Method for preparation of ethylene vinylacetate copolymer

A vinyl acetate copolymer, vinyl acetate technology, applied in the direction of pressure vessels used in chemical processes, etc., can solve problems such as low mechanical strength and low crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

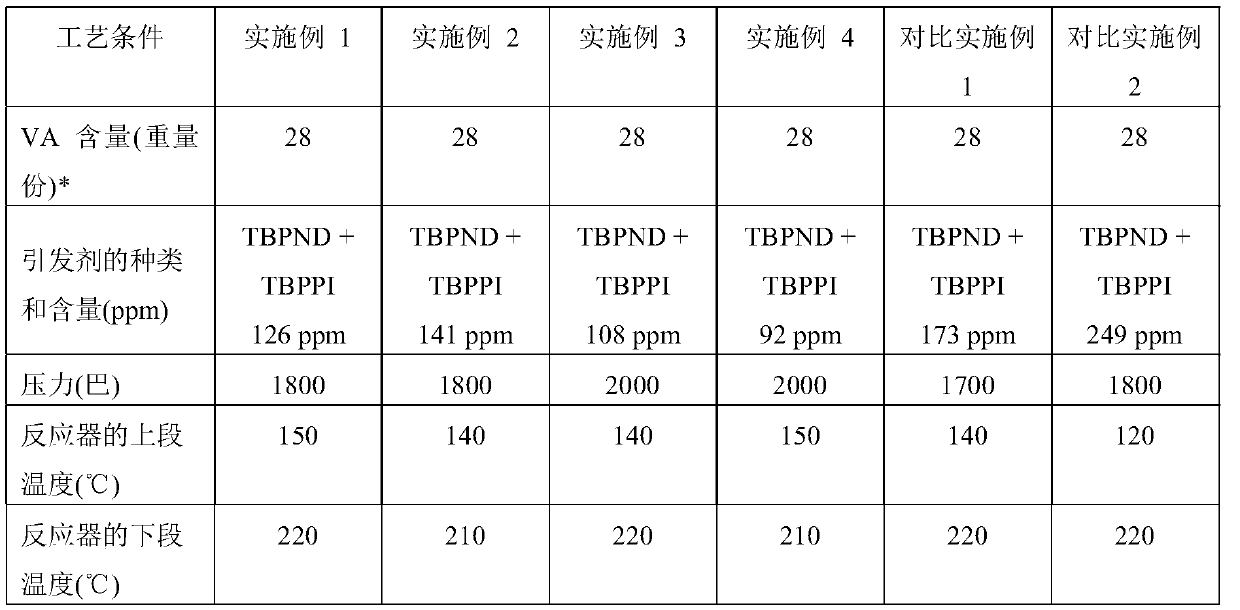

[0023] According to one embodiment of the present invention, a kind of preparation method of ethylene-vinyl acetate copolymer is provided, the method comprises the following steps: in the presence of initiator, make ethylene monomer and vinyl acetate Monomer polymerization, wherein the temperature of the upper section of the autoclave reactor in the polymerization step is 130°C to 160°C, the temperature of the lower section of the autoclave reactor in the polymerization step is 170°C to 230°C, and the pressure of the autoclave reactor is 1800 bar to 2100 bar.

[0024] Ethylene-vinyl acetate (EVA) copolymers can be prepared in autoclave reactors or tubular reactors, generally, ethylene-vinyl acetate prepared in autoclave reactors has a broad molecular weight distribution, while in tubular reactors Ethylene-vinyl acetate produced in a reactor has a narrow molecular weight distribution, and thus, can be produced by selecting a reactor according to usage.

[0025] Meanwhile, in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com