Preparation method of noble metal/submicron spherical shell arrays

A precious metal, sub-micron technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of non-dense metal shell, easy agglomeration of metal particles, complicated preparation method, etc. Simple and controllable growth process and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

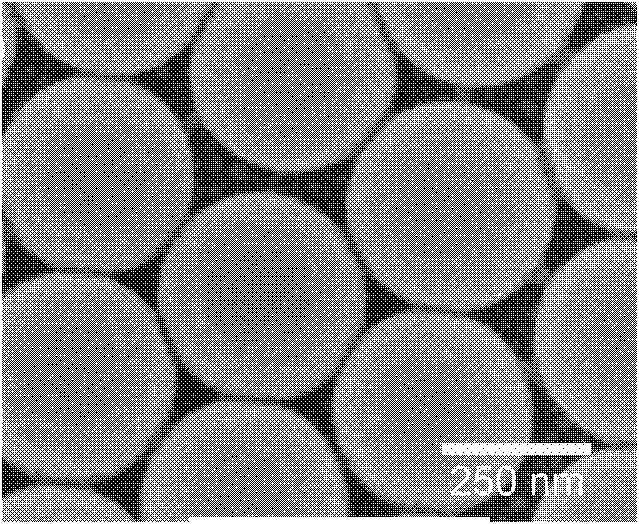

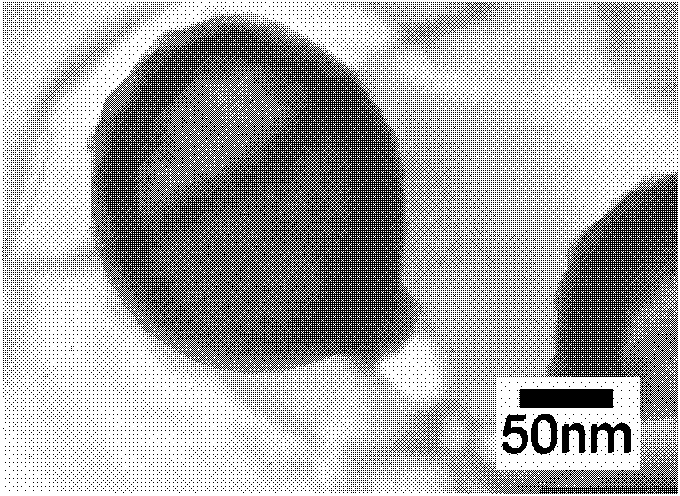

[0028] Disperse polystyrene microspheres with a diameter of 200nm in a mixed solution of water and alcohol with a volume ratio of 1:1 to prepare a mixed solution with a concentration of polystyrene microspheres of 1.89g / ml; take 20 μl of the above-mentioned mixed solution Drop the solution on the quartz substrate and dry it at room temperature to obtain a quartz substrate with a polystyrene microsphere array; put the quartz substrate with a polystyrene microsphere array into the reaction chamber of a DC reactive magnetron sputtering device for deposition silver layer, the reaction chamber was vacuumed to 5×10 -3 Pa, argon gas is introduced as a protective gas, the flow rate of argon gas is controlled at 30sccm, the pressure of the reaction chamber is adjusted to 10Pa, and silver with a purity of more than 99% is used as the target for sputtering deposition, and the sputtering current and power are respectively controlled at 0.2A and 60W, the sputtering time is 60s, and the gro...

Embodiment 2

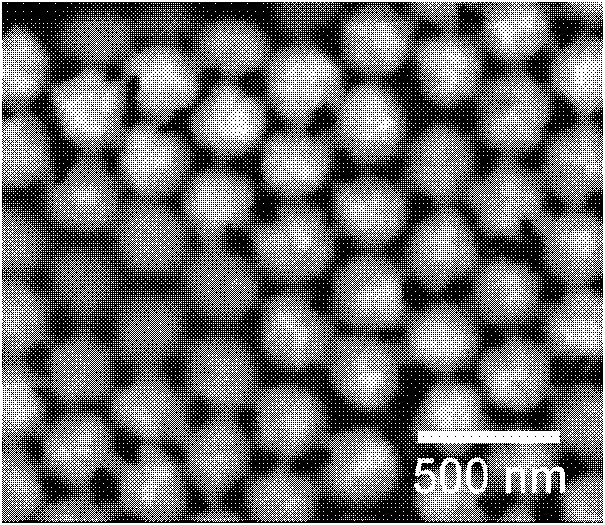

[0034] Disperse polystyrene microspheres with a diameter of 200nm in a mixed solution of water and alcohol with a volume ratio of 1:1 to prepare a mixed solution with a concentration of polystyrene microspheres of 1.89g / ml; take 20 μl of the above-mentioned mixed solution Drop the solution on the quartz substrate and dry it at room temperature to obtain a quartz substrate with a polystyrene microsphere array; put the quartz substrate with a polystyrene microsphere array into the reaction chamber of a DC reactive magnetron sputtering device for deposition silver layer, the reaction chamber was vacuumed to 5×10 -3 Pa, argon gas is introduced as a protective gas, the flow rate of argon gas is controlled at 30sccm, the pressure of the reaction chamber is adjusted to 10Pa, and silver with a purity of more than 99% is used as the target for sputtering deposition, and the sputtering current and power are respectively controlled at 0.2A and 60W, the sputtering time is 45s, and the gro...

Embodiment 3

[0037]Disperse polystyrene microspheres with a diameter of 200nm in a mixed solution of water and alcohol with a volume ratio of 1:1 to prepare a mixed solution with a concentration of polystyrene microspheres of 1.89g / ml; take 20 μl of the above-mentioned mixed solution Drop the solution on the quartz substrate and dry it at room temperature to obtain a quartz substrate with a polystyrene microsphere array; put the quartz substrate with a polystyrene microsphere array into the reaction chamber of a DC reactive magnetron sputtering device for deposition silver layer, the reaction chamber was vacuumed to 5×10 -3 Pa, argon gas is introduced as a protective gas, the flow rate of argon gas is controlled at 30sccm, the pressure of the reaction chamber is adjusted to 10Pa, and silver with a purity of more than 99% is used as the target for sputtering deposition, and the sputtering current and power are respectively controlled at 0.2A and 60W, the sputtering time is 20s, and the grow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com