Polyester filament preparation technology and equipment

A polyester filament and preparation technology, which is applied in filament/thread forming, artificial filament heat treatment, melt spinning, etc., can solve problems such as uneven thickness, broken end, and poor stretching effect of polyester filament

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

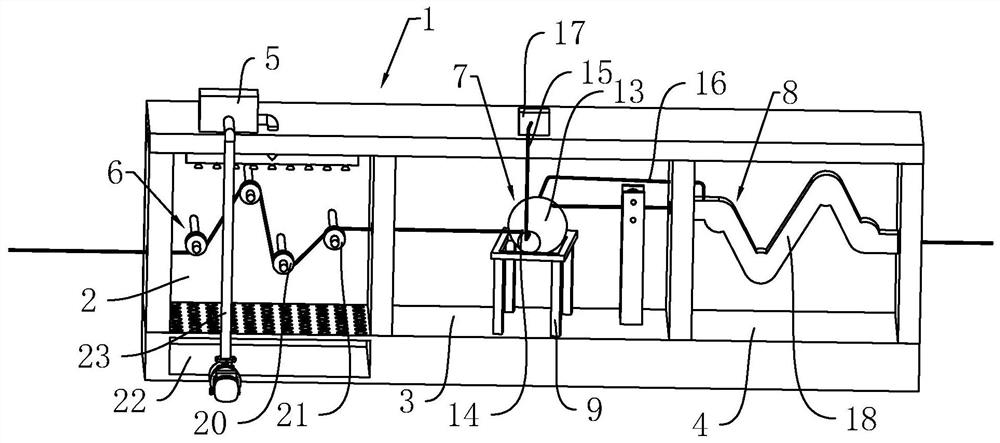

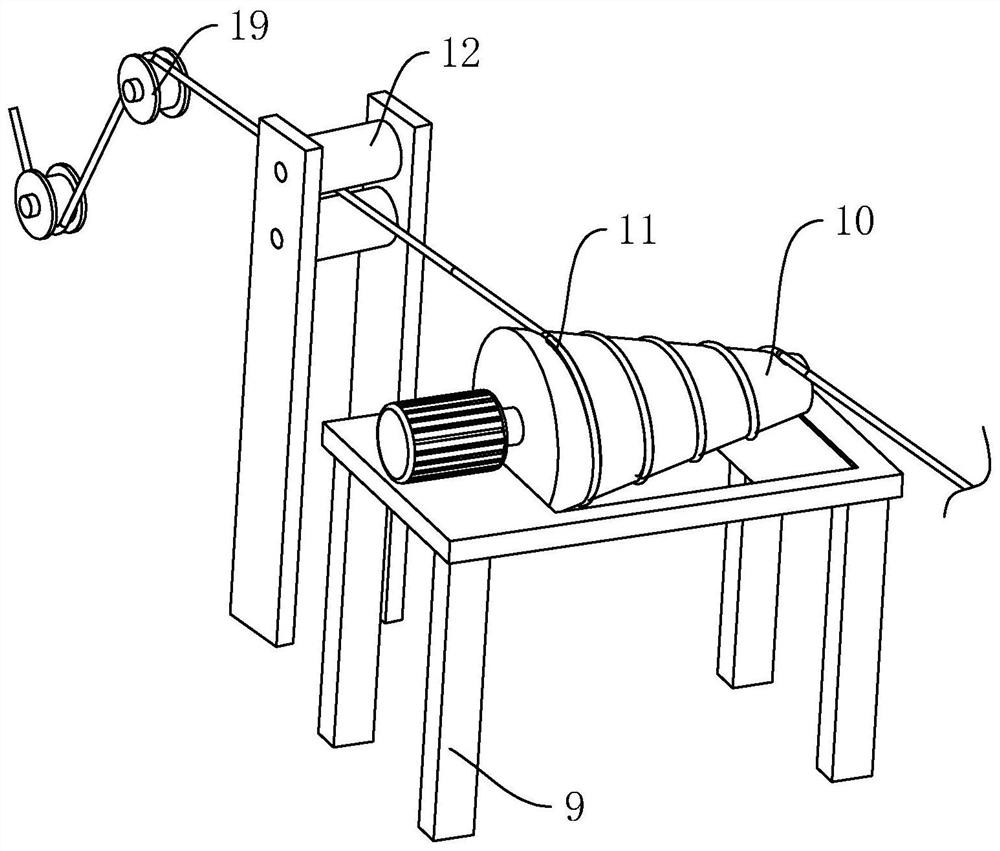

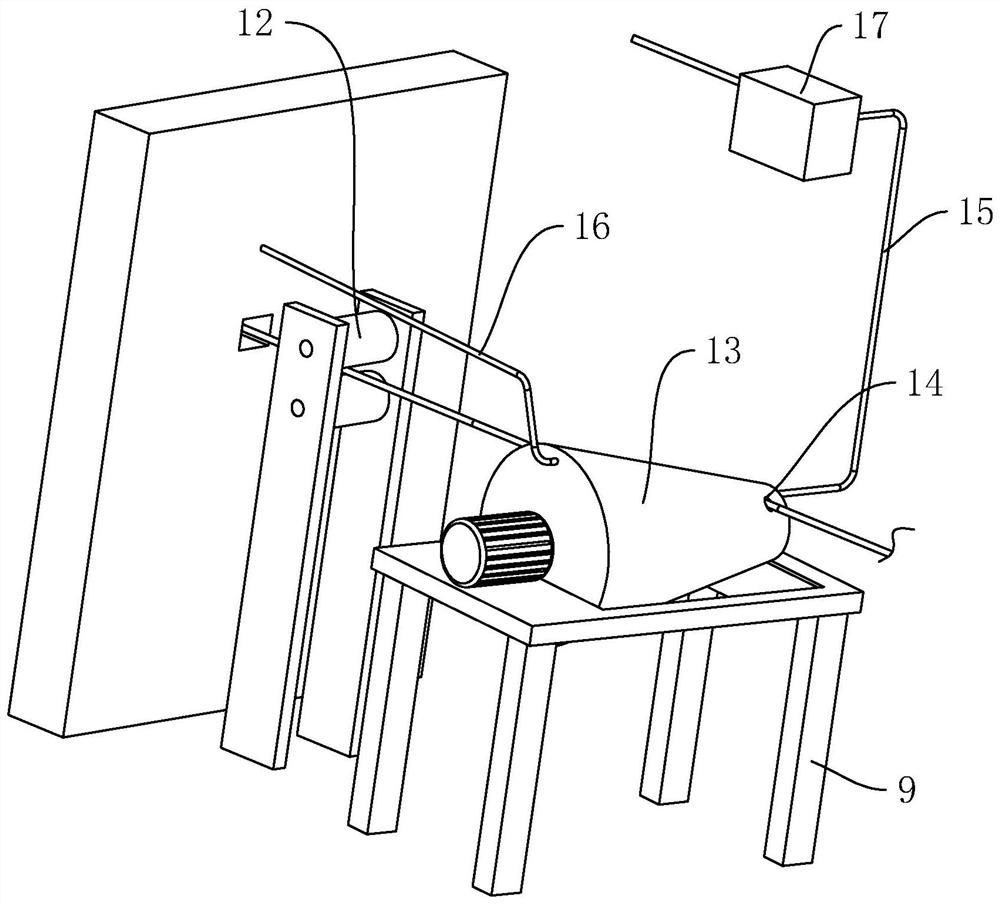

[0040] The following is attached Figure 1-3 The application is described in further detail.

[0041] The embodiment of the present application discloses a polyester filament preparation process. The process includes the following steps: step S1, melting, first select polyester slices, feed the polyester slices into a screw extruder and melt and extrude them into spinning stock solution; step S2, spinning, send the spinning stock solution into the spinning machine and It is sprayed out from the spinneret to form a mother filament with a thicker diameter; step S3, cooling and oiling, blowing the sprayed mother filament to cool it, and then oiling the mother filament, when oiling, immerse the mother filament in polyester oil agent, the mother silk is oiled through the polyester oil agent; first, the oiled mother silk is sent to the network device and pre-networked; step S4, stretching and setting, firstly, the mother silk is preheated, and the preheating temperature is 105 -11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com