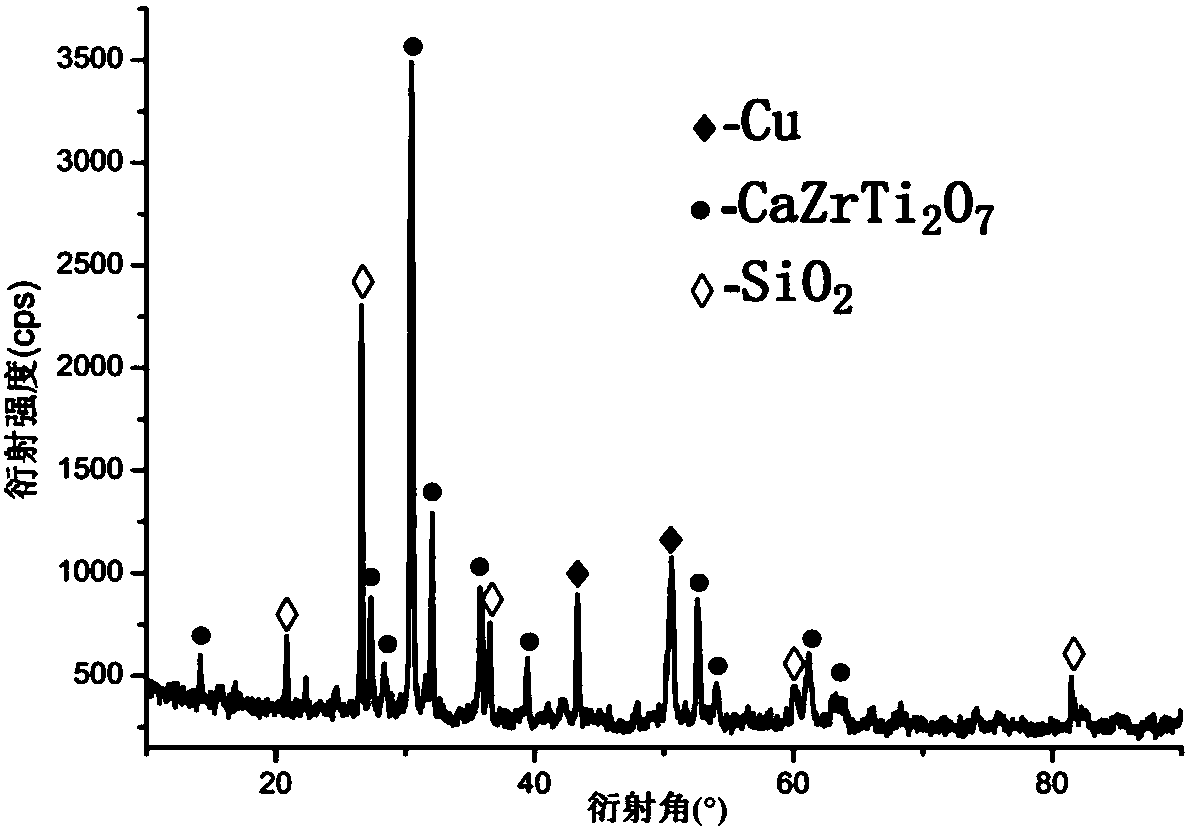

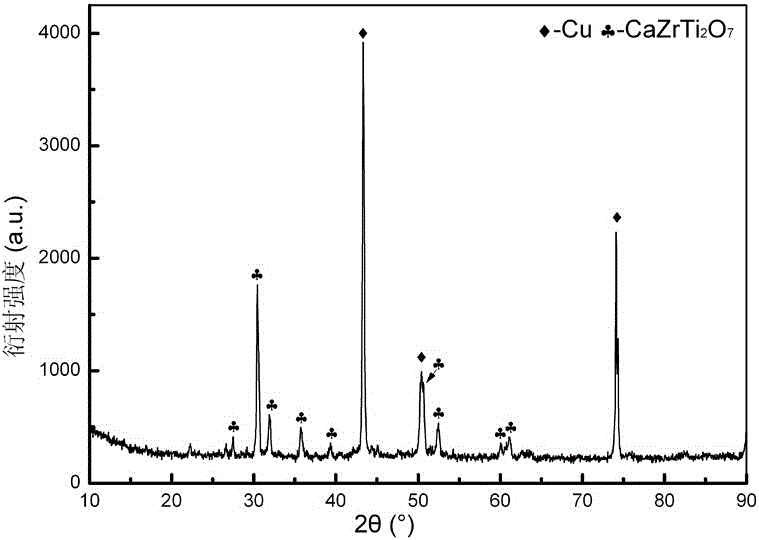

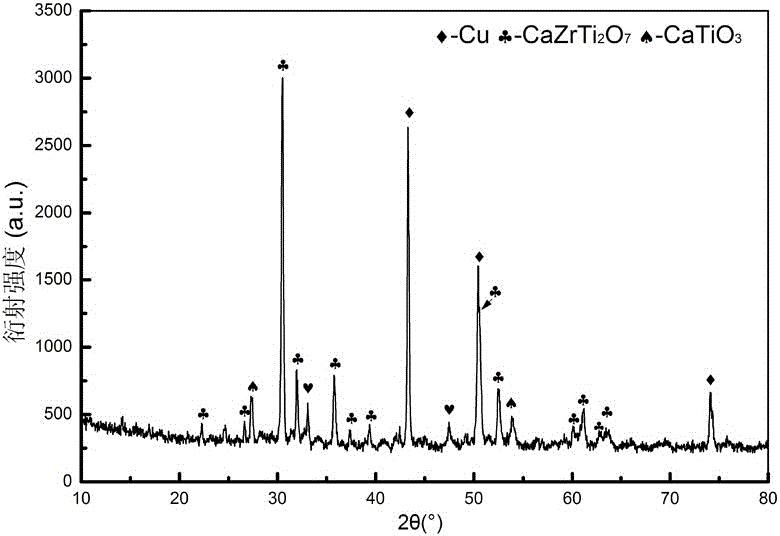

Preparation method for zirconolite type manmade rock

The invention discloses a preparation method for a zirconolite type manmade rock. The preparation method is characterized by comprising the following steps: preparing materials from CuO powder, CaO powder, Ti powder, TiO2 powder and ZrO2 powder; performing dry-process ball-milling on the raw materials, uniformly mixing the raw materials and enabling the raw materials to pass through a 100-mesh sieve; feeding 10-50g of the mixed materials into a stainless steel mould, and pressing the mixed materials into cylindrical blank; introducing the blank into a self-propagating quasi-isostatic device, igniting the blank through a tungsten filament to react, and applying pressure of 50-200MPa after the combustion reaction is ended, thereby preparing the high-compactness zirconolite type manmade rock. The preparation method disclosed by the invention can be used for synthesizing the zirconolite type manmade rock within several minutes by adopting a self-propagating high-temperature combined quick compacting process, has the advantages of being high in synthesis speed, high in efficiency, high in reaction temperature, high in product purity, low in energy consumption, simple, and the like; the prepared zirconolite type manmade rock is suitable for long-term safety solidification treatment and disposal of actinide in high-level waste.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Refractory castable for blast furnace iron runner

The invention provides a refractory castable for a blast furnace iron runner. The refractory castable is composed of the following components in parts by weight: 40-50 parts of corundum, 8-12 parts of zircon, 8-30 parts of silicon carbide, 5-6 parts of magnesium oxide, 2-6 parts of silica fume, 1-5 parts of calcium aluminate cement, 1-3 parts of boron carbide, 0.2-0.3 part of sodium hexametaphosphate, 0.1-0.2 part of sodium polyacrylate, 3-5 parts of water and 1-10 parts of carbon black. The refractory castable for the blast furnace iron runner has good thermal shock resistance and slag resistance.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

Encapsulation of waste

InactiveUS7078581B1Volume of waste can be minimizedImproved plant flexibilityOther chemical processesShieldingSlurryMaterials science

A ceramic waste immobilizing material for the encapsulation of high level radioactive waste (HLW), e.g. resulting from the reprocessing of irradiated nuclear fuel. The ceramic waste immobilising material enables waste ions from at least fission products in irradiated nuclear fuel to be dissolved in substantially solid solution form. The ceramic waste immobilising medium has a matrix comprising phases of hollandite, perovskite and zirconolite in which the waste ions are dissolved. The invention also includes a method of immobilizing HLW from reprocessed nuclear fuel assemblies comprising the steps of mixing a liquor containing the HLW with a precursor material comprising oxides or oxide precursors of at least titanium, calcium and barium to form a slurry, drying the slurry, and calcining the dried slurry under a reducing atmosphere to form a powder comprising 30–65 weight % waste.

Owner:NUCLEAR DECOMMISSIONING AUTHORITY

Zirconium-base sintered product

The invention relates to a sintered product, which is manufactured from starting materials containing 75% to 99% zircon and having the following weight average chemical composition, based on the oxide weight percentage: 60% ≤ ZrO2 + HfO2 ≤ 75%; 27%≤SiO2≤34%; 0.2%≤TiO2≤1.5%; 0.3%<Y2O3≤3.5%; and other oxides: ≤1%; total 100%. It also relates to the use of said sintered article in glass melting furnaces.

Owner:SAINT GOBAIN CENT DE RES & DEVS & DETUD EUROEN

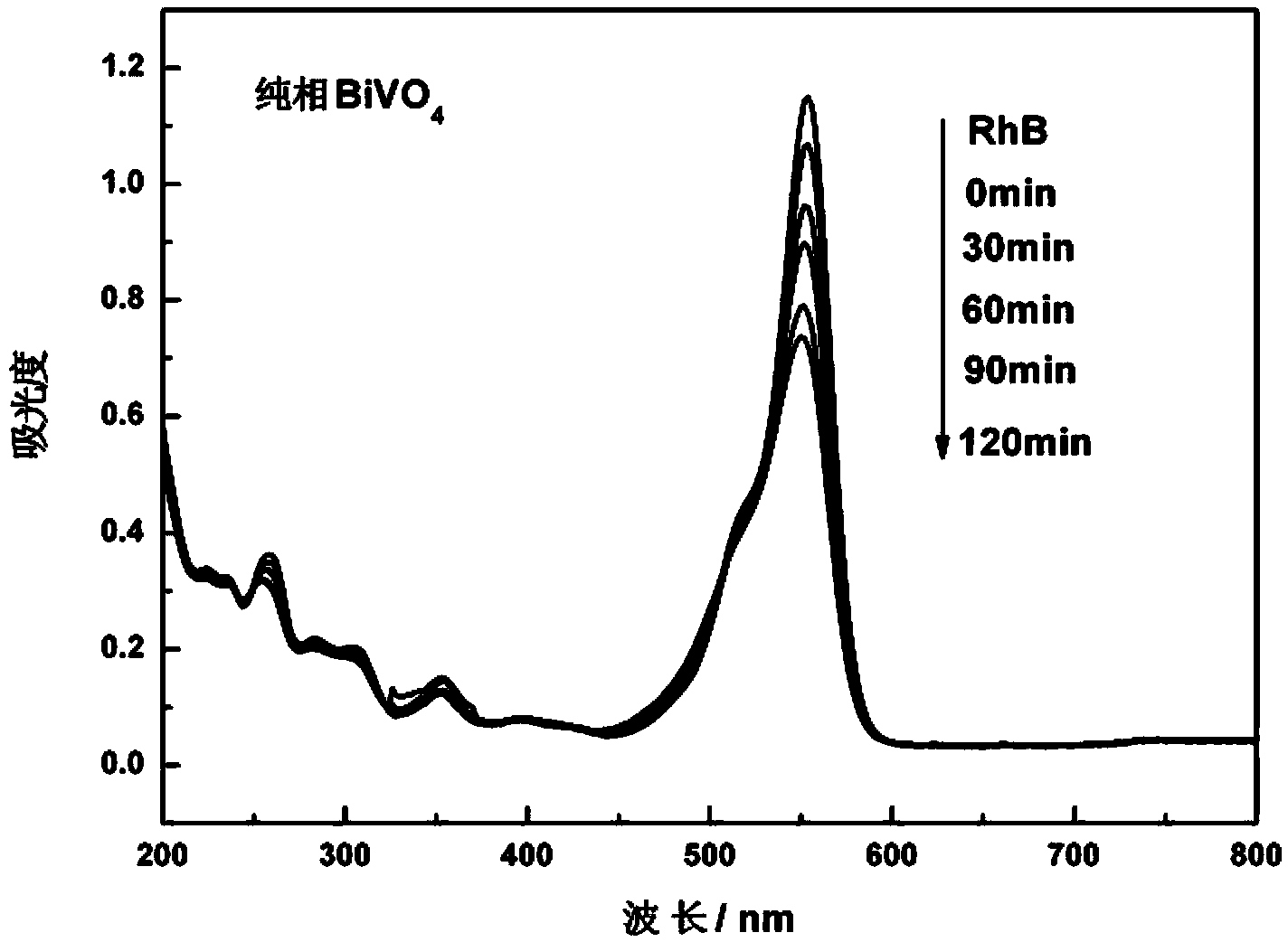

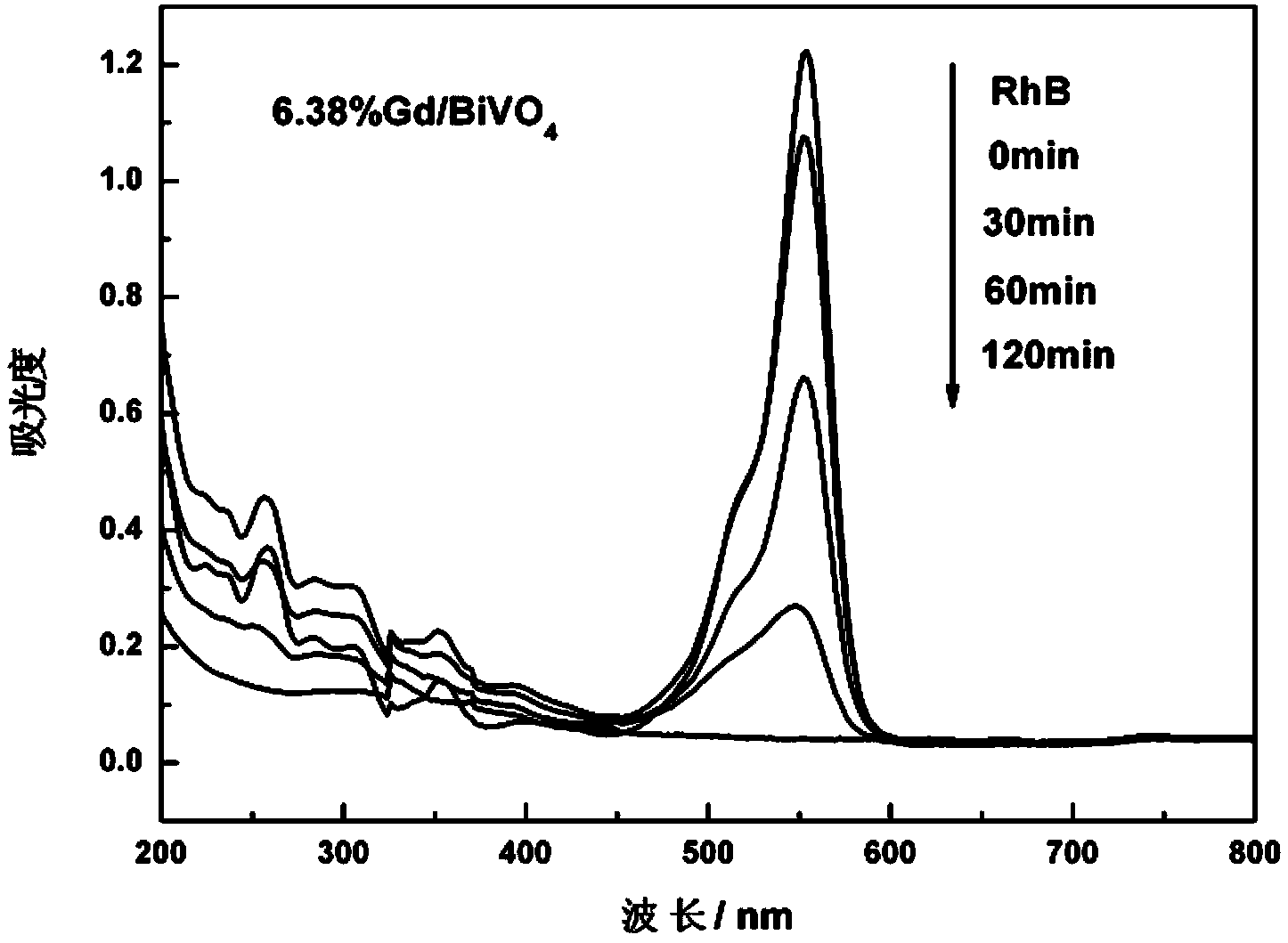

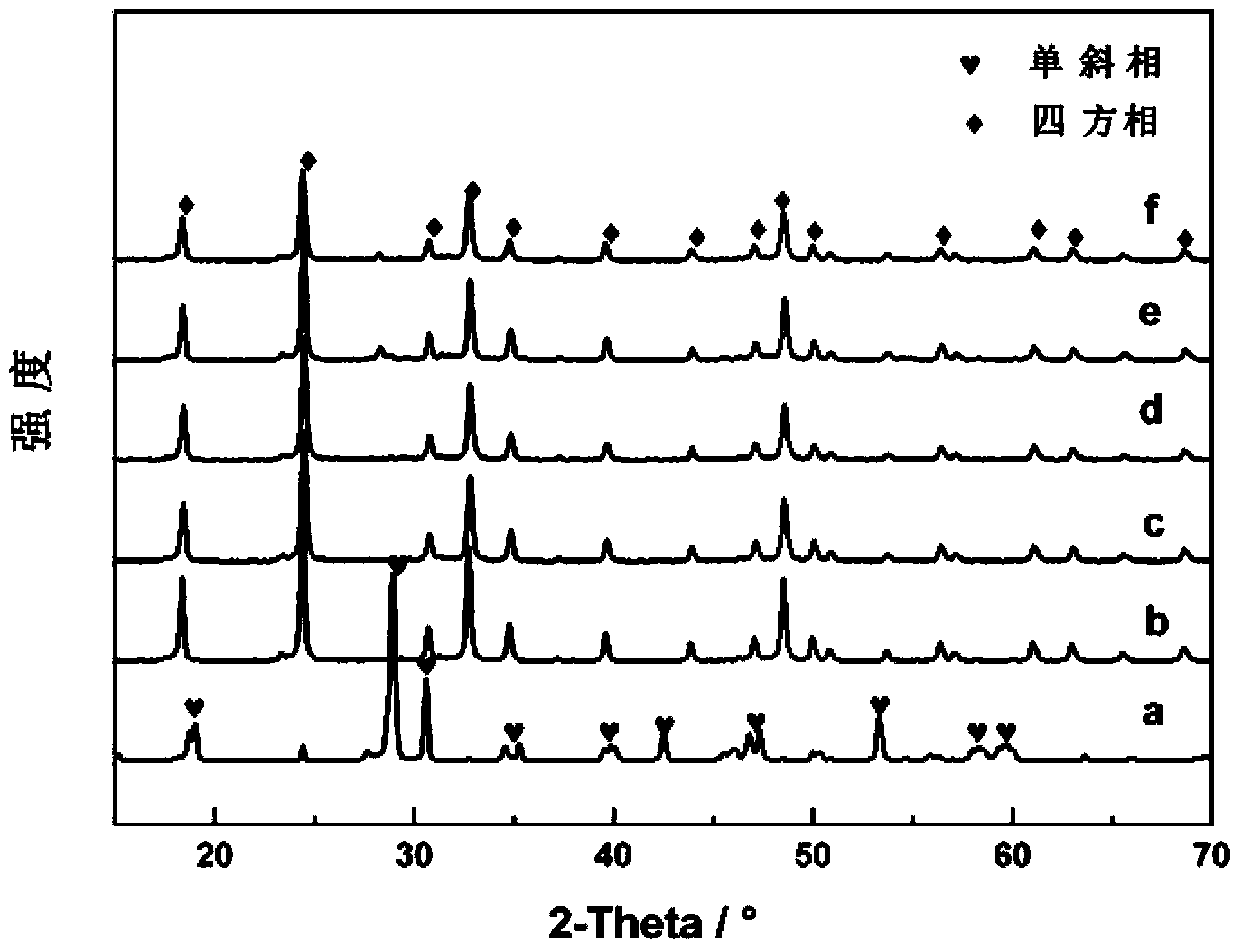

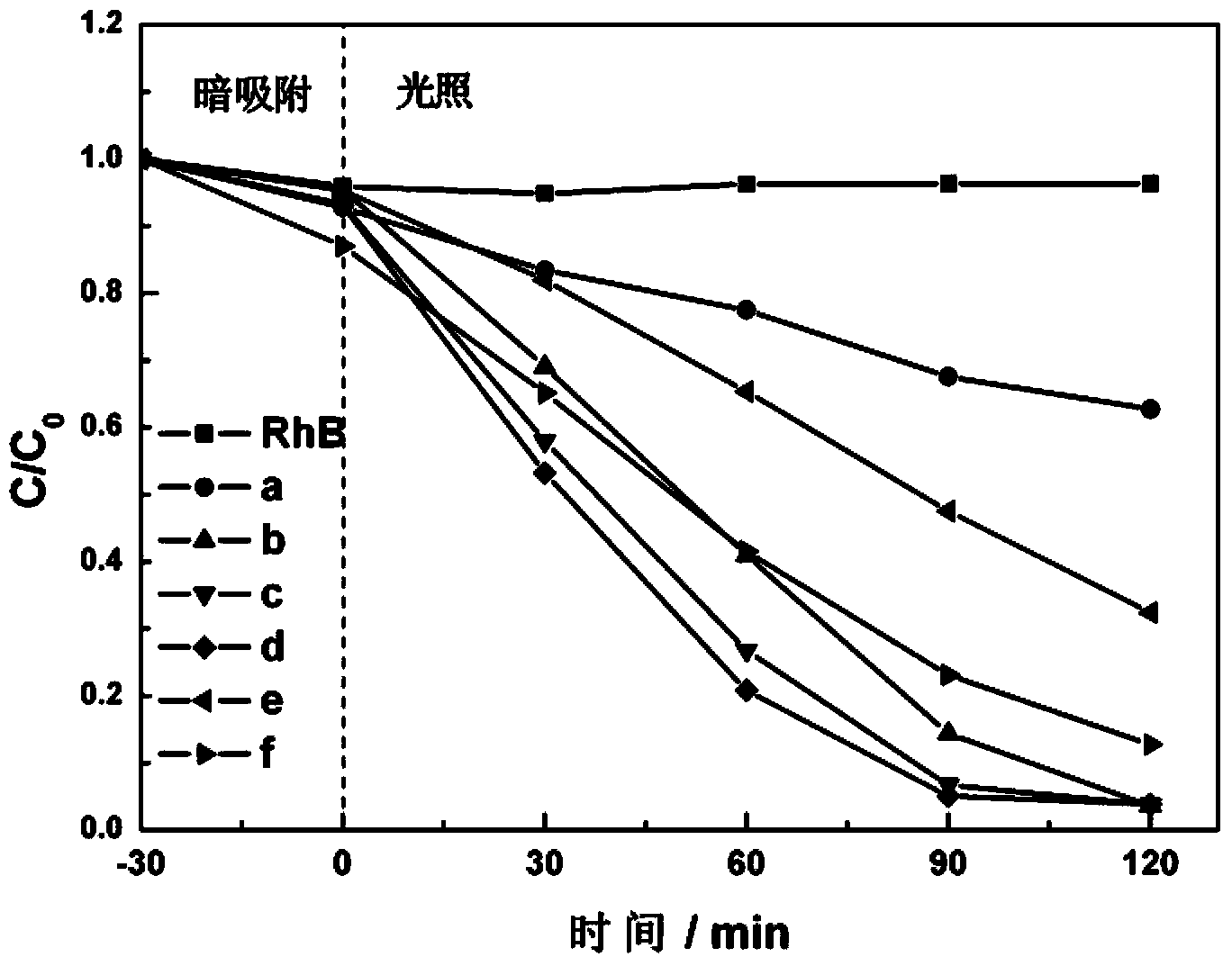

Gd-doped BiVO4 photocatalyst as well as preparation method and application thereof

ActiveCN103433023AImproving the efficiency of photocatalytic degradation of organic matterIncrease productivityMetal/metal-oxides/metal-hydroxide catalystsAmmonium metavanadateCrystal

The invention discloses a Gd-doped BiVO4 photocatalyst as well as a preparation method and application thereof. The Gd-doped BiVO4 photocatalyst takes BiVO4 as a main component and is of a quartet zircon phase structure; a crystal lattice of the BiVO4 contains Gd<3+>. The preparation method comprises the following steps: respectively dissolving bismuth nitrate pentahydrate and ammonium metavanadate into water to obtain bismuth salt solution and vanadium salt solution; adding the vanadium salt solution into the bismuth salt solution under the condition that the mol ratio of Bi to V is 1:1 to obtain a mixes solution; adjusting the pH value of the mixed solution to be 8; adding gadolinium nitrate hexahydrate, wherein the mol ratio of Gd to Bi is (2.04-11.11):100; preserving heat at the power of 300W and the temperature of 180DEG C for 40 minutes by using a microwave hydrothermal method to obtain the Gd-doped BiVO4 photocatalyst. The preparation method disclosed by the invention has the advantages of simple flow, simplicity in operation, short reaction time and mild reaction condition; the synthesized Gd-doped BiVO4 photocatalyst has higher photocatalytic activity and a favorable application prospect and can be used for degrading organic matters.

Owner:SHAANXI UNIV OF SCI & TECH

Froth flotation separation and analysis

ActiveUS20160051993A1Accurate identificationQuantitative precisionVortex flow apparatusCentrifugesPrillMineral particles

A method of separating heavy mineral particles, such as zircon, monazites, xeno time etc., from a sample of quartz crystal powder, comprises the steps of:a. conditioning the quartz powder suspected of containing heavy mineral particles as an aqueous pulp using a froth-flotation agent;b. subjecting the conditioned pulp to froth flotation to obtain a tailing;c. combining the tailing with an aqueous solution having a density greater than that of quartz and less than that of a heavy mineral which it is desired to separate; andd. centrifuging the combination.The separated heavy mineral crystals can then be characterised using a micro-analysis technique.

Owner:HERAEUS QUARTZ UK

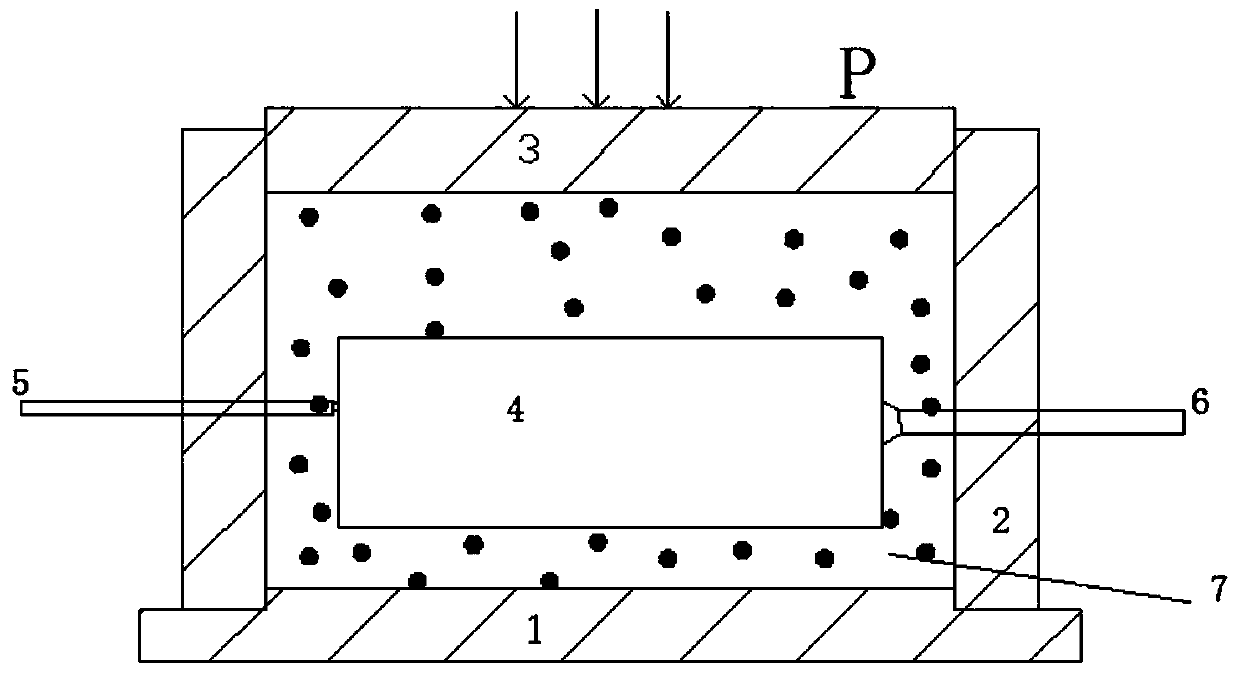

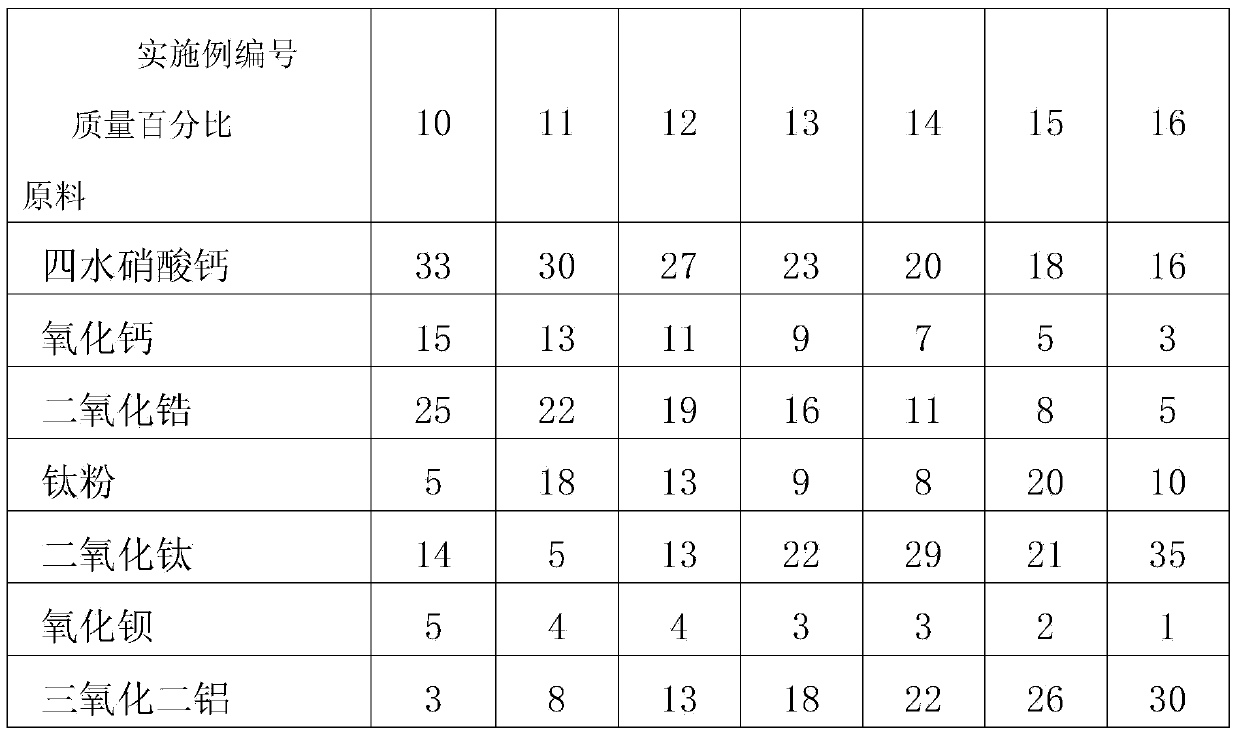

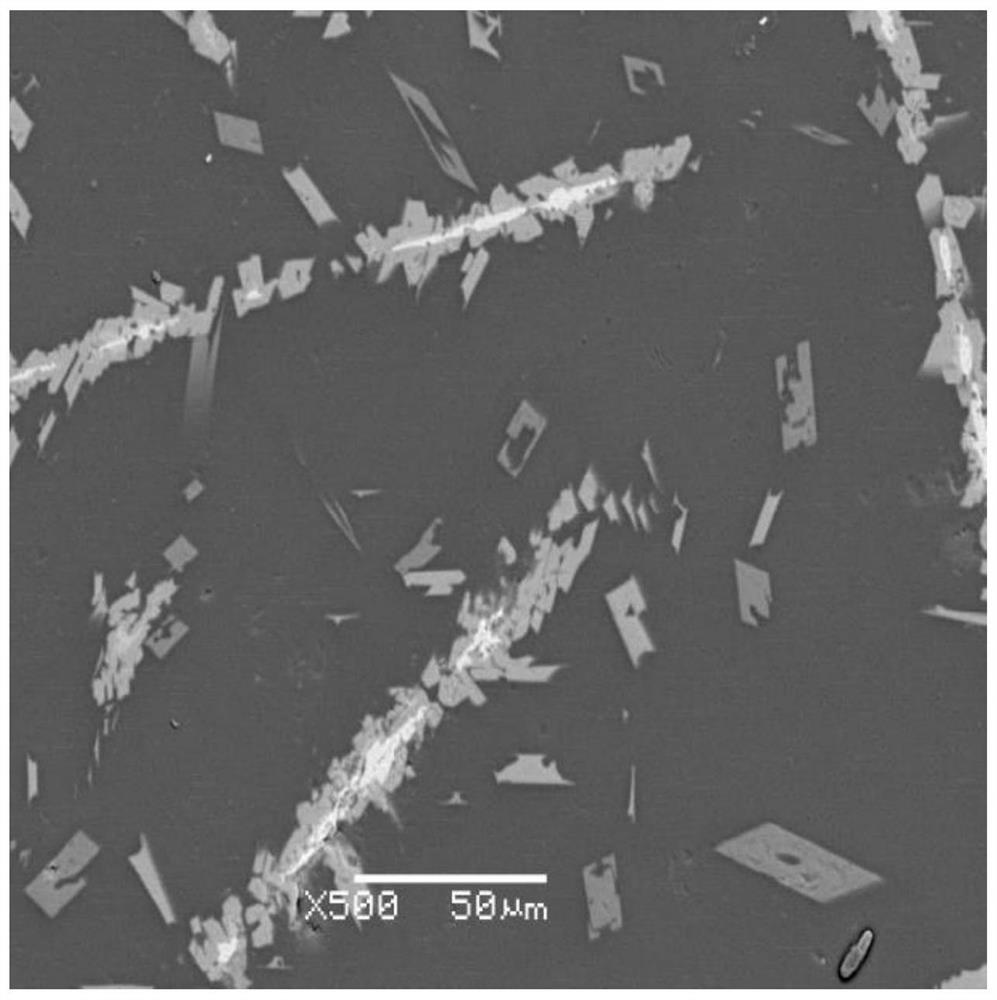

Self-propagating high-temperature synthesis and densification method of zirconolite-rich type man-made rock

InactiveCN103992095AStrong curingEasy to cureRare-earth elementSelf-propagating high-temperature synthesis

The invention discloses a self-propagating high-temperature synthesis and densification method of a zirconolite-rich type man-made rock. The method is characterized by comprising the steps of performing mixing, ball milling and screening on raw materials such as calcium nitrate tetrahydrate, calcium oxide, zirconium dioxide, titanium powder, titanium dioxide, barium oxide, aluminum oxide and the like to obtain a mixed material; putting the mixed material into a mold, and pressing to obtain a blank; preparing the blank into the densified zirconolite-rich type man-made rock by using a self-propagating pseudo isostatic pressing device. By adopting the self-propagating high-temperature synthesis and densification method, the prepared irconolite-rich type man-made rock has relatively large capacity on rare earth elements, actinide elements and the like, and is wide in element containment range. The self-propagating high-temperature synthesis and densification method disclosed by the invention adopts a high-temperature self-propagating synthetic method, is high in synthesis speed, short in production cycle and high in production efficiency, does not need a heat source provided externally, and is simple in process and strong in practicability; the prepared zirconolite-rich type man-made rock is suitable for solidification treatment of radioactive wastes.

Owner:SOUTHWEAT UNIV OF SCI & TECH

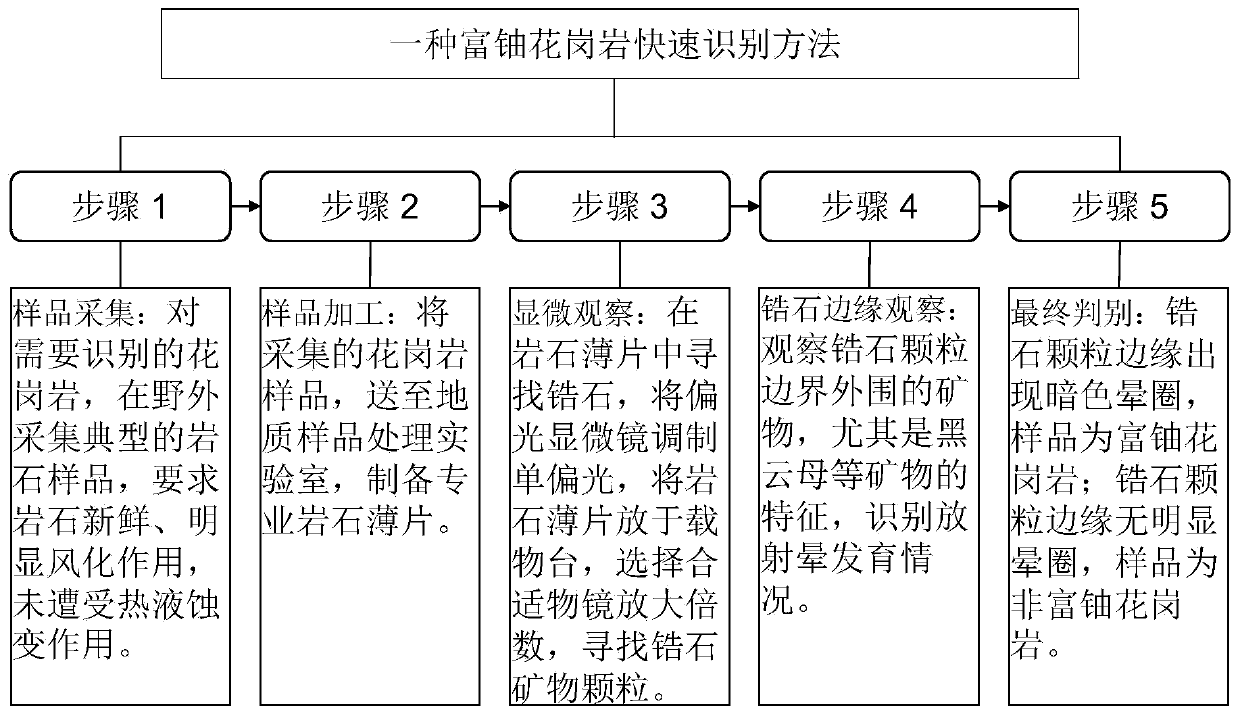

Method for quickly identifying uranium-rich granite

InactiveCN109813712ALow costImprove efficiencyColor/spectral properties measurementsZirconoliteUranium mineralization

The invention belongs to the field of uranium mineralization prediction, and particularly discloses a method for identifying uranium-rich granite based on polarizing microscope observation of rock slices. The method comprises the following specific steps that 1, a granite sample is collected; 2, the granite sample collected in the step 1 is processed into the rock slices; 3, granite zircon particles are found in the granite rock slices obtained in the step 2; 4, the edge characteristics of the granite zircon particles obtained in the step 3 are observed, and whether the granite zircon is uranium-rich zircon or not is judged; 5, the steps 3 and 4 are repeatedly executed on the rock slices obtained in the step 2, the edge characteristics of the zircon particles of the granite rock slices areobtained, and finally, whether the granite zircon is the uranium-rich zircon or not is judged. According to the method, through polarizing microscope observation of the granite rock slices, the uranium-rich granite can be quickly identified.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

Cermet material

InactiveCN106086721AHigh corrosion resistanceHigh resistance to water seepageBarium hydroxideMaterials science

The invention discloses a cermet material. The cermet material is prepared from the following raw materials in parts by mass: 50 to 60 parts of kaolin, 12 to 16 parts of quartz sand, 8 to 11 parts of zircon, 5 to 7 parts of aluminum oxide, 10 to 15 parts of anorthite, 9 to 11 parts of albite, 12 to 14 parts of talcum powder, 8 to 10 parts of mica powder, 5 to 9 parts of zirconia powder, 6 to 8 parts of lithium, 7 to 10 parts of sodium borohydride, 1 to 3 parts of calcium hydrophosphate, 4 to 5 parts of agate, 5 to 6 parts of borax, 2 to 4 parts of nano ferrum dioxide, 7 to 12 parts of glass fiber, 5 to 7 parts of magnesium oxide and 2 to 5 parts of barium hydroxide. The cermet material has the advantages of high temperature resistance, corrosion resistance, water seepage prevention and high strength.

Owner:青岛燕园海洋生物科技有限公司

Eu/BiVO4 photocatalyst as well as preparation method and application thereof

ActiveCN103433020AImproving the efficiency of photocatalytic degradation of organic matterIncrease productivityMetal/metal-oxides/metal-hydroxide catalystsAmmonium metavanadateEuropium

The invention discloses a Eu / BiVO4 photocatalyst as well as a preparation method and application thereof. The Eu / BiVO4 photocatalyst takes BiVO4 as a main component and is of a tetragonal zircon phase structure; a crystal lattice of the BiVO4 contains Eu<3+>. The preparation method comprises the following steps: respectively dissolving bismuth nitrate pentahydrate and ammonium metavanadate into water to obtain bismuth salt solution and vanadium salt solution; adding the bismuth salt solution into the vanadium salt solution under the condition that the mol ratio of Bi to V is 1:1 to obtain a mixed solution; adjusting the pH value of the mixed solution to be 8; adding europium nitrate hexahydrate, wherein the mol ratio of Eu to Bi is (4.17-13.64):100; preserving heat at the power of 300W and the temperature of 180 DEG C for 40 minutes by using a microwave hydrothermal method to obtain the Eu / BiVO4 photocatalyst. The Eu / BiVO4 photocatalyst disclosed by the invention is quickly synthesized, has higher photocatalytic performance under the irradiation of visible light and can be used for degrading organic matters. The preparation method has the advantages of fewer preparation process flows, simplicity in operation, short preparation period and regular crystal.

Owner:盐城市鹤业实业投资有限公司

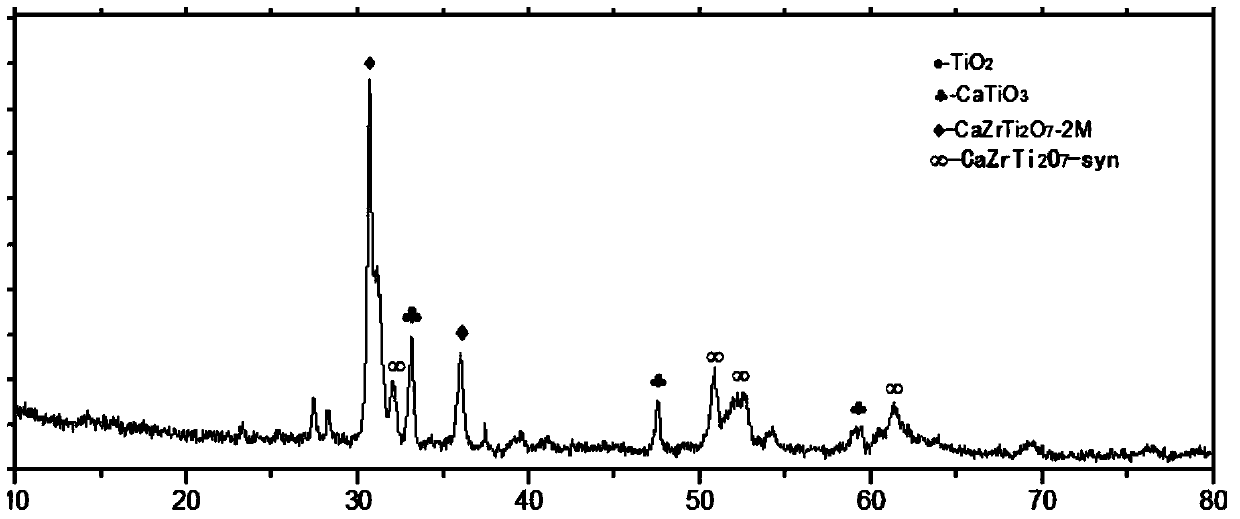

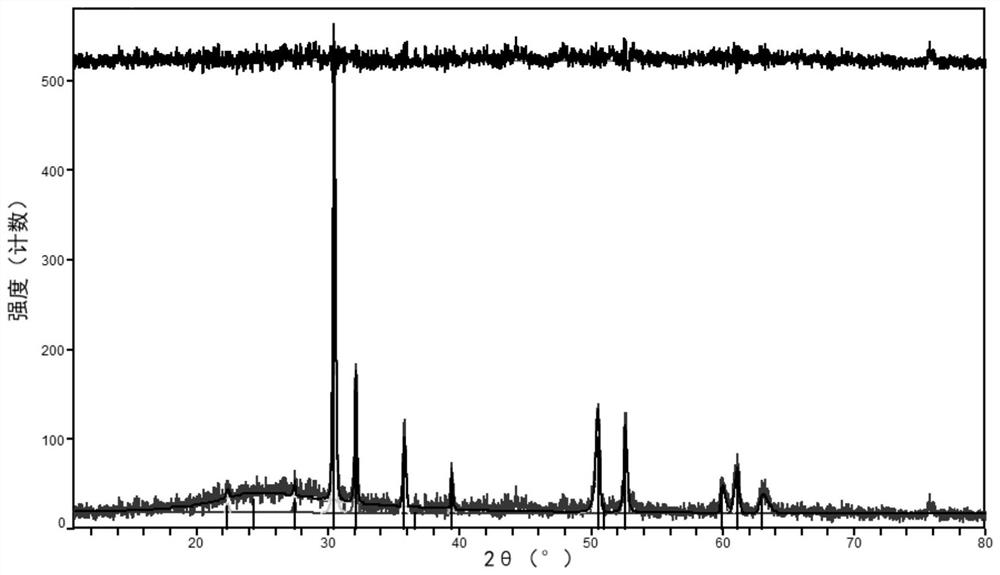

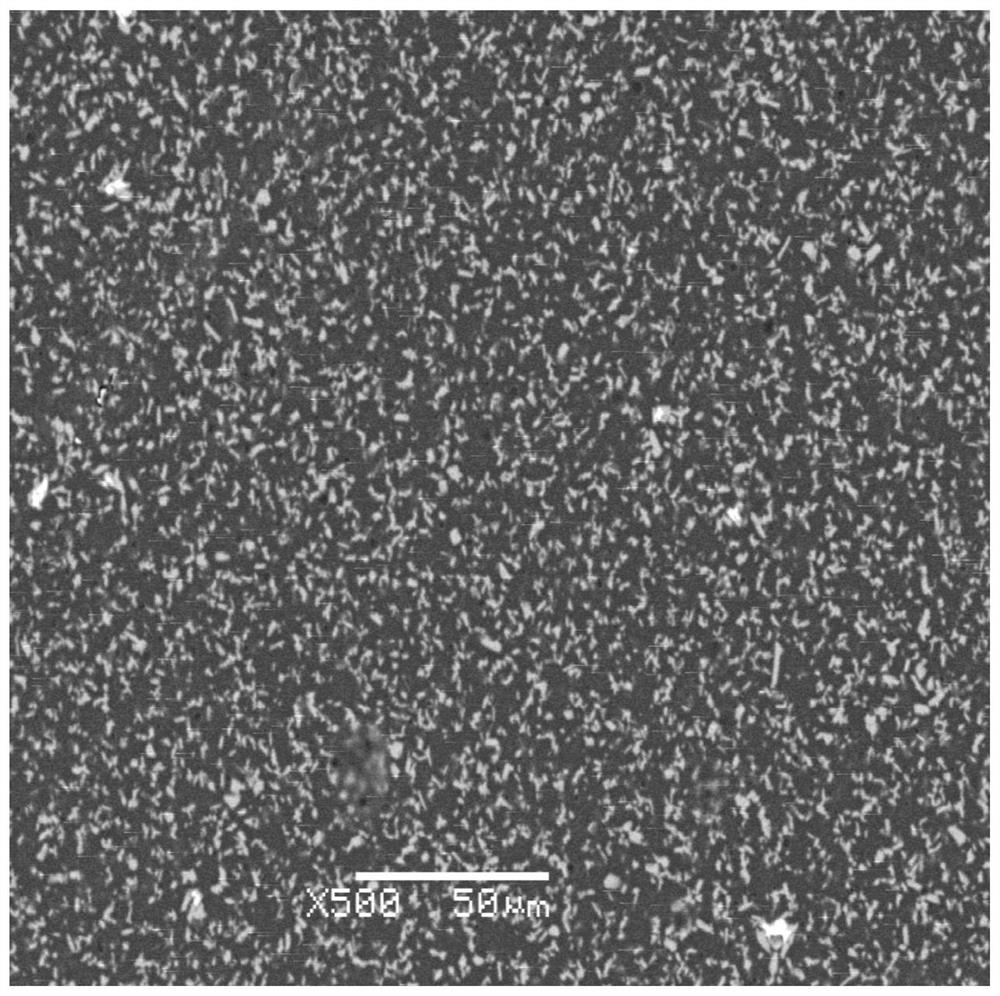

Zirconolite glass ceramic curing base material and preparation method thereof

The invention provides a zirconolite glass ceramic curing base material and a preparation method thereof. The zirconolite glass ceramic curing base material is prepared from the following raw materials in percentage by mass: 30 to 35 percent of SiO2, 9 to 11 percent of B2O3, 12 to 13.5 percent of Na2CO3, 3 to 4 percent of Al2O3, 9.5 to 11 percent of CaO, 10.5 to 12 percent of ZrO2, 13 to 15 percent of TiO2 and 2 to 10 percent of CeO2. The size of crystals in the prepared zirconolite glass ceramic ranges from 1 micrometer to 5 micrometers, the crystals are evenly distributed in a glass body, the single crystal component is the zirconolite crystals, and the zirconolite glass ceramic is stable in chemical property, good in heat stability, excellent in mechanical property, not prone to breakage, suitable for long-term geological storage and low in nuclide leaching rate; and the zirconolite glass ceramic can simultaneously solidify nuclides with long service life and other radionuclides, and has good high radioactive waste inclusiveness.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Steel ladle fireproof casting material

The invention relates to a steel ladle fireproof casting material, which is prepared from the following components by weight: 50-70 parts of magnesite, 5-20 parts of dolomite, 5-10 parts of zircon, 1-20 parts of carbon, 2-5 parts of an anhydrous binder, and 1-8 parts of hercynite, wherein the magnesite, the dolomite, the zircon and the hercynite are mixed to prepare 40-50 parts by weight of particles and 50-60 parts by weight of fine powder, the particle size of the particles is 2.0-2.5 mm, and the particle size of the fine powder is 0.1-0.9 mm.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

Electric-fused AZS (Al2O3-ZrO2-SiO2) brick with low-iron glass erosion resistance

ActiveCN108218192ALow Static ErosionImprove corrosion resistanceGlass furnace apparatusPorosityZirconolite

The invention relates to an electric-fused AZS (Al2O3-ZrO2-SiO2) brick with low-iron glass erosion resistance, and belongs to the field of refractory materials. The electric-fused AZS brick is prepared from the following substances in percent by mass: 31-45% of ZrO2, 9-14% of SiO2, 0.6-1.9% of Na2O, 0.5-16.5% of doped oxide and the balance of aluminium oxide, wherein the doped oxide is one or moreof Y2O3, Ta2O5, Nb2O5 or SrO. The prepared electric-fused AZS brick has good erosion resistance, lower porosity and the higher capability of bearing baddeleyite phase-change stress, and compared withthe common AZS brick, the erosion resistance is improved by 30% or more, and the glass-phase leakage rate is reduced by 30%.

Owner:淄博艾杰旭刚玉材料有限公司

Ceramic metal material

InactiveCN105399401AImprove performanceImprove stabilityClaywaresPotassium borohydrideTemperature resistance

The invention discloses a ceramic metal material. The ceramic metal material consists of the following raw material components in parts by weight: 8 to 14 parts of ferric oxide, 10 to 14 parts of aluminum oxide, 4 to 10 parts of silicon dioxide, 80 to 120 parts of kaolin, 80 to 100 parts of quartz sand, 4 to 8 parts of zinc oxide, 40 to 60 parts of zircon, 4 to 8 parts of silicon nitride, 4 to 6 parts of aluminum nitride, 15 to 25 parts of hydroxyapatite, 10 to 15 parts of titanium and 4 to 8 parts of potassium borohydride. Components of the ceramic metal material are reasonable and harmonious in proportion, and the prepared ceramic metal material is excellent in performance and good in stability, has excellent performances such as high temperature resistance, corrosion resistance and water resistance and is applied to various fields; moreover, the wettability is good, the vulnerability of the material is reduced, and the strength of the material is effectively improved.

Owner:TAICANG JIEGONG PRECISION METAL MATERIALS CO LTD

Preparation method of calcium-magnesium-zirconium apatite compounded dissolvable fireproofing material

ActiveCN106367896AImprove toughnessExtend the life cycleGlass making apparatusHeating/cooling textile fabricsApatiteFiltration

The invention discloses a preparation method of a calcium-magnesium-zirconium apatite compounded dissolvable fireproofing material. According to the preparation method, dolomite, podolite and zircon are taken as main raw materials, and xenotime, ilmenite, strontianite and graphite are taken as auxiliary materials. The preparation method comprises the following steps: (1) preparation of the main raw materials; (2) preparation of the auxiliary materials; (3) fusion; (4) filtration, and thread throwing; (5) formation of gray fabric; and (6) formation of a finished product. The density of the calcium-magnesium-zirconium apatite compounded dissolvable fireproofing material is 260Kg / m<2>-350Kg / m<2>, the tensile strength is 0.01MPa-0.08MPa, the use temperature is 1500-1800 DEG C, and the dissolution rate constant in a simulated human lung fluid is 1000ng / (cm<2>.hr)-1500ng / (cm<2>.hr); and the calcium-magnesium-zirconium apatite compounded dissolvable fireproofing material is low in preparation cost, nontoxic and harmless and beneficial to the environment-friendly production because no any polluted gas is released.

Owner:CHANGXING MENGYOU REFRACTORIES

High-strength and high-temperature-resistance molding sand and preparation method thereof

InactiveCN105478654AImprove liquidityImprove breathabilityFoundry mouldsFoundry coresBrickCalcium formate

The invention discloses high-strength and high-temperature-resistance molding sand and a preparation method thereof. The high-strength and high-temperature-resistance molding sand is prepared by the following raw materials in parts by weight: 14-22 of allophane, 24-38 of attapulgite, 12-18 of obsidian, 10-15 of baddeleyite, 8-14 of waste brick chips, 5-10 of refining slag, 16-24 of emery, 9-16 of glauconite, 7-11 of calcium formate, 5-10 of nanometer magnesium titanate, 4-7 of polyethylenimine, and 270-330 of modifying agents. The molding sand, prepared with allophane, obsidian, baddeleyite, waste brick chips, refining slag, emery and the like as main raw materials, is better in thermal stability and higher in refractoriness, and is added with calcium formate, nanometer magnesium titanate, polyethylenimine and the like to improve the green compression strength and the wet tensile strength. The prepared molding sand is excellent in breathability, fluidity, strength, collapsibility and high-temperature resistance; and a casting produced by the molding sand is smooth in surface and low in rejection rate.

Owner:安徽创奇乐智能游乐设备有限公司

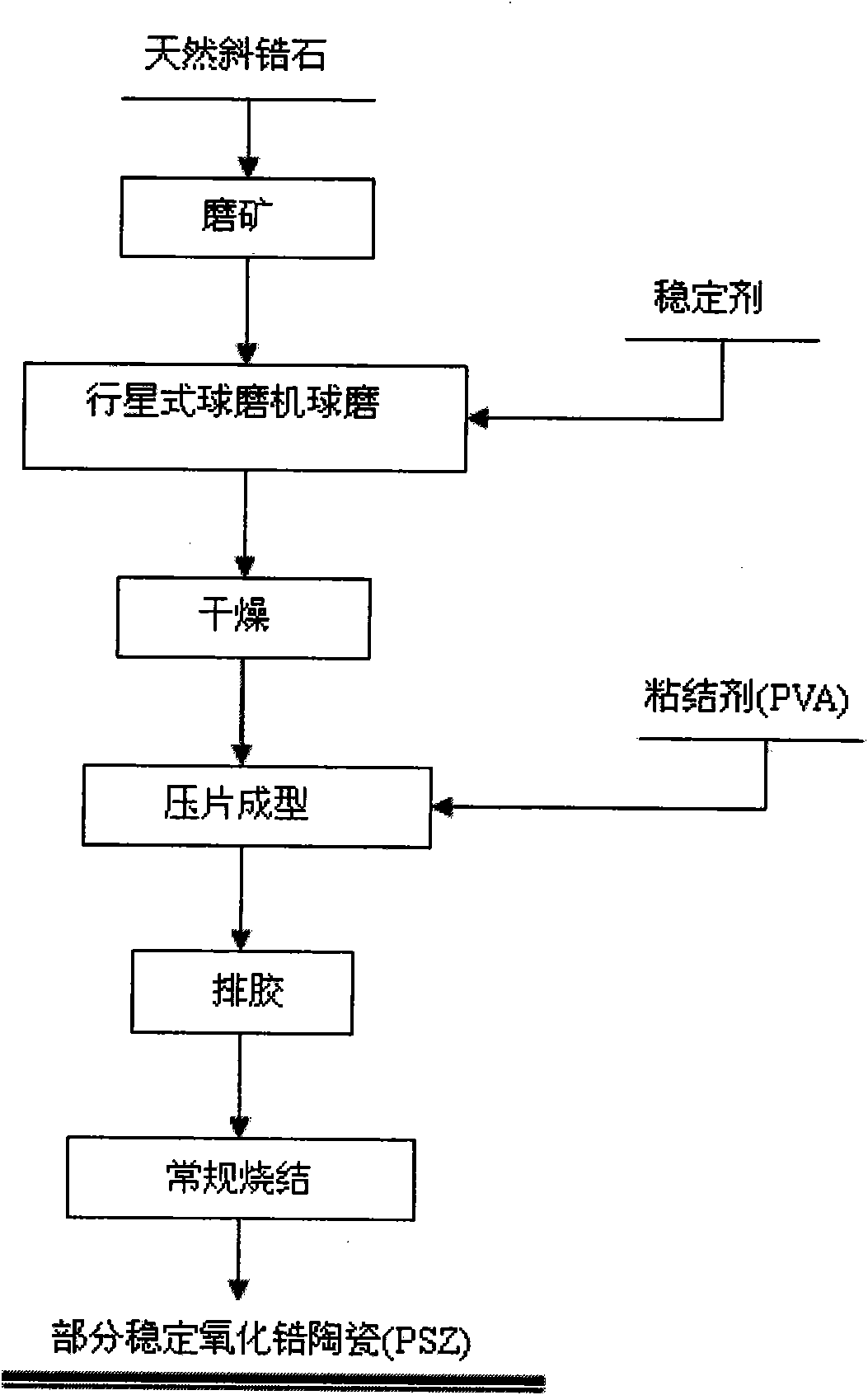

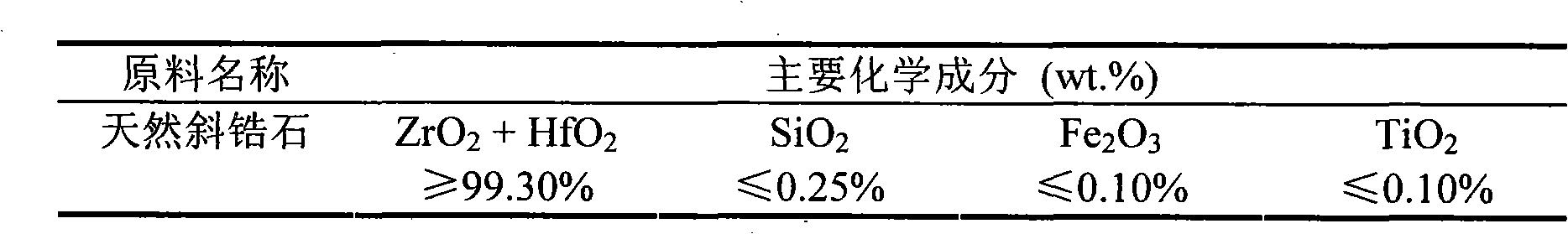

Method for preparing partially stabilized zirconia ceramics by adopting natural baddeleyite

The invention discloses a method for preparing partially stabilized zirconia ceramics by adopting natural baddeleyite. A finished product of the partially stabilized zirconia ceramics serving as a special ceramic material and a refractory material is prepared from the natural zirconia serving as a raw material by crushing, preparing materials, ball-milling, sintering at the temperature of between 1,300 and 1,600 DEG C and keeping the temperature for 2 to 6 hours. By directly adopting the natural baddeleyite obtained by beneficiation as the raw material without using a processed industrial pure raw material, so no waste residue, no waste gas or no waste liquor is generated in a process. Because the natural zirconia is used as the raw material, the partially stabilized zirconia ceramics can be prepared by only adding a certain amount of stabilizer, ball-milling, caking and sintering without performing additional treatment; process flow is short; energy consumption is reduced; and harmless treatment is realized. The partially stabilized zirconia ceramics is used as the special ceramic material or the refractory material.

Owner:KUNMING UNIV OF SCI & TECH

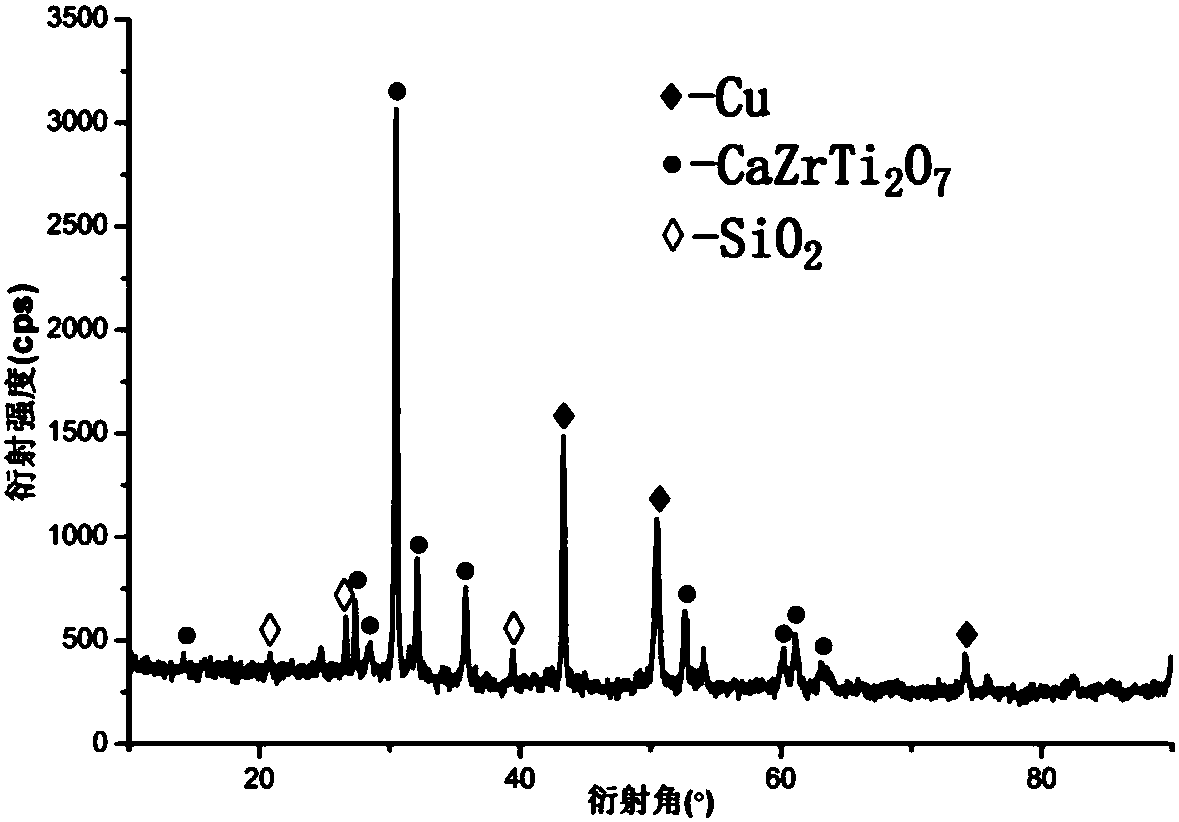

Self-propagating solidifying method for radioactive contaminated sandy soil

InactiveCN108022665AImprove leaching resistanceEfficient curingRadioactive decontaminationZirconoliteSelf-propagating high-temperature synthesis

The invention discloses a self-propagating solidifying method for radioactive contaminated sandy soil. The method is characterized in that a radioactive sandy soil solidified body is prepared from theradioactive contaminated sandy soil, and the method includes the following steps: taking raw materials according to the molar ratio of CuO to CaO to Ti to ZrO2 of 4:1:2:1, adding the radioactive contaminated sandy soil which accounts for the total mass of 10%-20%, performing dry ball milling, performing sieving, performing drying, and performing pressing to obtain a blank material; and placing the blank material into a self-propagating quasi-isostatic pressure device, and performing self-propagating high-temperature synthesis to make the radioactive contaminated sandy soil solidified into a high-thermal-stability, high-chemical-stability zirconolite-typed compact man-made rock. The method provided by the invention has the advantages of a rapid synthetic speed, high production efficiency,high reaction temperature, low energy consumption, a simple process and the like, and the method provided by the invention is particularly suitable for the safe solidifying treatment and disposal of the radioactive contaminated sandy soil.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Anhydrous pressed-in mud for blast furnace

The invention provides anhydrous pressed-in mud for a blast furnace. The anhydrous pressed-in mud comprises aggregate, a matrix, a binder and an additive, wherein the aggregate is composed of high-alumina bauxite, silicon carbide and zircon, the adding amount of the aggregate is 45-55 parts and the granularity of the aggregate is smaller than 0.4 mm; the matrix is composed of silicon micro powder and magnesium oxide, and the adding amount of the matrix is 10-25 parts; the binder is liquid phenolic resin, and the adding amount of the binder is 15-35 parts; and the additive is sodium hexametaphosphate, and the adding amount of the additive is 2-4 parts.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

Electroless nickel plating method for the preparation of zirconia ceramic

InactiveUS7147896B2Equally distributedPretreated surfacesLiquid/solution decomposition chemical coatingElectroless nickelZirconolite

An electroless nickel plating method for the preparation of zirconia ceramic material. The surface of the zirconia ceramic material is first cleaned of contaminants. This is followed by an etching step where the surface of the material is etched by an acid. Then, activating the surface of the material is achieved by first applying a tin sensitizer, and then a palladium activator. Following the palladium activator step, applying an electroless nickel to the surface of the post activated material. After the electroless nickel bath, the zirconial ceramic material can then be further electroless or electrolytically plated with a variety of finishes. Applying the method of the present invention provides a suitable, commercially practicable method for the preparation of zirconia ceramic material for electroless nickel plating, so that the electroless nickel chemistry is distributed evenly on the material's surface.

Owner:RINE MARK D

Preparation method of dense and stable type ceramic pigment

The invention discloses a preparation method of a dense and stable type ceramic pigment and belongs to the technical field of ceramic pigments. The preparation method firstly takes diatomite and zircon as raw materials and the raw materials are crushed and sieved to obtain sieved powder; the diatomite has a porous structure, stable chemical properties, low density and relatively large specific surface area, and can be used for filling gaps generated by solvent evaporation in the ceramic pigment, so that the microstructure of the ceramic pigment is more dense; lignin is extracted from corn straws; after the lignin is added, the strength of the ceramic pigment can be increased and the cracking of the ceramic pigment is prevented; the reserved sieved powder and the lignin are mixed so that the lignin can be adsorbed in gap structures of inorganic minerals; a hydrogen bond adsorption force can be generated between active groups and an active group of the surface of a ceramic substrate; the inorganic minerals stuck with the lignin and copper ammonia fibers are mixed and then are calcined and ground to prepare the dense and stable type ceramic pigment. The dense and stable type ceramicpigment has a wide application prospect.

Owner:佛山市慕瓷建材有限公司

Ferrovanadium slag and manganese slag castable

The invention relates to a ferrovanadium slag and manganese slag castable. The ferrovanadium slag and manganese slag castable contains the following raw materials in parts by weight: 30-40 parts of aggregate, 40-50 parts of powder material and 5-10 parts of admixture, wherein the aggregate is prepared from ferrovanadium slag, zircon and silicon carbide; the powder material is prepared from ferrovanadium slag powder, alpha-Al2O3 powder and manganese slag powder; the admixture is composed of hexamethylenetetramine and phenol-formaldehyde resin.

Owner:NINGXIA TIANZONG HONGGUANG COGENERATION TECH

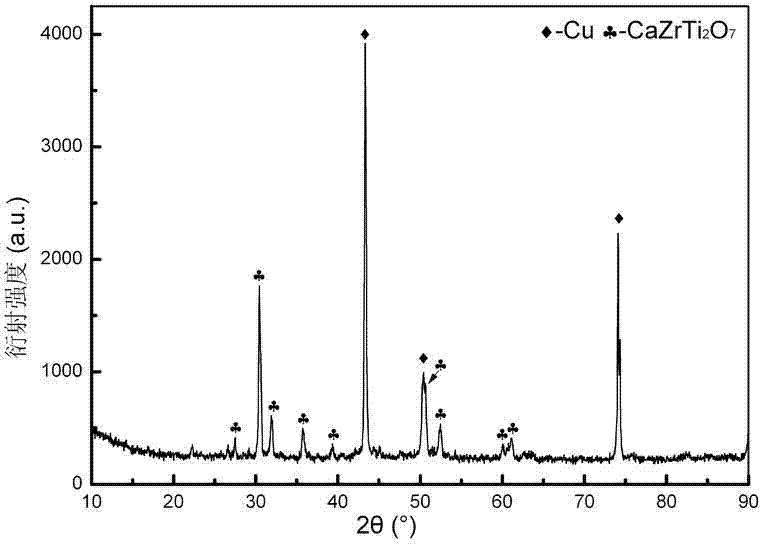

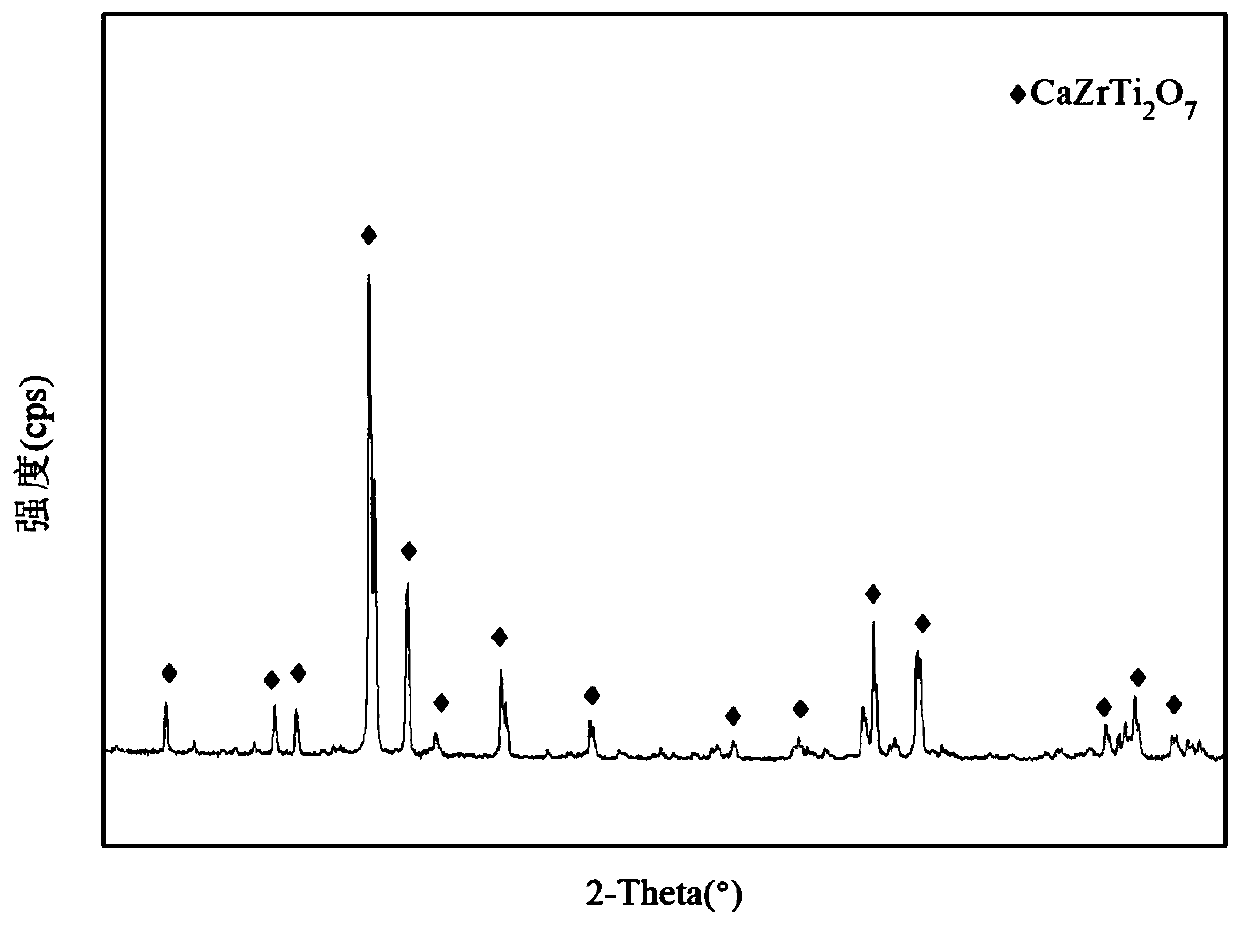

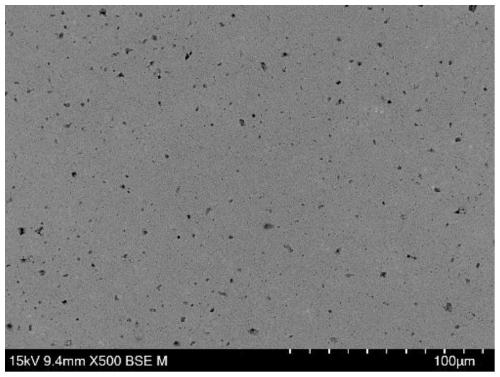

Zirconolite type ceramic solidified body and preparation method and application thereof

InactiveCN111138190AEvenly sinteredReduce energy consumptionRadioactive decontaminationZirconoliteMetallurgy

The invention belongs to the field of solidification treatment for high-radioactivity solid-state nuclear waste, and discloses a zirconolite type ceramic solidified body (CaZrTi2O7) and a preparationmethod and application thereof. The preparation method comprises the following steps: mixing a calcium compound, nanometer titanium dioxide and zirconium oxide, adding a solvent and zirconium oxide grinding balls, carrying out ball-milling and mixing, then successively performing drying and screening to obtain mixed powder; and carrying out dry pressing on the mixed powder to form a ceramic blank,and heating the ceramic blank to 1100-1400 DEG C, carrying out microwave sintering, conducting cooling to 800-1000 DEG C, and carrying out cooling in a furnace. The zirconolite solidified body is more uniform, a reaction temperature is lower, preparation process is simple, a synthesis speed is high, energy consumption is low, and a good foundation is laid for engineering of zirconolite type man-made rock solidified high-level solid waste.

Owner:GUANGDONG UNIV OF TECH

A kind of preparation method of perovskite zircon type artificial rock

The invention discloses a preparation method for a zirconolite type manmade rock. The preparation method is characterized by comprising the following steps: preparing materials from CuO powder, CaO powder, Ti powder, TiO2 powder and ZrO2 powder; performing dry-process ball-milling on the raw materials, uniformly mixing the raw materials and enabling the raw materials to pass through a 100-mesh sieve; feeding 10-50g of the mixed materials into a stainless steel mould, and pressing the mixed materials into cylindrical blank; introducing the blank into a self-propagating quasi-isostatic device, igniting the blank through a tungsten filament to react, and applying pressure of 50-200MPa after the combustion reaction is ended, thereby preparing the high-compactness zirconolite type manmade rock. The preparation method disclosed by the invention can be used for synthesizing the zirconolite type manmade rock within several minutes by adopting a self-propagating high-temperature combined quick compacting process, has the advantages of being high in synthesis speed, high in efficiency, high in reaction temperature, high in product purity, low in energy consumption, simple, and the like; the prepared zirconolite type manmade rock is suitable for long-term safety solidification treatment and disposal of actinide in high-level waste.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com