Self-propagating solidifying method for radioactive contaminated sandy soil

A solidification method and self-propagating technology, which are used in the solidification treatment of sand and the self-propagating solidification of radioactively polluted sand, can solve the problems of destructive damage to the treated ecosystem, long repair time, and high plant requirements, so as to improve the resistance to Leaching performance, good effect, good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for self-propagating solidification of radioactively contaminated sand, comprising the following process steps:

[0032] (1) Using Ti as the reducing agent and CuO as the oxidizing agent, the ingredients are prepared according to the following reaction equation:

[0033] 4CuO + CaO + 2Ti + ZrO 2 = CaZrTi 2 o 7 + 4Cu ( )

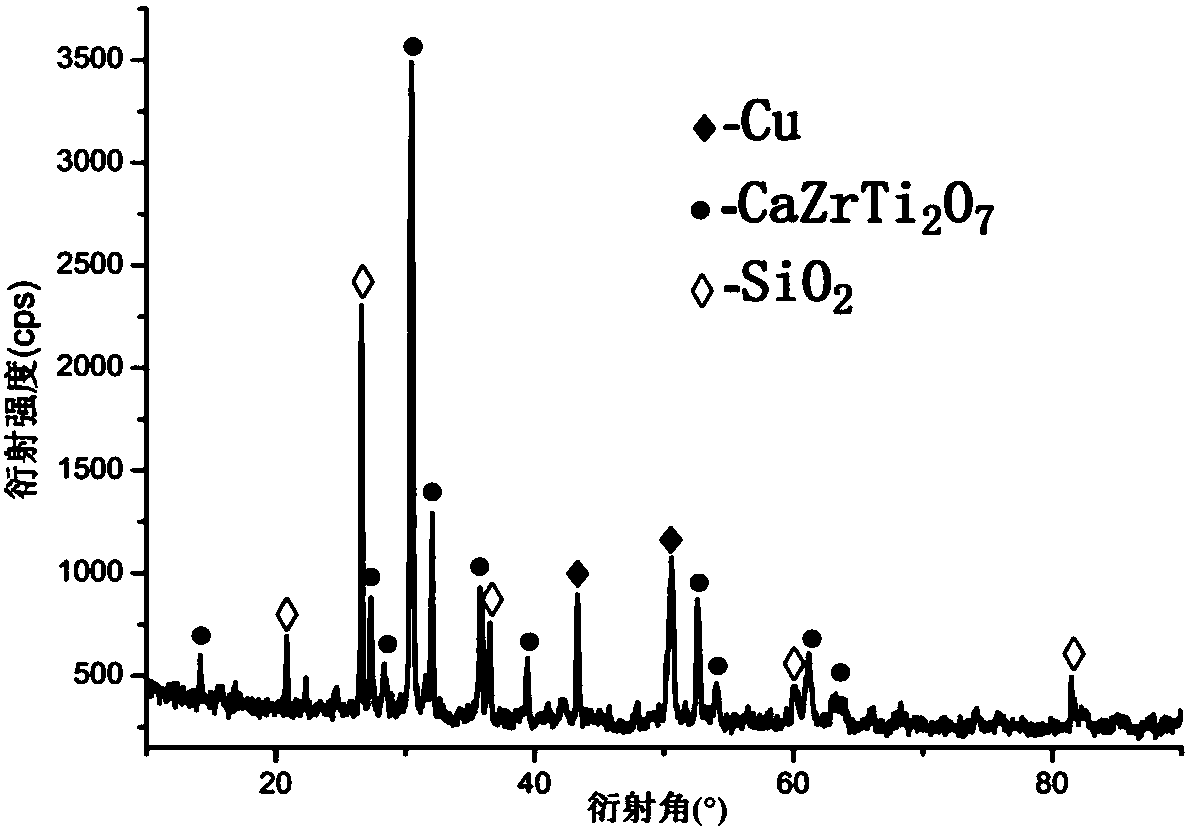

[0034] The molar ratio of each reactant in the reaction formula is CuO: CaO: Ti: ZrO 2 =4:1:2:1; according to their molecular weight and content, the corresponding mass percentage content is: CuO: 48.27%, CaO: 8.5%, Ti: 14.53%, ZrO 2: 18.7%; the remaining 10% is sand (i.e. radioactively contaminated sand) content; then the main component is SiO 2 The radioactively contaminated sand should make the radioactively contaminated sand account for 10wt.% of the total material mass.

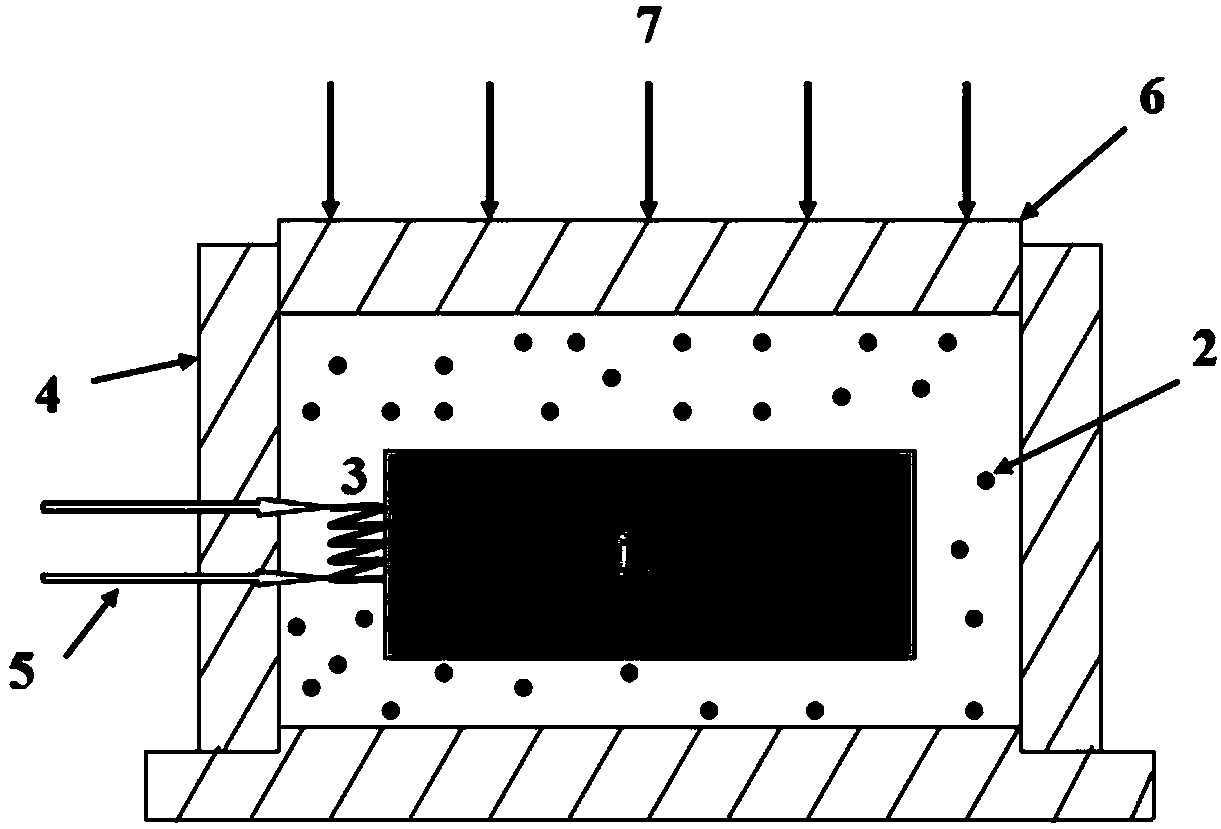

[0035] (2) The raw materials of the above components CuO, CaO, Ti, ZrO 2 Mix with contaminated sand and dry ball mill for 10 minutes, mix evenly to obtain a m...

Embodiment 2

[0042] A method for self-propagating solidification of radioactively contaminated sand, comprising the following process steps:

[0043] (1) Using Ti as the reducing agent and CuO as the oxidizing agent, the ingredients are prepared according to the following reaction equation:

[0044] 4CuO + CaO + 2Ti + ZrO 2 = CaZrTi 2 o 7 + 4Cu ( )

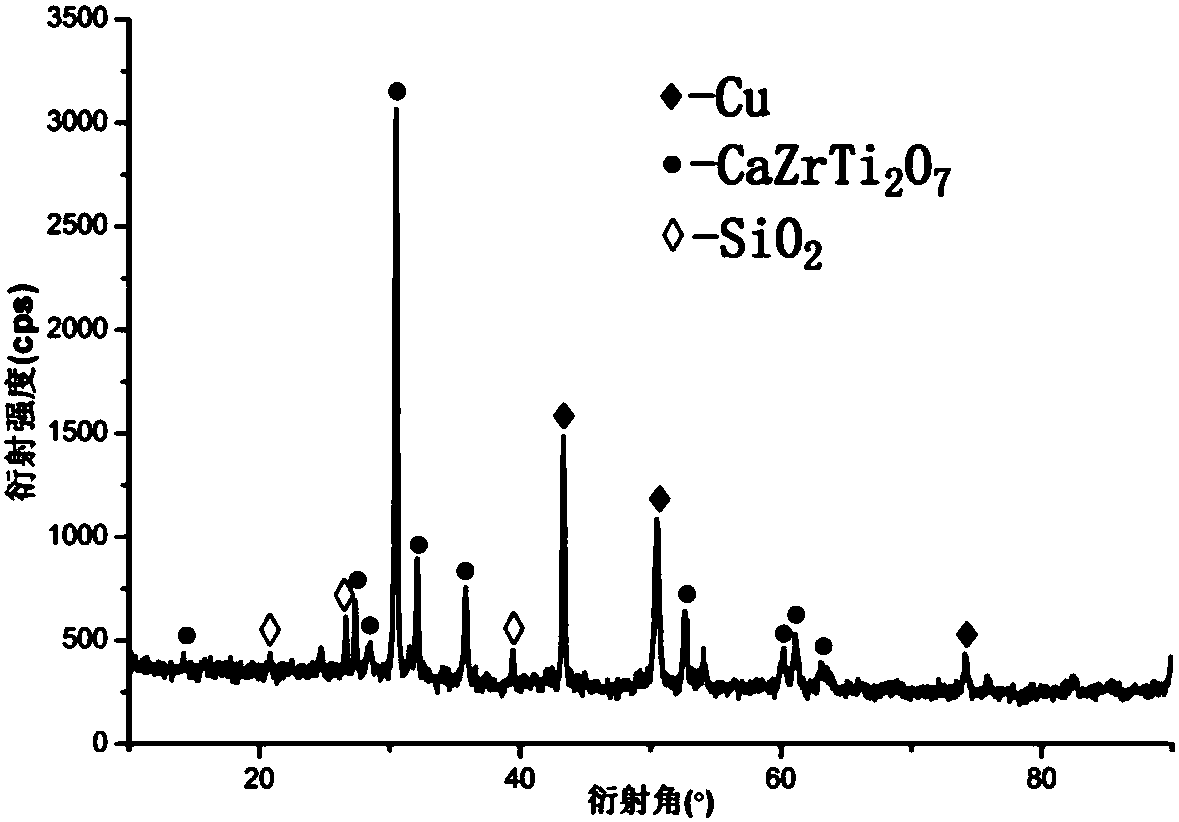

[0045] By CuO:CaO:Ti:ZrO 2 = 4:1:2:1 molar ratio to take raw materials CuO, CaO, Ti and ZrO 2 Powder;

[0046] Described raw material is by above-mentioned CuO, CaO, Ti and ZrO 2 The solidification system is composed of powder; the radioactive contaminated sand and solidification system are taken according to the mass percentage of 10% to 20% of the radioactive contaminated sand and 80% to 90% of the solidification system;

[0047] (2) The raw materials of the above components CuO, CaO, Ti, ZrO 2 and radioactive contaminated sand by dry ball milling for 30 minutes, mix evenly to obtain a mixture, put the mixture in an oven, and dry...

Embodiment 3

[0054] A method for self-propagating solidification of radioactively contaminated sand comprises the following steps of preparing the radioactively polluted sand into a solidified body of radioactive sand:

[0055] a. Ingredients: according to CuO: CaO: Ti: ZrO 2 = 4:1:2:1 molar ratio to take raw materials CuO, CaO, Ti and ZrO 2 Powder;

[0056] Described raw material is by above-mentioned CuO, CaO, Ti and ZrO 2 The solidification system is composed of powder; the radioactive contaminated sand and the solidification system are taken according to the mass percentage of 12% of the radioactive contaminated sand and 88% of the solidification system;

[0057] b. Mixing materials: mix the above radioactive contaminated sand with solidification system raw materials (CuO, CaO, Ti and ZrO 2 Powder) mixed, dry ball milled for 15 minutes, mixed evenly, passed through a 20-mesh sieve to obtain a mixture, and dried the mixture (in an oven or other drying equipment) at a temperature of 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com