Preparation methods of metal surface treatment agent containing nano boron nitride and corrosion-resistant coating

A technology of metal surface treatment and nano-boron nitride, which is applied in the preparation of metal surface treatment agents and corrosion-resistant coatings, and in the field of corrosion-resistant coatings, can solve the problems of poor anti-corrosion effects of organic coatings, and achieve super High corrosion resistance, good bonding force, good high temperature resistance and lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

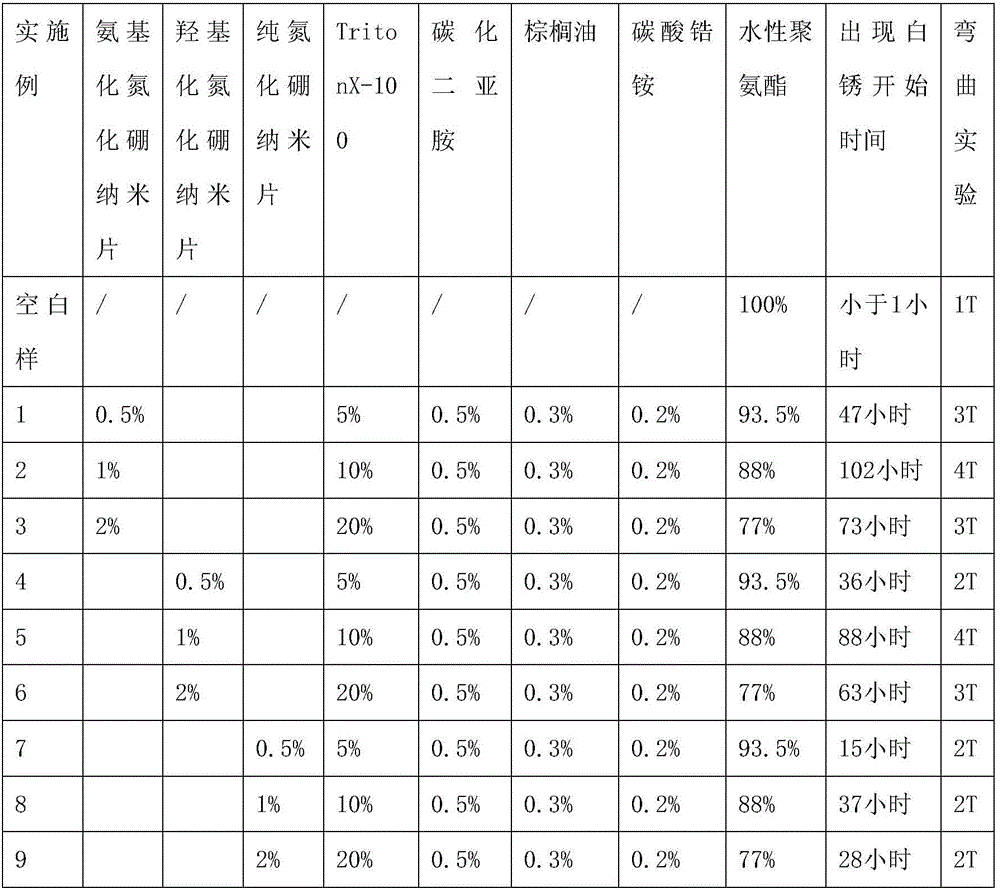

Embodiment 1

[0039] First, mix commercially available boron nitride nanosheets and urea and calcinate them at 300°C to obtain modified boron nitride nanosheets with amino groups, which will be dissolved in water and ultrasonically mixed uniformly so that the mass fraction of the solute will be 0.5% boron nitride The aqueous dispersion is added to the waterborne polyurethane. Then, the solute mass fraction of 5% silane coupling agent KH-550 aqueous dispersion was added to the water-based polyurethane to form a mixed solution. Wherein, the mass fraction of the polyurethane in the waterborne polyurethane accounts for 93.5% of the solute. Then add 0.5% carbodiimide, 0.3% palm oil and 0.2% ammonium zirconium carbonate, accounting for solute mass fraction. A certain amount of deionized water is added so that the mass fraction of the solvent in the total solution is 55%-85%, and the metal surface treatment agent is formed after uniform mixing.

Embodiment 2

[0041] First, mix commercially available boron nitride nanosheets and urea and calcinate them at 300°C to obtain modified boron nitride nanosheets with amino groups, which will be dissolved in water and ultrasonically mixed uniformly so that the mass fraction of the solute will be 1% boron nitride The aqueous dispersion is added to the waterborne polyurethane. Then, the solute mass fraction of 10% silane coupling agent KH-550 water dispersion was added to the water-based polyurethane to form a mixed solution. Wherein, the mass fraction of the polyurethane in the water-based polyurethane accounts for 88% of the solute. Then add 0.3% carbodiimide, 0.3% palm oil and 0.4% ammonium zirconium carbonate, accounting for solute mass fraction. A certain amount of deionized water is added so that the mass fraction of the solvent in the total solution is 55%-85%, and the metal surface treatment agent is formed after uniform mixing.

Embodiment 3

[0043]First, mix the commercially available boron nitride nanosheets and urea and calcinate them at 300°C to obtain modified boron nitride nanosheets with amino groups, which will be dissolved in water and ultrasonically mixed uniformly so that the mass fraction of the solute will be 2% boron nitride The aqueous dispersion is added to the waterborne polyurethane. Then, the water dispersion of silane coupling agent KH-550 with a solute mass fraction of 20% was added to the water-based polyurethane to form a mixed solution. Wherein, the mass fraction of the polyurethane in the waterborne polyurethane accounts for 77.1% of the solute. Then add 0.4% carbodiimide, 0.2% palm oil and 0.3% ammonium zirconium carbonate, accounting for solute mass fraction. A certain amount of deionized water is added so that the mass fraction of the solvent in the total solution is 55%-85%, and the metal surface treatment agent is formed after uniform mixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com