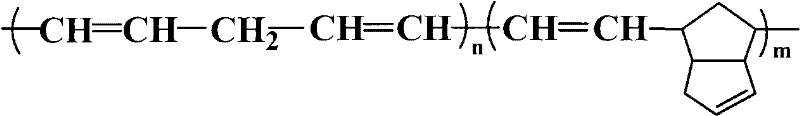

Poly (cyclopentadiene-dicyclopentadiene) copolymer and synthesis method thereof

A technology of dicyclopentadiene and cyclopentadiene, applied in the field of poly(cyclopentadiene-dicyclopentadiene) copolymer and its synthesis, to achieve the effect of improving the index of elasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

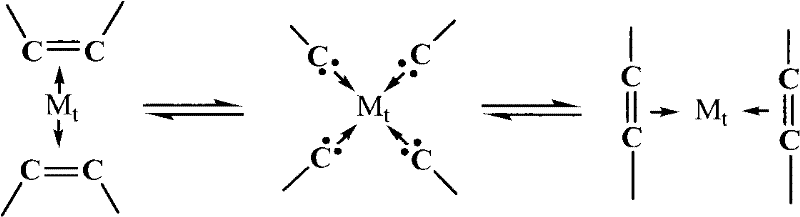

Method used

Image

Examples

Embodiment 1

[0044] Add 0.5mmol of tungsten hexachloride and 10mmol of triisobutylaluminum to a 150ml sealed tube under nitrogen protection, mix well and then add 40ml of toluene.

[0045] After mixing evenly, aging at 30° C. for 1 hour to form a purple-black heterogeneous solution.

[0046] Add 40ml cyclohexane, 0.06mol cyclopentadiene and 0.09mol dicyclopentadiene to a 250ml dry polymerization bottle under nitrogen protection, mix well and then add 80ml cyclohexane to mix;

[0047] Then, 6.7 ml of the catalyst solution prepared above was added. After mixing evenly, polymerize at room temperature for 3 hours;

[0048] Subsequently, an appropriate amount of ethanol solution containing anti-aging agent 264 was added to terminate the reaction, washed with distilled water, and dried in a vacuum oven at 60°C until constant weight.

[0049] The obtained copolymer number average molecular weight (M n ) is 3.7×10 4 g / mol, molecular weight distribution index (M w / M n ) is 5.2.

Embodiment 2

[0051] Under nitrogen protection, 0.5 mmol of molybdenum pentachloride and 2.5 mmol of aluminum trichloride were added to a 150 ml sealed tube. The aging method was used to prepare the catalyst according to the method in Example 1. After aging, a blue-purple heterogeneous solution was obtained.

[0052] Add 0.12mol cyclopentadiene and 0.06mol dicyclopentadiene to a 250ml dry polymerization bottle under nitrogen protection;

[0053] After mixing evenly, 120ml of cyclohexane was added, and then mixed evenly, and then 5.8ml of the prepared catalyst solution was added.

[0054] After mixing evenly, polymerize at room temperature for 8 hours, then add an appropriate amount of ethanol solution containing anti-aging agent 264 to terminate the reaction, wash with distilled water and dry in a vacuum oven at 60°C until constant weight.

[0055] Gained copolymer has certain elasticity, number average molecular weight (M n ) is 15.6×10 4 g / mol, molecular weight distribution index (M w ...

Embodiment 3

[0057] Add 0.5mmol tungsten hexachloride and 0.25mmol aluminum tribromide to the 150ml sealed tube under the protection of nitrogen, and prepare the catalyst according to the method in Example 1 for the aging method. After aging, it becomes a blue-violet heterogeneous solution.

[0058] Add 0.172mol cyclopentadiene and 0.01mol dicyclopentadiene to a 250ml dry polymerization bottle under the protection of nitrogen, mix well, then add 90ml cyclohexane, mix well, then add the prepared catalyst solution 16.2ml. After mixing evenly, place in a 10°C water bath to polymerize for 6 hours;

[0059] Then add an appropriate amount of ethanol solution containing anti-aging agent 264 to terminate the reaction, wash with distilled water and dry in a vacuum oven at 60°C until constant weight.

[0060] The obtained copolymer number average molecular weight (M n ) is 9.5×10 3 g / mol, molecular weight distribution index (M w / M n ) is 6.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com