Curing process method for radioactive nuclide polluted sandy soil

A technology for radionuclide and solidification treatment, applied in the field of radioactive waste treatment, can solve the problems of unsuitable large-scale engineering application, small processing capacity, unrealistic and other problems, and achieves improved stability, increased glass phase content, and improved resistance to Effects of Alteration Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

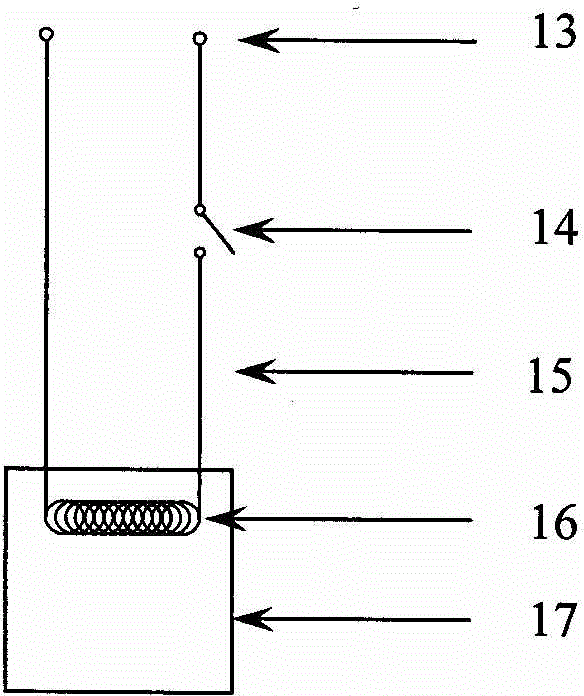

[0030] Combine aluminum powder, iron oxide powder, CaO 2 , SiCa is weighed according to the mass ratio of 0.5:1.5:0.03:0.04, placed in the mixer in turn, stirred at 60 rpm for 40 minutes at room temperature and pressure, and mixed evenly; then it is mixed with sand, soil, TiO 2 And three analog radionuclides SrO, Er 2 O 3 , CeO 2 Weighed according to the mass ratio of 2.07:1:0.01:0.01:0.01:0.01, placed in the mixer in turn, stirred at 45 rpm for 90 minutes at room temperature and pressure, and mixed evenly; the diameter of the landfill Install an electric ignition device in a cement pool with a height of 2m and a height of 2m, fill 35cm of dry sand around the pool, cover 80cm of dry sand on the top, and install a cover plate; after the ignition reaction, the solidified body is taken for analysis and the result is The contents of erbium, cerium and cerium are basically the same as their addition. The 28-day average leaching rate of Ce is 1.9×10 -5 g / (m 2 ·D), Sr is 2.0×10 -3 g / (m...

Embodiment 2

[0032] Combine aluminum powder, iron oxide powder, KMnO 4 , Na 2 B 4 O 7 ·10H 2 O is weighed according to the mass ratio of 0.46:1.39:0.14:0.03, placed in the mixer in turn, stirred at 90 rpm for 50 minutes under normal temperature and pressure, and mixed evenly; then mix it with sand and ZrO 2 , Y 2 O 3 , CeO 2 Weighed according to the mass ratio of 2.02:1:0.01:0.01:0.03, placed in the mixer in turn, stirred at 60 rpm for 100 minutes at room temperature and pressure, and mixed uniformly; the diameter of the landfill was 1m and In a self-made cylindrical steel container with a height of 1m, an electric ignition device is installed, 25cm of dry sand is filled around, 78cm of dry sand is covered on the top, and a cover plate is added; after the ignition reaction, the solidified body is taken for analysis, and the result is , The 28-day average leaching rate of simulated radionuclide Ce is 1.0-1.8×10 -5 g / (m 2 · D).

Embodiment 3

[0034] Combine aluminum powder, iron oxide powder, CrO 3 , MoO 3 Weighed according to the mass ratio of 0.53:1.58:0.1:0.1, placed in the mixer in turn, stirred at 120 revolutions / min for 30 minutes at room temperature and pressure, and mixed well; then mixed it with sand, TiO 2 , ZrO 2 , CeO 2 Weighed according to the mass ratio of 2.31:1:0.18:0.14:0.18, placed in the mixer in turn, stirred at 45 rpm for 120 minutes at room temperature and pressure, and mixed well; the diameter of the landfill was 1m and In a self-made cylindrical steel container with a height of 1m, an electric ignition device is installed, 40cm of dry sand is filled around, 90cm of dry sand is covered on the top, and a cover plate is added; after the ignition reaction, the solidified body is taken for analysis, and the result is , The 28-day average leaching rate of simulated radionuclide Ce is 4.3×10 -6 g / (m 2 · D).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com