A kind of ultra-smooth white glaze and preparation method thereof

A white glaze and smooth technology, applied in the field of ceramics, can solve the problems of reduced refractoriness, pinhole bubbles, affecting the anti-fouling ability of the glaze, and achieve the effect of reducing the gas phase content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the best embodiments.

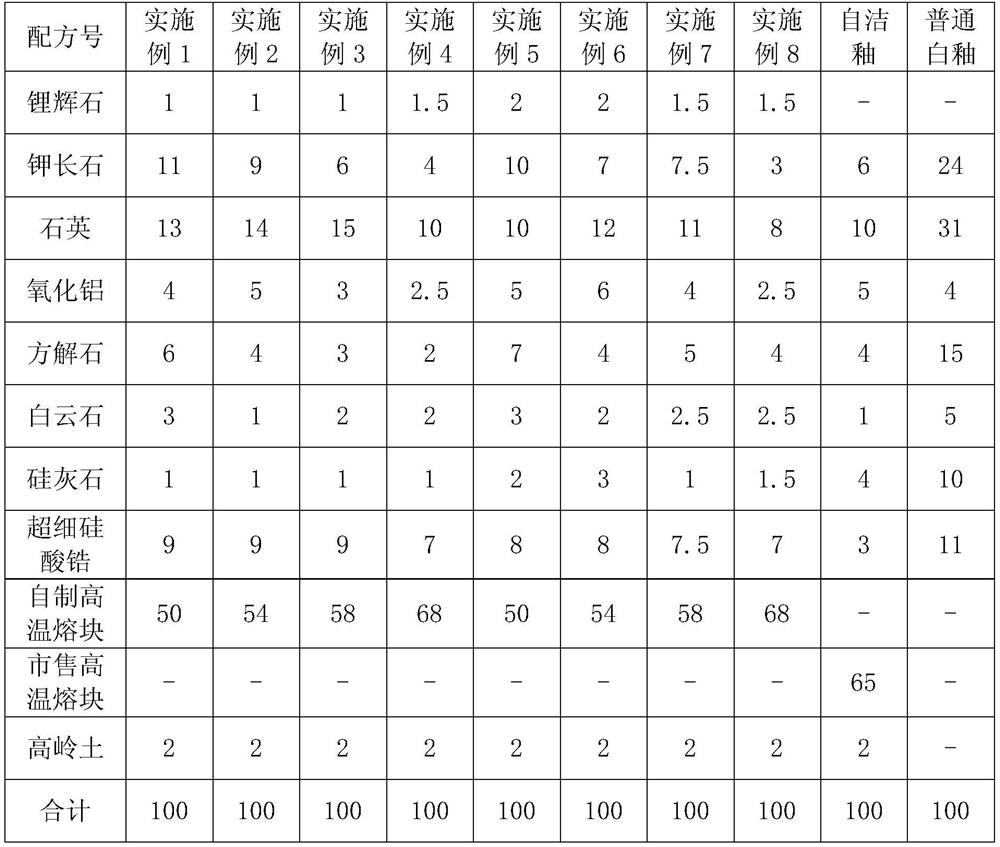

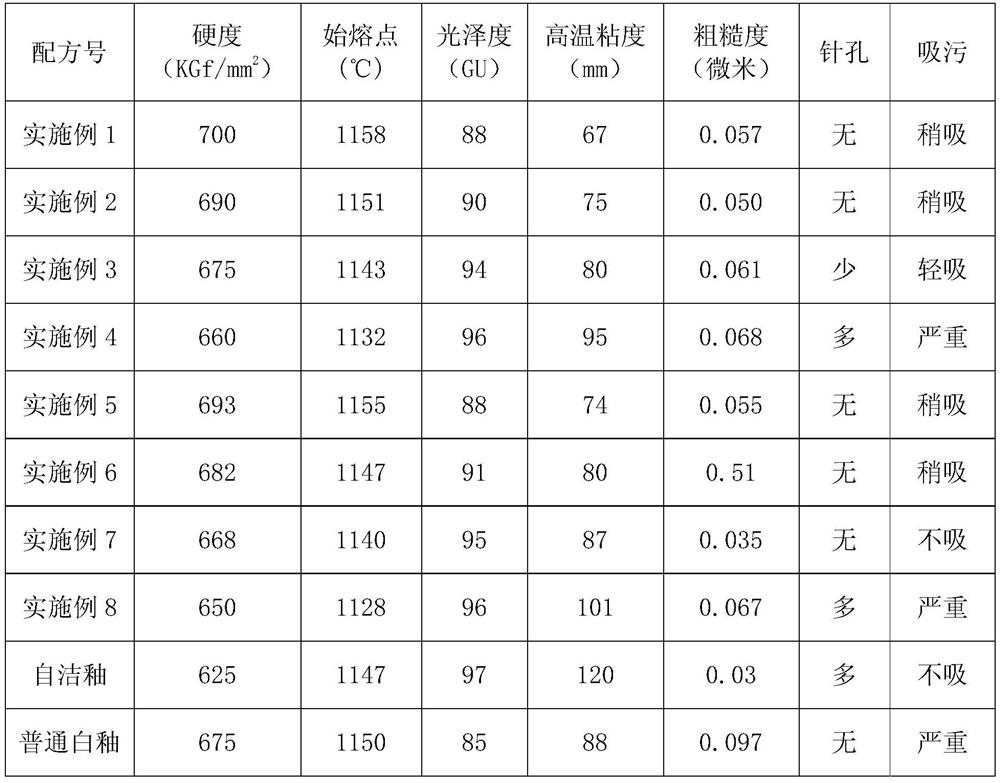

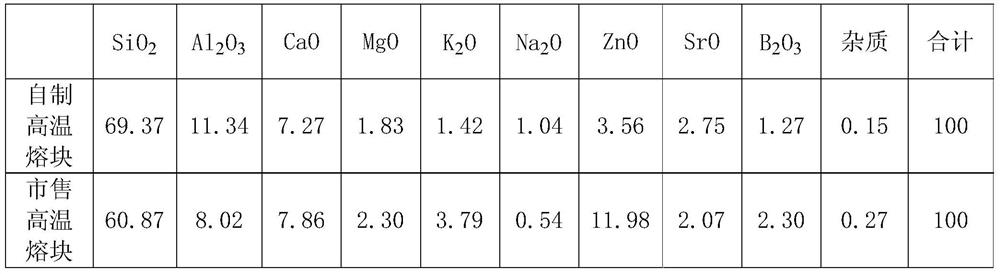

[0020] An ultra-smooth white glaze is characterized in that it consists of the following raw materials in parts by mass: 1-2 parts of spodumene, 3-11 parts of potassium feldspar, 8-15 parts of quartz, 2.5-6 parts of alumina, calcite 2-7 parts, 1-3 parts of dolomite, 1-3 parts of wollastonite, 7-9 parts of ultrafine zirconium silicate, 50-68 parts of high-temperature frit, and 2 parts of kaolin.

[0021] A method for preparing an ultra-smooth white glaze, characterized in that it comprises the following steps: weighing the raw materials of the ultra-smooth white glaze according to their mass fractions, mixing them, putting them into a ball mill, adding water and ball milling until the glaze particle size is ≤ 10 μm and the proportion is 66 -69%, pass t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com