Self-propagating high-temperature synthesis and densification method of zirconolite-rich type man-made rock

A self-propagating high-temperature, artificial rock technology, applied in the field of artificial rock preparation, can solve the problems of poor practicability, high synthesis temperature, and long synthesis cycle, and achieve the effects of large storage capacity, high product density, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for self-propagating high-temperature synthesis and densification of perovskite-rich zircon-type artificial rocks, comprising the following steps:

[0040] (1) The raw material is treated with Ca(NO 3 ) 2 .4H 2 O: 41.3%, CaO: 3%, ZrO 2 : 24.5%, Ti: 8.4%, TiO 2 : 23.2%, BaO: 1.5%, Al 2 o 3 : 1% mass percentage is taken and mixed evenly;

[0041] (2) Grind the uniformly mixed raw material for 20 minutes and pass through a 100-mesh sieve, take 30 g of fully ground raw material and put it into a steel mold, and cold press it under a pressure of 50 MPa to obtain a cylindrical blank with a diameter of 30 mm and a thickness of about 5 mm;

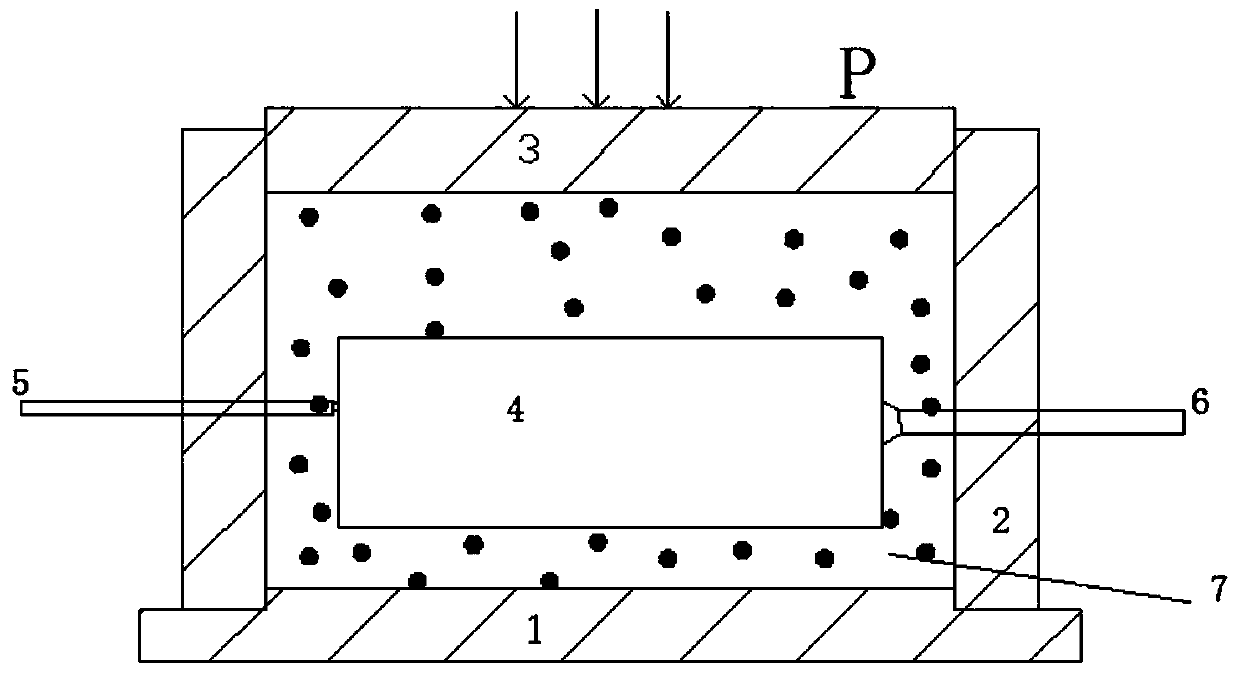

[0042] (3) Self-propagating high-temperature synthetic artificial rock: a self-propagating quasi-isostatic pressure device is used. The composition of the device includes a thermocouple 5, an ignition tungsten wire 6, and a steel plate composed of a bottom 1, an annular side wall 2 and an upper pressure head 3. mold; see att...

Embodiment 2

[0044] A method for self-propagating high-temperature synthesis and densification of perovskite-rich zircon-type artificial rocks, comprising the following steps:

[0045] (1) The raw material is treated with Ca(NO 3 ) 2 .4H 2 O: 46.2%, CaO: 4.7%, ZrO 2 : 26.9%, Ti: 7.6%, TiO 2 : 26.9%, BaO: 2.4%, Al 2 o 3 : 1.6% of the mass percentage is taken and mixed uniformly;

[0046] (2) Grind the uniformly mixed raw materials for 20 minutes and pass through a 100-mesh sieve, take 30 g of fully ground raw materials, put them into a steel mold, and cold press them under a pressure of 50 MPa to obtain a cylindrical blank with a diameter of 30 mm and a thickness of about 4.8 mm ;

[0047] (3) Self-propagating high-temperature synthetic artificial rock: a self-propagating quasi-isostatic pressure device is used. The composition of the device includes a thermocouple 5, an ignition tungsten wire 6, and a steel plate composed of a bottom 1, an annular side wall 2 and an upper pressure h...

Embodiment 3

[0049] A method for self-propagating high-temperature synthesis and densification of perovskite-rich zircon-type artificial rocks, comprising the following steps:

[0050] (1) Ingredients of raw materials:: mix raw materials with Ca(NO 3 ) 2 .4H 2 O: 42.8%, CaO: 1.5%, ZrO 2 : 22.3%, Ti: 8.7%, TiO 2 : 22.6%, BaO: 1.5%, Al 2 o 3: 0.5% of the mass percent example is taken and mixed uniformly;

[0051] (2) Grind the uniformly mixed raw materials for 30 minutes and pass through a 150-mesh sieve, take 25 g of fully ground raw materials and put them into a steel mold, and cold-press them under a pressure of 20 MPa to obtain a cylindrical blank with a diameter of 30 mm and a thickness of about 4.6 mm ;

[0052] (3) Using self-propagating high-temperature synthetic artificial rock: adopting self-propagating quasi-isostatic pressure device, the composition of the device includes thermocouple 5, ignition tungsten wire 6, and the bottom 1, annular side wall 2 and upper pressure hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com